Rfz 140: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for RFZ 140

RFZ 140 demand is rising across off-road retailers and rental fleets, but global supply is fragmented and specifications vary by batch and brand. Buyers in the USA and Europe face uneven pricing, shifting availability, and differing compliance rules—issues that erode margins and extend lead times if not addressed upfront.

This guide distills what matters when sourcing RFZ 140–class machines and equivalent 140cc mid-size dirt bikes:

– Model clarity: Identify exact variants and their spec profiles (e.g., Apollo RFZ 140 Z40 and DBZ40) to avoid mismatches in transmission, frame, and suspension.

– Compliance guardrails: Map USA emissions context and EU type-approval (L-category) requirements; confirm CE, RoHS, and labeling standards and any local trail regulations.

– Supply risk mitigation: Set minimum order quantities (MOQs), negotiate buffer stock for critical components (tires, ignition, CDI), and secure service-parts support.

– Pricing strategy: Benchmark across regions, incorporate freight and duties, and plan for tariff contingencies.

– Quality assurance: Validate welding, wheel accuracy, brake systems, and torque specs; verify tire sizing (commonly 70/100-17 / 90/100-14 for RFZ 140 variants).

– Logistics: Optimize crating and freight class, select Incoterms, and plan for packaging dimensions to avoid surcharges.

Table 1. RFZ 140 snapshot (model-specific confirmation required)

| Variant | Engine | Displacement | Transmission | Tires (F/R) | Seat Height | Ground Clearance | Weight |

|—|—|—|—|—|—|—|—|

| Apollo RFZ 140 Z40 | Single cylinder, 4-stroke, air-cooled, CDI | 140cc | 4-speed manual | 70/100-17 / 90/100-14 | ~32.5–33 in | ~13.5 in | ~168–196 lb |

| Apollo DBZ40 (RFZ40) | Single cylinder, 4-stroke, air-cooled | 140cc | 4-speed manual | 70/100-17 / 90/100-14 | 32.5 in | 13.5 in | 168 lb |

What’s inside the guide:

– Regional demand outlook and buyer profiles

– Compliance requirements for USA/EU and their impact on sales channels

– Vendor vetting, warranties, and service parts provisioning

– Sourcing timelines, MOQs, and lead-time contingencies

– Total landed cost models, Incoterms, and payment protection

Avoid the common pitfalls—unverified emissions claims, inconsistent sizing, and hidden logistics costs—and use the decision frameworks in this guide to lock in compliant stock at predictable margins.

Illustrative Image (Source: Google Search)

Top 10 Rfz 140 Manufacturers & Suppliers List

1. APOLLO – Top-Tier Dirt Bike and ATV Manufacturer – 浙江阿波罗 …

Domain: apollino.com

Registered: 2023 (2 years)

Introduction: APOLLO: An top-tier dirt bikes and atvs manufacturer, boasts 20 years of experience and infuses thrill into every ride….

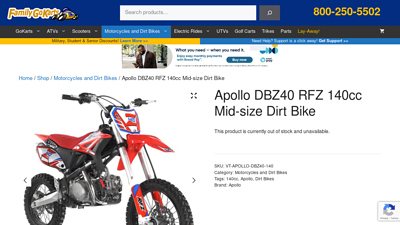

2. Apollo DBZ40 RFZ 140cc Mid-size Dirt Bike – FamilyGoKarts.com

Domain: familygokarts.com

Registered: 2003 (22 years)

Introduction: 12-day delivery 60-day returnsApollo’s RFZ DBZ40 mid-size dirt bike features a 140cc engine and 33 inch seat height. So, it’s perfect for older teens and adults!Missing: manufacturers suppliers…

3. Apollo RFZ 140 open | mazimotorsports

Domain: mazimotorsports.com

Registered: 2015 (10 years)

Introduction: PRICE $1299.99 · New latest generation plastic kit · More comfortable, equipped with large wheels 14 “/ 17” · Saddle longer, more comfortable, removable by the top….

4. Apollo RFZ 140 Z40 Dirt Bike – Manual Transmission (17’/14′) tires …

Domain: automaximizer.com

Registered: 2014 (11 years)

Introduction: In stock Free deliveryApollo’s RFZ DB Z40 dirt bike features a 140cc engine putting out 11hp. A 33-inch seat height and 17-inch front tire make it perfect for teens and adults….

