Chopping Board Pink: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Chopping Board Pink

Pink cutting boards sell across multiple price tiers and materials, from budget plastic sets below $20 to premium titanium options near $60, with consumer interest reflected in 2,000+ Amazon results and recurring “Best Seller” placements. For U.S. and EU buyers, the real challenge isn’t demand—it’s scaling supply without sacrificing food-contact safety, brand trust, and margin.

This guide provides a practical framework to source, certify, price, and launch pink chopping boards in these two regions:

- Market & consumer expectations: how pink segments by material, features, and price

- Compliance & labeling: FDA, EU 10/2011, LFGB/California Prop 65; BPA-free claims; dishwasher safety; CE/EUR.1 for Europe

- Materials & colorant suitability: PP/HDPE/TPE, wood/biomass, titanium; dye/pigment stability and traceability

- Supplier strategy & production: vendor vetting, MOQ, lead times, color matching (Pantone), factory audits, QC checklists

- Cost, margin, and pricing bands: landed cost models, duty impacts, pack configurations

- Sustainability & certification: BPA-free/REACH, recycled content, FSC/biodegradability vs. greenwashing, verified offsets

- Brand/IP and safety: consumer reports, age labels, choking hazards, juice groove design defects, third-party testing

- Logistics & cross-border: HS codes, cartons, palletization, transit times

- KPIs & continuous improvement: defect rates, returns, carbon reporting, AQL

Use this guide as your operating blueprint to move from opportunity to scale.

Top 10 Chopping Board Pink Manufacturers & Suppliers List

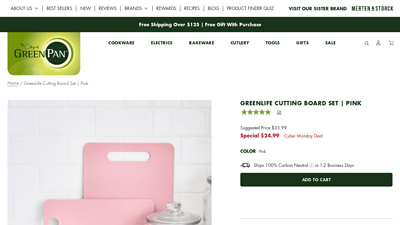

1. GreenLife Cutting Board Set | Pink – GreenPan

Domain: greenpan.us

Registered: 2015 (10 years)

Introduction: In stock Free delivery over $125With medium and large boards, you’ll find the right size for every job—from slicing and dicing produce to breaking down chicken ……

2. BUBBLEGUM – pink chopping board – CHOPIT

3. Colourful Chopping Boards – Pinchy Products

Domain: pinchyproducts.com.au

Registered: N/A

Introduction: Not just a chopping board. Designed in Melbourne, Pinchy chopping boards are crafted from high-strength, FDA-approved, food-grade plastic – the same durable ……

4. I want to purchase new chop board .which is gud plastic, wooden or …

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Below, we’re rounding up four of the best oversized cutting boards according to our in-depth testing of brands like John Boos, OXO, and Teakhaus ……

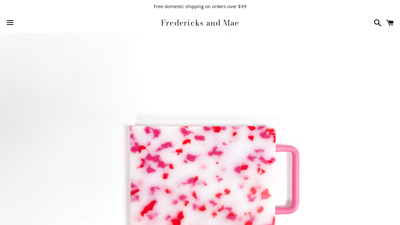

5. Small Pink/White Cutting Board – Fredericks and Mae

Domain: fredericksandmae.com

Registered: 2009 (16 years)

Introduction: In stock Free delivery over $99Small Pink/White Cutting Board … These HDPE cutting boards are made from non-toxic, FDA-approved material, the industry standard in professional kitchens….

Understanding chopping board pink Types and Variations

Understanding Chopping Board Pink: Types and Variations

The following table summarizes the main chopping board pink types available to USA and Europe buyers, including core features, target applications, and key pros/cons.

| Type | Features | Applications | Pros | Cons |

|---|---|---|---|---|

| Standard Plastic Pink Cutting Boards | Lightweight PP/PE/HDPE; non-porous; juice groove (select models); hang hole; dishwasher safe; often listed as BPA-free or unstated | Home kitchens, light commercial prep, small cafés | Low cost; broad retail availability; easy to clean; reversible surfaces | Can show knife marks; some SKUs lack explicit BPA-free labeling; color may fade under heavy use |

| High-Hygiene & Heavy-Duty Plastic Pink Cutting Boards | Thicker gauges; durable PP/HDPE with anti-slip feet; deep drip grooves; ergonomic handles; professional-grade dishwasher cycles; some ClimatePartner-certified SKUs | Professional kitchens, central prep, multi-station prep lines | Strong durability; safety-conscious features (anti-slip, deep grooves); sustainability certifications on select SKUs | Higher price; additional features may require bulk purchasing or tiered pricing |

| Specialty Non-Plastic Pink Cutting Boards | Metallic titanium boards (no pink variants in available SKUs), glass/ceramic boards (pink achievable via pigmented finishes); very hard surfaces; often marketed as hygienic and durable | Limited; retail gift segments, specialty or branded items (non-plastic pink less common in professional settings) | Aesthetic appeal; premium positioning | Hard surfaces dull knives; titanium boards typically silver/gray; glass/ceramic chips; color limited by supplier |

| Pink-Themed Retail & Bundled Sets (Dual-Sided, Juice Groove) | Branded dual-sided boards with built-in juice grooves; easy-grip handles; BPA-free claims; marketed as heavy-duty; retail-friendly packaging | Retail bundles, gifting, premium home collections | Bundle value; consumer appeal; dual functionality; BPA-free marketing | Consumer focus; professional durability not certified; marketing varies by brand |

1) Standard Plastic Pink Cutting Boards

- Materials: PP (polypropylene), PE (polyethylene), HDPE (high-density polyethylene).

- Features: Non-porous surface; some with hang hole; juice groove on select SKUs; dishwasher safe; price range on reference: approximately $7.32–$19.99.

- Applications: General-purpose prep in home and small commercial kitchens; everyday vegetable and fruit prep; budget-friendly retail stocking.

- Pros: Cost-effective; broad availability; easy maintenance.

- Cons: Visible knife scoring; color may fade; BPA-free status varies by SKU.

2) High-Hygiene & Heavy-Duty Plastic Pink Cutting Boards

- Materials: Thick PP/HDPE with professional-grade construction.

- Features: Non-slip feet; deep drip/juice grooves; easy-grip handles; dishwasher safe at professional cycles; select SKUs certified by ClimatePartner (carbon footprint measured/reduced/offset).

- Applications: High-throughput prep lines; meat/vegetable separation in multi-station kitchens; central commissaries.

- Pros: Durability; safety and hygiene features; sustainability certifications on some SKUs.

- Cons: Higher total cost of ownership; bulk packaging may be required for best pricing.

3) Specialty Non-Plastic Pink Cutting Boards

- Materials: Metals (titanium) and glass/ceramic.

- Features: Rigid, hard surfaces; dishwasher safe for metal; scratch resistance varies for glass/ceramic; pigmentation to achieve pink finish.

- Applications: Niche retail (gifting/collector boards) or themed presentations; not ideal for professional knife-intensive use.

- Pros: Visual appeal; premium branding opportunities.

- Cons: Hard surfaces dull knives; higher risk of chipping; titanium boards in reference listings appear in silver/gray rather than pink.

4) Pink-Themed Retail & Bundled Sets (Dual-Sided, Juice Groove)

- Materials: Heavy-duty plastic with BPA-free claims (select SKUs).

- Features: Dual-sided; built-in juice grooves; easy-grip handles; branded theme; value-oriented retail packaging.

- Applications: Gift sets, premium home collections, bundled retail assortments.

- Pros: Consumer-friendly features; strong marketability; dual-purpose utility.

- Cons: Focus on retail rather than heavy commercial use; certifications may be limited to consumer marketing.

