6 Inch Pipe Clamp: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for 6-inch Pipe Clamp

Across the USA and Europe, sourcing a 6-inch pipe clamp is a high-consequence decision. A mis-specified clamp can trigger leaks, safety risks, and failed audits. This guide delivers fact-based specifications, selection criteria, and region-ready requirements so procurement and engineering teams can move quickly with confidence.

Market snapshot

Clamps in this size fall into two primary categories—standard repair clamps and emergency clamps—with third-party accessories like conduit/pipe straps for mounting. Materials, gasket options, and performance limits drive safety, compliance, and total cost of ownership.

Representative specifications (sample)

| Category | Material | Key Specs |

|—|—|—|

| Standard repair clamp | 316 stainless steel | Pipe OD: 6.625″; Bolt: 3/4″; Max load: 1615 lb; Weight: 5.63 lb |

| Emergency clamp | Steel with gasket options | Working pressure: 400 psi; Torque: 50 ft·lb; Gasket: Buna-N (250°F), Viton (450°F); Bolt: 1/2″ x 4″ (3 bolts) |

What this guide covers

- Compliance and safety: ISO 9001–certified manufacturing, risk assessment (EN ISO 12100), and safe working practices for installation and maintenance.

- Standards and compatibility: ASME/ASTM piping fit-up practices, EN-based expectations for industrial equipment (e.g., EN 13480 for piping), and documentation requirements.

- Material selection: 316 vs. 304 stainless, gasket chemistry (Buna-N vs. Viton), bolt and torque requirements, and corrosion resistance.

- Product types and use-cases: Standard clamps for repairs, emergency clamps for pressure containment, and conduit/pipe straps for mechanical support.

- Performance and safety margins: Pressure ratings, torque values, temperature limits, and recommended load capacity.

- Budget and sourcing: Price anchoring and budgeting guidance (emergency clamps cost significantly more than standard clamps); procurement documentation and QA expectations.

Price snapshot and budgeting

Expect emergency clamps to carry a premium due to pressure rating and torque requirements; a representative 6″ emergency clamp lists around $580, while a standard 316 stainless 6″ clamp is often around $121. Define ratings first, then align spend to the lowest-cost option that meets compliance and performance.

Quick procurement checklist

- Pressure/temperature rating vs. service medium (gas/liquid) and state.

- Gasket material selected for chemical compatibility and temperature.

- Clamp bolt spec and required torque documented in installation SOPs.

- Manufacturer documentation (spec sheets, test data) for inspection sign-off.

- Region-specific conformity (e.g., US OSHA site safety; EU CE/PED where applicable) verified before PO.

Top 10 6 Inch Pipe Clamp Manufacturers & Suppliers List

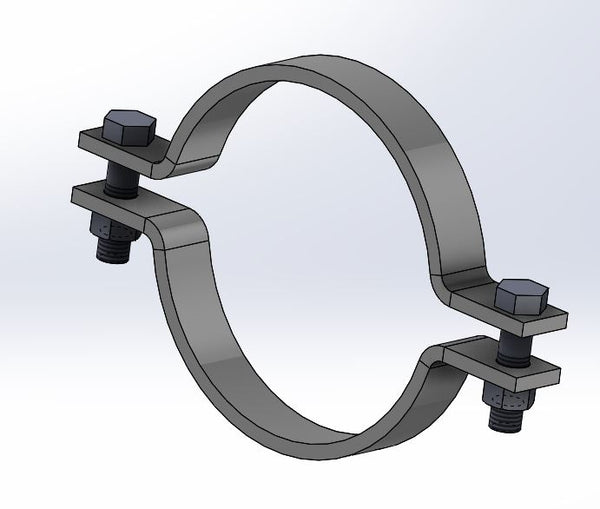

1. 6″ Stainless Steel Pipe Clamp Standard T-316 #212SX0600

Domain: pipingnow.com

Registered: 2015 (10 years)

Introduction: In stock Free deliveryCheck out this 6-inch pipe clamp online at PipingNow. This standard T-316 Stainless steel repair clamp weighs 5.63 pounds and has a bolt size of 3/4 inch….

2. The Best Clamps for Your Hydraulic Projects at Brennan Industries

Domain: brennaninc.com

Registered: 1996 (29 years)

Introduction: Brennan offers a variety of clamps for many different projects and systems, such as high-pressure hose clamps, stainless steel hose clamps, pipe clamps and more ……

3. Top 6% Hose Clamps Suppliers for 6-inch Hose Products and …

Domain: puxingclamp.com

Registered: 2023 (2 years)

Introduction: Butterfly hose clamp manufacturers for secure and easy pipe assembly requirements. · Durable 316 Hose Clamps for Industrial Applications | ……

Illustrative Image (Source: Google Search)

Understanding 6 inch pipe clamp Types and Variations

Understanding 6 inch pipe clamp Types and Variations

Pipe clamps in the 6-inch size span multiple functional categories—from low‑leak temporary fixes to permanent support and routing. For procurement in the USA and Europe, the material and performance ratings (pressure, torque, temperature, and load) should be aligned with your installation method, fluid service, and compliance requirements.

Standard repair clamp (permanent bolting)

- Purpose: Mechanical repair of small defects on steel pipe. Not a structural replacement.

- Pressure rating (example): 400 psi (emergency-type, not all standard clamps are pressure rated—consult manufacturer).

- Torque (example): 50 ft·lbf on the emergency example.

- Materials: 316 stainless steel; gasket materials include Buna‑N (up to 250°F) and Viton (up to 450°F).

- Installation: Even, crisscross torquing to prevent misalignment; verify gasket seating before pressure testing.

Table 1. 6-inch pipe clamp types (features, applications, pros/cons)

| Type | Features | Applications | Pros | Cons |

|---|---|---|---|---|

| Standard repair clamp (T‑316 stainless, bolted) | 316 stainless clamp body; gasket sealing; 3/4″ bolts; max recommended load ~1615 lb | Corrosion‑resistant permanent repair; water, chemicals; process lines | High corrosion resistance; high mechanical load; straightforward to install | Requires correct gasket selection; not a structural replacement; torque discipline required |

| Emergency/band clamp (temporary repair) | 3 bolts; 1/2″ dia x 4″ length; 50 ft·lbf torque; 400 psi WP; gasket options: Buna‑N 250°F, Viton 450°F; width ~8.5″, length ~8″ | Temporary leak control for shutdown; emergency response kits; line isolation | Quick installation; high pressure capability; gasket options for temperature | Temporary by design; higher cost per unit; torque consistency critical to seal |

| Conduit/structural support strap (U‑strap) | 150 mm (≈6″) U‑shaped stainless strap; two‑hole rigid bracket; non‑pressure | Mechanical support, routing, or fixing of conduits, tubing, or cables | Low cost; rigid support; corrosion resistance | No pressure rating; for non‑pressurized systems only; limited adjustability |

| Strut-based pipe/strut clamp (metal strut channel system) | Metal channel + hardware; various strap/housing configurations; installation via strut nuts/rails | Building services routing; mechanical/electrical support; ceiling grids and trays | Adjustable; modular; fast installation | System‑specific hardware; must validate pressure rating (many are non‑pressure) |

| Bolted single‑section clamp (generic model) | One‑piece clamp body; gasket; bolt set; pressure ratings vary by vendor | Permanent or semi‑permanent leak repair | Balanced force distribution | Higher material volume than band clamps; verify geometry with pipe OD |

Detailed guidance by type

Standard repair clamp (T‑316 stainless, bolted)

- Features and notes: A corrosion‑resistant stainless steel clamp (e.g., T‑316) with integral gasket sealing. Bolting sizes are commonly 3/4″ on standard clamps; one exemplar lists a maximum recommended load of approximately 1615 lb. Ensure clamp body and gasket are compatible with the fluid medium, including temperature and chemical resistance.

- Applications: Long‑term repair of pinholes, seams, or minor corrosion on steel pipe, often in water, wastewater, or chemical service.

- Pros: High corrosion resistance; strong mechanical load capacity; permanent or semi‑permanent solution. Cons: Gasket compatibility must be carefully selected; sealing depends on correct torque and alignment; not structural and cannot replace pipe.

- Typical specs (examples): 6″ nominal pipe clamp; pipe OD ≈ 6.625″; 316 stainless material; 3/4″ bolt size; max recommended load ≈ 1615 lb.

Emergency/band clamp (temporary repair)

- Features and notes: A band‑style clamp designed for rapid leak control, typically with three bolts (1/2″ diameter x 4″ length) and an 8.5″ width. Working pressure and torque are specified (400 psi and 50 ft·lbf respectively). Gasket material choice controls temperature performance: Buna‑N up to 250°F or Viton up to 450°F.