Illustrative Image (Source: Google Search)

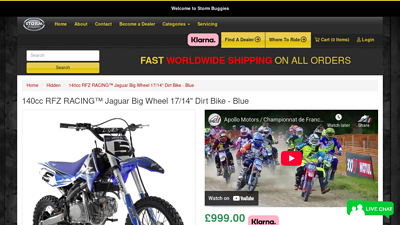

5. 140cc RFZ RACING™ Jaguar Big Wheel 17/14″ Dirt Bike – Blue

Domain: stormbuggies.com

Registered: 2006 (19 years)

Introduction: Genuine YX 140cc engine – Manual 4 speed gearing · Front & rear hydraulic brakes with wavy discs · Latest technology 32mm tubular & profiled frame · 17” Front & 14 ……

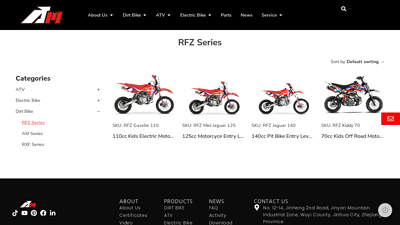

6. RFZ Series

Domain: apollovehicle.com

Registered: 2003 (22 years)

Introduction: RFZ (Beginner) Series goods supplier in China,we help our prospects with greatest high-quality items and high level service….

Understanding rfz 140 Types and Variations

Understanding RFZ 140 Types and Variations

The RFZ 140 family centers on a 140cc, air-cooled, single-cylinder 4-stroke engine with 4-speed manual transmission and chain final drive. Across markets, it is commonly packaged in a mid-size, trail-ready chassis with a double-beam steel frame, hydraulic discs, and a 17″/14″ tire combo. Within that footprint, buyers typically differentiate use-cases and configuration choices rather than distinct new engines. Below are the main types used in procurement, fleet, and dealer planning, followed by a market-facing table to aid SKU selection.

Variation Types vs Key Features vs Typical Applications vs Pros/Cons

| Type | Key Features | Typical Applications | Pros | Cons |

|---|---|---|---|---|

| RFZ 140 Off-Road Trail (Standard) | 4-stroke, 4-speed manual; kickstart; hydraulic discs (F/R); 70/100-17, 90/100-14; double-beam steel frame; 32.5 in seat; 13.5 in clearance | Trail riding, dual-sport practice, rental fleets, club rides | Balanced power/torque for trails; predictable manual clutch; strong ground clearance; widely supported | Carburetion requires routine fuel system care; non-adjustable front fork limits fine-tuning |

| RFZ 140 MX-Inspired (Stiffer Setup) | Trail chassis with upgraded rear shock preload/damping; smaller rear sprocket possible; MX-style geometry | Motocross practice, enduro training, higher-speed trail | Better big-hit control; more responsive handling | Firmer ride off-line; higher maintenance under sustained MX loads |

| RFZ 140 Pit/Utility (Durability Focus) | Simplified components; robust cable/harness; reliable CDI and hydraulic discs | Pit use, farm/paddock mobility, short-haul transport | Simple, rugged, cost-effective maintenance | Not optimized for long-distance trail mileage |

| RFZ 140 Learner/Adult Mid-Size (Ergonomic) | 32.5 in seat; tractable 4-stroke delivery; predictable manual shifting | Novice to intermediate adults; training programs | Manageable power; confidence-inspiring geometry; accessible seat height | Upper power range modest for advanced riders |

RFZ 140 Off-Road Trail (Standard)

- What defines it: A trail-ready 140cc package designed for mixed off-road use—loose dirt, woods, and fire roads—without the complexity of modern fuel injection or electric start.

- Core specs: 140cc single-cylinder, 4-stroke, air-cooled; 56 x 57 mm bore/stroke; 9.8:1 compression; 11 HP @ 8,000 rpm; 10.2 N·m @ 7,500 rpm; 4-speed manual (N-1-2-3-4); chain final drive; kickstart; CDI ignition; hydraulic discs front/rear; 70/100-17 (F) and 90/100-14 (R); non-adjustable telescopic forks; adjustable mono-shock rear; double-beam steel frame; 13.5 in ground clearance; 32.5 in seat height; approx. 52 mph top speed.

- Where it fits: Rental and trail centers, recreational clubs, entry-level training programs, and general off-road riding where serviceability and predictable behavior are priorities.

