6Tl Battery: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for 6TL Battery

Procurement teams, OEMs, and fleet operators need a reliable 6TL battery—12V, Group Size 6T with top-post terminals—built for commercial trucks, buses, and industrial equipment. Sourcing in the USA and Europe brings recurring pain points: inconsistent specifications, complex freight rules, and mismatched warranties that can cause downtime and hidden costs.

A typical, verified 6TL profile is shown below. Use it as your baseline when comparing offers and quotes.

Typical 6TL Specs (Pro-Series Commercial)

| Attribute | Value |

|—————————|————————————|

| Voltage | 12 V |

| BCI Group Size | 6T (top post) |

| Cold Cranking Amps (CCA) | 750 |

| Reserve Capacity (RC) | 215 min @ 25 A |

| Capacity (Ah) | ~120 Ah (typical) |

| Dimensions (L x W x H) | 11 1/4″ x 10 1/2″ x 9″ (285.8 x 266.7 x 229 mm) |

| Weight | 58 lb (26.3 kg) |

| Warranty | 18-month free replacement; 30-month pro-rata |

| Shipping Note | LTL freight or local pickup due to sulfuric acid |

| Compliance | UL listed; factory-fresh available |

What this guide delivers

- Sourcing strategy for USA/EU and supplier due diligence.

- How to verify specs (CCA/CA, RC, Ah) and warranty terms.

- Logistics, freight, core credits, and exchange programs.

- Total cost of ownership, battery management, and lifecycle optimization.

- Safety, compliance, and sustainability requirements.

How to use this guide

1) Confirm application requirements and baseline specs.

2) Cross-check supplier claims against the table above.

3) Compare freight, packaging, warranty, and core handling.

4) Select the option that delivers lowest TCO with acceptable risk.

This guide gives you a clear path to source consistent, compliant, and cost-effective 6TL batteries across both markets.

Illustrative Image (Source: Google Search)

Top 10 6Tl Battery Manufacturers & Suppliers List

1. Group 6TL Military / Ordnance Battery Dry, 12V 725 CCA

2. Top 15 Lithium-ion Battery Manufacturers | Blackridge Research

Domain: blackridgeresearch.com

Registered: 2019 (6 years)

Introduction: China is one of the largest lithium-ion battery manufacturers in the world, with companies like CATL, BYD, and CALB….

3. Top 10 Lithium Battery Manufacturers in China – HIITIO

Domain: hiitio.com

Registered: 2022 (3 years)

Introduction: 1. CATL (Contemporary Amperex Technology Co. Limited) · 2. BYD (Build Your Dreams) · 3. GEM (GEM Co., Ltd.) · 4. Gotion (Guoxuan High-tech) · 5….

4. Source for 6TL Battery | SteelSoldiers

Domain: steelsoldiers.com

Registered: 2000 (25 years)

Introduction: We’ve been able to order NAPA Part BAT-7256 and come up with a 6TL battery. Cost is around $200/ea, but they gave me 20% off with the bucket sale….

Illustrative Image (Source: Google Search)

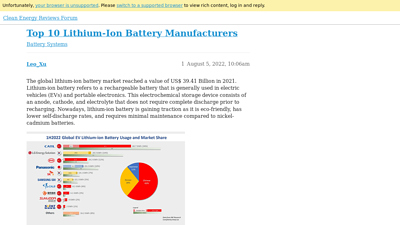

5. Top 10 Lithium-Ion Battery Manufacturers

Domain: forum.cleanenergyreviews.info

Registered: N/A

Introduction: Top 10 Lithium-Ion Battery Manufacturers … The global lithium-ion battery market reached a value of US$ 39.41 Billion in 2021. Lithium-ion ……

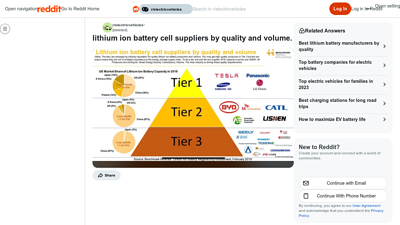

6. lithium ion battery cell suppliers by quality and volume. – Reddit

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The Top 10 EV Battery Makers CATL, LG Chem, and Panasonic control 69% of the market · r/batteries – The Top 10 EV Battery Makers CATL, LG Chem, ……

7. Super Start Fleet & Heavy Duty Standard Flooded Top Post Battery …

Domain: oreillyauto.com

Registered: 1996 (29 years)

Introduction: Rating 4.6 (17) · Free deliverySuper Start Fleet & Heavy Duty Standard Flooded Top Post Battery Group Size 6T – 6TL ; Length (in):. 11-1/4 Inch ; Length (mm):. 286mm ; Width (in):. 10-1/2 Inch….

8. 6T battery sources in North Atlanta area? – Facebook

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Anyone have a good source on 6T batteries? I used to have a surplus shop around with good take outs for $40. O’Reilly has new ones for $250.Missing: top manufacturers…

Illustrative Image (Source: Google Search)

Understanding 6tl battery Types and Variations

Understanding 6TL Battery Types and Variations

The 6TL battery refers to a 12-volt BCI Group Size 6T/6TL battery commonly used in heavy-duty starting applications. Typical values seen in commercial listings include 12 V, approximately 750 Cold Cranking Amps (CCA), 120 Ah at the 20-hour rate, and about 215 minutes Reserve Capacity (RC) at 25 A. Physical dimensions typically fall around 11 1/4 in (L) x 10 1/2 in (W) x 9 in (H), with a weight near 58 lb. While many stock SKUs are flooded lead-acid, sealed AGM and lithium (LiFePO4) alternatives are also offered for customers seeking lower maintenance, improved cycling, or weight savings.

6TL type summary

| Type | Key Features | Typical Applications | Pros / Cons |

|---|---|---|---|

| Standard Flooded Lead-Acid (FLA), 6TL | 12 V; ~750 CCA; ~120 Ah (20‑hr); ~215 min RC @ 25 A; top posts; vented; electrolyte serviceable | Heavy-duty cranking for trucks, buses, equipment; stationary Genset starting | Pros: High cranking power; broad market availability; proven technology; lower purchase price. Cons: Requires periodic maintenance; venting and gassing; must be shipped per hazardous material rules; shorter cycle life under deep cycling. |

| High-Performance FLA (6TL-HD) | 12 V; higher starting current vs. standard FLA (e.g., 915 CA); similar Ah/RC; top posts | Large displacement engines; high-compression diesels; extreme cold starts; fleets needing extra burst current | Pros: Enhanced cranking for hard-start conditions; same form factor and voltage. Cons: Higher cost; similar maintenance and shipping constraints as FLA; cycle life may still be limited under cycling duty. |

| Sealed AGM (Absorbent Glass Mat), 6TL | 12 V; maintenance-free; typically lower CCA than high-output FLA; sealed, spill-proof; often lighter weight | Modern fleet vehicles with higher cycling; duty cycles with moderate depth-of-discharge; applications requiring low gassing and tilt tolerance | Pros: No maintenance; no spill risk; better vibration resistance; improved deep-cycle tolerance. Cons: Lower cranking output vs. high-output FLA; higher purchase price; ensure model-specific fit/performance. |

| LiFePO4 (Lithium Iron Phosphate), 6TL | 12 V nominal; high BMS continuous current; lightweight; long cycle life; integrated BMS; fast charging | Weight-sensitive trucks/equipment; high-crest-factor loads; extended runtime; remote monitoring/analytics (for smart versions) | Pros: Significant weight savings; long cycle life; flat discharge curve; fast recharge; minimal maintenance; high usable capacity. Cons: Highest initial cost; requires compatible charging system; cold performance and BMS configuration considerations. |

Below, each type is detailed with chemistry differences, typical specs, fitment considerations, and purchasing notes.

Standard Flooded Lead-Acid (FLA), 6TL

- Chemistry and construction

- Flooded lead-acid with liquid electrolyte; vented design with removable caps for periodic maintenance.

- Typical specs (representative commercial listings)

- Voltage: 12 V

- CCA: ~750 (example Pro-Series SKU)

- Capacity: ~120 Ah (20‑hr); Reserve Capacity ~215 min @ 25 A

- Form factor: top posts; typical envelope around 11.25″ x 10.5″ x 9″; ~58 lb

- Applications

- Heavy-duty cranking for commercial trucks, buses, and off-highway equipment; stationary generator starting where robust cold-crank output is prioritized.

- Pros / Cons (summary)

- Pros: High cranking output at low cost; widespread market support; mature, proven technology.

- Cons: Requires water maintenance; produces gases—requires ventilation; shipping subject to hazmat rules; limited cycle life when deep cycled.

- Purchasing notes

- Many SKUs (e.g., Pro-Series 6TL) list an 18-month free replacement warranty with a pro‑rata period thereafter; verify warranty terms with the supplier. Flooded designs often incur core charges and freight surcharges due to hazardous materials regulations.

High-Performance Flooded Lead-Acid (6TL-HD)

- Chemistry and construction

- Flooded lead-acid tuned for higher starting current (greater plate surface area or optimized grid design).