- Applications: Shutdowns, isolation, temporary containment of leaks, emergency response kits for utilities or industrial plants.

- Pros: Fast installation; significant pressure capability; choice of gasket material for temperature. Cons: Temporary solution; higher unit cost; sealing quality depends on consistent torque.

- Typical specs (examples): Length ≈ 8″; width ≈ 8.5″; 3 bolts (1/2″ x 4″); torque ≈ 50 ft·lbf; WP ≈ 400 psi; gasket materials: Buna‑N (250°F) or Viton (450°F); price ≈ $580 (example listing).

Conduit/structural support strap (U‑strap)

- Features and notes: A rigid U‑shaped strap with two mounting holes, used for support and routing of conduits, tubing, or cables. Commonly supplied in stainless (e.g., 304 or 316) or zinc‑plated steel; sold in bulk.

- Applications: Non‑pressurized systems; mechanical/electrical support; industrial cable or tubing management.

- Pros: Low cost; robust mechanical support; corrosion‑resistant options. Cons: Not pressure rated; not a leak repair device; limited adjustability compared to strut‑based systems.

Strut‑based pipe/strut clamp (metal strut channel system)

- Features and notes: Assembled from metal strut channel, clamps or brackets, and fasteners. Offers modular, adjustable routing with repeatability across project sites.

- Applications: Building services; HVAC; electrical tray and conduit support; mechanical rooms and utility racks.

- Pros: Adjustable; scalable; rapid installation; widely stocked in construction trades. Cons: System‑specific components; verify that the clamp configuration you choose is pressure‑rated if required (many strut clamps are support‑only).

Bolted single‑section clamp (generic model)

- Features and notes: A single‑piece clamp body with gasket and bolt set; pressure rating depends on the vendor and gasket. Often used for permanent or semi‑permanent repairs where the geometry matches pipe OD.

- Applications: General pipe repair, small‑to‑medium defects; compatible with steel pipe systems where mechanical integrity is needed.

- Pros: Balanced load distribution; standard installation methods. Cons: Requires confirmation of pressure/temperature ratings; higher material cost than band designs.

Selection considerations

- Pipe OD vs nominal size: Ensure clamp geometry matches the actual outside diameter (for 6″ steel pipe, OD ≈ 6.625″).

- Pressure/temperature vs gasket material: Align gasket selection (e.g., Buna‑N up to 250°F; Viton up to 450°F) with the process fluid and temperature.

- Materials: Prefer 316 stainless for corrosion resistance; zinc‑plated steel for lower cost in non‑corrosive, non‑pressurized support uses.

- Installation torque: Follow torque specs (e.g., 50 ft·lbf on emergency‑style) and use a crisscross pattern to prevent uneven seating.

USA vs Europe buying notes

- Units: Clamps are typically listed by nominal pipe size (e.g., 6″) and actual pipe OD (e.g., 6.625″). Bolt sizes may be shown in inches (e.g., 3/4″).

- Gaskets and materials: Availability varies by vendor; confirm temperature and chemical compatibility (e.g., Buna‑N vs Viton).

- Dimensional standards: European mechanical/electrical support systems (struts) are widely used in the USA; conversely, USA listings often use inch‑based sizes and imperial bolt threads (confirm stud/nut threadform: UNC/UNF vs metric).

By matching the clamp type to the service (pressure, temperature, medium), material compatibility, and installation torque practice, procurement teams can consistently achieve reliable leak control and support performance on 6‑inch pipe systems.

Key Industrial Applications of 6 inch pipe clamp

Key Industrial Applications of 6 inch pipe clamp

6-inch pipe clamps are used wherever large-diameter rigid pipe needs leak isolation, repair, or mechanical support. The 6 in (DN150) size serves 6.625 in OD Schedule 40/80 steel/stainless pipe. In industrial practice, clamps fall into two classes: stainless repair clamps for permanent or semi-permanent remediation and emergency clamps for rapid isolation under pressure.

Illustrative Image (Source: Google Search)

- Stainless (T‑316) clamps: corrosion-resistant bands/bridges with ≥1/2–3/4 in hardware; suitable for water, steam condensate, and general chemical service where stainless steel is compatible. Typical max recommended load ≈1615 lb.

- Emergency clamps: multi-bolt, gasket-sealed bands rated for isolation under pressure, e.g., up to 400 psi (material dependent), with ≥250°F (Buna-N) or ≈450°F (Viton) temperature limits for short-duration service.

Applications by industry and why they matter:

| Industry | Application | Why it matters |

|---|---|---|

| Water & Wastewater | Temporary repair of 6 in header leaks at plants and pump stations; mechanical support for 6 in branch lines to filters/controls; bypass jumper isolation | Speeds shutdown-free remediation and reduces downtime; 316 stainless resists corrosion in municipal/industrial water service; clamp hardware and band materials are compatible with municipal standards |

| Oil & Gas (Facilities/Refining/Compression) | Isolation of 6 in process lines and vapor return lines; temporary seal for small pinholes or gasket failures in hydrocarbon service | Emergency clamps allow line pressure isolation with defined psi and temperature limits; stainless clamp body and hardware resist H2S and corrosion; Viton or NBR options improve fluid compatibility |

| Chemical & Petrochemical | Repair/isolation of 6 in process lines; secondary containment clamps for jacketed or lined pipe; support of skids and pipe racks | 316 stainless resists a broad range of chemicals; clamp rigidity supports vibration control and alignment on process skids |

| Power Generation (Thermal & HRSG) | Isolation of 6 in auxiliary lines (feedwater/condensate/cooling water); temporary repair clamps on low‑pressure segments | Emergency clamps support short‑duration isolation at elevated temperatures; 316 stainless resists condensate corrosion; defined torque and bolt size ensure reliable clamping force |

| HVAC/R (Chillers/Boilers) | Temporary seal for 6 in condensate or hot water lines; repair of corrosion leaks on steel pipe racks; support brackets for equipment drops | Emergency seals minimize chiller/boiler downtime; stainless clamps add durability to equipment connections and pipe supports |

| Food & Beverage | Repair clamps for 6 in process lines; support brackets for stainless lines to packaging; stainless hardware to meet hygienic requirements | T‑316 stainless and stainless hardware meet clean‑in‑place and hygienic standards; clamps can be reused/relocated during line changes |

| Marine & Shipbuilding | Repair clamps for 6 in cooling water/hydraulic lines; support on deck pipe racks | Stainless hardware resists salt spray and seawater; robust clamp hardware provides mechanical load capacity for shipboard vibration |

| Pulp & Paper | Repair clamps on 6 in steam/condensate lines; support brackets in board machines | 316 stainless resists paper‑mill environments; clamps handle large pipe diameters and provide reliable alignment under plant vibration |

| Pharmaceutical | Repair clamps for 6 in utility/process lines; hygienic support in clean zones | Stainless assembly and smooth surfaces support cleanroom hygiene; clamp reuse reduces changeover costs |

| General Industrial Manufacturing | Support clamps for 6 in compressed air/steam service; repair clamps for cooling water loops | Stainless and coated hardware extend clamp life; standardized bolt size and torque simplify maintenance inventories |

Typical performance and materials (from source models)

– 6 in T‑316 stainless repair clamp (model #212SX0600): pipe OD 6.625 in; bolt size 3/4 in; weight 5.63 lb; max recommended load ≈1615 lb.

– 6 in emergency clamp: working pressure up to 400 psi; torque ≈50 ft‑lb; bolt diameter 1/2 in; bolts 3; gasket options: Buna‑N (≈250°F) or Viton (≈450°F).

Selection guidance

– Choose stainless repair clamps for long‑term service where corrosion resistance and mechanical load support are critical.

– Choose emergency clamps for rapid, pressure‑safe isolation (limited time/temperature) with gasket materials matched to the medium and temperature.

– Verify clamp OD range and bolt torque against project standards (USA/EU) to ensure pressure containment and load compliance.

3 Common User Pain Points for ‘6 inch pipe clamp’ & Their Solutions

3 Common User Pain Points for 6 inch pipe clamp & Their Solutions

Pain Point 1: Fit and sealing issues (incorrect OD/temperature compatibility)

- Scenario: Installer fits a standard 6-inch pipe clamp (OD 6.625″) to pipe that is out-of-round, undersized, or at elevated temperatures. Bolt torque is applied, but leakage persists.