- Pros: Balanced power and torque for moderate trails; manual clutch with four speeds keeps control predictable; robust frame and clearance; familiar maintenance footprint.

- Cons: Carbureted fuel system requires stable fuel and periodic tune-ups; front forks are non-adjustable, limiting fine-dialing for heavier or faster riders.

RFZ 140 MX-Inspired (Stiffer Setup)

- What defines it: The same RFZ 140 drivetrain and frame, tuned toward quicker handling and bigger-hit control by increasing rear shock preload/damping and, in some cases, fitting a smaller rear sprocket.

- Where it fits: Motocross-style practice, enduro training, and aggressive trail riding where riders want sharper chassis response without stepping to a larger displacement.

- Pros: Better control on jumps and whoops; more responsive turn-in; easier to keep momentum when the terrain speeds up.

- Cons: Firmer ride on choppy trails; accelerated component wear under frequent MX cycles; requires more frequent checks on fasteners and suspension hardware.

RFZ 140 Pit/Utility (Durability Focus)

- What defines it: A utility-first packaging of the RFZ 140—simplified wiring, robust routing, and reliable hydraulics—favoring durability over peak performance.

- Where it fits: Pits, paddocks, and short-haul transport; farms or training facilities where riders need consistent starts, stable idling, and predictable braking.

- Pros: Cost-effective service intervals; consistent starting; straightforward controls that stand up to repetitive use.

- Cons: Lower long-distance comfort; suspension and gearing optimized for utility, not sustained trail mileage.

RFZ 140 Learner/Adult Mid-Size (Ergonomic)

- What defines it: The same RFZ 140 frame and seat height delivered as an accessible platform for adult novices or returning riders who want manageable power in a stable chassis.

- Where it fits: Adult training, refresher courses, community riding groups, and riders transitioning from 110–125cc platforms.

- Pros: Low-stress power delivery; predictable manual shifting; approachable ergonomics—32.5 in seat and 13.5 in clearance—without harshness.

- Cons: Power ceiling is modest for advanced riders; non-adjustable front fork limits personalization without upgrades.

Note: Across markets, RFZ 140 configurations commonly include the 4-stroke engine, 4-speed manual, kickstart, hydraulic discs, and 17″/14″ tire sizes. Buyers should align choice with rider profile, terrain severity, and maintenance cadence rather than seeking a fundamentally different engine within this displacement.

Illustrative Image (Source: Google Search)

Key Industrial Applications of rfz 140

Key Industrial Applications of RFZ 140

The Apollo DBZ40 (RFZ 140) is a compact 140 cc single‑cylinder, air‑cooled, 4‑stroke dirt bike with a double‑beam steel frame, 17″/14″ wheels (70/100‑17 front; 90/100‑14 rear), 4‑speed manual transmission, hydraulic disc brakes front/rear, telescopic fork/swing‑arm mono‑shock suspension, and approximately 13.5 in of ground clearance. Its robust, accessible, and serviceable design supports B2B use in controlled environments and non‑public operations across training, validation, and operational support functions.

Application-to-Benefit Matrix

| Industry / Application | Detailed Benefits |

|---|---|

| Off-road training grounds and vehicle dynamics testing | Approx. 52 mph top speed with 140 cc single-cylinder and 4-speed gearbox enables repeatable low/high-speed handling drills; 13.5 in ground clearance improves trail obstacle negotiation; double‑beam steel frame supports sustained testing cycles; accessible maintenance (kick start, chain final drive, air‑cooled engine) reduces downtime. |

| Rider training academies (private/closed-course) | Manual clutch and 4-speed transmission support skill development from novice to intermediate; 17/14 in wheel combo balances agility on single‑track with stability; hydraulic discs and non‑adjustable/adjustable suspensions support progressive training modules; compact dimensions aid safe instructor oversight on tight ranges. |

| Test labs and R&D validation (mobility prototypes, component durability) | Air‑cooled 140 cc platform is a simple baseline for powertrain, brake, and suspension component testing; 49.2 in wheelbase and 168 lb net weight facilitate instrumented runs and repeatable measurement; kick start and CDI ignition minimize electronics complexity in test setups. |

| Agriculture and ranch support (closed fields/private land) | Approx. 1.03 gal fuel capacity supports routine patrols; 13.5 in clearance navigates ruts and uneven ground; manual transmission enables fine control at low speeds; chain drive is easy to service in remote settings; aggressive knobby tires enhance loose‑soil traction. |