- Typical specs (representative commercial listing)

- Voltage: 12 V

- CA: ~915; CCA often ~750 (example DEKA 6TL-1)

- Capacity: ~120 Ah; Reserve Capacity per spec; similar envelope to 6TL

- Applications

- Large engines, high-compression diesels, extreme cold environments; fleets that experience frequent hard starts or need extra burst current margin.

- Pros / Cons (summary)

- Pros: Higher cranking performance; drop-in replacement for 6TL.

- Cons: Higher purchase cost; same maintenance and shipping constraints as standard FLA; cycle life remains limited under deep cycling.

- Purchasing notes

- Supplier listings may note sulfuric acid content and shipping via LTL freight or local pickup only; ensure model-specific CCA/CA meets engine requirements.

Sealed AGM (Absorbent Glass Mat), 6TL

- Chemistry and construction

- Sealed VRLA with AGM separators; valve-regulated and maintenance-free. Electrolyte is immobilized, preventing spills.

- Typical specs (varies by brand/model)

- Voltage: 12 V

- CCA: often lower than high-output flooded SKUs

- Capacity: typically in the 80–120 Ah range, model dependent

- Weight: often lighter than flooded equivalents

- Applications

- Modern fleets and equipment with higher cycling needs; applications requiring lower gassing, tilt tolerance, and vibration resistance.

- Pros / Cons (summary)

- Pros: Maintenance-free; spill-proof; better cycling tolerance vs. standard FLA; robust to vibration.

- Cons: Lower cranking capability than high-output FLA at similar price points; higher upfront cost; verify fit and performance for your specific starting/charging profile.

- Purchasing notes

- Because AGM is sealed, shipping restrictions are less stringent than flooded batteries, but model-specific fit and electrical characteristics still require validation.

LiFePO4 (Lithium Iron Phosphate), 6TL

- Chemistry and construction

- Lithium iron phosphate cells with integrated Battery Management System (BMS); sealed, maintenance-free.

- Typical specs (varies widely by brand/BMS)

- Voltage: 12 V nominal; 4S configuration typical

- Continuous discharge current: sized by BMS (often 100–200 A+ for commercial SKUs)

- Usable capacity: high; model dependent

- Weight: substantially lower than lead-acid

- Cycle life: thousands of cycles depending on depth-of-discharge and operating conditions

- Applications

- Weight-sensitive commercial vehicles and equipment; high crests or sustained loads; applications demanding long runtime and minimal maintenance; smart versions add telematics/analytics.

- Pros / Cons (summary)

- Pros: Significant weight reduction; long cycle life; flat discharge curve; fast recharge; minimal maintenance.

- Cons: Highest purchase price; may require charger/alternator compatibility checks; cold-temperature performance and BMS configuration must be validated.

- Purchasing notes

- Confirm continuous current rating against peak/cranking needs and ensure the BMS is rated for your loads. Expect higher upfront cost offset by life and maintenance savings.

Key takeaways

– Standard 6TL flooded lead-acid remains the baseline for heavy-duty starting, offering strong CCA at the lowest cost.

– High-performance flooded SKUs add starting margin for hard-start conditions.

– Sealed AGM trades some cranking output for maintenance-free operation and better cycling.

– LiFePO4 maximizes life and reduces weight, but requires careful electrical integration and budget planning.

Key Industrial Applications of 6tl battery

Key Industrial Applications of 6TL Battery

Summary: 6TL (BCI Group Size 6T) is a 12 V flooded lead‑acid starting battery with strong cranking power (typically ~750 CCA), robust reserve capacity (~215 minutes @25 A), and a commercial‑grade form factor (top‑post terminals; ~11.25 x 10.5 x 9 inches; ~58 lb). It is commonly specified for heavy‑duty starting, stop‑start duty cycles, and APU/auxiliary loads in commercial vehicles and equipment where group 6T dimensions are required.

Illustrative Image (Source: Google Search)

Applications and benefits by industry:

| Industry | Typical Applications | Detailed Benefits | 6TL Specs to Leverage |

|---|---|---|---|

| Commercial Trucking & Fleet | Tractor/trailer combination starts; hotel loads (APU, inverters, climate standby) | High CCA supports reliable cold‑weather cranking; reserve capacity supports hotel loads without deep discharge; top‑post design simplifies OEM replacement | ~750 CCA; ~215 min RC; 12 V; top‑post; 6T form factor |

| Bus & Coach | Engine starting; door/heating/air systems during layovers | Consistent cranking for multi‑stop duty; RC maintains essential systems during idle; durable flooded construction | ~750 CCA; ~215 min RC; rugged flooded chemistry |

| Off‑Highway & Construction | Mobile generators/compressors; diesel engine start in excavators, loaders, dozers | Strong starting current under high parasitic loads; vibration‑tolerant package; easy service and topping | ~750 CCA; ~215 min RC; Group 6T dimensions |

| Mining & Quarrying | Engine starting for haul trucks, drills, loaders; auxiliary power for work lights, radios | Dependable cranking in extreme temperatures; RC supports essential accessories; robust terminals for demanding environments | ~750 CCA; ~215 min RC; top‑post |

| Agriculture & Material Handling | Tractor/engine start; implements with electric drives or PTO generators; forklift support vehicles | High CCA for cold starts; RC maintains implements and controls; flooded design allows field maintenance | ~750 CCA; ~215 min RC; 12 V |

| Utility & Municipal Services | Service trucks with hydraulic lifts; lighting towers; small generators | Reliable starting after long idle; RC supports onboard tools and lighting without harming starting battery | ~750 CCA; ~215 min RC; group‑matched footprint |

| Oil & Gas (Field Service) | Rig support equipment and well‑service trucks; hydraulic tools | Stable cranking under accessory loads; RC supports extended tool use while idling; serviceable flooded design | ~750 CCA; ~215 min RC |

| Rail & Transit Maintenance | Track maintenance vehicles; diesel gensets | Strong cranking and reserve for onboard systems; consistent performance in varying climates | ~750 CCA; ~215 min RC |

| Marine (Auxiliary & Workboats) | Engine start for workboats and ferries; auxiliary power for electronics | Adequate cranking for diesel auxiliary engines; RC sustains electronics during stand‑by; group‑appropriate size | ~750 CCA; ~215 min RC; 6T footprint |

| Stationary & Backup Power Support | Small diesel gensets; compressors; emergency starting duty | Proven reserve for short‑duration loads; quick recharge; flooded construction simplifies maintenance | ~750 CCA; ~215 min RC |

Selection guidance and regional notes:

– Compatibility: Verify BCI Group 6T/6TL physical fit, terminal layout (top post), polarity, and OEM requirements. In many platforms, 6TL serves as the high‑performance counterpart to 6T; ensure replacement alignment with vehicle/equipment documentation.

– Cold‑weather performance: ~750 CCA provides reliable starting in cold climates typical of northern USA and European winters; confirm minimum CCA per OEM.

– Shipping and handling: Flooded lead‑acid batteries with sulfuric acid may require LTL freight or local pickup. Comply with ADR/GHS/OSHA handling and venting in facilities.

– Warranty: Common commercial coverage is an 18‑month free replacement plus a 30‑month pro‑rata period; confirm specific warranty terms and availability in your region.

– Chemistry note: Flooded lead‑acid requires periodic electrolyte checks and topping with distilled water; ensure your maintenance program and safety procedures (PPE, eyewash, spill kits) are in place.

This 6TL profile is best used where consistent high cranking power and moderate reserve are required within the Group 6T footprint, supporting heavy‑duty vehicles and equipment common across USA and European commercial operations.

3 Common User Pain Points for ‘6tl battery’ & Their Solutions

3 Common User Pain Points for 6TL Battery & Their Solutions

Below are three practical scenarios (B2B buyer and service manager viewpoints) with clear problems and proven solutions, plus quick reference specs and checklists to reduce risk and total cost of ownership.