- Why it happens: Clamp sealing relies on gasket compression over a consistent OD. If the pipe is undersized/ovaled or operating at a temperature outside the gasket’s rating, compression is uneven and leaks occur.

- Solution:

- Verify pipe OD and roundness: 6-inch Schedule 40/80 OD is typically 6.625″; clamp gasket cavity must match this OD. Use calibrated calipers and a straightedge.

- Choose the correct emergency clamp type:

- For high-temp service (up to 450°F), specify Viton gasket and metal components compatible with the fluid.

- For standard temperature (≤250°F), Buna-N gasket is adequate; standard carbon steel or stainless hardware is usually fine.

- Torque properly to ensure uniform gasket compression:

- Example: Emergency clamp at 50 ft·lb torque (3 bolts × 0.5″ diameter) provides rated sealing up to 400 psi.

- If OD is significantly off, use a larger OD clamp or add a compliant gasket/shim; do not over-torque small bolts (risk of leakage and bolt yield).

Quick selection reference:

| Condition | Recommended clamp spec | Temperature limit | Pressure rating | Notes |

|—|—|—|—|—|

| Standard 6″ (6.625″ OD), ambient/≤250°F | 316 SS standard clamp or emergency clamp with Buna-N gasket | 250°F (Buna-N) | Up to 400 psi (emergency clamp example) | Verify torque to spec; confirm pipe roundness |

| High-temp service (up to 450°F) | Emergency clamp with Viton gasket and compatible metal | 450°F (Viton) | Up to 400 psi | Match clamp body/bolt material to fluid (e.g., 316 SS for corrosion resistance) |

| Out-of-round/undersized pipe | Use oversize clamp, corrective gasket/shim; avoid over-torquing | As per gasket | As per clamp | Re-measure OD; adjust before final torque |

Illustrative Image (Source: Google Search)

Pain Point 2: Underrated load/pressure and insufficient clamp rating

- Scenario: A 6-inch standard clamp is used on a line that later needs higher internal pressure or external loads; the clamp deforms or fails.

- Why it happens: Standard clamp ratings can be exceeded when pressure surges, thermal cycling, or dynamic forces are not accounted for.

- Solution:

- Match clamp rating to worst-case loads:

- Example spec: 6″ 212SX0600 (316 SS) has a Max Recommended Load of 1,615 lb. If your loads exceed this, switch to a heavy-duty clamp, multi-clamp arrangement, or a repair clamp designed for higher pressure.

- Emergency clamp example provides 400 psi working pressure at 50 ft·lb torque; ensure your service pressure is comfortably below rating.

- Secure attachment points and distribute load:

- Use strut/hanger systems or brackets to support external loads. Avoid relying only on the clamp body for weight/force.

- Validate installation:

- Use a calibrated torque wrench; verify bolt diameter and quantity match spec.

- Retorque after initial thermal cycles and at routine PM intervals.

Load/pressure check list:

| Input | Example/limit | Action if exceeded |

|—|—|—|

| Internal pressure | 400 psi (emergency clamp example) | Increase clamp rating or add clamps in series |

| External tensile/impact loads | 1,615 lb (212SX0600 clamp rating) | Upgrade to higher-capacity clamp or add structural support |

| Temperature | 250°F (Buna-N) / 450°F (Viton) | Select appropriate gasket; derate clamp if needed |

| Bolt torque | 50 ft·lb (emergency clamp) | Use calibrated torque wrench; document torque logs |

Pain Point 3: Corrosion/compatibility (material mismatch and chemical exposure)

- Scenario: Stainless clamp bolts/gasket deteriorate rapidly in aggressive media; the clamp appears fine initially but fails during inspection or after a short cycle.

- Why it happens: The gasket polymer and clamp material were not selected for the actual medium, temperature, or cleaning agents.

- Solution:

- Confirm material compatibility:

- Use 316 stainless clamp bodies and hardware for corrosives and outdoor exposure (e.g., Empire Industries 212SX0600 is 316 SS).

- Select gasket polymer for the fluid:

- Buna-N: Standard for ≤250°F; good for many oils/hydrocarbons; check compatibility with aromatics/solvents.

- Viton: High-temp (≤450°F), better chemical resistance; required for aggressive services and elevated temperature.

- Maintain and inspect:

- Avoid caustic cleaning agents that attack elastomers. Inspect gasket seating surfaces for nicks or debris before assembly.

- For long layups or thermal cycling, re-torque and inspect per PM plan.

Compatibility at a glance:

| Service condition | Gasket | Clamp body/bolts | Notes |

|—|—|—|—|

| Water/steam ≤250°F | Buna-N | 316 SS (e.g., 212SX0600) | Confirm pressure rating; avoid sharp edges |

| Hydrocarbon/alkaline ≤250°F | Buna-N (if compatible) | 316 SS | Verify chemical compatibility; derate if uncertain |

| High-temp/chemical up to 450°F | Viton | 316 SS | Viton offers broader chemical resistance; check specific media |

| Outdoor/coastal | Buna-N or Viton | 316 SS | Prefer 316 SS to reduce corrosion risk; monitor gasket hardening |

Practical takeaway

– Always verify pipe OD, gasket material, clamp rating, and bolt torque against the actual service. When in doubt, step up to a higher-rated clamp or a Viton gasket for high-temp/chemical services, and document the installation with torque logs and PM inspection intervals.

Strategic Material Selection Guide for 6 inch pipe clamp

Strategic Material Selection Guide for 6 inch pipe clamp

Selecting the right 6-inch pipe clamp begins with aligning material and component choices to application needs: medium, pressure/temperature, corrosion exposure, and life-cycle cost. For 6-inch line sizes, two dominant configurations are used across USA and Europe:

Illustrative Image (Source: Google Search)

- Standard repair clamps with metallic housings (often stainless steel) used for mechanical retention and corrosion protection on sound pipe.

- Emergency clamps with gasket isolation, rated for pressure containment as leak repair devices.

Material options you will encounter

From referenced products and common practice, the principal materials used at this size are:

– 316 stainless steel (T-316) housing and hardware (typical for corrosion resistance and moderate mechanical loads).

– Buna-N (Nitrile) gaskets (general service oil and fuel hydrocarbons; standard temperature).

– Viton (FKM) gaskets (high-temperature hydrocarbon and chemical service).

– Carbon steel hardware (common on emergency clamp housings/bolts when not stainless).

Evidence snapshot from available references

- Empire Industries, Figure #212SX, 6-inch clamp:

- Housing: 316 Stainless Steel

- Pipe size: 6 in (Pipe OD: 6.625 in)

- Hardware: 3/4-inch bolt

- Weight: 5.63 lb

- Max recommended load: 1,615 lb

- Emergency 6-inch pipe clamp:

- Pressure: 400 psi (working)

- Torque: 50 ft-lb

- Gasket options: Buna-N (250°F max), Viton (450°F max)

- Hardware: three 1/2-inch bolts × 4 inches long

- Dimensions: 8-inch length × 8.5-inch width; weight 18 lb

- Conduit-style metallic U-clamps are also available in stainless for cable/piping support, typically non-pressure, indicating metal choices like stainless are prevalent in the 6-inch size category.

Decision guidance for 6-inch pipe clamps

- If pressure containment is required (e.g., temporary leak repair under line pressure), use a dedicated emergency clamp with gasket isolation and a verified pressure rating. Examples in the market show 400 psi working pressure at ≤250°F (Buna-N) and ≤450°F (Viton).

- For mechanical retention, support, or clamping on sound pipe where pressure is not expected through the clamp body, stainless housings (T‑316) provide broad corrosion resistance and a published maximum recommended load. Example data: 3/4-inch bolt, 1,615 lb rating on a 6-inch clamp.

- For gasket compatibility:

- Buna-N (standard): suited for general hydrocarbon service at moderate temperatures (reference product shows 250°F maximum).

- Viton (high-temp): higher temperature and chemical resistance capability (reference product shows 450°F maximum).

- Hardware specification:

- Standard clamp bolt size is commonly 3/4-inch (example: T‑316 repair clamp).

- Emergency clamp bolt pattern often uses multiple 1/2-inch bolts with specified torque; for one example, three 1/2-inch bolts at 50 ft-lb torque.

Compliance and regional fit

- Material and pressure/temperature ratings are published per the product family and SKU; check individual specifications and certifications for USA and EU projects.

- Where gasket media compatibility and temperature limits are critical (fuel/chemical service, elevated temperature lines), select Buna-N or Viton gaskets per the required limits and verify with the manufacturer’s document set.