| Parks, grounds, and facilities maintenance (private, closed access) | 17 in front wheel improves obstacle rollover in trails and medians; compact footprint aids maneuverability around obstacles; accessible maintenance lowers lifecycle costs; non‑adjustable/adjustable suspensions absorb rough terrain without rider fatigue during patrols. |

| Film and media production (controlled locations/stunts) | 140 cc platform with manageable power and 4‑speed box supports controlled action sequences; manual clutch enables scripted starts/stops; hydraulic discs provide predictable braking; robust frame/suspension combo tolerates repeated use on set; 17/14 in tire mix strikes a balance between agility and stability on varied terrain. |

| Drone/robotics test range support and chase‑bike operations | Low‑maintenance air‑cooled engine supports frequent short runs; chain drive simplifies repairs; compact dimensions are practical for tight test areas; 1.03 gal fuel tank supports day‑to‑day operations; CDI/kick start reduce electronics complexity. |

| Dealer/manufacturer training and ride‑along demos | 33–33 in approximate seat height range supports older teens and adults (per vendor variant listings); manual clutch and 4‑speed support teaching; accessible service points shorten instruction time; hydraulic discs and dual-suspension provide confidence-building demos. |

| Event and field operations support (staff mobility, logistics shuttle in controlled areas) | Approx. 52 mph top speed supports quick point‑to‑point movement; compact size eases storage and transport; chain drive and air‑cooled engine lower maintenance overhead for event fleets; brake setup improves safe stopping on mixed terrain. |

Operational notes:

– Specifications are per vendor listing (Apollo DBZ40 RFZ 140) and may vary by market; confirm availability and compliance for your region.

– Ensure use complies with local regulations; many applications imply private, closed-course, or non‑public operations.

3 Common User Pain Points for ‘rfz 140’ & Their Solutions

3 Common User Pain Points for RFZ 140 & Their Solutions

1) Parts & Service Readiness

- Scenario: A regional dealer needs to fulfill service tickets and warranty checks for RFZ 140 mid-size units but has limited access to a verified parts list and support documentation.

- Problem: Missing or inconsistent parts data slows repairs, undermines customer confidence, and can stall sales activity during peak season.

- Solution: Maintain an indexed parts and service kit aligned to the RFZ 140 spec sheet; bundle common wear-and-tear items (chain, sprockets, brake pads, filters, levers, grips) and provide downloadable manuals with torque specs (e.g., engine torque 10.2 N.m @ 7500 r/min) and maintenance intervals.

2) Fitment & Rider Matching

- Scenario: A distributor plans a launch for older teens and adults, but team members struggle to match rider height/skill to the bike’s sizing and drivability.

- Problem: Mis-sized placements lead to returns and lower conversion, particularly when the seat height, wheel size, and drivetrain are not clearly mapped to rider profiles.

- Solution: Use a fitment matrix that maps the RFZ 140’s characteristics to target segments:

- 32.5 in seat height and 13.5 in ground clearance for intermediate to advanced teens/adults.

- 17 in front / 14 in rear wheel and telescopic forks/swing-arm mono shock for confidence off-road.

- 4-speed manual with kick start and chain drive for tactile control and simple maintenance.

3) Compliance & Documentation Across Markets

- Scenario: A USA/Europe distributor prepares to sell Apollo RFZ 140 mid-size bikes and needs region-specific documentation to clear customs and satisfy dealer onboarding.

- Problem: Incomplete or missing compliance documents (labels, manuals, conformity certificates) create delays, returns, and added costs in both markets.

- Solution: Standardize a compliance kit that includes:

- Model and VIN location notes, engine specs (140 cc, 4-stroke air-cooled, 11 HP), and tire sizes (70/100-17 / 90/100-14).

- Owner’s Manual and service documentation; ensure any required emissions labeling and regional conformity documentation are affixed/applicable prior to shipment.

Note: Use Apollo DBZ40 (RFZ 140) family specifications to anchor technical claims and ensure consistent messaging across USA and Europe.

Strategic Material Selection Guide for rfz 140

Strategic Material Selection Guide for RFZ 140

Platform baseline and constraints

- Target platform: Apollo DBZ40 (RFZ40) 140cc mid‑size off‑road dirt bike (17″/14″ wheels; manual clutch; 4‑speed; chain drive).