Key Industrial Applications of chopping board pink

Key Industrial Applications of Pink Chopping Boards

| Industry | Primary Application | Detailed Benefits |

|---|---|---|

| Foodservice & Restaurants (USA/EU) | Dedicated prep stations for allergen control (e.g., dairy/egg, produce) and general produce prep | Enables strict color-coding programs to prevent cross-contact; non-porous, BPA-free plastics (per model listings) help resist stains and odors; built-in juice grooves and easy-grip handles improve prep efficiency and safety; dishwasher-safe designs reduce labor costs and support sanitation compliance (NSF/Directive 2006/118/EC referenced at platform level); durable high-impact plastics extend service life and reduce replacement frequency. |

| Meat & Seafood Processing (USA/EU) | Dedicated raw prep boards marked for protein workflows | Clearly designated pink surfaces support HACCP-style line segregation and allergen/allergen-adjacent protocols; drip grooves and non-slip feet reduce slip hazards and cross-contamination risk; dishwasher-safe designs (often at high temps) support pathogen control and throughput; easy-grip handling aids in wet, high-throughput environments. |

| Bakeries & Patisserie (USA/EU) | Dough/ingredient prep and produce handling | Supports color-coded zoning for dairy/egg vs. produce; non-slip feet and deep juice grooves provide stability and clean working surfaces; dishwasher-safe surfaces support frequent sanitation; durable plastics withstand moderate impact and frequent cleaning cycles. |

| Healthcare & Senior Care Kitchens (USA/EU) | Tray assembly and allergen-aware prep | Dedicated color for specific allergen/produce streams improves tray accuracy and safety; BPA-free claims (per listings) align with institutional hygiene standards; easy-clean, dishwasher-safe boards speed turnaround; grip surfaces reduce drop risk in constrained spaces. |

| Retail Delis & Prepared Foods (USA/EU) | Deli meat/cheese slicing and produce prep at the counter | Clear color-coding aids staff training and consistency; juice grooves keep counters drier; non-porous boards are stain-resistant and easy to sanitize; compact, grip-friendly designs fit limited counter space; competitive unit pricing enables frequent rotation without high capex. |

| Schools & University Foodservice (USA/EU) | Student dining prep lines and allergen stations | Color clarity supports safe service and staff orientation; robust plastic construction supports heavy use in centralized kitchens; dishwasher-safe sanitizing aligns with school sanitation protocols; economical price points ($7–$20 per board typical on the referenced platforms) reduce lifecycle cost. |

| Food Trucks & Catering (USA/EU) | Mobile prep and event service | Lightweight yet durable boards speed prep under time constraints; built-in grooves and handles improve portability and safety; easy sanitize on site due to dishwasher-safe materials; low-cost sets (3–4 boards) support dedicated lanes for proteins, produce, and allergens. |

Notes:

– Prices and availability vary by size and configuration; the referenced platforms show pink polyethylene/PP boards typically in the ~$7–$20 range per board, with 3–4 piece sets reducing per-unit cost.

3 Common User Pain Points for ‘chopping board pink’ & Their Solutions

3 Common User Pain Points for ‘chopping board pink’ & Their Solutions

Pain Point 1 — Staining, odors, and colorfastness (pink fades or transfers)

Scenario:

USA/EU households and small kitchens buy pink boards for aesthetic reasons. Over time, red/berries/tomatoes/pigments (e.g., beets, sauces) stain the surface. Colors can leach, leading to pink transfer and lingering odors. Boards get replaced sooner, hurting margins and NPS.

Illustrative Image (Source: Google Search)

Problem:

Plastic boards in vibrant colors can be pigment-heavy and porous. Pigments migrate; acid/juice exposure degrades colorfastness; board retains smells.

Solution (buy-side requirements):

– Material: PP/HDPE with colorfast masterbatch and anti-odor additives; or high-density polyethylene (HDPE) in molded color. Avoid paints/coatings on surface.

– Feature set: Non-porous surface; dishwasher-safe construction; stain-resistant and odor-resistant testing.

– Colorfastness: Pre-market wash cycles (dishwasher and hand-wash) to validate resistance to typical pigments.

– Visual integrity: Gloss surfaces are easier to clean; matte surfaces can show micro-scratches faster.

Actionable SKU examples:

– Pink plastic cutting board (BPA-free, non-slip drip groove): indicates non-porous, BPA-free, and drip groove—features that support stain/odor management.

– Paris Hilton 3-piece pink/cream: dual-sided, juice grooves, heavy-duty plastic, dishwasher safe—reduces residue trapping and supports colorfastness via uniform surface.

– 100% pure titanium cutting board: non-porous, non-toxic, dishwasher safe—very stain/odor resistant with superior durability.

– 4-piece pink/gray set with non-slip feet: includes non-slip base and deep drip groove to minimize mess and retain integrity through repeated cycles.

Procurement guidance:

– Require written performance standards for stain/odor/colorfastness (internal QA to mirror kitchen use).

– Prefer surfaces with anti-microbial or anti-odor additive packages where permitted in target markets.

– Offer kits: one premium (titanium or high-spec PP/HDPE) and one mid-tier (colorfast PP) to protect price points.

Illustrative Image (Source: Google Search)

Pain Point 2 — Knife dulling, slippage, and food transfer

Scenario:

Chefs and home cooks avoid pink boards if they believe they dull knives, slip during prep, or allow liquids to spill.

Problem:

Cheaper boards have harder resin fillers; flat surfaces slip; liquids run off edges; grooves may be shallow or nonexistent.

Solution (buy-side requirements):

– Knife-friendliness: Material choice (HDPE/PP) or premium alternative (titanium) to reduce edge wear. Avoid glass or ceramic.

– Grip: Non-slip feet/edges; textured or dual-sided surfaces.

– Fluid management: Deep juice grooves that hold liquids during heavy prep; dual-sided designs for wet vs. dry.

– Board thickness: 12–18 mm range to stabilize cuts; avoid flimsy boards.

Actionable SKU examples:

– 4-piece pink/gray set with non-slip feet and deep drip grooves: addresses slippage and spillover; dishwasher safe.

– Paris Hilton dual-sided with built-in juice grooves and easy-grip handles: dual function and stability during prep.

– 100% pure titanium boards: knife-friendly with high rigidity; dishwasher safe and non-toxic.

– Pink plastic chopping block with hang hole: lighter feature set; consider only for lower price positioning.

Illustrative Image (Source: Google Search)

Procurement guidance:

– Insist on anti-slip base design and deep grooves in spec; select only boards rated for frequent use.

– Position premium titanium in pro channels; PP/HDPE with grips and grooves for mass market.

Pain Point 3 — Hygiene concerns and cross-contamination risk

Scenario:

USA/EU consumers face stricter hygiene expectations. Pink boards marketed for specific tasks (fruit/veg, meat) must prevent cross-contact and bacteria ingress.

Problem:

Porous boards hold bacteria; grooves trap residues; shallow or absent grooves complicate cleaning; color coding for allergens isn’t consistent.

Solution (buy-side requirements):

– Material: Non-porous, dishwasher-safe PP/HDPE, or premium titanium; avoid cracked or damaged boards.

– Hygiene features: Deep, continuous grooves that resist bacteria traps; rounded corners for easy cleaning; non-absorbent finish.

– Color-coding: Provide pink boards with a system (e.g., pink=veg/fruit; blue=seafood; green=meat) via separate boards or clearly labeled sets.

– Certifications: BPA-free claims (where applicable); consider relevant EU food-contact compliance (e.g., EU 10/2011 where applicable).

– Maintenance: Dishwasher-safe labeling and replacement guidance to mitigate micro-scratches over time.

Illustrative Image (Source: Google Search)

Actionable SKU examples:

– Pink plastic 4-piece set (BPA-free, non-slip, drip groove): supports hygiene with cleanable surfaces and separation by color/function.

– Paris Hilton set: includes handles, grooves, dishwasher safe—simplifies cleaning and separation by function.

– Titanium boards: non-porous, dishwasher safe—low-maintenance hygiene.

Procurement guidance:

– Offer color-coded multi-board sets to minimize cross-contact; train retail staff on allergen separation by color.

– Specify dishwasher-safe testing; include consumer instructions for sanitizing.

– Include replacement cycles in product education to avoid prolonged use of worn boards.

Feature Snapshot (from referenced options)

- Paris Hilton 3-piece set (pink & cream): dual-sided, built-in juice grooves, handles, BPA-free, dishwasher safe.

- 4-piece pink/gray set: non-slip feet, deep drip groove, dishwasher safe, BPA-free.

- 100% pure titanium cutting boards: non-toxic, dishwasher safe, double-sided; very stain/odor resistant.

- Basic pink chopping block: lightweight, no-slip groove; suitable for entry price points.

Takeaways for Procurement

- Prioritize stain/odor resistance and colorfastness for vibrant pink SKUs.

- Choose non-slip bases, deep grooves, and material types that are knife-friendly (HDPE/PP) or premium (titanium).

- Provide color-coded sets and clear hygiene guidance to reduce cross-contamination.

- Ensure dishwasher-safe construction and replacement recommendations to maintain hygiene over time.

Strategic Material Selection Guide for chopping board pink

Strategic Material Selection Guide for Chopping Board Pink

For USA and Europe, pink cutting boards must meet food-contact safety standards, operate reliably in commercial dishwashing, and sustain brand identity over repeated cleaning. Material choice drives performance (knife-edge care, hygiene, heat tolerance), lifecycle cost, and end-of-life outcomes. Below is a pragmatic assessment of pink board materials observed in current market references, with selection guidance for foodservice and retail buyers.