Illustrative Image (Source: Google Search)

1. Mis-specification: 6T vs 6TL Compatibility and Fit Issues

| Element | Details |

|---|---|

| Scenario | A fleet is replacing batteries on a Class 6–7 truck or bus equipped with a top-post, 12V system. A buyer orders “6T” assuming interchangeability and later finds post/top-hat geometry, terminal layout, or hold-down differences. |

| Problem | 6T and 6TL are not the same; wrong group size can cause fitment failures, loose hold-downs, or misaligned terminals. Incorrect post type may require adapters or lead to poor connectivity. |

| Solution | Always specify BCI Group 6TL (top-post) explicitly; confirm 12V, 6TL dimensions, terminal style, and hold-down configuration. Cross-reference equipment OEM documentation or service manual and choose from verified 6TL SKUs. |

| Key Specs / Checklist | • Voltage: 12V • Group: 6TL (not 6T) • Dimensions (6TL): L 11 1/4 in (285.8 mm), W 10 1/2 in (266.7 mm), H 9 in (229 mm) • Weight: ~58 lb (26.3 kg) • Terminal: Top post (confirm top-hat/post fit) • Example pricing: ~$270–$320 (USA, typical retail; freight may apply) |

2. Cold-Weather Starting and Under-Spec’d CCA/Reserve Capacity

| Element | Details |

|---|---|

| Scenario | Northern operations require reliable cold starts and accessory load support. A buyer selects a battery with insufficient Cold Cranking Amps (CCA) or Reserve Capacity (RC), risking slow cranking, no-start, or under-voltage events in cold ambient. |

| Problem | Under-spec’d CCA reduces available cranking current at low temperatures; low RC shortens runtime for hotel loads, telematics, or APU support, leading to dead batteries and service interruptions. |

| Solution | Specify 6TL batteries with verified specs: 12V, 750 CCA minimum, RC ≥ 215 minutes at 25A. Confirm capacity and application load demands before selection; choose proven 6TL SKUs from reputable lines. |

| Key Specs / Checklist | • CCA: 750 (typical verified range for 6TL in market) • Reserve Capacity: 215 minutes @ 25A • Capacity reference (market example): 120 Ah (for comparison) • Warranty: Review coverage (e.g., 18-month free replacement; confirm term with vendor) |

3. Logistics: Hazmat Shipping and Freight for 6TL Batteries

| Element | Details |

|---|---|

| Scenario | A distributor needs fast delivery to a yard or shop. Some carriers restrict shipping for batteries containing sulfuric acid, and parcel options may be limited for 6TL’s size and weight. |

| Problem | Unexpected carrier restrictions, core charges, and freight requirements delay installations and increase landed costs. Incompatible shipping method can lead to shipment rejection or re-bills. |

| Solution | Use LTL freight or local pickup for flooded 6TL batteries; confirm hazmat handling and core charge policies up front. Include an installation lead time buffer. |

| Key Specs / Checklist | • Shipping: LTL freight or local pickup required for hazmat • Core charge: May apply if no core is exchanged (policy varies by vendor) • Weight: ~58 lb (26.3 kg) • Dimensions: L 11 1/4 in, W 10 1/2 in, H 9 in (plan palletized freight) |

Strategic Material Selection Guide for 6tl battery

Strategic Material Selection Guide for 6TL Battery

Performance fit and typical ratings

6TL is a 12 V, BCI Group Size 6T flooded lead–acid battery commonly used in commercial and heavy‑duty applications. Typical characteristics include high cold cranking amps (CCA) and robust reserve capacity (RC), with a sealed top‑post design that simplifies routing and packaging.

- Chemistry: Flooded lead–acid (FLA)

- Nominal voltage: 12 V

- Typical configuration: 6 cells in series

- Typical dimensions (L × W × H): approximately 11.25 × 10.5 × 9.0 in

- Weight: about 58 lb

- Orientation: Upright with fixed hold‑down

- Terminals: Top post (top‑post terminals; stud adapters optional)

Use‑case mapping

- Commercial truck and bus fleets, especially when frequent short‑trip duty cycles are combined with high cranking demands

- Heavy‑duty stationary equipment and industrial platforms that require consistent cranking power and moderate deep‑cycle behavior

- Workhorse applications that benefit from flooded chemistry (replaceability, serviceability) and robust RC to support accessory loads

Key specification bands to target

| Parameter | Typical target band | Notes |

|---|---|---|

| CCA | 650–800 | Reserve margin helps in cold starts and high‑load cranking |

| CA/SA | ≥ 850–950 | Higher ambient temps and idle loads favor stronger SA/CA performance |

| Reserve Capacity (25 A) | 185–225+ min | Improves accessory support during alternator downtime |

| Ah (20 h) | 100–120+ | Useful for sizing accessory loads and duty cycles |

| Warranty | 18 months free replacement common | Verify per brand and distributor terms |

| Chemistry | Flooded lead–acid | Serviceable and commonly stocked in fleet channels |

| Listing | UL‑listed (brand dependent) | Confirm for regulated installations |

Procurement considerations

- Form factor: 6T vs 6TL—ensure tray geometry, hold‑down style, and terminal type match; 6TL typically denotes top‑post flooding

- Warranty: Free‑replacement windows vary; 18 months is common; pro‑rata terms depend on brand and dealer program

- Core: Deposit/credit may apply depending on jurisdiction and channel

- Packaging: Top‑post batteries with solid maintenance requirements may ship LTL freight; local pickup often available

- Date code: Use within 3–6 months for peak performance; avoid aged inventory when possible

- Certification: Look for UL listing on spec sheets where applicable

Strategic material notes for 6TL

- Plate alloys (typical):

- Positive grid: lead‑antimony or lead‑calcium systems; antimony improves durability and deep‑cycle tolerance, calcium improves grid stability and reduces gassing; antimony‑calcium hybrids exist to balance performance

- Negative grid: lead‑calcium or antimony—choice impacts self‑discharge, water loss, and charge acceptance

- Separators: Absorbent glass mat (AGM) variants may appear in 6TL for specific duty cycles, but standard 6TL units commonly use microporous polyethylene/polyvinyl chloride (PE/PVC) separators to support flooded operation and high cranking

- Electrolyte: Dilute sulfuric acid solution; serviceable under proper ventilation and PPE; ensure compliance with material handling standards

- Case and cover: Polypropylene (PP) for durability, chemical resistance, and ease of post‑seal molding; top‑post design with vent caps or covers

- Terminal hardware: Lead‑alloy posts compatible with stud‑style adapters; corrosion control via anti‑corrosion washers and hardware

- Additives and features (brand dependent): Selenium, tin, and calcium in positive grids to control grid growth and corrosion; vent designs to regulate gas release and reduce electrolyte loss

Quality and compliance

- Verify shipping classifications and restrictions for sulfuric acid content; many top‑post flooded units ship LTL freight or require local pickup

- Check brand and model specs for UL/ANSI compliance; confirm against procurement requirements and regional codes

- Maintain a consistent fill and charge schedule per brand procedures to ensure stable life and performance

Material selection actions for specifiers and buyers

- Confirm plate alloy and separator technology—critical to cranking vs deep‑cycle emphasis

- Align warranty and logistics terms with fleet availability and cost structure

- Validate physical fit (L × W × H), hold‑down geometry, and terminal orientation against the target platform

- Standardize electrolyte handling protocols to ensure safety and uptime

6TL specifications snapshot across common brands (as referenced)

| Brand | Model/SKU | Chemistry | Voltage | CCA | CA/SA | RC (min @ 25 A) | Ah (20 h) | L × W × H (in) | Weight (lb) | Warranty | Listing | Notes |

|—|—|—|—|—:|—:|—:|—:|—|—|—|—|

| Pro‑Series | 6TL (PSC6TL) | Flooded | 12 V | 750 | — | 215 | — | 11.25 × 10.5 × 9.0 | 58 | 18 months FR | UL‑listed | Flooded top‑post; top‑post terminals |

| Remy/DEKA | 6TL‑1 (6TMF) | Flooded | 12 V | 750 | 915 | — | 120 | — | — | — | — | 12 V 750 CCA; CA 915; AH listed as 120 |

| Super Start | 6TL | Flooded | 12 V | — | — | — | — | — | — | — | — | Standard flooded top‑post; details vary |

Sources used:

– Battery Outfitters Cloud: Pro‑Series 6TL spec details

– Remy Battery: Group Size 6TL (Remy/DEKA) ratings and hazardous shipping notice

– Super Start Fleet & Heavy Duty (O’Reilly): 6TL page title reference

In-depth Look: Manufacturing Processes and Quality Assurance for 6tl battery

In-depth Look: Manufacturing Processes and Quality Assurance for 6TL Battery

Overview: The 6TL specification denotes a 12V flooded lead–acid, top-post battery sized to BCI Group 6T/6TL. Representative metrics for commercial-grade 6TL batteries include 750 Cold Cranking Amps (CCA), a Reserve Capacity around 215 minutes at 25 A, and a 120 Ah (C/20) capacity rating. Physical dimensions for the case typically center near 11.25 x 10.5 x 9.0 inches (285.8 x 266.7 x 229 mm) with an approximate mass of 58 lb (26.3 kg).

Illustrative Image (Source: Google Search)

Note: This section outlines a standard manufacturing flow and a quality assurance program consistent with commercial 6TL production. For exact model ratings and dimensions, consult your supplier’s part data sheet.

Manufacturing Process Flow

Preparation (Plate and Material Prep)

- Grid fabrication: Lead-calcium/tin-alloy grids for positive and negative plates are cast to precise alloy tolerances to support corrosion resistance and conductivity.

- Paste preparation: Lead oxides are mixed with sulfuric acid and additives to form active material pastes optimized for paste density, porosity, and cycle life.

- Pastet application: Grids are pasted to target thickness and cured under controlled temperature and humidity to develop active mass structure and adhesion.

- Plate classification: Plates are sorted and binned by weight/active mass to ensure consistent capacity across cells.