- Typical configuration at the wheel/tire: 17″ front, 14″ rear; hydraulic disc brakes front/rear; telescopic forks non‑adjustable; swing‑arm with mono shock (rear adjustable); heavy‑duty double‑beam steel frame.

- Use conditions (typical): Loose dirt, trails, hill climbs, gnarly off‑road; rider weights variable; high impact loads to frame and wheels; frequent cleaning; exposure to water and dust.

Material families by component and rationale

Frame and subframes

– 4130 chromoly (low‑alloy steel, normalized; weldable): superior strength‑to‑weight vs. mild steel; better fatigue life; cost mid‑high; widely accepted for off‑road frames.

– 1020/1045 mild carbon steel (tube or sheet): low cost, ductile; heavier than 4130; easy to weld; acceptable for budget frames.

– 6061‑T6 aluminum: lighter than steel; lower fatigue strength vs. chromoly at tube wall thicknesses used in off‑road frames; susceptible to fatigue cracking at high stress concentrations; high corrosion resistance.

Illustrative Image (Source: Google Search)

Wheels and rims

– Forged 6061‑T6 aluminum rims (front 17″ / rear 14″): best strength‑to‑weight for off‑road impacts; high corrosion resistance; cost mid‑high.

– Cast aluminum rims: heavier; lower impact toughness; cost low‑mid; acceptable for lighter use.

– Spoked steel rims: robust, repairable; heavier; prone to corrosion; lower precision and balance vs. aluminum.

Drivetrain

– Case and covers: aluminum alloy (often 380/383; Si‑Al); lightweight; good dimensional stability; susceptible to galvanic corrosion vs. steel fasteners; sealing quality critical.

– Sprockets: high‑strength low‑alloy steel (case‑hardened) for wear resistance; some lightweight sprockets use 7075‑T6 aluminum (trade wear for weight).

– Chain: O‑ring/X‑ring sealed chains with carbon steel pins and bushings; plated for corrosion resistance; high wear resistance; cost mid‑high.

Engine internals

– Cylinder/head: cast aluminum (often A‑380/AL‑Si) with cast‑iron or steel liners; efficient cooling; cost effective; serviceability via sleeve replacement.

– Crankcase: aluminum alloy; robust to vibration; service life tied to sealing and oil control.

Brakes

– Discs: stainless steel (martensitic) for corrosion resistance; cost mid; consistent friction performance; non‑rotors/rotor hats are usually steel.

– Calipers and master cylinders: aluminum housings with steel pistons; seals: EPDM/NBR for fluid and heat resistance.

– Hoses: braided stainless/aramid reinforced with PTFE liner (DOT fluid compatibility) for high burst pressure and low expansion.

Illustrative Image (Source: Google Search)

Suspension

– Tubes: high‑strength low‑alloy steel (e.g., 35CrMo for fork legs); chrome finish (decorative, limited corrosion protection); oil‑sealed sliders; cost mid.

– Shock body: steel; high strength; mass higher; corrosion protection (painted/phosphated); spring steel; aluminum shock body is possible but costly.

– Bushings and linkage pins: hardened steel with polymer bushings for wear and friction control.

Controls and ergonomics

– Handlebars: 6061‑T6 aluminum (bend‑back tolerant); optional 7075 for reduced weight; finish anodized.

– Grips/clutch lever boot: NBR/SBR rubber compounds; UV and oil resistant; low cost; replaceable.

– Seat cover: NBR/PVC or PU; UV resistant; puncture resistant; medium to high abrasion resistance.

Material and component decisions by priority

- Durability/reliability (fleet, rental, trail centers): chromoly frame; forged aluminum rims; stainless discs; steel shock body; case‑hardened sprockets; braided hoses; heavy‑duty seat material; robust bushings.

- Weight/race‑oriented: 4130 frame with optimized tubes; forged aluminum rims; lightweight sprockets (7075 for non‑dragging components); aluminum shock body; minimize unsprung mass.

- Corrosion resistance (humid/coastal climates): stainless fasteners and discs; anodized handlebars/rims; sealed cables/hoses; EPDM or NBR seals; protective coatings (phosphate/paint on steel).