Key decision levers

- Knife-friendliness and surface durability

- Hygiene and cleaning: dishwasher, bleach, sanitize cycles

- Heat tolerance and warping risk

- Chemical safety and food-contact compliance

- Color stability and dye fastness

- Weight, grip, and stability (non-slip)

- Sustainability and end-of-life options

- Total cost of ownership (TCO)

Observed material options in the pink category

- 100% Pure Titanium

- Claimed non-toxic; dishwasher-safe; double-sided designs present; mid-high price tier.

- Pros: highly durable; excellent chemical inertness; odor/stain resistance; very long life potential.

- Cons: heavier than plastics; harder surface can dull knives faster; pricing sensitivity for large fleets.

- Compliance: USA (FDA) and EU (1935/2004) generally compatible for metals; verify grade and surface finish; consider nickel sensitivity of end-users for handles if present.

-

TCO: higher upfront; lowest replacement frequency in heavy use.

Illustrative Image (Source: Google Search)

-

Plastic: HDPE/PP (BPA-free claims common)

- Wide adoption across price bands ($7–$20 single units, $20+ multi-pack); many sets feature non-slip feet and deep drip grooves.

- Pros: light; good knife-friendliness; affordable; widely available.

- Cons: can retain odors if not cleaned promptly; potential warping at high heat; color may fade with repeated bleaching.

- Compliance: USA (FDA) and EU 10/2011 for plastics; BPA-free labeling prevalent; confirm dye migration resistance to acids (e.g., beet, tomato).

-

TCO: medium; moderate replacement rate depending on usage intensity and sanitation practices.

-

Heavy-duty Plastic (no BPA)

- Dual-sided boards with juice grooves and easy-grip handles; mid pricing tier.

- Pros: added robustness; groove helps manage liquids; improved grip; typically dishwasher-safe.

- Cons: slightly heavier than budget plastics; wear increases with aggressive cleaning chemicals.

- Compliance: similar to HDPE/PP; check color additive certifications for indirect food-contact.

-

TCO: medium to medium-low; resilient for mixed workflows.

Illustrative Image (Source: Google Search)

-

Silicone (TPE silicone blends)

- Flexible, non-porous, heat-tolerant; often paired with rigid cores.

- Pros: stain and odor resistance; good non-slip behavior; dishwasher-compatible; heat deflection reduces warping.

- Cons: not always the primary cutting surface in mixed-material sets; long-term dye fastness varies with formulations.

- Compliance: EU 10/2011; confirm filler content and colorant types for food-contact safety.

-

TCO: medium; depends on dual-material construction and usage patterns.

-

Mixed-material constructions (Plastic + Silicone)

- Core board (plastic) with silicone perimeter or reversible designs; handles and grooves common.

- Pros: combines knife-friendliness with liquid management; stable; ergonomic.

- Cons: higher complexity; cost variability; cleaning must reach seams.

- Compliance: both components must meet food-contact standards.

-

TCO: medium; durable enough for professional kitchens with proper care.

Illustrative Image (Source: Google Search)

-

Sustainable and certified options

- ClimatePartner-certified plastic boards are appearing in the market; lifecycle carbon measured and offset through the program.

- Pros: demonstrable carbon impact accounting; brand sustainability credentials.

- Cons: availability limited; cost may be slightly higher; verify scope of certification.

- Compliance: program-specific; ensure underlying materials still meet FDA/EU food-contact rules.

- TCO: comparable to standard plastics; brand value adds.

Hygiene and maintenance patterns

- Dishwasher-safe claims are common across both plastic and titanium; place boards flat to reduce warping; avoid prolonged high-heat sanitizing cycles for plastics.

- Odor management: prompt cleaning after strong-smelling foods; occasional baking soda soak for plastics; titanium resists odors intrinsically.

- Grooves and juice channels reduce cross-contact; non-slip feet add stability, especially on smooth stainless surfaces.

USA/EU regulatory considerations

- USA: 21 CFR materials (HDPE/PP) and colorants; ensure declarations of compliance for boards/dyes.

- EU: Framework Regulation 1935/2004 and plastics-specific 10/2011; national GB/UK regulations post-Brexit; CEKAL or other glass/acetal components (if applicable) must comply.

- BPA-free: relevant for plastics; verify dye formulations and migration under acidic foods.

Sourcing and supplier expectations

- Minimums (MOQs), private label customization for pink color-matching (Pantone), and set configurations (3–4 boards with distinct grooves/feet).

- Certifications: BPA-free, ClimatePartner or equivalent carbon programs; dishwasher-safe validation; material declarations (DoC).

- Packaging: retail-ready, color stability, and case quantity alignment.

Sustainability end-of-life

- Plastics: identify recyclable streams; avoid mixed-material assemblies that complicate recycling.

- Titanium: extremely long service life and fully recyclable; high intrinsic value.

- Carbon impact: prefer suppliers with measured footprints and verified offset programs where possible.

Performance snapshot from market references

- Titanium boards: 11.8–13.2 inches; ~$20–$25 single; ~$60 per 3-pack; double-sided; dishwasher-safe; 4.3/5 rating.

- Plastic/heavy-duty plastic: $7.50–$20 single; $20 for 4-pack sets; 4.7–4.8/5 ratings; juice grooves, handles, non-slip feet; many dishwasher-safe, BPA-free.

- Sustainability: ClimatePartner-certified 4-pack plastic sets at ~$20; carbon lifecycle measured and offset.

Recommended selection matrix

- Budget-forward, high-usage stations: HDPE/PP or heavy-duty plastic (BPA-free), groove + feet.

- Premium/long-life lines: 100% Pure Titanium, especially where chemical resistance and odor neutrality are critical.

- Mixed kitchens needing flexibility: dual-material boards (plastic core with silicone features).

- Sustainability-forward procurement: select ClimatePartner-certified plastic boards for carbon accountability without sacrificing performance.

Comparison table (pink cutting boards: materials vs. key attributes)

| Material | Knife-friendliness | Durability | Heat tolerance | Dishwasher compatibility | Compliance fit (USA/EU) | Odor/stain resistance | Sustainability notes | Typical price band (USD) | Typical ratings | Notable features (from refs) |

|---|---|---|---|---|---|---|---|---|---|---|

| 100% Pure Titanium | Medium | Very High | High | Yes | Metal standards (verify) | Strong | Fully recyclable; low replacement | $20–$60 per set (3-pack) | 4.3/5 | Double-sided; non-toxic; dishwasher-safe |

| Plastic (HDPE/PP, BPA-free) | High | Medium | Medium (warps at high heat) | Yes (common) | FDA + EU 10/2011 | Medium (improves with quick wash) | Recyclable in many streams | $7–$20 single; $20+ multi-pack | 4.7/5 | Non-slip feet; juice grooves; handles |

| Heavy-duty Plastic (no BPA) | High | Medium-High | Medium | Yes (common) | FDA + EU 10/2011 | Medium | Recyclable; varies by dye/assembly | ~$12–$20 single | 4.8/5 | Dual-sided; built-in juice grooves; easy-grip handles |

| Silicone (TPE silicone blend) | Medium | Medium | High | Yes (common) | EU 10/2011; USA materials vary | Strong | Mixed回收; depends on filler and color | N/A (often secondary surface) | N/A | Flexible; stain/odor resistant; often paired with core |

| Mixed-material (Plastic + Silicone) | High | Medium-High | Medium-High | Yes (common) | Both materials must comply | Strong | Depends on components and assembly | ~$20–$30+ (varies) | N/A | Reversible; grooves; non-slip; ergonomic |

| ClimatePartner-certified Plastic | High | Medium | Medium | Yes | FDA + EU 10/2011 | Medium | Carbon measured/offset | ~$20 (4-pack) | 4.7/5 | Non-slip feet; juice grooves; sustainability certified |

This guide prioritizes fit-for-purpose performance, regulatory confidence, and practical lifecycle economics for USA and Europe. For new product development or bulk procurement, secure material declarations and, where possible, select suppliers offering carbon-impact transparency aligned with recognized programs.

In-depth Look: Manufacturing Processes and Quality Assurance for chopping board pink

In-depth Look: Manufacturing Processes and Quality Assurance for chopping board pink

The pink chopping board is produced predominantly by injection molding of thermoplastics (HDPE/PP). Process selection aligns with the desired features highlighted in market references such as thickness, juice grooves, and handles. The following framework assumes HDPE at 1.9–2.2 g/cc; PP can be substituted when higher stiffness or heat resistance is required.