Snapshot comparison table: material options for 6-inch pipe clamps

| Material/Component | Corrosion resistance | Pressure capability | Temperature capability | Bolt/hardware spec | Example reference | Typical use |

|---|---|---|---|---|---|---|

| 316 stainless steel (T‑316) housing/hardware | High (marine/chemical exposure) | Not rated for through-clamp pressure; retention/fixing device | No published limit in source; use product’s spec | 3/4-inch bolt (example) | Empire 6″ clamp (212SX0600) | Repair/retention clamp; mechanical support; corrosion-prone lines |

| Buna‑N (Nitrile) gasket | Good for hydrocarbons and oils | Emergency clamp: up to 400 psi (working) per example | Up to 250°F (example product) | Emergency clamp: three 1/2-inch bolts at 50 ft-lb torque | 6″ Emergency pipe clamp | Standard-temp hydrocarbon service; emergency leak repair |

| Viton (FKM) gasket | Broad chemical resistance; high-temp capability | Emergency clamp: up to 400 psi (working) per example | Up to 450°F (example product) | Emergency clamp: three 1/2-inch bolts at 50 ft-lb torque | 6″ Emergency pipe clamp | High-temp hydrocarbon and chemical service; emergency leak repair |

| Carbon steel hardware (with/without coating) | Lower corrosion resistance than SS; coating can help | As per clamp design | As per clamp design | Often 1/2-inch bolts for emergency clamps | 6″ Emergency pipe clamp | Non-stainless emergency clamps; budget-oriented, less corrosion tolerance |

Note: Always confirm bolt quantity, torque, gasket material, and pressure/temperature ratings against the specific clamp’s data sheet for final specification and compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for 6 inch pipe clamp

In-depth Look: Manufacturing Processes and Quality Assurance for 6-inch Pipe Clamp

Overview

This section consolidates manufacturing and quality practices for 6-inch stainless steel pipe clamps used in process piping, plant maintenance, and emergency repairs. Two common configurations—standard band clamp (e.g., Fig. #212SX0600) and emergency pipe clamp—share a 6-inch nominal pipe compatibility (6.625 inch pipe OD) but differ in geometry, gasket integration, torque, and working pressure.

Manufacturing Process

A disciplined, ISO 9001–compliant process ensures repeatability, traceability, and corrosion resistance.

Illustrative Image (Source: Google Search)

| Step | Activities | Materials & Tooling | Key Controls | ISO/ASTM References |

|---|---|---|---|---|

| Prep (Receiving & Preparation) | Verify stainless grade (e.g., 316/EN 1.4401). Confirm bolt spec (A4-70/316, 3/4″ or 1/2″). Inspect gasket (Buna-N or Viton). Review specification sheet and drawings. | Stock check on certificate of conformity (CoC). Marking/stamping. Calibration records for torque wrenches. | Material traceability, CoC/reporting for each heat/lot. Pre-sampling of gasket batches for temperature/pressure ratings. | ISO 9001; ISO 15510; ASTM A479/A276 for stainless bar/stock; ASTM A193/A4-70 bolts; ISO 3506-1; ISO 16048/ASTM A967 passivation. |

| Forming (Band/Body & Saddles) | Laser/plasma cut bands and saddles from sheet/stock. Form arcs to fit 6.625″ OD with controlled bend radii. Machine/ream bolt holes (3/4″ band; 1/2″ emergency). Deburr and finish. | CNC bending, mandrels; drills and reamers; protective films during handling. | Dimensional verification against tolerance stack-up (band gap, hole-to-hole). Visual inspection for edge defects. | ISO 9001 QMS; ISO 2768-m for general tolerances (unless otherwise specified); drawing-based SPC for critical dimensions. |

| Assembly | Position gasket (groove/clamp body). Thread bolts and hardware; install washers; pre-tension to spec. Apply recommended torque (see tables). | Torque wrench calibrated to traceable standard; anti-galling lubricant for stainless threads as required. | Torque logs per job. Marking of torque set point; re-torque verification if applicable. | ISO 16048 passivation (pre-/post-assembly); torque practices per bolt spec (e.g., ISO 3506-1). |

| QC (Quality Control) | Final dimensional, visual, and performance checks. Functional pressure test for emergency clamps (e.g., 400 psi). Verify max recommended load for band clamps. | CMM/gauges, dye penetrant (if required), hydrostatic test bench. | Nonconformance control and corrective actions. Retention of test records. | ISO 9001; ISO 9004 (performance improvement); ISO 17025 principles for calibration/testing lab equivalence; pressure testing with documented media/safety controls. |

Quality Standards and Documentation

- Quality management system: ISO 9001; continuous improvement via ISO 9004.

- Stainless steel traceability: ISO 15510; bar/forging spec via ASTM A479/A276.

- Bolting: ISO 3506-1 (A4-70 stainless, equivalent to 316/EN 1.4401); for ASME-coded pressure boundary bolts, ASTM A193 B8M (Class 2) is also commonly used.

- Passivation: ISO 16048 or ASTM A967; verify free-iron removal with water break test and sampling per spec.

- Dimensional tolerances: ISO 2768-m (general tolerances), unless defined by customer drawing.

- Calibration: ISO/IEC 17025 principles for test/calibration equipment used in torque, measurement, and hydrostatic tests.

- Documentation package: MTRs, CoC, assembly drawings, test records, cleaning/packaging logs.

Materials and Specifications: Standard vs Emergency Clamp

| Attribute | Standard T-316 Clamp (Empire #212SX0600) | Emergency Pipe Clamp |

|---|---|---|

| Nominal Pipe Size | 6 in (6.625 in pipe OD) | 6 in (6.625 in pipe OD) |

| Material | 316 Stainless Steel (EN 1.4401) | Band/bolts stainless; gasket integrated |

| Bolt Size | 3/4 in | 1/2 in |

| Bolt Length | Not specified | 4 in |

| Number of Bolts | Not specified | 3 |

| Gasket | Not integrated | Integrated (Buna-N standard up to 250°F; Viton up to 450°F) |

| Torque | Per bolt spec/manufacturer guidance | 50 ft·lb |

| Working Pressure | Not specified | 400 psi |

| Max Recommended Load | 1615 lb | Not specified |

| Dimensions (L×W) | Not specified | 8 in × 8.5 in |

| Weight | 5.63 lb | 18 lb |

| Temperature Limits | Gasket-dependent (if present); clamp body typical of 316 SS | Up to 250°F (Buna-N); 450°F (Viton) |

Notes:

– For stainless 1/2″-13 bolts, A4-70 (316) working torque in clean, lubricated threads is typically ~50 ft·lb. Verify actual torque based on lubricant, joint conditions, and customer requirements.

– Gasket choices (Buna-N vs Viton) must be aligned with media compatibility and service temperature.

Key QA Checks

- Visual: No cracks, burrs, or edge tears; gasket seating clean and uniform.

- Dimensional: Band gap within spec; hole spacing per drawing; bolt engagement ≥ full thread engagement.

- Torque: Adhere to 50 ft·lb for 1/2″ stainless bolts unless otherwise specified; record wrench calibration status.

- Pressure: Emergency clamps tested at ≥ working pressure (e.g., 400 psi) with documented media and duration; verify no leakage.

- Corrosion resistance: Passivation verification; confirm no residual iron contamination; maintain clean packaging.

Field Installation Guidance

- Surface prep: Clean pipe OD and clamp seating surfaces; remove oil, scale, and debris.

- Gasket placement: Ensure uniform gasket seating; avoid twists/creases.

- Torque sequence: Cross-pattern tightening to evenly distribute load; re-check torque after initial thermal cycles if service temperature approaches gasket limits.

- Safety: Observe working pressure and temperature limits; verify gasket material compatibility with media and temperature.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘6 inch pipe clamp’

Practical Sourcing Guide: 6-inch Pipe Clamp — Step-by-Step Checklist

Step 1 — Define service conditions

- Pressure: internal pressure to be sealed or supported (if containment is required).

- Temperature: continuous and transient peaks; gasket/bolt/lubricant compatibility.

- Medium: water, steam, oil, chemicals (gasket material).

- Duty: temporary/emergency repair vs permanent installation; duration and inspection plan.

- Environmental: outdoor/UV, washdown, corrosive atmospheres, potable-water exposure.

Step 2 — Choose the clamp type

- Repair/stainless clamp (non-pressure-bearing band): for mechanical support, securing, or low‑risk sealing; depends on gasket and clamp design.

- Emergency clamp (pressure‑containing): for temporary leak mitigation at defined pressure/temperature; must match published ratings and torque.