Forming (Formation and Formation Control)

- Electrolyte fill and formation: Cells are filled with diluted sulfuric acid. Formation charges convert lead oxides to lead dioxide (positive) and spongy lead (negative), establishing initial capacity.

- Charge profiles: Controlled current/voltage regimes drive repeatable conversion, minimizing sulfation and ensuring uniform plate performance.

- Formation monitoring: Parameters such as Ah delivered, voltage, temperature, and plateau timing are logged to validate conversion.

Assembly (Cell Integration and Pack-Out)

- Stack and weld: Positive/negative plates are interleaved with separators, then welded into groups. Inter-cell connectors and terminals (top-post) are formed and sealed.

- Case and cover assembly: The container and cover are assembled; the battery case is sealed and leak-tested.

- Final electrolyte level and topping: Electrolyte is adjusted to the correct level. Post-formation charging ensures state-of-charge stability.

- Final inspection: Post assembly, visual and mechanical checks ensure post torque, polarity, case integrity, and label compliance.

Post-Assembly and Dispatch

- Final charge and stabilization: Batteries undergo a finishing charge and a rest period to stabilize open-circuit voltage.

- Labeling and packaging: Ratings (CCA, RC, Ah), BCI group, safety markings, and regulatory labels are applied. Packaging is prepared for LTL freight or pickup in line with battery transport regulations.

- Dispatch QC: Random sampling before shipment verifies performance stability and absence of visible defects.

Quality Assurance and Testing Program

Commercial-grade 6TL QA commonly follows ISO 9001 quality management requirements and applies battery-relevant test standards such as IEC 60095-1 (flooded starting batteries). Depending on product scope and market targets, ISO 14001 (environmental management), ISO 45001 (occupational health and safety), and RoHS/REACH compliance documentation are typically maintained.

Table 1: Incoming, In-Process, and Final QA Controls for 6TL

| Test Category | Checks | Equipment | Criteria/Standards |

|---|---|---|---|

| Incoming Materials | Alloy composition; grid dimensions; paste density | XRF, calipers, pycnometer | Within alloy spec; dimensional tolerance bands |

| In-Process (Cure) | Paste hardness; moisture; adhesion | Durometers, moisture probes | Within cure windows |

| Formation | Ah acceptance; voltage plateaus; temperature | Formation rigs with logging | Stable voltage; acceptable Ah throughput |

| Post-Formation | OCV; SCC (specific gravity) consistency | OCV meters; hydrometers | OCV within spec; SG window |

| Final Electrical | CCA; Reserve Capacity; Capacity (Ah); Self-Discharge | Load testers; constant-current cyclers | Meet or exceed model-specific thresholds (e.g., 750 CCA; ~215 min RC; ~120 Ah) |

| Final Mechanical | Dimensions; post torque; weight | CMM/calipers; torque tools; scales | Meet BCI 6T/6TL geometry; secure terminals; expected mass |

| Integrity | Leak/pressure tests; polarity check; internal short detection | Pressure/leak testers; polarity/hi-pot testers | Pass leak test; correct polarity; no internal short |

| Shipping Readiness | Labeling completeness; hazardous markings; packaging integrity | Visual inspection; barcode scans | Regulatory-compliant labels; hazard signage; intact packaging |

Note: Test thresholds are model-specific; use supplier type-approval test protocols to set acceptance bands. Where applicable, batteries are UL-listed and carry a warranty such as 18 months free replacement with pro-rata extension (example 30 months).

Illustrative Image (Source: Google Search)

Table 2: Illustrative 6TL Test Benchmarks for QA Targeting

| Parameter | Benchmark |

|---|---|

| CCA | 750 A |

| Reserve Capacity (25 A) | ~215 minutes |

| Capacity (C/20) | ~120 Ah |

| Case Dimensions | ~11.25 x 10.5 x 9.0 inches (L x W x H) |

| Weight | ~58 lb |

| Warranty | 18 months free replacement; up to 30 months pro-rata (where offered) |

Use these figures to calibrate QA acceptance and to verify supplier-to-supplier variation for your specific SKU.

Compliance, Safety, and Shipping

- Regulatory labeling and safety: Batteries contain sulfuric acid. Top-post connectors and polarity labeling must be correct. If listed, UL labeling indicates third-party conformity for relevant safety aspects.

- Environmental management: ISO 14001 practices typically cover electrolyte handling, lead recovery, and waste minimization; RoHS/REACH documentation aligns with material restrictions where applicable.

- Transport and shipping: Shipped as Class 8 corrosive. Common modes are LTL freight or local pickup due to weight and hazard classification. Ensure packaging, labeling, and MSDS accompany shipments per DOT/ADR requirements.

Why This Matters for Buyers (USA/EU)

- Consistency at scale: Controlled grid alloy and paste cure parameters reduce batch variation in cold-crank and reserve performance—critical for fleet reliability.

- Traceable quality: Formation logs, final electrical tests, and dimensional verification under ISO 9001 provide traceability across lots for warranty and compliance audits.

- Safe and compliant delivery: UL-listed products, proper hazmat packaging, and hazardous shipping documentation reduce transit risk and regulatory exposure for professional users.

Tip: Lock your QA gates to the target 6TL benchmarks (CCA, RC, Ah, geometry, warranty). Require suppliers to provide formation logs, final test reports, and current ISO/RohS/REACH documentation for every lot.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘6tl battery’

Practical Sourcing Guide: 6TL Battery Step-by-Step Checklist

This checklist is for sourcing a Group Size 6TL (6T) flooded, 12V lead–acid starting battery with top-post terminals for North America and Europe.

1) Define Requirements (Non-negotiable)

- Confirm group and terminal type:

- BCI Group 6T (6TL variant), top-post (typical automotive style).

- Flooded lead–acid (FLA), not AGM or gel.

- Electrical and performance:

- Voltage: 12 V

- Cold Cranking Amps (CCA): ≥ 750 (typical for 6TL in this class)

- Reserve Capacity (RC): target ≥ 180–215 minutes at 25 A (per brand)

- Capacity (optional): ~120 Ah for backup/inverter support (brand dependent)

- Environmental and compliance:

- RoHS/REACH (EU buyers)

- UL listing (if available from brand)

- Sulfuric acid handling and shipping restrictions (hazardous)

2) Build the RFQ

- Include:

- Battery family: Group 6TL, flooded lead–acid, top-post, 12 V

- Minimum performance: 750 CCA; RC ≥ 180 minutes; capacity ~120 Ah if needed

- Warranty: 18 months free replacement (typical), plus 30 months pro‑rata (brand dependent)

- Delivery locations (NA and EU), preferred Incoterms

- Quantity and lead time

- Safety documents: MSDS, spec sheets, UN numbers for shipping

- Shipping terms: LTL freight for hazardous batteries or local pickup

- Core credit policy for returns

- Certification marks (UL, CE, RoHS/REACH as applicable)

3) Screen Suppliers (B2B-first, USA and Europe)

- Vet vendors for:

- Clear brand provenance (manufacturer or official distributor)

- Warranty terms, service network, and core acceptance policy

- Ability to ship across US/EU or provide equivalent EU alternatives

- Example US sources (specs vary by brand):

- Pro‑Series 6TL: 12 V, 750 CCA, RC 215 min, 120 Ah (brand dependent), 18‑month replacement + 30‑month pro‑rata; height 229 mm; UL listed (vendor claim); freight/pickup required; exchange core policy available.

- Super Start Fleet & Heavy Duty 6TL: 6TL part number indicates 6T group; validate 12 V, CCA/RC with spec sheets at supplier.

- East Penn/DEKA 6TL (part 6TL‑1): 12 V, 750 CCA, 915 CA, 120 Ah, RC (brand dependent), hazmat shipping via LTL or pickup.

- EU buyers: If equivalent 6TL is not readily available, request a brand‑equivalent Group 6T flooded battery (top‑post) meeting the same performance requirements and EU certifications. Confirm fitment dimensions and terminal style before ordering.

4) Evaluate Quotes

- Compare apples to apples:

- CCA, RC, and Ah ratings

- Warranty length and structure

- Dimensions and mass (ensure tray/compartment fit)

- Shipping method and hazmat surcharges

- Core charge, return logistics, and credit value

- Lead time and MOQs

5) Logistics and Compliance

- Shipping:

- Flooded lead–acid batteries typically require LTL freight or local pickup due to hazmat classification.

- Confirm carrier restrictions for cross‑border shipments (US/EU), paperwork (MSDS, UN numbers), and palletization requirements.

- Incoterms:

- If shipping to the US and EU, use suitable Incoterms for freight coordination and customs clearance.

- Safety:

- Ensure proper acid handling procedures, spill kits, and PPE for receiving and installation teams.

6) Place the Order

- Include in the PO:

- Exact part number(s) (e.g., 6TL‑1, PSC6TL, 6TL for the chosen brand)

- Quantity, required delivery dates, shipping terms, and receiving address

- Warranty and core return instructions

- Compliance documents (MSDS/spec sheets)

7) Receive, Inspect, Test

- Check:

- Packaging integrity (no cracks, leaks, or loose terminals)

- Polarity orientation and terminal condition

- Freshness date/charge state if available

- Specs and warranty card match the PO

- Test:

- Perform open‑circuit voltage (OCV) check and top‑up if flooded electrolyte is accessible per the brand’s instructions.