Manufacturing steps

Prep

– Resin specification: Select food-contact compliant HDPE or PP grade that supports:

– Dishwasher cycles (market listings often state dishwasher-safe)

– Non-porous surface and chemical resistance

– Color stability during use and wash

– Pigmenting: Use a pink masterbatch formulated for food-contact resins; ensure:

– Color traceability and lot control

– Heat stability up to MFI test conditions (e.g., 190/2.16)

– Lightfastness to resist fading under typical kitchen use

– Additives (optional): Antimicrobial agents only if regulatory clearance is confirmed; otherwise note “Not treated” if claims are not permitted

– Drying and blending: Dry hygroscopic resins per manufacturer guidance; premix masterbatch with base polymer to targeted dosage (e.g., 2–3 wt% for color intensity)

– Process aids: Ensure mold release compliance with food-contact rules

Illustrative Image (Source: Google Search)

Forming

– Primary method: Injection molding is preferred for boards with features like juice grooves and handles (as seen in market listings)

– Feeding: Dried resin into the feed throat

– Plastication and injection: Melt resin to recommended range (e.g., HDPE 180–230°C), inject into a heated, textured mold

– Packing and cooling: Pack to compensate shrinkage; cool to ejection-safe temperature (often 20–40 seconds total depending on tool)

– Mold design: Multi-cavity tooling for throughput; textured cavity to mask knife marks

– Alternate method: Extrusion for simple sheets/boards; thermoforming thereafter if deep features are needed (less common for pink, feature-rich boards listed)

– Finishing: Trim sprues and flash; optional deburring, edge chamfer, or antiskid treatment

Assembly

– Subcomponents: Boards may incorporate features such as built-in juice grooves or handles (dual-sided designs appear in listings). Assemble only non-detachable elements, as mechanical joints require sanitation and durability validation

– Cleaning and drying: Rinse and dry prior to packing; confirm dust/mold release residue removal

– Pack-out and labeling: Carton, retail sleeve, or barcode label; include compliance marks (e.g., food-contact) where applicable

– Storage: Protect from UV and dust; stack in compliant packaging to prevent warpage or surface abrasion

QC

– Incoming: Resin MFI and pellet uniformity; color lot traceability

– In-process: Cycle stability, melt viscosity, warpage checks after cooling; defect rate trending (flash, sinks, warpage, surface delamination)

– Dimensional inspection: Length/width/height within tolerance; groove geometry; handle-to-board interface integrity

– Functional checks: Juice groove integrity under load, non-slip performance (if applied), dishwasher-safe verification where marketed

– Visual defects: Color uniformity, surface defects, inclusions; gate/burn-line quality

– Sampling plans: Apply ISO 2859-1 sampling (AQL commonly used in the industry, e.g., aesthetic AQL 2.5–4.0; dimensional/functional AQL 1.0–2.5). Reference: ISO 2859-1 Acceptance sampling by attributes

Quality standards (ISO and supporting frameworks)

- ISO 9001 – Quality Management Systems (QMS). Establishes process discipline, corrective/preventive actions, and continuous improvement; integrates with ERP/traceability for resin lots, pigments, and tooling changes.

- ISO 14001 – Environmental Management Systems. Documents energy, materials use, and waste mitigation for compliance with corporate sustainability programs (some listings highlight climate certifications).

- ISO 45001 – Occupational Health & Safety. Controls exposure to polymer dust, heated equipment, and forklift operations in planta.

- ISO 2859-1 – Acceptance Sampling by Attributes. Operationalizes incoming and final inspections with lot-based acceptance criteria.

- ISO 22000 – Food Safety Management Systems. For organizations handling food-contact products; ensures HACCP principles, allergen/foreign material controls, and traceability. Where applicable, include packaging validation and storage hygiene.

- ISO 4589-2 (optional, context-driven) – Oxygen index for flammability characterization if boards are used near heat sources.

Notes on material compliance

– Resins and pigments must meet regional food-contact requirements (e.g., U.S. FDA regulations for food-contact plastics; EU/EU10/2011 for plastic materials). Use food-contact-compliant resin grades and masterbatches; maintain certificate traceability and retention.

– Antimicrobial or antibacterial claims require substantiation and regulatory approval. In their absence, specify that the product is “not antimicrobial-treated.”

– Market signals (Amazon listings) show consistent dishwasher-safe expectations and BPA-free messaging. Where relevant, document absence of BPA in the resin system and dishwasher-cycle verification in the QMS.

– Sustainability: If marketing sustainability, ensure lifecycle carbon footprint measurement and reductions follow an auditable methodology; align with recognized labels (e.g., ClimatePartner) as applicable.

Illustrative Image (Source: Google Search)

Process KPI snapshot (benchmarks)

- Yield: ≥97–99% first-pass yield

- Dimensional defect rate: <1.0%

- Warpage: Within defined flatness tolerance (e.g., <1.5 mm across usable surface)

- Cosmetic defects: ≤1.0% minor (grain/surface), ≤0.5% major (flash/inclusions)

- Customer returns: Target <0.3% for first year post-launch

Practical QC checklist for pink chopping boards

- Verify masterbatch lot and concentration against color standard under D65 light

- Confirm resin certificates and food-contact declaration per region

- Run dimensional sampling: grooves’ depth/width; handle recess radii; thickness uniformity

- Validate surface finish: low-gloss pattern consistent across cavities

- Dishwasher cycle test: Functional and cosmetic performance per internal protocol

- Shipping-packaging: Drop tests and carton compression within warehouse/distribution profiles

Risk and control summary

- Color fading: Control pigment heat stability and exposure; set maintenance cycles for molds to preserve texturing.

- Warpage: Optimize cooling and pack pressure; enforce post-mold handling SOPs.

- Regulatory drift: Supplier qualification and annual certificate renewals; change control for resin grade or colorant.

- Sustainability claims: Link data to ISO 14001; keep documented footprint calculations for market alignment (some listings feature carbon impact disclosures).

Manufacturing and quality assurance for pink chopping boards hinge on disciplined control of material traceability, molding parameters, and inspection plans embedded in an ISO-driven QMS. Where market expectations favor durability, dishwasher safety, and reliable color performance, tight in-process control and robust sampling plans under ISO 2859-1 are essential to achieve consistent, compliant output.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chopping board pink’

Practical Sourcing Guide: A Step-by-Step Checklist for “Chopping Board Pink”

1) Define requirements

- End use: household kitchen; foodservice; dual-purpose (both).

- Material preference: plastic (PP/HDPE), titanium, or hybrid sets.

- Performance: dishwasher-safe; non-porous/BPA-free; anti-slip; juice grooves; durable.

- Color: primary color pink; include complementary colors (e.g., gray/cream) for set differentiation.

- Pack configuration: single boards, sets of 3–4; sizes S/M/L or small/medium/large.

- Dimensions: common sizes observed 11.8″ x 7.9″ (S), 13.2″ x 9.4″ (M); verify target sizes for retailer assortments.

2) Map to common market tiers

Use the table below to guide target specifications and expected price bands. Select the tier that matches your channel strategy and margin targets.

| Tier | Typical features | Example specs (observed) | Reference examples | Typical FOB price band (USD) |

|---|---|---|---|---|

| Budget plastic | Basic board, no grooves, basic pink color | Not specified (basic) | Plastic Chopping Block Meat Vegetable Cutting Board, Pink | ~3–5 (vendor-dependent) |

| Midrange plastic set | Anti-slip feet, deep drip groove, easy-grip handle, dishwasher-safe, BPA-free, color options (pink + gray) | Sizes vary | Plastic Chopping Board Set of 4 (Pink/Gray), Deep Juice Groove | ~5–7 per unit |

| Branded/curated | Dual-sided, built-in juice grooves, easy-grip handles, dishwasher-safe, BPA-free | Sizes vary | Paris Hilton Cutting Boards, 3-Piece Pink and Cream | ~12–16 |

| Premium titanium | 100% pure titanium, double-sided, non-toxic, dishwasher-safe, high hygiene | 11.8″ x 7.9″ and 13.2″ x 9.4″; sets of 3 | Pure Titanium Cutting Board; Set of 3 (S+M+L) | ~20–25 single; ~60 for set of 3 |

Notes: Pricing varies by size, finish, and set composition. Many sellers offer multiple sizes and colorways. Verify dimensions, weight, and packaging on each product detail page.

3) Confirm material and compliance

- US: Food-contact plastics should comply with 21 CFR 175.300 (resinous and polymeric coatings); confirm BPA-free status for marketing claims.

- EU: Plastics must comply with EU 10/2011; overall food contact with EU 1935/2004; GMP with EU 2023/2006; optionally LFGB for Germany.

- Claim support: Request test reports (migration, BPA, heavy metals where applicable) from the supplier before placing orders.

- Metals: For titanium boards, obtain material purity documentation and dishwasher resistance validation.