Examples (verify each listing’s ratings before use):

– 6″ Stainless Steel Repair Pipe Clamp (T‑316, #212SX0600): pipe OD 6.625″, 3/4″ bolts, 5.63 lb, max recommended load 1,615 lb (support/securing).

– 6″ Emergency Pipe Clamp: 50 ft·lb torque, 400 psi working pressure, 3 bolts 1/2″ × 4″, gasket options include Buna‑N (250°F) and Viton (450°F); 18 lb; overall ~8″ × 8-1/2″.

Step 3 — Match materials to environment

- Clamp band/frame: 316 stainless steel for corrosion resistance; 304 for general use; coated carbon steel for indoor/low‑corrosion.

- Bolts/hardware: stainless (316/304) or galvanized; confirm torque value and lubrication with manufacturer.

- Gasket: Buna‑N (standard, ~250°F), EPDM (~–40°F to 250°F), Viton (~–10°F to 450°F); ensure media compatibility and potable-water compliance where required.

Step 4 — Verify sizing (critical for 6″ clamp)

- Always target the pipe’s actual outside diameter (OD). For 6″ schedule 40/80 pipe, OD is 6.625″. Select or machine the clamp saddle to match this OD with appropriate gasket compression.

- Nominal pipe size (NPS) 6″ does not equal 6.00″ OD. Confirm OD with calipers or mill certs.

Step 5 — Confirm mechanical/performance requirements

- Bolt size and quantity: ensure wrench clearance and adequate clamp force (e.g., 3/4″ bolts on stainless clamps; 1/2″ × 4″ on emergency clamp).

- Torque: use manufacturer-recommended torque values and lubrication; record actual torque during installation.

- Load (for supports/securing): ensure Working Load Limit (WLL) and safety factor meet your application; example stainless clamp lists 1,615 lb max recommended load.

- Containment rating (emergency clamps only): pressure and temperature must not exceed published limits (e.g., 400 psi at gasket‑specific temperature).

Step 6 — Compliance and approvals

- Potable water: ANSI/NSF 61 or equivalent where applicable.

- Fire protection: UL/FL/Factory Mutual approvals if used on sprinkler or related systems.

- Harmonization: EU Mechanical Directive 2006/42/EC, CE marking as required; UK UKCA for Great Britain.

- Other: RoHS/REACH where relevant; seismic certification if required by jurisdiction.

Step 7 — Define documentation

- Datasheet/spec sheet with material, torque, pressure, temperature, gasket compound, and OD range.

- Certificate of Conformity (CoC) or material test reports (MTR).

- CAD/drawing showing drilling patterns, bolt centers, and clearances.

Step 8 — Finalize procurement and logistics

- SKU/catalog number; manufacturer and part family (e.g., Empire #212SX0600).

- Lead time, inventory location (USA/EU), and shipping constraints.

- Minimum order quantities; pricing tiers; maintenance/field service support.

- Terms: Incoterms (e.g., FOB, DAP), warranty, return policy, and field support.

Step 9 — Receiving and quality control

- Verify OD match and gasket compound per order.

- Inspect for corrosion, completeness of hardware, and correct bolt lengths.

- Confirm documentation pack (CoC, spec sheet, drawing).

- Record serials/QR codes for traceability.

Quick spec snapshot (from example listings)

| Attribute | Stainless Steel Repair Clamp | Emergency Pipe Clamp |

|---|---|---|

| Nominal size | 6″ | 6″ |

| Pipe OD | 6.625″ | 6″ (confirm OD; verify listing) |

| Material | T‑316 stainless | Steel frame; gasket options |

| Bolts | 3/4″ | 3 bolts, 1/2″ × 4″ |

| Weight | 5.63 lb | 18 lb |

| Max load | 1,615 lb (support) | Pressure containment only |

| Working pressure | — | 400 psi |

| Temperature | — | Up to 250°F (Buna‑N); 450°F (Viton) |

| Torque | — | 50 ft·lb |

Notes:

– The 6″ Emergency Pipe Clamp listing provides torque and pressure data; verify gasket options and exact OD compatibility before purchase.

– Emergency clamps are rated for temporary use; confirm acceptance with your engineering/QA policy.

Comprehensive Cost and Pricing Analysis for 6 inch pipe clamp Sourcing

Comprehensive Cost and Pricing Analysis for 6 inch Pipe Clamp Sourcing

Product and Price Segments (USA/EU)

The 6-inch pipe clamp market spans utility-grade banding and high-performance repair clamps. Prices vary by material (typically 304/316 stainless), thickness, gasket type (for emergency clamps), load rating, and certifications. Three practical examples anchor the range:

Illustrative Image (Source: Google Search)

- Low-cost, bulk utility clamps: ~$2.43/unit (USD) for 304 stainless conduit strap-style clamps; priced per 20-piece case on e-commerce marketplaces.

- Industrial repair clamp (316 stainless, full band): $121.32/unit (USD), spec includes 3/4-inch bolts, weight 5.63 lbs, max recommended load 1,615 lbs.

- Emergency repair clamp (250°F Buna-N gasket, 3/4–1 inch bolts, heavy housing): ~$580/unit (USD), rated for 400 psi working pressure and 50 ft·lb torque.

Table: Price benchmarks and features

| Product type | Material | Gasket/Seal | Bolts (diameter/length) | Size/Dim | Weight | Pressure/Torque | Max Load | Price (USD) |

|—|—|—|—|—|—|—|—|—|

| Utility clamp (bulk pack) | 304 SS | None | M10/M12 (varies) | U-strap, two-hole | Not specified | N/A | N/A | $2.43 |

| Industrial repair clamp | 316 SS | None | 3/4 in x (length varies) | 6 in, OD 6.625 in | 5.63 lb | N/A | 1,615 lb | $121.32 |

| Emergency repair clamp | 304/316 housing, SS hardware | Buna-N (250°F) | 1/2 in x 4 in | 8 in x 8.5 in | 18.00 lb | 400 psi; 50 ft·lb | N/A | ~$580.00 |

Notes:

– Utility clamps are not emergency or pressure-rated; they are intended for routing/support, not leak repair.

– Emergency clamps are purpose-built for pressure containment and can cover 1–2 pipe diameters depending on design and application. Check manufacturer ratings and torque sequences.

Unit Cost Breakdown (USD/EUR)

Typical drivers behind the quoted price include materials, labor/fabrication, coatings/gaskets, packaging, and logistics.

Table: Illustrative unit cost breakdown

| Component | Typical range (USD) | Comments |

|—|—|—|

| Materials (band housing, gasket, bolts, washers) | $25–$60 | Driven by SS grade (304 vs 316), band thickness, and gasket material (Buna-N vs Viton). |

| Labor (stamping/bending, welding, finishing) | $8–$20 | Depends on automation level, welds per clamp, and finishing (passivation, polish). |

| Coatings/Gaskets | $3–$10 | Gasket material and temperature rating drive cost; some units may include corrosion-resistant coating. |

| Packaging | $1–$3 | Corrugated carton, protective inserts, label. |

| Overhead (facility, QA, admin) | $5–$15 | Higher for certified QA, lot testing, documentation. |

| Freight (door-to-door depending on lane) | $2–$6 | Air costs significantly higher; ocean + drayage for LCL; varies by Incoterm. |

| Total landed unit cost (ex-factory to DC) | $44–$114 | Approximate for bulk runs of emergency-repair style; utility bands land far lower due to thinner materials and mass production. |

Illustrative Image (Source: Google Search)

USD/EUR conversion:

– For EU buyers, convert using current spot rates or your hedge rates (e.g., at 1.08 USD/EUR, $121.32 ≈ €112). If pricing includes EU VAT, adjust comparably.

Shipping, Duties, and Total Landed Cost (TLC)

Assumptions:

– 40 lb average clamp weight (emergency-type); utility bands are much lighter.

– Ship mode: LCL ocean for bulk quantities (palletized), or air for small-volume emergency orders.

Table: Example TLC components (USD)

| Lane | Ex-Factory Price | Ocean LCL Freight | Air Freight | Import Duty (typical range) | Incoterms | TLC (Ocean) |

|—|—|—:|—:|—:|—|—:|

| China → USA East Coast | $80 | $7 | $25–$60 | 0%–8% (verify HTS 7307.93) | DDP (vendor-all-in), DAP/DPU (buyer pays freight/duty), EXW (buyer pays all) | ~$87–$93 |

| China → EU (Rotterdam) | $80 | $8 | $25–$60 | ~3.7% for certain stainless pipe fittings (verify CN code) | DDP/DAP/DPU/EXW per sourcing plan | ~$91 |

Guidance:

– Use DDP when you want price certainty; the vendor quotes all-in. DAP/DPU splits risk and cost control; EXW maximizes buyer control and risk.