- Optional: capacity/load test for QC (aligned with your in‑house protocols).

8) Core Return and Closeout

- Coordinate core pickup within the vendor’s window.

- Keep records: invoices, spec sheets, MSDS, warranty card, and test logs.

- If sourcing EU equivalents, capture the new equivalent part number(s) and specs for future replenishment.

Quick Spec Benchmarks for RFQ/RFP

| Parameter | Typical Value (US market examples) | Notes |

|---|---|---|

| Voltage | 12 V | Standard |

| BCI Group | 6T (6TL variant) | Confirm top‑post design |

| Cold Cranking Amps (CCA) | 750 | Minimum target |

| Cranking Amps (CA) | ~915 (brand dependent) | Not mandatory but useful context |

| Reserve Capacity (RC) | 180–215 minutes @ 25 A | Brand dependent |

| Capacity (Ah) | ~120 Ah | Useful for backup/inverter use |

| Warranty | 18 months free replacement + 30 months pro‑rata | Brand dependent |

| Dimensions (L × W × H) | ~285.8 × 266.7 × 229 mm | Verify against tray |

| Mass | ~26.3 kg | Check handling and mounting |

| Listing | UL listed (vendor dependent) | EU: ensure CE/RoHS/REACH compliance |

| Shipping | LTL freight or local pickup (hazmat) | Acid handling required |

Vendor Examples and Where They Fit (for RFQ benchmarking)

| Vendor/Brand | Key Specs (as listed) | Warranty | Shipping Policy | Notes |

|---|---|---|---|---|

| Pro‑Series 6TL (PSC6TL) | 12 V, 750 CCA, RC 215 min, 120 Ah (brand dependent), H 229 mm, 26.3 kg | 18‑month replacement + 30‑month pro‑rata | Freight or pickup | UL listed claim; exchange core policy |

| Super Start Fleet & Heavy Duty 6TL | 6T/6TL part identifier; confirm specs | Brand dependent | Standard ground/freight | Validate against product spec sheets |

| East Penn/DEKA 6TL (6TL‑1) | 12 V, 750 CCA, 915 CA, 120 Ah, RC ~180–215 min (brand dependent) | Brand dependent | LTL freight or pickup | Hazmat classification for shipping |

Notes:

– EU buyers can substitute an equivalent Group 6T flooded battery from EU brands (e.g., Exide, Varta, Banner) with matching 12 V/CCA/RC and top‑post terminals. Confirm dimensions and certifications before finalizing.

– Verify brand/series warranty and listing claims directly with the supplier before purchase.

Comprehensive Cost and Pricing Analysis for 6tl battery Sourcing

Comprehensive Cost and Pricing Analysis for 6TL Battery Sourcing

Cost breakdown (12V flooded Group 6TL lead-acid)

The table below isolates core cost components and the primary drivers to watch. Use it as a diagnostic checklist before locking in agreements; plug in supplier quotes to quantify impact.

| Cost driver | What it covers | Why it matters | Key negotiation lever |

|---|---|---|---|

| Materials (lead, Pb/Ca grids, separators, electrolyte) | Lead-acid chemistry and plate stacks | Lead price volatility; Pb/Ca construction affects performance/CCA stability | Request indexed pricing (LME lead/lasticity) and fixed-cap clauses with review gates |

| Manufacturing and labor | Casting, assembly, formation, filling, testing | Consistency in CCA/RC and warranty claim rates | Tie price to performance specs (e.g., meets 750 CCA end-of-life) |

| Overheads & warranty | Plant overhead; warranty reserve (18 months free replacement, 30 months pro‑rata typical) | Warranty policy shifts effective TCO | Prefer free-replacement-only terms; cap defect rate/term where possible |

| Logistics to DC | Inbound to your DC from OEM/factory | Freight is variable by mode and fuel | Consolidate partials; target LTL-to-FTL thresholds |

| Last-mile and fulfillment | LTL, delivery to job sites, dock delivery | Hazmat surcharges; accessorial fees add up | Negotiate liftgate, inside delivery, limited access fees |

| Returns, exchange, cores | Defect returns; used core handling | Lost cores raise net cost; $26 core charge typical | Require timely core credit, free replacement pickup, and core-credit policy clarity |

| Compliance & documentation | Hazmat declarations; UL listing verification | Prevents penalties and shipment holds | Require UL listing, MSDS, UN numbers, and HS codes upfront |

Total cost of ownership (TCO) framework

TCO focuses on what you keep and what breaks even. Use the formula to compare SKUs consistently.

Illustrative Image (Source: Google Search)

| Element | Formula | Where to get data |

|---|---|---|

| Acquisition cost | Supplier quote or retail street price | Supplier quotes; retail snapshots below |

| Freight & handling | LTL quote or calculated: (linehaul + fuel) × pallet count + accessorials | Carrier quotes; your freight audits |

| Warranty impact | Warranty unit cost = (Defect rate × free replacement cost × units) ÷ units sold | Your historical rates; supplier defect data |

| Effective net cost | Effective cost = Acquisition + freight/handling − warranty benefit | Combine rows |

| Residual value | Refund for returnable cores, if applicable | Supplier core-credit policy |

| Periodized TCO | Periodized TCO = (Effective net cost − residual value) ÷ planned units/period | Your utilization plan |

Pricing landscape snapshot (USA)

Prices vary by brand, stock availability, and core policy.

| Retailer / Supplier | SKU | MSRP (USD) | CCA | Warranty | Shipping policy | Notes |

|---|---|---|---|---|---|---|

| Pro-Series via Battery Outfitters | PSC6TL | $268.99 | 750 | 18 months free replacement; 30 months pro‑rata | Additional shipping options; core exchange $26 if no exchange | UL listed; factory fresh; “Pro-Series Commercial” positioning |

| Remy Battery (East Penn/DEKA) | 6TL-1 | $318.99 | 750 | Dealer-specific | LTL freight or local pickup due to sulfuric acid | Requires hazmat freight; part number 6TMF listed |

Implications:

– Expect USA retail band around $270–$320 for a 6TL 12V 750 CCA flooded lead-acid.

– Freight to your door may add material cost if LTL is required; retail quotes often exclude LTL accessorials.

Unit-cost math (for benchmarking)

Estimate unit cost using linehaul, LTL fuel surcharges, and accessorials.

| Item | Formula | Example inputs | Output |

|---|---|---|---|

| Linehaul per pallet | Carrier quote per mile × distance (miles) | $2.25/mile × 900 miles | $2,025 |

| Fuel surcharge | Linehaul × fuel % (e.g., 22%) | $2,025 × 22% | $445.50 |

| Accessorials | Liftgate (e.g., $175) + inside delivery ($100) + limited access ($95) | $175 + $100 + $95 | $370 |

| Total LTL for pallet | Linehaul + fuel + accessorials | $2,025 + $445.50 + $370 | $2,840.50 |

| Per-unit freight | Total LTL ÷ units per pallet (pallet tolerance permitting) | $2,840.50 ÷ 20 | $142.02 |

Note: Always validate unit placement and weight limits with the carrier before confirming per-pallet counts.

Logistics and compliance considerations

- Hazardous material: Sulfuric acid content triggers hazmat rules. Expect LTL freight or local pickup. Factor UN numbers, proper placarding, and MSDS in your documents and routing.

- Packaging: Ensure reinforced pallets, tie-downs, and terminal protection. Palletized and strapped configurations reduce damage claims and delays.

- Returns: Plan free-replacement pickup routes and verify core-credit windows. Core credits vary; clarify net impact in your TCO model.

Cost-saving levers (tactical and structural)

| Lever | How it reduces cost | Action to take | Typical impact (qualitative) |

|---|---|---|---|

| Volume bundling to LTL/FTL | Lowers per-unit freight | Aggregate demand across sites; set a weekly consolidation cadence | Moderate to significant |

| Warranty-first policies | Reduces cash outlay for early failures | Prioritize 18-month free replacement only; cap total pro‑rata exposure | Significant |

| Fast claims and replacement turn-around | Cuts downtime costs | Negotiate direct ship to job sites; 24–48-hour replacement windows | Moderate |

| Freight accessorial controls | Eliminates avoidable fees | Bundle inside delivery; schedule dock-high loading; avoid limited-access stops where possible | Moderate |

| Core return standardization | Improves core-credit recovery | Define core staging, labeling, and pickup windows; track core aging | Moderate |

| Price indexation (lead) | Stabilizes materials volatility | Include lead-index clauses with quarterly reviews and floors/ceilings | Moderate |

| SKU rationalization | Simplifies SKU mix and inventory | Standardize around 6TL configurations (CCA/RC) that cover the majority fleet | Moderate |

| Cross-dock to branch stores | Reduces last-mile costs | Establish a cross-dock cadence to your retail/service branches | Moderate |

| Multi-vendor sourcing | Avoids single-point failures | Maintain two qualified SKUs with interchangeable specs; avoid proprietary features | Minor to moderate |

Regional considerations (USA vs Europe)

- USA sourcing: Expect retail LTL freight, UL listing, and brand availability (e.g., Pro-Series, East Penn/DEKA). Core-return handling and documentation are straightforward when aligned with standard hazmat freight.