4) Set product standards and certifications

- Hygiene: non-porous surface; dishwasher-safe per manufacturer test.

- Safety: slip resistance; secure grip handles; radius edges to reduce injury risk.

- Sustainability: assess supplier sustainability programs; look for programs with transparent impact accounting (e.g., ClimatePartner’s five-step climate action approach).

- Packaging: polybag + cardboard insert or retail-ready box; ensure barcode/UPC/EAN and compliance markings.

- Documentation: CoC (Certificate of Compliance), test reports, material declaration, care instructions in English.

5) Source options

- Option A: Retail marketplace scan (e.g., Amazon “pink cutting board”) to benchmark features and price.

- Observe common attributes: dual-sided boards with juice grooves, easy-grip handles, BPA-free claims, dishwasher-safe claims, sets of 3–4, sizes S/M/L, price range ~$12–$20 for branded sets; ~$6–$20 for midrange plastic; ~$20–$25 for premium titanium singles.

- Extract product detail page (PDP) specifications, dimensions, materials, certifications, and customer feedback themes (durable, easy clean).

- Option B: Tiered supplier development

- Tier 1: Branded/licensed and premium materials (e.g., dual-sided, built-in grooves).

- Tier 2: OEM plastic (midrange features) with factory audits and documented compliance.

- Tier 3: Premium titanium or specialty materials for premium channels.

6) Shortlist criteria and sample plan

- Criteria: material safety documentation; feature completeness (anti-slip, grooves, handles); SKU breadth (sizes/colors); packaging readiness; QA process; sustainability claims evidence; lead times; payment terms.

- Sample request: Request lab-dyed pink color swatches and finished samples of representative SKUs; test dishwasher cycles per your QA protocol; evaluate groove efficacy and handle ergonomics.

7) Cost, MOQ, and lead time

- Confirm minimum order quantities (MOQ) per SKU/size/color; request ladder pricing.

- Target unit costs aligned to tier (see Table 2) and your landed cost model.

- Lead times: typical 30–45 days from PO to first shipment; verify factory capacity and logistics constraints.

8) Quality assurance (QA) and pre-shipment inspection

- Incoming QC: check dimensions, color uniformity (pink), surface finish, drip groove integrity, handle strength, non-slip features.

- Functional tests: dishwasher cycles (per spec), knife scratch resistance, slip resistance.

- Packaging QC: correct SKU labeling, barcode quality, protective packaging for shipment.

- Pre-shipment inspection (PSI): AQL sampling for appearance, function, and packaging; random tests for dishwasher safety and durability.

9) Logistics and market alignment

- Distribution: consider single-unit vs. set packaging for retailer shelf plans.

- Seasonality: align production with retail promotional calendars; ensure adequate inventory for peak seasons.

- Sustainability reporting: if claiming carbon impact or sustainability features, secure supplier documentation and ensure clear consumer disclosures.

10) Terms, risk, and go-to-market

- Contract essentials: specifications, compliance documents, QA protocol, packaging standards, lead-time SLAs, remedy clauses.

- Risk mitigation: dual sourcing for core SKUs; buffer safety stock for high-velocity sizes; retain samples for future reference.

- Go-to-market: map feature sets to price tiers (budget, midrange, branded, premium titanium); develop PDPs with clear materials, dimensions, certifications, and care instructions; ensure consistent pink colorway and complementary colors for sets.

Comprehensive Cost and Pricing Analysis for chopping board pink Sourcing

Comprehensive Cost and Pricing Analysis for Pink Chopping Board Sourcing

Market price anchors (retail context)

Use these publicly visible price points to benchmark retail expectations and your target landed cost:

Illustrative Image (Source: Google Search)

| Product (Amazon) | Material | Size | Rating | Retail price | Approx. unit price (if set-size stated) |

|---|---|---|---|---|---|

| 100% Pure Titanium Cutting Board | Titanium | 11.8” x 7.9” | 4.3/5 | $19.88 | $19.88 |

| 100% Pure Titanium Cutting Board | Titanium | 13.2” x 9.4” | 4.3/5 | $24.88 | $24.88 |

| Paris Hilton Cutting Boards (3-piece set) | Plastic (BPA-free claim) | ~3-piece set | 4.8/5 | $12.50 (set) | ~$4.17 per board |

| Plastic Chopping Block, Pink | Plastic | — | 4.3/5 | $7.52 | $7.52 |

| 4-piece Plastic Set (Pink/Gray) | Plastic | — | 4.7/5 | $19.99 (set) | ~$5.00 per board |

B2B takeaway:

– Single-board pink plastic items in retail commonly sell between ~$5–$20, with sets averaging $5–$7 per board when sold together.

– At comparable sizes/features, your landed B2B target (to retailer/brand) should aim for 25–50% of the lower retail band to leave margin for packaging, QC, freight, and retail markup.

Cost breakdown framework

Structure landed cost so you can plan price and margin:

| Cost category | What it includes | Key levers |

|---|---|---|

| Materials | Resin (PP/HDPE/PE), color masterbatch, additives | Grade choice, color depth, recycled content, groove/detail complexity |

| Tooling | Injection molds, cut/fillets, logos | Steel grade (P20/H13), cavity count, lifetime guarantees |

| Manufacturing | Molding, trimming, packaging | Automation, cycle time, assembly (if handle), QA/QC |

| QA/Compliance | Testing, certificates, lab fees | FDA/LFGB/BPA-free, Prop 65, REACH, CA Prop 65, packaging compliance |

| Logistics | International freight, local drayage, customs, insurance, duties, VAT | MOQ/full container load (FCL) vs less-than-container-load (LCL), packaging density, Incoterms (FOB/CIF/DDP) |

| Margin & overhead | Supplier margin, your overhead, payment fees | Payment terms, currency, order cadence, vendor consolidation |

Typical landed unit cost (B2B) breakdown for a pink plastic board:

– Materials: 20–45%

– Manufacturing (mold/assembly): 10–25%

– Compliance/QA: 5–10%

– International logistics: 15–30%

– Margin/overhead: 10–20%

Ranges vary by material, size, complexity, MOQ, and freight.

B2B cost examples by material and MOQ

Estimates assume FOB China single-piece retail packaging, 3–4 mm thickness, pink color, basic compliance (US FDA + EU LFGB + BPA-free; Prop 65 screening), and typical freight. Tooling amortized over 10–30k units.

| Scenario | Material | Tooling amortization | Landed unit cost (USD, range) |

|---|---|---|---|

| A: Low volume, simple board | PP/PE | $1.0k–$1.8k | $0.45–$0.70 |

| B: Mid-volume, simple board | HDPE/PP | $2.5k–$4.0k | $0.55–$0.85 |

| C: Add grooves/handle (medium) | PP/HDPE | +$2.0k–$5.0k | $0.70–$1.20 |

| D: Dual-sided/non-slip feet | PP/HDPE | +$1.5k–$3.0k | $0.80–$1.40 |

| E: 4-piece set | Mixed (same materials) | Consolidated packaging | $2.00–$3.50 per set |

Notes:

– These are indicative B2B landed costs under LCL/FCL mixed conditions and are affected by resin price cycles and freight volatility.

– For EU destinations, local VAT (e.g., 19–24%) applies at import/distribution and affects retail pricing strategy.

Logistics cost estimates (illustrative)

Use these as planning ranges; verify current spot rates.

| Route | Mode | Volume baseline | Cost components | Total (USD, range) |

|---|---|---|---|---|

| Shanghai/Guangzhou → Los Angeles/Long Beach | Ocean FCL | 20’ ~25 CBM | Freight, drayage, customs, insurance, duties | $1,500–$3,500 total; $60–$140 per CBM |

| Shanghai/Guangzhou → Rotterdam/Hamburg | Ocean FCL | 20’ ~25 CBM | Freight, drayage, customs, insurance, duties/VAT | $1,800–$4,000 total; $72–$160 per CBM |

| China → USA/EU | Air (consolidated) | ~2.0 CBM | Air freight, last mile | $8–$16 per kg |

Packaging density considerations:

– Unit dims: 11.8” x 7.9” x 0.4” ≈ 0.0013 CBM; ~750–800 units per CBM.

– Pack-in-carton optimization (e.g., 24 units/carton) can reduce handling costs and improve density.

Illustrative Image (Source: Google Search)

Pricing guidance for USA and Europe

- Align your B2B price with retailer expectations:

- USA: Landed target ≤ $1.50–$2.50 for single board when competing near $7–$20 retail.

- Europe: Landed target ≤ $1.70–$3.00 factoring EU VAT and distribution margins; price to consumers typically £/€/CHF higher than US.