– For emergency/urgent needs, air freight can compress lead time from 30–45 days (ocean) to 7–12 days, but TLC will increase by $0.40–$1.00 per lb in many corridors.

Lead Times and Working Capital

- Standard stocked clamps (utility/band): 1–3 weeks (USA/EU inventory).

- Industrial repair clamp (full band): 2–4 weeks depending on finish/schedule.

- Emergency clamp: 3–8 weeks; expedited options often involve air freight and premium production slots.

- Impact on total cost: Shorter lead times reduce pipeline inventory and expedite handling overhead, offsetting higher freight or rush premiums.

Negotiation Levers (Direct Impact on Price)

- Material grade: 304 vs 316; thinner band thickness vs thicker to meet load. For non-emergency applications, 304 with adequate passivation is often sufficient, lowering material cost.

- Finish/polish: Choose passivation over electropolish for savings without sacrificing corrosion resistance.

- Gasket selection: Standard Buna-N is less costly than high-temp Viton; confirm operating temperature limits to avoid over-spec.

- Bolt/hardware: Use standard sizes; custom lengths or special coatings add cost.

- Qty and MOQ: Target higher annual volume or multi-month releases to reduce per-unit price and freight per piece.

- Packaging: Simple corrugated packaging with recyclable inserts reduces cost versus custom foam or wooden crating.

- Freight terms: Consolidate shipments; negotiate freight-buying commissions; ensure accurate dimensional weight to avoid surprise fees.

Procurement Channel Considerations

- E-commerce (e.g., marketplace bulk): Lowest sticker price; suitable for utility bands, routing straps, non-emergency use; limited QA documentation; returns and warranty vary; often EXW/FOB semantics without true Incoterm coverage.

- Wholesale/Distributor: Stock for fast turn; modest discount; better credit terms and backorder management; helpful for emergency needs.

- Direct manufacturer: Best for engineered clamps and emergency products; can provide documentation (coC, test reports), custom gasket options, DDP service, and longer-term contracts with price stability.

Cost-Saving Tactics (Practical Checklist)

- Right-spec the application: Confirm pressure, temperature, media compatibility, and corrosion exposure before selecting 316 SS, gasket type, or heavy housing.

- Standardize: Adopt one band thickness and two gasket options (standard and high-temp) across projects to simplify inventory and pricing tiers.

- Volume pooling: Aggregate demand across plants or business units; anchor pricing with annual commitments.

- Off-peak bookings: Use slower shipping seasons and longer lead times; prioritize ocean LCL or FCL for large orders.

- Alternate suppliers: Run two qualified sources to create pricing tension and backup capacity.

- Documentation scope: Use vendor paperwork only when necessary (certificates, lot tests) to avoid premium charges.

Quick Comparison vs Value Check

- If the application requires pressure containment, do not substitute utility bands priced at ~$2.43 each; they lack rated seals and torque characteristics. Emergency clamps at ~$580 deliver tested containment (up to 400 psi), sealing, and bolt geometry designed for leak repair.

- For non-pressurized support, bands are cost-effective at single-digit dollars, especially in bulk; select 304 SS with passivation, M10/M12 hardware, and appropriate mounting hardware.

Final Notes

- Duty rate and VAT vary by HS code classification and country of origin; confirm HTS/CN codes before final pricing.

- Always validate ratings (pressure, torque, temperature) and gasket compatibility for emergency use.

- A small number of high-cost emergency clamps can quickly escalate TLC; prioritize multi-mode logistics planning and vendor capability for expedited scenarios.

Alternatives Analysis: Comparing 6 inch pipe clamp With Other Solutions

Alternatives Analysis: Comparing 6-inch Pipe Clamp with Other Solutions

Selection should balance functionality, operating conditions, and total cost. The 6-inch stainless steel pipe clamp (T-316) is a general-purpose mechanical clamp for support/strapping of 6.625-inch OD pipe. Two useful alternatives are emergency pipe repair clamps and rigid U-bolt pipe straps.

Key comparison points: core purpose, temperature/pressure capability, mechanical load capacity, materials, hardware, price, and typical use case.

| Feature | 6 in. Pipe Clamp, T-316 #212SX0600 (Empire) | 6 in. Emergency Pipe Clamp (Repair Clamp) | 6 in. U-Clamp (Conduit Strap) |

|---|---|---|---|

| Intended use | Support/strapping, non-pressurized applications | Emergency or temporary repair of minor leaks/holes | Light-duty support or hanging of conduit/pipe |

| Pressure rating | Not pressure-rated (mechanical clamp) | 400 psi working pressure | Not pressure-rated (strap) |

| Temperature rating | Not specified on spec | Up to 250°F (Buna-N gasket) | Not specified |

| Mechanical capacity | Max recommended load: 1,615 lb | Not specified | Not specified |

| Materials | 316 stainless steel body | Carbon steel housing with stainless bolts; gasket (Buna-N std., Viton optional) | 304 stainless steel U-bracket |

| Hardware | 3/4 in. bolts | 1/2 in. bolts (3), length 4 in. | Two-hole mounting; M8–M10 class (not specified on listing) |

| Dimensions | 6 in. nominal; 6.625 in. OD | 8 in. length; 8.5 in. width | 6 in. (150 mm); U-shaped |

| Weight | 5.63 lb | 18 lb | Not stated (lightweight) |

| Price (list) | $121.32 (per clamp) | ~$580.00 (per clamp) | ~$15 for 20 pcs (≈$0.75 per unit) |

Analysis

- Emergency pipe clamp

- Purpose-built for pressurized repair scenarios. The 400 psi rating and 250°F gasket temperature suggest suitability for minor defects on 6-inch lines under controlled conditions. It carries a premium price and heavier hardware, reflecting its engineered repair intent. Note: Pressure ratings are context-dependent (defect size/type and fluid). Use per the manufacturer’s instructions and site-specific engineering.

- U-clamp (conduit strap)

- Designed for light-duty support or hanging of conduit/pipe. Lowest-cost option by far and simple to install. However, it is not pressure-rated and has undefined mechanical load capacity; it should not be used to secure critical pipelines or pressurized lines.

Recommendation by use case

– Temporary/emergency repairs to 6-inch lines under pressure (e.g., minor through-wall defects): choose an emergency pipe clamp sized for 6-inch OD; confirm gasket compatibility with fluid and temperature, and verify pressure containment against the defect profile.

– General mechanical support/strapping of 6-inch pipe (non-pressurized) with high mechanical load requirements: choose the 316 stainless steel T-316 pipe clamp with 3/4-inch hardware and 1,615 lb max load rating.

– Budget-sensitive light-duty mounting/hanging: U-clamp can suffice, but apply conservative load limits and additional mechanical restraints for any critical or pressurized service.

Illustrative Image (Source: Google Search)

Bottom line: If you need pressure containment or emergency leak mitigation, select the emergency clamp. For mechanical support with known load demand, the T-316 pipe clamp delivers robust capacity. If only light-duty support is needed, the U-clamp offers a low-cost path—without any pressure capability.

Essential Technical Properties and Trade Terminology for 6 inch pipe clamp

Essential Technical Properties and Trade Terminology for 6 inch Pipe Clamp

Core dimensions and identifiers (per referenced 6″ standard clamp)

- Pipe size: 6 in

- Pipe outside diameter (OD): 6.625 in (168.3 mm)

- Clamp housing length: 8.0 in

- Width across body: 8.5 in

- Bolt size (standard clamp): 3/4 in

- Bolt size (emergency clamp): 1/2 in; length 4.0 in; 3 bolts

- Weight (standard clamp): 5.63 lb

- Material: 316 stainless steel (SS)

Performance parameters (per referenced products)

- Max recommended load (standard clamp): 1,615 lb

- Emergency clamp working pressure: 400 psi

- Installation torque (emergency clamp): 50 ft·lbf

- Temperature range (emergency clamp with standard Buna-N gasket): up to 250°F (121°C)

Materials and finish

- Standard housing: 316 stainless steel (ASTM A240/ASME SA-240; typical UNS S31600)

- Gasket materials (emergency clamp):

- Buna-N (NBR): standard, 250°F rating

- Viton (FKM): high-temperature option, 450°F rating

- Fasteners: per spec; confirm grade and plating (e.g., SS cap screws, T-bolts, washers) before ordering

Fitment and coverage (per referenced 6″ clamp)

- Pipe OD tolerance: typically 6.625 in ± small variation

- Clamp housing length: ~8.0 in (coverage)