- Europe sourcing: Include customs/duty (CN 8507), VAT handling, ADR compliance (hazmat road transport), and potential delivery time variability. Confirm CE/UL equivalents and regional warranty terms. Duty/VAT and cross-border returns can materially increase landed cost—validate a sample landed-cost quote before scaling.

What to request from suppliers

- Certified specs and performance: 12V, Group 6T/6TL; CCA ≥ 750 at test; RC ≥ 215 minutes; AH where applicable; terminal layout.

- Compliance: UL listing reference; UN number; MSDS; hazmat shipping statements; HS code (likely 8507.10).

- Warranty terms: 18-month free replacement and 30-month pro‑rata or equivalent; claim process and turnaround.

- Logistics: Pallet configuration, unit weight/dimensions, liftgate feasibility, and accessorial fees.

- Commercials: Price bands (single vs LTL), freight terms (FOB vs delivered), lead time, payment terms, MOQ/QMOQ, and rebate/eligible discounts.

Use these parameters to operationalize your cost model, tighten your net cost per unit, and lower total cost of ownership for 6TL battery procurement.

Alternatives Analysis: Comparing 6tl battery With Other Solutions

Alternatives Analysis: Comparing 6TL Battery With Other Solutions

Purpose: This comparison helps fleet managers, OEMs, and mobile power integrators choose between a Group 6TL flooded lead-acid battery, a Group 6TL AGM configuration, and a LiFePO4 “drop‑in” 12V alternative that fits a Group 31 footprint. Criteria focus on cold cranking amps (CCA/CA), reserve capacity (RC), cycle life, duty and environmental robustness, safety, charge profile, maintenance, weight, warranty, and total cost of ownership (TCO).

Key takeaways

– If your application relies on 12V cranking with simple charging and moderate parasitic loads, flooded 6TL delivers value and strong cold weather cranking at the lowest purchase price.

– If you need longer life, deeper cycling of accessories, maintenance‑free operation, and better vibration tolerance, a Group 6TL AGM or Group 31 AGM is the next step.

– If you need 4–5x cycle life, fast charging, and stable mid‑trip throughput from accessories, a 100–150Ah LiFePO4 “drop‑in” can lower lifecycle cost and improve availability—if charging infrastructure and BMS integration are properly designed.

Data table: side-by-side comparison (typical specifications and TCO)

Illustrative Image (Source: Google Search)

| Attribute | Flooded Lead‑Acid: Super Start/Pro‑Series 6TL | AGM: East Penn/DEKA 6TL | LiFePO4 12V Drop‑in (Group 31 footprint) |

|---|---|---|---|

| Voltage / BCI group | 12V / Group 6TL | 12V / Group 6TL | 12V / Group 31 footprint (universal case; ensure fit) |

| Cranking (CCA/CA) | 750 CCA; CA not specified | 750 CCA; 915 CA | CCA rarely rated; typically ≥1000A surge BMS-limited |

| Reserve capacity (RC) | 215 min @ 25A | ≥215–230 min (typical for comparable 6TL/6T) | 100Ah equivalent ≈ 200 min at 5A draw (usable ~80Ah for 20h) |

| Capacity (Ah) | Not specified | ~120 Ah (C/20) | 100–150Ah nominal (usable 80–120Ah depending on model) |

| Dimensions (L×W×H, in) | 11.25 × 10.5 × 9.0 (Pro‑Series) | Typical 6TL: ~11.25 × 10.5 × 9.0 | Group 31: ~13.0 × 6.8 × 9.4 (varies) |

| Weight (lb) | ~58 | ~58–60 | ~30–34 (lighter by ~24–28 lb) |

| Cycle life | 200–400 cycles at 50% DoD | 400–700 cycles at 50% DoD | 2,000–5,000 cycles at 50–80% DoD |

| Maintenance | Periodic fluid checks; terminal cleaning | None (sealed) | None (sealed) |

| Safety / venting | Vented; acid handling; hydrogen gas | Sealed VRLA; no acid, improved vibration resistance | Sealed; BMS protection; no gas; thermal management required |

| Temperature performance | Good cold cranking; capacity falls in cold | Better deep‑cycle tolerance in heat; improved vibration resistance | Excellent usable capacity in cold; may require low‑temp protection |

| Charge profile | Conventional lead‑acid (bulk/absorb/float) | Lead‑acid (bulk/absorb/float; can handle partial SoC cycling) | Constant current + constant voltage; typically higher charge acceptance |

| Warranty | Flooded: 18–30 months typical | AGM: 24–36 months typical | LiFePO4: 3–10 years typical (brand dependent) |

| Core & freight | Core charge; may ship LTL | Core charge; may ship LTL | No core; can ship parcel for 100–150Ah units |

| MSRP (USD) | ~$269 (Pro‑Series 6TL) | ~$319 (DEKA 6TL‑1) | ~$1,000–$1,500 (100–150Ah “drop‑in”) |

| TCO (per 5 years) | Lowest upfront; higher refresh rate | Mid cost; mid replacement interval | Highest upfront; lowest replacement frequency if used cyclically |

Notes:

– Flooded 6TL and AGM 6TL specifications are based on public listings for Super Start/Pro‑Series and DEKA 6TL. The AGM listing shows 915 CA, 750 CCA, and a 120 Ah rate; RC is inferred from comparable 6TL specifications (215–230 min). Dimensions/weight are similar to Group 6TL.

– The LiFePO4 column represents a typical “Group 31 footprint” 100–150Ah product category. Actual weight, capacity, and charge profiles vary by manufacturer. Select a model with a suitable BMS and low‑temp charging cutoff if frequent sub‑freezing operation is expected.

Use-case fit

– Start-stop service and auxiliary loads (moderate), minimal maintenance: Flooded 6TL

– Good cold cranking and high reserve support; budget-friendly purchase and swap.

– Mixed cranking + cycling, vibration/heat exposure, no-maintenance needed: AGM (6TL or Group 31)

– Better deep-cycle tolerance and vibration resistance vs. flooded; sealed and easy to manage.

– Accessory cycling, high depth-of-discharge, frequent partial state-of-charge operation: LiFePO4 “drop‑in”

– Stable voltage under load; fast recharge; long life. Requires correct charging (LiFePO4 profile) and integration with alternators/BMS.

Charging considerations (operational)

– Flooded 6TL and AGM 6TL:

– Bulk 14.4–14.8V; float 13.2–13.5V; temperature compensation recommended.

– Flooded requires regular watering; equalization may be applicable in deep-cycle service.

– LiFePO4 drop‑in:

– Bulk/absorb ~14.4–14.6V; float 13.4–13.6V (brand-specific).

– Higher charge acceptance enables shorter recharge cycles; monitor BMS temperature limits.

Risk and compliance

– Flooded: Safety data sheet required for sulfuric acid; electrolyte handling training and secondary containment for storage. Shipping under hazardous classifications may apply.

– AGM: Sealed VRLA reduces acid handling risks; still subject to standard battery shipping regulations and local disposal requirements.

– LiFePO4: Shipping restrictions may apply by air; verify ground shipping status and temperature control. Compliance with UL 1973 or UL 9540 is advisable for stationary or auxiliary power installations.

Illustrative Image (Source: Google Search)

Integration guidance

– Physical fit: If a Group 31 LiFePO4 is preferred, verify case length, terminal layout (top-post vs. stud), hold-down compatibility, and tray clearance.

– Electrical protection: Use appropriately rated fusing on accessory feeds. For LiFePO4, ensure BMS compatibility with vehicle electronics and alternator charging profiles.

– Monitoring: For fleet operations, add battery monitoring (voltage, current, temperature, and SOC) to manage SoC, detect parasitic drains, and schedule charging.

Bottom line

– For straightforward start-cranking duty with minimal auxiliary cycling, a flooded 6TL offers the best cost per start and reserve capacity at the lowest upfront price.

– For higher vibration/heat exposure and moderate cycling, AGM (6TL or Group 31) extends service life and removes maintenance without a major price jump.

– For sustained accessory loads and cycling, LiFePO4 drop‑ins reduce lifecycle cost and downtime despite higher purchase prices—assuming proper charging and thermal management.

Essential Technical Properties and Trade Terminology for 6tl battery

Essential Technical Properties and Trade Terminology for 6TL Battery

6TL (BCI Group Size 6T with the “L” length variant) is a 12V flooded lead-acid, top-post, heavy-duty commercial group used widely in trucks, buses, industrial equipment, and stationary backup. Buyers in the USA and Europe typically source 6TL batteries from national distributors and OEMs, choosing based on cold cranking amps (CCA), reserve capacity (RC), warranty, and logistics conditions.