- Use cost-plus pricing:

- Target retail price × 0.30–0.45 = your landed B2B price (typical retail markup).

- Include competitive analysis:

- $4–$7 per board for sets; $8–$20 for premium single boards (metal, heavier-duty, or branded).

- Contract terms:

- Currency (USD/EUR), FX exposure, and payment methods (TT/LC) impact net margin.

Compliance and testing cost impacts

- USA:

- FDA 21 CFR 177.1520 (PP/PE) or 21 CFR 175.300 (coatings/inks if used).

- BPA-free testing where claimed.

- Prop 65 screening for California buyers (heavy metals, some additives).

- Europe:

- EU 10/2011 migration tests (overall/specific).

- LFGB Section 30 & 31 for Germany.

- REACH (e.g., cadmium/lead in colorants).

- Typical compliance budget: $1,500–$4,000 for initial package and supplier dossier; periodic checks $600–$1,500.

- Choose EU/US-compliant inks/print methods (e.g., pad printing) and document them.

Design/material decisions that drive cost

- Material:

- PP/PE: lower cost, good cut resistance; slightly softer.

- HDPE: better durability and chemical resistance; slightly higher cost.

- ABS/PETG: higher impact; more expensive; ensure compliance for food contact.

- Color:

- Masterbatch cost increases with depth and coverage; deep pink may use more colorant.

- Features:

- Juice groove adds 10–20% to mold complexity and 10–15% to cost.

- Handles/feet add material and assembly; 10–30% cost uplift depending on mold complexity.

- Tooling:

- P20 steel typical; H13 for high-cavities/long life.

- Multi-cavity molds reduce per-unit cost at the expense of higher capex and lead time.

- Packaging:

- E-commerce-ready cartons and protective wraps affect unit cost by $0.05–$0.20 depending on design.

Tips to save cost

- Optimize MOQ and consolidate orders:

- Target ≥ one FCL to improve per-CBM cost; align with seasonal demand.

- Right-size cartons and reduce air:

- Stacking efficiency and carton optimization can cut freight by 10–20%.

- Feature discipline:

- Limit non-essential grooves/handles early; add on subsequent SKUs once volume stabilizes.

- Color and material harmonization:

- Standardize materials and colorants across SKUs to reduce resin and colorant SKUs.

- Supplier pooling and volume commitments:

- Annual volume bands can unlock 3–10% discounts and faster tooling/capacity.

- Negotiate Incoterms and payment:

- CIF or DDP can provide clarity; watch FX, insurance, and payment fees.

- Tooling amortization:

- Spread capex over 10–30k units and lock repeat production to keep unit costs stable.

- Regional sourcing for EU:

- Consider EU-based contract manufacturers to reduce import logistics and VAT friction; trade off higher material/labor costs.

Sample margin scenarios (illustrative)

- Retail target $12.50 (Paris Hilton set, US):

- Landed B2B target: ~$3.50–$5.50 per set.

- Your gross margin target: 30–45% on landed cost.

- Retail target $19.99 (4-piece set, US):

- Landed B2B target: ~$6.00–$9.00 per set.

- Your gross margin target: 30–45% on landed cost.

- Single-board retail $9–$15 (EU/US):

- Landed B2B target: ~$2.50–$4.50 per board.

- Your gross margin target: 35–55% on landed cost.

By aligning your cost structure to these benchmarks, validating compliance early, and optimizing logistics, you can hit target B2B prices that leave room for retail success in the USA and Europe.

Alternatives Analysis: Comparing chopping board pink With Other Solutions

Alternatives Analysis: Comparing chopping board pink With Other Solutions

Direct price/feature comparison shows why pure titanium pink boards are increasingly adopted by procurement and facilities teams.

Quick comparison (selected pink options)

| Option | Brand/Model (pink) | Material | Thickness (approx.) | Size (approx.) | Price (approx.) | Notable features | Durability/Hygiene | Sustainability highlights |

|---|---|---|---|---|---|---|---|---|

| Pink titanium cutting board | XTBSE 100% Pure Titanium Cutting Board | 100% pure Ti | 8–10 mm | 11.8″ × 7.9″ | $19.88 | Double‑sided; non‑toxic; dishwasher safe | Very high durability; corrosion/rust resistant; non‑porous | Long service life reduces replacements (no explicit certification listed) |

| Pink plastic cutting board set | Paris Hilton Dual‑Sided Cutting Board Set (3 pc, Pink + Cream) | BPA‑free plastic | ~10–12 mm | Not specified | $12.50 | Built‑in juice grooves; easy‑grip handles; dishwasher safe | Good hygiene if sanitized; prone to knife scores over time | Recyclable plastics vary by local programs (no specific certification listed) |

Sources: Amazon product pages for XTBSE Pure Titanium Cutting Board and Paris Hilton Cutting Boards.

Decision analysis

- Durability and lifecycle cost

- Titanium: Exceptional wear resistance; resists knife scoring, warping, and corrosion. Higher initial cost ($19.88), but lower lifetime cost due to fewer replacements and reduced waste.

-

Plastic: Lightweight and affordable ($12.50 for 3‑piece set), but softer material accumulates knife scores, which can harbor bacteria and necessitate frequent replacement.

-

Hygiene and sanitation

- Titanium: Non‑porous surface; inert and corrosion resistant; suitable for frequent dishwasher cycles and food‑safe use.

-

Plastic (BPA‑free): Non‑porous and dishwasher safe; grooves aid in controlling juices, but grooves and knife marks require thorough cleaning to mitigate bacterial growth.

-

Heat and chemical tolerance

- Titanium: Highly heat and chemical tolerant; not prone to warping or thermal damage under normal kitchen use.

-

Plastic: Heat sensitivity limited; dishwasher safe, but excessive heat can cause warping or surface degradation over time.

Illustrative Image (Source: Google Search)

-

Weight and handling

- Titanium: Moderately heavier than thin plastics, improving stability on counters; still manageable for a board of this size.

-

Plastic: Lightweight for easy handling and storage, especially in multi‑piece sets.

-

Knife care

- Titanium: Hard surface preserves edge longevity; low abrasion reduces knife wear compared to very hard stone/glass boards.

- Plastic: Softer material is generally knife‑friendly; knife edges last well but boards wear faster.

Buying notes

- Sizing: Titanium model shown is 11.8″ × 7.9″; plastic set size varies by product page.

- Warranty: Product pages list None; assume standard returns only.

- Certifications: Titanium page does not display third‑party food contact certification; BPA‑free claim present for plastic model.

- Sustainability: Titanium’s durability and non‑reactive properties support longevity; plastics vary in end‑of‑life recyclability and depend on local collection programs.

Bottom line

- Choose titanium pink boards when durability, sanitation, and lifecycle efficiency are priorities; accept a slightly higher unit cost.

- Choose lightweight plastic sets for budget‑constrained or high‑turnover environments, with routine replacement planned; leverage juice grooves and non‑slip handling features.

- The pink color option is available across both materials; selection should be driven by usage intensity and hygiene risk tolerance.

Essential Technical Properties and Trade Terminology for chopping board pink

Essential Technical Properties and Trade Terminology for Chopping Board Pink

B2B decision-makers in the USA and Europe need clarity on technical properties and trade terms to standardize specs, ensure compliance, and manage costs reliably.

Illustrative Image (Source: Google Search)

Quick Product Snapshot (Market Signals)

- Materials observed: 100% pure titanium boards (premium line); plastic boards typically PP/HDPE-based (commercial line).

- Sizes in market: 11.8″ × 7.9″; 13.2″ × 9.4″; S+M+L sets.

- Features: double-sided; dishwasher safe; BPA-free claims; non-toxic claims; non-slip feet (select SKUs); juice grooves.

- Price points: budget plastic (~$7.5–$20); premium titanium (~$19.9–$59.9 for sets).

Core Technical Properties (What Buyers Should Standardize)

- Material & grade

- Plastic: PP (polypropylene) or HDPE (high-density polyethylene); confirm base polymer to match EU 10/2011 and FDA CFR 21 migration limits.

- Premium: 100% pure titanium (where applicable); validate composition and claimed hygiene.

- Dimension & thickness

- Define board length × width × thickness; specify tolerances (e.g., ±2–3 mm).

- Typical market sizes: 11.8″ × 7.9″; 13.2″ × 9.9″; sets include S/M/L.

- Weight per unit

- Record by SKU; consider shipping impacts on CBM and LTL freight.

- Knife-friendliness & service life

- Target low knife scoring for daily prep; specify cycle life for intended use (e.g., washes/week).

- Hygiene & cleanability

- Dishwasher safe (top rack if specified); non-porous surface; stain resistance to pigments like beet/pink dyes.