- Body width: ~8.5 in

- Bolt pattern: 1/2 in bolts; quantity 3 (emergency clamp)

- Torque and pressure limits: emergency clamp rated for 50 ft·lbf at 400 psi (do not exceed)

Marking and traceability

- Look for stampings on housing: brand, figure/model, pipe size, material, pressure rating (if applicable)

- Bolt heads often marked for grade identification

- Keep bill of materials (BOM) and installation instructions with purchase records

Certifications and compliance (typical; confirm with supplier)

- EU: CE Marking (where applicable), RoHS/REACH statements

- Pressure equipment (PED) only for pressure-bearing equipment (e.g., some emergency clamps)

- US: MSS SP-69 (pipe hangers and supports), UL/ULC (if used for electrical raceway), ASTM material certificates

Trade Terms and Definitions (B2B procurement)

| Term | Definition | Typical Offer Basis |

|---|---|---|

| MOQ (Minimum Order Quantity) | Smallest quantity a supplier accepts per SKU/pattern | Often varies by finish/material; request per supplier |

| Lead time | Time from PO to ready-to-ship | Confirm per factory load; emergency stock may be expedited |

| Incoterms | Delivery responsibilities between seller/buyer | EXW or FOB (US), EXW or FCA/DAP (EU) common for clamps |

| Customization (OEM/ODM) | Modifications to design, finish, or packaging | Typical for large-volume B2B suppliers |

| HS Code | Harmonized System classification for import/export | Often 7326.90 (metal articles); confirm per product |

| REACH/RoHS | EU chemicals compliance | Statement of compliance available from suppliers |

| Packaging | Method to protect products in transit | Palletized, banded, boxed; label compliance (CE/UL as needed) |

| Documentation | Supporting documents for audit/compliance | Datasheets, test reports, certs, CoC/CoA, packing list, invoice |

Ordering checklist (fitment essentials)

- Pipe OD: 6.625 in required; verify with calipers

- Clamp coverage/housing length: e.g., 8 in for emergency clamp

- Bolt pattern: diameter/length/quantity (e.g., 1/2 in × 4 in, 3 bolts)

- Pressure rating: confirm working pressure and temperature (e.g., 400 psi at 250°F for emergency clamp)

- Gasket material: Buna-N (standard) or Viton (high temp), as needed

- Material: 316 stainless steel for corrosion resistance

- Marking: confirm model figure, pipe size, material, and any pressure markings

- Documentation: ask for datasheet/spec sheet and relevant compliance (CE/MSS/ASTM/REACH/RoHS)

Installation notes

- Apply uniform torque to maintain seal and prevent leakage (emergency clamp: 50 ft·lbf)

- Ensure clamp alignment; do not exceed rated pressure or temperature

- For repeated service, inspect gasket condition; replace if degraded

- Keep load within stated max (e.g., 1,615 lb for the referenced standard clamp)

Sourcing and delivery

- EXW and FOB (US) or EXW and FCA/DAP (EU) commonly used for clamp orders

- Confirm lead times and any rush capacity for emergency repairs

- Typical order packaging: palletized banding, labeled per compliance

- Emergency clamp: check stocked SKUs; some suppliers offer off-the-shelf availability

Navigating Market Dynamics and Sourcing Trends in the 6 inch pipe clamp Sector

Navigating Market Dynamics and Sourcing Trends in the 6‑inch Pipe Clamp Sector

6‑inch Pipe Clamp Types and Typical Use

- Standard (mechanical) pipe clamp: rigid, bolted clamp to support or position pipe. Example: 6-inch T-316 stainless, bolt size 3/4 inch, max recommended load 1,615 lb, 6.625-inch pipe OD, 5.63 lb unit weight.

- Emergency (pressure-repair) clamp: designed as a temporary or urgent repair clamp under pressure. Example: 6-inch, 400 psi working pressure, 50 ft·lb torque, 250°F Buna-N gasket option; Viton version rated up to 450°F.

Market Snapshot and Demand Drivers

- Maintenance, repair, and operations (MRO) and shutdown/turnaround (TAR) programs intensify unplanned demand for emergency clamps. Standard clamps align with planned structural support, hangers, and equipment installs.

- Industrial automation and utility upgrades drive steady demand for conduit supports and rigid U‑strap clamps. Note: conduit support clamps are non-pressure-rated and often low-carbon steel or coated; they are not substitutes for pipe clamps in pressure or structural service.

- Pricing is influenced by material volatility (nickel for 316 stainless steel), bolt spec, number of bolts, and gasket configuration. Emergency clamps with more robust gaskets or temperature ratings trade at higher price points.

Regional Sourcing Differences (USA vs. Europe)

- USA: direct distribution through MRO suppliers; emergency clamp options show clear working pressure and torque. Online catalogs frequently present torque, psi, and temperature ratings for field selection.

- Europe: buyers typically require traceability to EN/DIN/MTR documentation for metallurgical verification. Emergency clamps deployed on European sites must be scoped with host piping codes (e.g., EN 13480‑3 for piping systems; EN 1090 for steel execution) and the Pressure Equipment Directive (PED) applicability for pressure-retaining components.

Material and Performance Trade-offs

- 316 stainless steel (SS316) offers strong corrosion resistance and long service life, with good high‑temperature properties. Preferred for coastal/chemical environments. Weight and nickel content increase cost.

- 304 stainless steel (SS304) provides good corrosion resistance at lower cost. Suitable for many general industrial uses but inferior to 316 in chloride/chemical exposure.

- Coated carbon steel is the most economical for non-corrosive, indoor, or light-duty applications. Durability depends on coating quality; not recommended for aggressive corrosion environments.

Buna‑N gaskets typically cover -40°F to 250°F and good oil/solvent resistance; Viton gaskets extend service to around 450°F and improve chemical resistance, especially aromatics and chlorinated solvents.

Specification Validation and Compliance

- Confirm operating pressure, temperature, media compatibility, and relevant code alignment early to avoid re‑qualification. Emergency clamps are temporary unless explicitly certified for continuous use under the applicable piping code.

- Validate material certification (MTRs) to grade 316/304 and finish requirements.

- Bolt size, number of bolts, and torque-to-clamp performance must be validated against the host pipe system (wall thickness, OD tolerance, gasket compression). Document clamp installation procedures, retorque windows, and inspection criteria in the maintenance plan.

Price Range and Lead Time Signals

- Standard 6-inch 316 stainless pipe clamp: commonly priced near the low hundreds of dollars per unit, depending on supplier, quantity, and finish; example market data shows approximately $121 per unit for a 316 stainless standard clamp.

- Emergency 6-inch clamp: priced at approximately $580 per unit in retail listings; range varies with gasket options.

- 6-inch emergency clamps from other sizes show broad price variation: 1-inch ~$100–$235; 2-inch ~$145–$300; 4-inch ~$285–$485; 8-inch ~$900–$1,200; 10-inch ~$1,275–$1,750.

Sustainability Considerations

- Favor stainless steel 316/304 for durability and recyclability when corrosion risk justifies the higher embedded carbon; specify recycled content where possible.

- Coated carbon steel reduces initial cost and embodied carbon but may have shorter service life in corrosive environments, leading to earlier replacement and higher lifecycle impacts.

- Design for disassembly: select gasket materials and bolt configurations that enable clean separation and recycling at end of life.

Typical Cross-Comparison

| Clamp Type | Nominal Size | Material/Grade | Pressure Rating | Temperature Capability | Bolt Spec | Max Recommended Load | Weight | Common Price Signal |

|---|---|---|---|---|---|---|---|---|

| Standard Pipe Clamp | 6 in | 316 Stainless Steel | Mechanical (support only) | High (SS dependent; gaskets not specified) | 3/4 in bolts | 1,615 lb | 5.63 lb | Approx. $121 per unit (USA) |

| Emergency Clamp | 6 in | Stainless steel body | 400 psi | Buna‑N up to 250°F; Viton up to 450°F | 1/2 in × 4 in bolts; 3 bolts | N/A (pressure repair) | ~18 lb | Approx. $580 per unit (USA) |

| Conduit U‑Strap | 6 in (conduit) | 304/316 SS (varies) | Non‑pressure; structural support only | Ambient/indoor use typical | Varies; two‑hole brackets | N/A (support; not pressure) | Lightweight | Pack pricing; low cost |

Note: Conduit supports are not pressure-rated and should not substitute for pipe clamps in pressure service.

Actionable Sourcing Guidance

- Match clamp type to service: emergency clamps for urgent pressure repairs; standard clamps for planned support or non-pressurized piping.