Typical Technical Properties (verify per brand/model)

- Chemistry and Type: Flooded (wet) lead-acid, maintenance-accessible (vent caps).

- Nominal Voltage: 12V.

- Terminal Layout/Type: Top post (top terminal); L indicates the longer group length.

- Core BCI Dimensions (approximate, vary by brand):

- Length: ~285.8 mm (11 1/4 in).

- Width: ~266.7 mm (10 1/2 in).

- Height: ~228–229 mm (9.0 in).

- Cold Cranking Amps (CCA): 750 CCA (e.g., Pro‑Series 6TL).

- Cranking Amps (CA): ~915 CA (e.g., some Remy/East Penn variants).

- Reserve Capacity (RC): ~215 minutes @ 25A (Pro‑Series 6TL).

- Capacity (Ah): Some variants list ~120 Ah at the 20‑hour rate (brand‑specific; verify on datasheet).

- Weight: ~26.3 kg (58 lb) typical.

- Warranty (examples):

- 18‑month free replacement + 30‑month prorated (Pro‑Series).

- Terms vary by brand/distributor; confirm warranty length and coverage on the sales page or invoice.

- Certifications/Approvals (brand‑specific):

- UL listing is product‑dependent; verify on the product datasheet.

- Factory fresh supply common for new stock; confirm on product page.

- Compliance (general): 6TL is a wet lead‑acid battery classified as hazardous (corrosive) under applicable regulations; comply with packaging, labeling, and ground‑only shipping rules.

- Shipping Mode:

- US (common): LTL freight or local pickup; many suppliers do not ship by air; core exchange programs may apply.

- EU: Ground‑only freight with hazardous handling; carriers and mode vary by country; consult distributor terms.

Brand/Model Comparison (as listed by sources)

| Brand/Model | MPN (if shown) | CCA (A) | CA (A) | RC (min @ 25A) | Dimensions L × W × H (mm) | Weight (kg) | Voltage | Warranty (if shown) | Notes |

|---|---|---|---|---|---|---|---|---|---|

| Pro‑Series 6TL (PSC6TL) | – | 750 | – | 215 | 285.8 × 266.7 × 229 | 26.3 | 12V | 18‑month free replacement + 30‑month prorated | UL listed; factory fresh; freight/local pickup; core program |

| Remy/East Penn 6TL (6TL‑1) | 6TMF | 750 | 915 | – | – | – | 12V | – | Hazardous (sulfuric acid); LTL freight or pickup |

| 6T/6TL title variant | – | – | – | – | – | – | 12V | – | Title reference; specs vary by brand/model |

Note: Specifications such as CCA, CA, RC, capacity (Ah), warranty, and dimensions vary by manufacturer and SKU. Always verify on the product page and technical datasheet.

Illustrative Image (Source: Google Search)

Trade Terminology and Commercial Conditions

| Term | Meaning/Relevance to 6TL | Typical Range/Condition |

|---|---|---|

| MOQ (Minimum Order Quantity) | Minimum units per order; distribution dependent. | Often 1 pallet or full case for wholesale; confirm with distributor. |

| OEM | Original equipment manufacturer battery or direct from OEM. | Check brand‑specific OEM fitments or equivalency listings. |

| BCI Group Size | Physical and terminal standard. | 6T is the base; 6TL is the longer variant. |

| CCA (Cold Cranking Amps) | Battery’s 30‑second cranking power at −18°C. | 650–800 CCA typical for 6TL; select per vehicle/engine requirement. |

| CA (Cranking Amps) | Cranking power at 0°C. | ~850–950 CA common; 915 CA shown on one Remy variant. |

| RC (Reserve Capacity) | Minutes @ 25A the battery supports with engine off. | ~180–230 min typical; 215 min on Pro‑Series. |

| Ah (Amp‑Hour) | Capacity over 20 hours (C/20). | Some 6TL list ~120 Ah; verify on datasheet. |

| Warranty | Coverage duration and terms. | Many brands offer 18 months free replacement + extended prorated; terms vary. |

| Core Policy | Old battery return for credit. | Core charges may apply if no exchange; check distributor terms. |

| Freight Class | LTL classification for lead‑acid batteries. | Typically Class 65–70 for 12V SLI; confirm with carrier. |

| Shipping Mode | Mode allowed for hazardous batteries. | Ground only (LTL) common; air prohibited by many carriers; check destination rules. |

| Incoterms | Delivery risk/cost responsibility. | EXW/FOB common for distributor purchases; DAP/DDP available via some distributors. |

| Compliance/Approvals | Regulatory or standard compliance (e.g., UL). | Product‑specific; verify UL listing and regional requirements on datasheet. |

| Documentation | Invoice, SDS, MSDS, homologation. | Required for B2B procurement and transport; ensure SDS accompanies shipment. |

| Stock Condition | New vs. refurbished. | Most B2B transactions require factory‑fresh stock; verify on product page. |

Quick Buyer Checklist

- Confirm group size (6T/6TL), physical fit, and terminal orientation for your application.

- Match CCA and RC to engine requirements and expected accessory loads.

- Review warranty length and coverage; confirm core exchange policies.

- Verify shipping mode, freight class, hazmat labels, and delivery timeline.

- Request SDS/MSDS and, if applicable, UL listing confirmation.

- Align purchasing terms (MOQ, Incoterms, payment, and documentation) before ordering.

Always validate specifications and commercial terms against the product page and technical datasheet for the exact brand and MPN you are purchasing.

Navigating Market Dynamics and Sourcing Trends in the 6tl battery Sector

Navigating Market Dynamics and Sourcing Trends in the 6TL Battery Sector

The 6TL (BCI Group 6T/6TL) flooded lead–acid starter battery remains a staple in North American commercial and industrial fleets. Despite continued growth in 12V lithium in passenger vehicles, 6TL demand remains resilient in heavy-duty applications because of cost, robustness, and widespread service infrastructure. For U.S. and European buyers, the core challenge is not a lack of choice—rather, it’s the variability in chemistry (flooded vs. AGM), brand labeling, and cross-compatibility, plus freight and compliance constraints that complicate sourcing and long‑term cost.

Below is a concise guide to market dynamics and sourcing trends for the 6TL segment, with practical tables to speed selection and procurement.

What the 6TL category covers: specs and representative products

- Chemistry: Flooded lead–acid (FLA) is standard; AGM variants exist but are less common in Group 6T/6TL applications.

- Typical specs (representative): 12 V; 750 CCA (Cold Cranking Amps); ~215 min reserve capacity; ~120 Ah (20‑hour rate); 11.25 x 10.5 x 9 inches; ~58 lb.

- Core logistics: Lead‑acid contains sulfuric acid; freight is often restricted for small-parcel shipments and typically requires LTL freight or local pickup. Some sellers note hazardous handling and shipping constraints for this reason.

To anchor this, Table 1 compiles representative specs and disclosures from current sellers.

Table 1 — Representative 6TL products and key specifications

| Brand / Line | Part Number | Chemistry | CCA (CCA / CA) | Ah / RC (if stated) | Dimensions (in) | Weight | Price (USD) | Freight / Hazmat Notes | Warranty | Source(s) |

|---|---|---|---|---|---|---|---|---|---|---|

| Pro‑Series | PSC6TL | Flooded | 750 CCA | RC 215 min @25 A; 120 Ah (20‑h) | 11 1/4 x 10 1/2 x 9 | 58 lb | 268.99 | Hazmat noted; shipping options available | 18‑mo FR; 30‑mo pro‑rata | Battery Outfitters |

| East Penn / DEKA | 6TL‑1 | Flooded | 750 CCA; 915 CA | 120 Ah (20‑h) | Not stated | Not stated | 318.99 | Hazardous material; ship LTL or local pickup | Not stated | Remy Battery |

| Super Start (SSB) | 6TL | Flooded | Not stated | Not stated | Not stated | Not stated | N/A | Reference product listing | Not stated | O’Reilly (listing) |

Note: The East Penn/DEKA and Super Start entries reflect listing‑level disclosures; detailed spec sheets may vary by SKU.

Demand drivers in the U.S. and Europe (6T/6TL use)

- Heavy‑duty fleets and service bodies: Utility, telecom, construction, and municipal fleets continue to standardize on 12 V Group 6T for starting auxiliary equipment, compressors, and on‑board tools.

- Cold‑start environments: High reserve capacity and strong cold‑cranking performance favor flooded designs in regions with severe winters.

- Service model availability: Dealers and distributors across the U.S. maintain established interchange programs for 6T/6TL; European channels exist but are comparatively smaller and require more validation due to varying EN standards and labeling conventions.

- Electrification adjuncts: Even as 400 V systems expand in Class 6–8 trucks, 12 V remains essential for control modules and safety systems, stabilizing demand for reliable starter batteries.