- Functional features (select SKUs)

- Juice grooves, drain channels; non-slip feet/grip handles; stackability/nesting; edge profiles (radius); chamfered corners.

- Chemical & sensory

- Odor-free; colorfast; low migration; meet food-contact rules.

- Sustainability (where applicable)

- Recyclability of polymer; “BPA-free” claims; carbon-impact labels (ClimatePartner) for green credentials.

Spec Framework for Chopping Board Pink (Example B2B Spec Table)

| Attribute | Typical Options | Notes |

|---|---|---|

| Board size | 11.8″ × 7.9″; 13.2″ × 9.4″; S/M/L set | Confirm packaging and retail-ready dimensions |

| Thickness | 6–10 mm typical (plastic) | Titanium boards may be thinner due to stiffness |

| Material | PP / HDPE; 100% pure titanium | Base polymer dictates compliance regime |

| Compliance | FDA CFR 21 (US); EU 10/2011 (EU) | Provide migration test reports on request |

| Color | Pink (Pantone match if needed) | Ensure colorfastness against common stains |

| Features | Juice groove; non-slip feet; handles; double-sided | Align with SKU-level features observed in market |

| Cleanability | Dishwasher safe (top rack; 80–95°C typical) | Specify detergent resistance |

| Performance | Knife-friendliness; abrasion resistance; no warping | Provide cycle life and maintenance guidance |

Manufacturing, Logistics & Trade Terms (What to Negotiate and Standardize)

| Term | Meaning | What to Lock in for Pink Boards |

|---|---|---|

| MOQ (Minimum Order Quantity) | Lowest units per order per SKU | Confirm per color; pink may require dye-batch alignment |

| OEM (Original Equipment Manufacturer) | Supplier manufactures per buyer’s design | Define spec sheet, Pantone code, and packaging artwork |

| ODM (Original Design Manufacturer) | Supplier offers its own design | Confirm feature set, dimensions, and compliance claims |

| Lead time | Time from PO to shipment | Provide cut-off times; buffer for dye-run alignment |

| Packaging | Retail box, hanging tag, shrink-wrap, etc. | SKU labeling; barcode spec (EAN-13 / UPC-A); carton markings |

| Incoterms | Delivery responsibility | Typically FOB (US), DAP/DDP (EU) for door delivery |

| Freight | LTL / FTL; palletization; CBM | Optimize mixed-size loads; confirm per-SKU weight |

| Test reports | Food-contact, dishwasher cycles | Provide on request; ensure batch traceability |

| Warranty & returns | Defect rate and RMA window | Document defect thresholds; accept SKUs with documented nonconformities |

Compliance & Labeling (US/EU)

| Market | Compliance Focus | Labeling/Claim Notes |

|---|---|---|

| USA | FDA CFR 21 (food-contact polymers) | “BPA-free” and “dishwasher safe” are common claims; substantiate with tests |

| EU | EU 10/2011 migration limits; REACH | Provide EC declaration of conformity; CE-like self-decl conformity for food-contact plastics |

| Green | Sustainability labels | If offering ClimatePartner-type labels, provide lifecycle and offset info |

Sustainability Options (Positioning)

- Recyclability: HDPE/PP readily recyclable in US/EU streams; include material ID codes.

- Product stewardship: Provide end-of-life guidance; consider take-back programs.

- Certifications: “BPA-free”; carbon-impact labels (ClimatePartner) observed on select SKUs.

QA & QC Checkpoints

- Appearance: Color uniformity (pink), no warping, smooth radius edges.

- Dimensional conformity: Length, width, thickness, hole placement.

- Functional: Juice groove depth, non-slip foot adhesion, handle strength.

- Cleanability: Detergent resistance; stain resistance to pink dyes and pigments.

- Durability: Cycle testing (dishwasher wash-dry cycles), impact/chip resistance.

- Documentation: Certificates of analysis; batch traceability; test reports.

Buyer Checklist for Negotiations

- Confirm base polymer and compliance (US/EU).

- Lock size, thickness, features, and tolerances.

- Standardize packaging, barcode, and carton specs.

- Set MOQs, lead times, and freight terms.

- Agree on warranty/returns and defect rate.

- Align color standards (Pantone code) for pink consistency.

This standardized property set and terminology enables USA/EU buyers to source “chopping board pink” consistently, control quality, and manage costs across suppliers and SKUs.

Navigating Market Dynamics and Sourcing Trends in the chopping board pink Sector

Navigating Market Dynamics and Sourcing Trends in the Chopping Board Pink Sector

Market snapshot (pink boards, indicative from Amazon US sample)

- Price range (current listings): ~$7.50–$60

- Feature sets dominating at price bands:

- <$10: single plastic board, basic color, hang hole; typical unit cost <$1.50

- $10–$20: plastic sets (3–4 pcs), non-slip feet, juice grooves; typical unit cost $1.60–$3.40

- $20–$30: dual-sided plastic boards, larger sizes; typical unit cost ~$4.20–$6.20

- $50–$60: titanium (100% pure) boards (medium/large), dishwasher safe, non-toxic branding; typical unit cost ~$8.00–$13.00

- Materials observed: plastic (PP/HDPE), 100% titanium

- Feature cadence (retail-side): dishwasher safe, BPA-free claims, dual-sided, juice grooves, non-slip feet, easy-grip handles, celebrity/brand association, color sets

- Buyer signals: higher review velocity correlates with value sets at $12–$20; premium durability narratives sustain higher pricing in titanium

- Seasonality: giftable sets spike in Q4; core colors (including pink) maintain steady replenishment

Demand drivers and positioning

- Color-coded sanitation programs (HACCP/GFSI) keep pink as a mainstream choice within mixed sets; bundling pink with other colors reduces replacement friction and widens basket size

- Pink skews toward consumer gifting and lifestyle-led kitchens; pairing with pastel or neutral kitchenware improves cross-sell

- Premium narratives—hygiene, non-porosity, durability—sustain higher price points even without wood or glass

Regulatory and compliance (US/EU)

- US: ensure BPA-free, FDA-compliant food-contact resins; dishwasher claims supported by material selection and supplier testing; substantiate any “non-toxic” or “hygiene” language with lab data

- EU: materials and colorants must comply with EU 10/2011 on plastic food-contact; declare substances per Article 15; REACH obligations for SVHC (≤0.1% w/w); ensure conformity documents are available

- Documentation: maintain Declaration of Conformity, test reports (migration, durability cycles), and supplier traceability

Sustainability landscape and brand differentiation

- Climate transparency is emerging: buyers can rely on ClimatePartner-certified products indicating calculated carbon footprints and offset projects, signaling procurement sustainability readiness

- Packaging reduction (right-size, no excess plastic) and PCR (post-consumer recycled) resin content are viable differentiators; validate claims with supplier attestations and certification

- Durability reduces lifetime environmental impacts; titanium products emphasize hygiene and longevity, but check supply chain resilience and COGS before scaling

Sourcing and supply chain dynamics

- Supplier base: plastic boards are largely manufactured in China; titanium options sourced from specialty metal processors

- Lead times: 45–60 days typical for standard plastics; 60–90+ days for titanium or custom molds

- MOQs: plastic single/color sets ~500–1,000 units; sets of 3–4 ~1,000–3,000; custom color matched to Pantone ~3,000–5,000; titanium MOQs vary by thickness and finish

- Cost drivers: multi-color sets (tooling and QC), juice groove depth, non-slip inserts, size (11.8”–13.2”), finish (polish), branding (foil stamping), and packaging complexity (retail-ready boxes)

- Quality risks: color consistency in pink (batch drift under heat), warping in larger boards, edge finishing QC; mitigate with Pantone targets, incoming color checks, and AQL sampling

Feature/performance benchmarking (retail pricing as signal)

| Tier | Typical retail price | Material | Features | Claimed benefits |

|---|---|---|---|---|

| Budget | $7–$10 | Plastic | Basic pink board, hang hole | Entry-level hygiene and utility |

| Mid-value set | $12–$20 | Plastic | 3–4 pcs sets, non-slip feet, juice grooves | Convenience, hygiene, value |

| Large premium plastic | $20–$30 | Plastic | Dual-sided, larger sizes, handles | Durability for frequent use |

| Titanium premium | $50–$60 | 100% titanium | Double-sided, non-toxic, dishwasher safe | Hygiene, longevity, premium feel |

Strategic recommendations

- Portfolio mix: anchor on mid-value sets (pink plus complementary colors) with non-slip feet and juice grooves; allocate limited SKUs to titanium for premium positioning and brand halo

- Compliance-first: standardize FDA/EU compliance and substantiation of hygiene claims; formalize DoC package per SKU to reduce retailer friction

- Sustainability roadmap: pilot ClimatePartner labeling on high-volume sets; consolidate packaging, explore PCR resin options where mechanical properties and aesthetics allow

- Differentiation: offer modular sets or interchangeable inserts; introduce easy-clean finishes; leverage color and branding (celebrity collaborations) sparingly to boost velocity without compromising margins

- Procurement planning: reserve Q2–Q3 for new molds and color validations to support Q4 gift-season; maintain buffer on pink resin lot control to avoid stockouts due to color matching issues

Historical context (high-level)

- Cutting boards evolved from wood to plastics to accommodate industrial hygiene and dishwasher safety; color coding institutionalized sanitation practices, making pink a standard segmentation unit

- Recent years saw premiumization (titanium, glass alternatives) co-exist with value plastic sets; sustainability and transparency are now strategic levers, not just marketing tags

This section positions pink as a resilient, mainstream segment with clear tiering, compliance checkpoints, and emerging sustainability value-adds to inform both category planning and supplier negotiations.