- Compliance and maintenance: DOT‑rated hoses for on‑road swaps; EPDM seals for brake fluid exposure; E‑mark/EC conformity where applicable; easy‑to‑replace bushings and bearings.

Fasteners, sealing, and corrosion prevention

- Steel fasteners: grade 8.8–10.9 with anti‑seize/thread locker; zinc‑plated for corrosion resistance.

- Anti‑seize compounds at dissimilar metal interfaces; dielectric washers where steel‑aluminum contact is inevitable.

- Rubber seals: EPDM/NBR for heat and fluid compatibility; avoid long‑term exposure to aggressive solvents.

- Surface treatments: phosphate, black oxide, or powder coat for steel; anodized or clear coat for aluminum.

Supply and sourcing notes (USA/EU)

- 4130 tubing and aluminum 6061/7075: widely stocked across North America and Europe; 4130 normalized weld schedules widely available; heat‑treat capability required post‑weld if full‑T properties needed.

- Brake component compliance: EU requires E‑mark certification for braking systems when used on public roads; USA requires DOT FMVSS for on‑road. Off‑road kits typically unmarked; ensure appropriate labeling for intended use.

- Tire and tube compliance: adhere to ETRTO sizes (e.g., 70/100‑17 front; 90/100‑14 rear) and air pressure guidance; DOT/EC not typically required for off‑road competition unless road‑legalized.

Key risks and trade‑offs

- Fatigue and impact: aluminum frames are lighter but have lower fatigue strength and brittle fracture behavior; chromoly provides higher fatigue life and damage tolerance.

- Corrosion: steel is prone without protection; stainless and anodized aluminum mitigate.

- Cost and repairability: forged aluminum rims resist bending and cracks but are costly to replace; steel spoked wheels are cheaper and field‑repairable.

- Maintenance: sealed chain systems and braided hoses reduce maintenance; bushings and seals require periodic inspection.

Material comparison summary

| Material/Component | Primary Alloy/Grade | Typical Use on RFZ 140 | Pros | Cons | Compliance Notes (USA/EU) | Maintenance/Service | Relative Cost Tier |

|---|---|---|---|---|---|---|---|

| Frame tube | 4130 normalized | High‑strength off‑road frames | High strength‑to‑weight; good fatigue | Requires careful welding/heat treatment | Off‑road; not regulated as frame; road use requires proper testing/labeling | Inspect for cracks; weld repairs possible | Mid‑High |

| Frame tube | 1020/1045 | Budget frames | Low cost; ductile | Heavier; lower fatigue life | Same as above | Welds easier; higher wear | Low |

| Frame tube | 6061‑T6 | Lightweight experimental frames | Light; corrosion resistant | Lower fatigue strength at equal wall thickness | Same as above | Crack propagation risk; inspection critical | Mid‑High |

| Rims/forks | Forged 6061‑T6 | Front 17″/rear 14″ wheels; fork legs | High impact strength; light | Higher cost | Off‑road; no formal certification; road requires E‑mark/DOT if applicable | Monitor for dents/cracks | Mid‑High |

| Brake discs | Stainless steel | Front/rear discs | Corrosion resistant; consistent friction | Slightly heavier than some alternatives | Off‑road; road requires E‑mark (EU) or DOT (USA) when applicable | Check for warping; replace as needed | Mid |

| Calipers/master cylinder housings | Aluminum | Hydraulic disc systems | Light; strong | Corrosion risk at fittings if seals fail | Road requires E‑mark/DOT on complete systems | Replace seals; bleed system | Mid |

| Hoses | PTFE/braided stainless/aramid | Brake lines | Low expansion; high burst strength | Cost higher than rubber | DOT FMVSS (USA) and E‑mark (EU) for road use | Inspect annually; replace on cracks | Mid‑High |

| Engine block/head | Aluminum alloy (A‑380/AL‑Si) with iron/steel liners | 140cc air‑cooled engine | Good thermal performance; lightweight | Needs sealing; galvanic corrosion risk | Emissions not applicable for off‑road; check local regulations if road‑legalized | Monitor gasket integrity; sleeve service | Mid |

| Sprockets | Case‑hardened steel | Final drive | High wear resistance | Heavier | None (off‑road); watch noise if road | Replace at wear limits | Low‑Mid |

| Sprockets | 7075‑T6 aluminum | Lightweight final drive | Lower rotating mass | Faster wear | None (off‑road) | Replace more frequently | Mid‑High |