Supply chain and sourcing dynamics shaping 6TL

- Lead price and volatility: Lead is the dominant raw material cost component in flooded batteries, and price fluctuations pass through to pricing with some lag. Buyers should expect lead‑linked pricing and include index‑linked terms where feasible.

- Brand labeling and SKU consistency: The same group size may appear as “6T,” “6TL,” or a brand‑specific SKU. Interchange is common, but physical features (top‑post vs. terminal orientation), hold‑down configurations, and venting layouts can differ—always confirm by spec rather than name alone.

- QA and warranty: Commercial warranties vary widely—from “free replacement” windows to pro‑rata programs. Align warranty scope with fleet duty cycles and climate risk.

- Shipping and handling: Many vendors explicitly restrict small‑parcel shipments due to sulfuric acid. Freight class, ORM‑D/LTL, and liftgate needs can materially affect landed cost and lead time.

Sustainability, compliance, and regulatory trends

- Prop 65 and hazmat handling: Lead‑acid batteries carry Proposition 65 warnings in California; distributors must disclose hazard classifications and shipping limits.

- Prop 65 & RoHS/REACH: European buyers should expect RoHS/REACH compliance confirmation and conflict‑minerals documentation from suppliers and OEMs.

- Traceability: OEMs increasingly request unique identifiers or production lot traceability—more common in lithium today, but expanding to lead‑acid in select programs.

- ESG reporting: Corporate sustainability teams may request recycled‑lead content and recycling take‑back commitments. Plan for documentation and reporting alignment across fleet depots.

Risk management in sourcing 6TL

- Cross‑reference specs, not just part numbers: Use BCI group, voltage, CCA, and RC/Ah to validate equivalence. Confirm terminal type and layout.

- Freight strategy: Pre‑book LTL lanes, qualify liftgate vs. dock‑high options, and plan for local pickup where cost‑effective.

- Warranty alignment: Match warranty duration to expected duty cycle; ensure clear claims process and test criteria for pro‑rata adjustments.

- Environmental controls: Store upright in ventilated areas; maintain watering plans and spill kits to reduce failure rates and safety incidents.

Pricing and total cost of ownership (TCO)

Flooded lead–acid 6TLs are cost‑efficient, but TCO hinges on service life, charge management, and shipping. Table 2 compares headline pricing and key spec points from two active sources.

Table 2 — Price and spec snapshot (illustrative)

| Brand / Line | Part Number | Price (USD) | CCA (CCA / CA) | Ah / RC (if stated) | Freight / Hazmat Notes | Warranty | Source(s) |

|---|---|---|---|---|---|---|---|

| Pro‑Series | PSC6TL | 268.99 | 750 CCA | RC 215 min @25 A; 120 Ah | Hazmat noted; shipping options available | 18‑mo FR; 30‑mo pr‑rata | Battery Outfitters |

| East Penn/DEKA | 6TL‑1 | 318.99 | 750 CCA; 915 CA | 120 Ah (20‑h) | Hazardous; ship LTL or local pickup | Not stated | Remy Battery |

Indicative only; check SKU and test criteria before procurement.

Practical procurement checklist (6T/6TL)

- Validate fit and performance: Confirm BCI 6T/6TL, 12 V, CCA, and capacity (Ah/RC). Verify terminal type, polarity, and hold‑down configuration.

- Freight and hazmat: Plan LTL; verify ship‑to addresses for liftgate, accessorials, and delivery windows. Confirm hazmat declarations and lead times.

- Warranty and support: Map warranty terms to fleet duty cycles; confirm pro‑rata calculation and claims process; ensure local service coverage.

- Compliance: Obtain Prop 65 statements (U.S.) and RoHS/REACH statements (EU); align on documentation standards and retention for audits.

- Logistics and storage: Define staging areas, charging stations, and maintenance protocols (watering, top‑off, equalization) to extend life.

- Alternate SKUs and stocking: Evaluate at least two interchangeable SKUs to mitigate stock‑out risk; monitor lead times and spot freight lanes.

—

Bottom line: The 6TL segment remains steady, with flooded lead–acid designs dominant due to cost, availability, and serviceability. Buyers who benchmark by spec rather than name, plan freight under hazmat constraints, and align warranty and maintenance practices to duty cycles will achieve predictable total cost and uptime across U.S. and European operations.

Frequently Asked Questions (FAQs) for B2B Buyers of 6tl battery

FAQs for B2B Buyers: 6TL Battery (Group Size 6T/6TL)

1) What is the 6TL battery and how is it different from 6T?

- 6TL refers to the BCI Group Size for top-post starting batteries used in heavy-duty and fleet vehicles.

- 6T and 6TL are used interchangeably in the market. Check your chassis fit and terminal layout to confirm compatibility.

- Typical flooded lead-acid chemistry with top-post terminals.

2) What are the key specifications I should plan for?

Use these representative specs for capacity and fitment planning. Values vary by brand and country.

| Parameter | Example Value | Notes |

|---|---|---|

| Voltage | 12 V | Lead-acid starting battery |

| BCI Group | 6T / 6TL | Fitment group |

| Cold Cranking Amps (CCA) | 750 CCA | Reference: Pro-Series; remy indicates CA 915 CCA 750 |

| Reserve Capacity (RC) | 215 min @ 25 A | Reference: Pro-Series |

| Capacity (Ah) | ~120 Ah rate | Reference: remy; varies by brand |

| Dimensions (L×W×H) | 11 1/4 in × 10 1/2 in × 9 in | 285.8 mm × 266.7 mm × 229 mm |

| Weight | 58 lb | 26.3 kg |

| Warranty (example) | 18 months free replacement; 30 months pro‑rata | Brand and region dependent; verify at order |

3) Which applications and vehicles commonly use 6TL?

- Heavy-duty trucks, commercial fleets, buses, and industrial equipment where Group 6TL is specified.

- Confirm fit and electrical requirements (CCA/RC, Ah) against chassis recommendations and original equipment. Brand-specific fitment tools and catalogs are available from distributors and manufacturers.

4) How are these batteries shipped and handled?

- Shipping class: hazardous (sulfuric acid); shipped LTL freight or local pickup.

- Handle with care: wear eye/hand protection; keep upright; avoid extreme temperatures. Follow SDS guidance for spills and emergency response.

- Store and charge in ventilated areas; maintain recommended electrolyte levels in flooded batteries.

5) What warranty and return policy should I expect?

- Warranty varies by brand and region (USA vs. Europe). Example: 18‑month free replacement plus 30‑month pro‑rata.

- Freight damage claims: document condition at delivery, retain packaging, and contact carrier and supplier promptly.

- Core returns: a core charge may apply when no battery is exchanged. Return conditions, timelines, and fees vary by supplier.

6) What pricing and lead times are typical?

- Example price: ~$269–$319 per unit depending on brand and region; contact distributor for volume pricing.

- Freight minimums and surcharges may apply; local pickup can be more cost-effective.

- Stock varies; verify lead time before placing bulk orders.

7) What are the installation and maintenance requirements?

- Top-post terminals: confirm polarity and terminal hardware; secure hold-downs as per chassis spec.

- Electrolyte service: flooded designs require periodic checks and topping with distilled water; do not overfill.

- Charging: use appropriate voltage/current; avoid deep discharge; monitor state of charge during seasonal storage.

- Environmental: comply with local and EU regulations for storage, spill response, and disposal; batteries must be collected separately and recycled.

8) Are there equivalents, alternates, and brand options?

- Equivalent BCI groups and brands include East Penn/DEKA and Super Start Fleet & Heavy Duty in the 6T/6TL configuration.

- Validate equivalent fit and performance against chassis requirements; confirm warranty terms when substituting brands.

- Regional availability and warranty conditions may differ between USA and Europe; verify with the supplier.

Strategic Sourcing Conclusion and Outlook for 6tl battery

Strategic Sourcing Conclusion and Outlook for 6TL Battery

The 6TL remains a dependable, high-availability option for commercial and heavy-duty applications in the US and Europe. Its balanced performance, UL listing, and factory-fresh warranty make it an efficient procurement choice where consistent specifications matter.

Core specs

| Attribute | Value |

|---|---|

| Voltage | 12 V |

| Cold Cranking Amps (CCA) | 750 CCA |

| Reserve Capacity | 215 min @ 25 A |

| Capacity (alternative) | 120 Ah |

| Dimensions | 11 1/4 × 10 1/2 × 9 in (285.8 × 266.7 × 229 mm) |

| Weight | 58 lb (26.3 kg) |

| Warranty | 18-month free replacement; 30-month pro‑rata |

Short-term outlook: Stable availability from East Penn/DEKA and Super Start lines; freight or local pickup typically required. Expect price variance by brand (e.g., $268.99–$318.99) and a core charge on returns.

Mid-term outlook: Consistent specification baselines and warranty structures favor the 6TL as an interchangeable, commercial-grade choice for off-highway fleets, service vehicles, and stationary power needs.

Long-term outlook: Mature construction and widespread sourcing reduce lifecycle risk. Where 6TL is proven in fitment, it continues to deliver reliable total cost of ownership with predictable performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.