- Specify materials and gasket compounds upfront; include OD tolerance and installation torque requirements in purchase orders.

- Request MTRs and review gasket compound data sheets to ensure temperature and chemical compatibility.

- Align with regional codes: in Europe, map components to EN standards and PED; in the USA, align with ASME piping codes and applicable pressure mandates.

- Optimize total cost of ownership: durability, maintenance intervals, and replacement frequency often outweigh initial unit price.

Historical Context and Outlook

- Early pipe clamps evolved as bolted clamps for mechanical support and positioning. Modern emergency clamps emerged as standardized pressure-repair kits with defined psi and torque envelopes to manage unplanned leaks reliably.

- Outlook: continued MRO activity, coupled with material cost volatility (notably nickel), will keep buyers balancing cost, lead time, and compliance; stainless steel grades and gasket performance will differentiate offerings.

Field Selection Checklist

- Pipe nominal size and actual OD, wall thickness, pressure class, and temperature.

- Service environment: corrosion risk (chloride exposure), chemical compatibility, and ambient conditions.

- Code alignment (ASME/EN), gasket compound (Buna‑N vs. Viton), bolt spec, torque requirements, and installation instructions.

- Expected duty cycle (temporary vs. permanent), inspection and retorque intervals, and documentation deliverables (MTRs, compliance statements).

Frequently Asked Questions (FAQs) for B2B Buyers of 6 inch pipe clamp

Frequently Asked Questions (FAQs) for B2B Buyers of 6 inch pipe clamp

Q1. What is a 6″ pipe clamp and when should I use it?

- A 6″ pipe clamp secures, supports, or temporarily repairs pipe. There are two common uses:

- Standard repair/support clamp (e.g., 316 stainless steel band clamp): permanent repair of small leaks/cracks, general pipe support, and vibration damping.

- Emergency clamp (bolted, gasket-sealed): rapid, low-cost temporary repair to stop leaks on pressurized systems while a permanent solution is prepared.

- Use a standard clamp when a permanent or semi-permanent repair/support is acceptable. Use an emergency clamp for urgent leak isolation under pressure with minimal downtime.

Q2. Will a 6″ clamp fit my pipe?

Nominal 6-inch clamps are not universal. Confirm your pipe’s outer diameter (OD) and flange geometry.

Illustrative Image (Source: Google Search)

| Clamp type | Nominal pipe size | Pipe OD | Band/body material | Bolt size | Typical max load/pressure | Typical temperature |

|---|---|---|---|---|---|---|

| Standard repair/support clamp | 6″ | 6.625″ | 316 SS band/body | 3/4″ | 1,615 lb recommended load | By gasket (often ~250°F for Buna-N) |

| Emergency clamp | 6″ | Vendor to confirm | SS band/body | 1/2″ (3 bolts) | 400 psi, 50 ft·lb torque | Up to 250°F (Buna-N); up to 450°F (Viton option) |

Notes:

– Most stainless pipe is 6.625″ OD. Carbon steel, ductile iron, and other materials often differ. Measure OD and plan for gasket thickness.

– For US or EU projects, specify pipe standard and schedule (e.g., ANSI, DIN, ISO) and provide measured OD to confirm fit.

Q3. Which gasket material should I choose?

Select based on medium, temperature, and pressure. Options vary by clamp family:

| Option | Temperature limit | Media compatibility (typical) | Use cases |

|---|---|---|---|

| Buna-N (NBR) | ≈ 250°F | Water, petroleum products, many hydrocarbons; limited with ketones, strong oxidizers, aromatics | General-purpose water, oil, gas service; emergency leak control at moderate temperatures |

| Viton (FKM) | Up to 450°F | Better resistance to heat and many chemicals; ketones, amines, and some chlorinated solvents still aggressive | High-temp applications, certain chemicals, hot hydrocarbons |

Best practice:

– Validate chemical compatibility and pressure/temperature conditions with your fluid service engineer.

– For emergency clamps, ensure gasket aligns with pressure containment and temperature exposure until a permanent repair is completed.

Q4. What are the working pressure and torque requirements?

Working pressure depends on clamp design and gasket. Emergency clamps for pressurized systems commonly specify:

– Working pressure: up to 400 psi (example product).

– Torque: 50 ft·lb (example product).

Standard support/repair clamps typically define load capacity rather than pressure. Verify with the manufacturer’s specification sheet.

Illustrative Image (Source: Google Search)

| Clamp type | Pressure | Torque | Notes |

|---|---|---|---|

| Standard repair/support clamp | Not typically pressure-rated | By manufacturer spec | Use for mechanical support and low-pressure leak repair; confirm pressure suitability |

| Emergency clamp | Up to 400 psi (example) | 50 ft·lb (example) | Temporary containment; replace with permanent repair when feasible |

Q5. What are the material and corrosion considerations?

- 316 stainless steel (SS) band/body: excellent corrosion resistance for a broad range of services, including many chemical and marine environments. Suitable for outdoor and high-humidity conditions.

- For severe corrosive media (e.g., concentrated chlorides, strong acids/bases), consult a materials engineer for gasket and clamp selection; alternate body materials or coated hardware may be needed.

- Emergency clamp hardware commonly uses stainless steel bolts; finish and coating should suit your environment.

Q6. Can I use a clamp as a permanent solution?

- Standard clamp: may serve as a permanent or semi-permanent repair for small leaks on rigid pipe; suitable for general support applications. Assess long-term durability with your engineering team.

- Emergency clamp: designed for temporary use to stop leaks under pressure while arranging a permanent repair (e.g., welding, pipe replacement). Replace ASAP with a permanent solution.

Q7. What are lead times and stocking options?

- Standard 6″ 316 SS clamps: often available for immediate shipment from distributors.

- Emergency clamps: may be in stock or available within days; pricing is higher and typically project-specific.

- Large orders (e.g., full-crate quantities of support clamps) may require direct factory lead time.

Q8. Installation best practices and compliance

- Align clamp halves and evenly tension bolts. Use the manufacturer’s recommended torque pattern and values.

- Ensure the pipe surface is clean and free of scale, rust, or paint where the gasket contacts. Rough surfaces can compromise sealing.

- For pressurized services, verify that the clamp’s pressure/temperature rating and gasket material are suitable for your medium. Consider shock loads and vibration.

- Compliance: Mechanical pipe clamps are not pressure equipment per se, but if used on pressurized systems under the EU Pressure Equipment Directive (PED), ensure suitable conformity assessment. Follow local EHS guidelines and lockout/tagout procedures.

Strategic Sourcing Conclusion and Outlook for 6 inch pipe clamp

Strategic Sourcing Conclusion and Outlook for 6 inch pipe clamp

A robust 6-inch pipe clamp strategy hinges on matching application fit with material and performance requirements. For routine repair and maintenance where corrosion resistance is critical, 316 stainless steel clamps provide reliable mechanical strength at a favorable cost-per-performance ratio. For emergency leak containment, higher working pressure, gasket temperature ratings, and installation convenience become decisive.

To illustrate the practical trade-offs, Table 1 compares two representative SKUs:

| Attribute | 6″ Stainless Steel Clamp (212SX0600) | 6″ Emergency Pipe Clamp (089885-BU) |

|---|---|---|

| Type | Standard repair clamp | Emergency clamp |

| Material | 316 Stainless Steel | Steel body with Buna-N/Viton gaskets |

| Pipe OD | 6.625 in | Not stated |

| Bolt size | 3/4 in | 1/2 in (3 bolts) |

| Working pressure | Not stated | 400 psi |

| Temperature | Not stated | Buna-N 250°F; Viton 450°F |

| Recommended torque | Not stated | 50 ft-lb |

| Weight | 5.63 lb | 18 lb |

| Load capacity | 1,615 lb | Not stated |

| Price (indicative) | $121.32 | $580.00 |

| Source | PipingNow | skinnerco |

Key selection criteria:

– Verify pipe OD to prevent under/over-sleeving and leakage.

– Select materials and gasket compounds for temperature and chemical compatibility (316 SS for corrosion; Viton for high temperatures).

– Confirm mechanical demands (load, torque, pressure) and installation access for emergency kits.

– Standardize procurement on a short list of proven SKUs for repeatability and supply resilience.

Outlook: In North America and Europe, procurement should treat standard 316 SS clamps as C‑category replenishment for routine tasks and maintain an emergency clamp program for mission-critical incidents. Consolidating vendors reduces lead time and total cost of ownership, while documented specs (pressure, torque, temperature) simplify cross‑region alignment and compliance.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.