Frequently Asked Questions (FAQs) for B2B Buyers of chopping board pink

Frequently Asked Questions (FAQs) for B2B Buyers of Chopping Board Pink

What pink chopping board materials and grades are suitable for commercial kitchens?

Answer:

– High-density polyethylene (HDPE) and polypropylene (PP) are the most common plastic materials for pink cutting boards in foodservice. They are lightweight, non‑porous, and widely accepted for general prep, proteins, and produce. Examples found in retail include pink plastic boards and color‑coded plastic sets.

– 100% pure titanium boards are a premium, hypoallergenic alternative with high hygiene and durability (retail examples show double‑sided, non‑toxic, dishwasher‑safe boards with strong review counts).

| Material | Typical use cases | Dishwasher safe | Notable properties (as marketed) | Compliance relevance |

|---|---|---|---|---|

| HDPE/PP (plastic) | General prep; color‑coding by task/protein | Yes (residential/light commercial; verify rack wash) | Non‑porous; BPA‑free variants; deep grooves and non‑slip feet options | FDA 21 CFR (US), EU 10/2011 (Food Contact), LFGB (DE) |

| 100% pure titanium (metal) | High‑hygiene, heavy‑duty prep; long service life | Yes (retail listings show dishwasher safe) | Durable, non‑metallic taste transfer; double‑sided use; non‑toxic | Food‑grade material; check EU 1935/2004, specific declarations |

Do pink boards meet food‑contact safety standards?

Answer:

– Plastic (HDPE/PP) pink boards are generally offered with:

– FDA compliance for food contact in the United States.

– EU 10/2011 migration compliance for plastics in Europe.

– BPA‑free claims are common on retail listings and many B2B SKUs.

– Titanium boards marketed as “100% pure titanium” are considered food‑grade, but compliance documents must be requested (e.g., EU 1935/2004, ISO standards, and migration declarations).

– Request full regulatory documentation before procurement: declarations of conformity, test reports, and material safety data sheets.

Illustrative Image (Source: Google Search)

What sizes, thicknesses, and features are available?

Answer:

– Common sizes seen in the market include 11.8″ × 7.9″, 13.2″ × 9.4″, and multi‑board sets with grip handles and juice grooves.

– Typical thicknesses range 0.35–0.5 inch (≈9–13 mm) for plastic boards; premium plastics may be thicker.

– Feature options:

– Color‑coded pink for produce/allergen separation.

– Non‑slip feet for stability.

– Deep drip juice grooves and raised edges to contain liquids.

– Built‑in handles, hanging holes, and stackability.

– Double‑sided designs (plastic and titanium) for multi‑task use.

– For B2B, confirm dimensions and performance targets (e.g., impact resistance, knife‑friendliness, weight).

How are pink boards customized and branded for B2B?

Answer:

– Customization options include:

– Laser engraving for logos and HACCP/allergen icons.

– Pad printing and debossing (on select plastics).

– Color matching (e.g., to house standards or Pantone), and color‑coding systems.

– UV markings and surface textures for improved grip.

– Special features (feet, grooves) and packaging (retail boxes, polybags, cartons).

– MOQs typically apply to custom prints and Pantone matches; standard pink variants are usually available with lower MOQs.

What are typical MOQs, lead times, and pricing structures?

Answer:

– Standard pink SKUs: MOQs are commonly 200–600 units per size per color; mixed SKUs may be accommodated.

– Custom colors/logos: MOQs typically 500–1,000 units per SKU.

– Lead times: 10–20 business days ex‑works for stock pink; 25–45 business days for custom runs.

– Pricing: offered ex‑works (EXW), freight on board (FOB), or delivered duty paid (DDP). Tiered pricing is standard (e.g., 200–799, 800–1,999, 2,000+ units).

– Case pack options commonly align with carton weights and pallets for efficient shipping.

How should pink boards be cleaned and sanitized?

Answer:

– Plastic boards:

– Dishwashers are suitable for residential/light commercial use; rack washer compatibility should be confirmed with the supplier for heavy‑duty environments.

– Sanitize with food‑safe solutions (e.g., quaternary ammonia); avoid chlorine where it may degrade plastic over time.

– Air dry; use non‑abrasive pads to minimize scoring.

– Titanium boards:

– Commercial dishwasher safe per retail marketing; non‑porous and corrosion‑resistant.

– No metallic taste transfer; compatible with aggressive sanitizers and high‑temperature cycles.

– Hygiene best practices: separate boards by task (raw protein vs produce), maintain a dedicated pink board for high‑allergen control, and perform regular deep cleans.

Illustrative Image (Source: Google Search)

Do you offer sustainability or carbon‑label certifications?

Answer:

– Retail examples show climate and carbon‑impact labeling (e.g., ClimatePartner certification), suggesting suppliers can support comparable programs.

– For B2B programs, request:

– Lifecycle carbon measurement and reduction targets.

– Offset strategies and supporting certifications.

– Recycled content declarations and end‑of‑life options (recycling channels or take‑back where applicable).

– Confirm packaging sustainability (recyclable materials, reduced plastics) and country‑specific compliance for climate claims.

What warranty and returns do you support?

Answer:

– Warranty:

– Plastic boards: warranty against manufacturing defects under normal use; typical term is 12 months (confirm case by case).

– Titanium boards: extended warranty may be available given material durability (e.g., 24–36 months), subject to supplier policy.

– Returns:

– RMA accepted within defined windows for unopened cartons and verified defects.

– Inspections and photo documentation required for claims.

– After‑sales:

– Spare parts and replacements for accessories (e.g., feet, handles) if applicable.

– Technical support for sanitation protocols and compliance documentation.

Note: All certifications, performance claims, and lead‑time specifics should be confirmed in supplier documentation prior to purchase.

Strategic Sourcing Conclusion and Outlook for chopping board pink

Strategic Sourcing Conclusion and Outlook

The pink chopping board category remains a resilient, fast-moving B2B opportunity in the USA and EU, driven by color-coordinated sets, celebrity and pastel trends, and rising expectations for hygiene and durability. Retail price bands are well established: commodity plastic boards near $7–$12 (single/pack), designer/pink-themed sets at $12–$20, and premium titanium at $20–$60. Sustainability and carbon disclosure are increasingly visible on marketplace listings and should be factored into supplier onboarding and claims review.

Illustrative Image (Source: Google Search)

Material choice is a clear decision matrix:

– Plastic (HDP, PP) is the cost leader, with pink variants widely available and easy to bundle.

– Bamboo offers a “green” narrative but requires careful food-contact compliance (FDCA, EU 10/2011).

– Titanium commands a premium on hygiene and longevity, with strong ratings and niche but growing adoption.

Sourcing implications:

– Plastic: leverage commodity processors for competitive COGS; target wholesale ranges of $4–$6 with retail at $12–$18 (4-pack).

– Designer-themed: partner with license or style-forward brands; wholesale $7–$9; retail $10–$14.

– Titanium: source from established metal processors; wholesale $12–$35; retail $20–$60.

Action plan:

– Validate compliance and labeling (FDA, EU 10/2011, REACH, California Prop 65 if applicable).

– Request dishwasher durability and density tests; verify non-porous claims and cut resistance.

– Include carbon-impact statements only with verifiable certifications (e.g., ClimatePartner).

– Offer color family bundles (pink + gray/black) and juice-groove options to lift basket size.

Near-term outlook: steady demand for pink as a key accent color; accelerate listings by Q4 to catch gifting cycles; price to win against $19.99 reference points for premium sets while maintaining margin through mixed-material assortments.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.