| Shock body | Steel | Mono shock | Strong; robust | Heavier | Off‑road | Inspect seals; re‑service shock | Low‑Mid |

| Shock body | Aluminum | Lightweight mono shock | Lower unsprung mass | Costly; strength trade | Off‑road | Same | High |

| Handlebars | 6061‑T6 | Controls | Light; formable | Can crack after bending | Off‑road | Inspect clamps and bends | Mid |

| Seat cover | NBR/PVC/PU | Seat | Abrasion and UV resistant | Can harden with age | Off‑road | Replace when cracked | Low‑Mid |

| Fasteners | Grade 8.8–10.9 steel with zinc/phosphate | General assembly | Strong; common | Corrosion if uncoated | None | Replace if stripped/corroded | Low‑Mid |

| Seals (brake, fork) | EPDM/NBR | Sealing | Heat/fluid resistant | Swells with incompatible fluids | Road compliance via material choice | Replace annually or on failure | Low |

| Tires | Off‑road knobby compounds (rear 90/100‑14; front 70/100‑17) | Traction on loose terrain | High bite; self‑cleaning | Wear faster on hardpack | Off‑road; road requires E‑mark/DOT | Check pressure/inspection | Mid |

In-depth Look: Manufacturing Processes and Quality Assurance for rfz 140

In‑depth Look: Manufacturing Processes and Quality Assurance for RFZ 140

The RFZ 140 is built around a robust, mid‑size platform: a 140cc, air‑cooled, single‑cylinder four‑stroke engine paired with a 4‑speed manual transmission and chain final drive, mounted in a double‑beam steel frame. Its off‑road capability is shaped by significant wheel sizes (17″/14″), long‑travel suspension (approx. 13.8 in rear), and generous ground clearance (~13.5 in). The following outline focuses on the manufacturing disciplines and quality assurance practices that commonly govern production of this class of off‑highway motorcycle, aligned to the RFZ 140’s key features.

Manufacturing Flow (prep, forming, assembly)

| Stage | Typical Process Focus | Applied to RFZ 140 | Primary Controls |

|---|---|---|---|

| Prep | Material and vendor qualification; incoming inspection; sub‑supplier management; batch traceability | Vendor sourcing of powertrain components (engine, CDI, carburetor/fuel system), driveline (chain/sprockets), chassis (beam frames, swingarm), wheels/tires/brakes | ISO 9001 supplier qualification; receiving inspection plans; lot traceability; AQL sampling for fasteners and small parts |

| Forming | Metal fabrication (laser/plasma/fabrication), CNC machining, welding/heat treatment; wheel machining; tire/wheel assembly; post‑finish/coating | Double‑beam steel frame and swingarm fabrication; precision machining of hubs/brake components; 70/100‑17 and 90/100‑14 wheel/tire mfg; anti‑corrosion coatings/paint; knobby tire mounting | Dimensional inspection (CMM/_fixture checks); weld procedure qualification; chemical conversion/E‑coat where used; hardness/PTR checks post‑HT |

| Assembly | Pre‑build sub‑assemblies (engine/transmission, chassis/wheels), torque‑secured joints, wiring/lighting/controls; fuelling | 140cc single‑cylinder, 4‑stroke, air‑cooled engine assembly; 4‑speed manual gearbox; hydraulic discs (F/R); telescopic forks and rear mono‑shock; chain‑drive final drive; kick‑start; CDI ignition | Torque audits and SPC on critical fasteners; continuity/function checks for electrical; brake setup/leak/fade tests; chain tension and sprocket alignment |

| End‑of‑line and Pre‑delivery | Dyno/performance checks, NVH/safety verifications, emissions/noise verification (region‑specific); packaging/shipment | Functional road‑off testing (engine performance, drive‑line engagement, brake functionality); inspection of ground clearance/suspension travel/geometry; final QC sign‑off | Final audit sampling; regional labeling/controls (EPA/CARB off‑highway for U.S.; CE for EU as applicable); packaging integrity/damage‑in‑transit checks |

Quality Management and Standards Alignment

- ISO 9001: Quality Management System—governs process control, corrective/preventive actions, calibration, and nonconformance control.

- ISO 14001: Environmental Management—supports material selection and compliance for coatings and processes.

- ISO 45001: Occupational Health & Safety—used in welding, machining, and assembly environments to control HSE risks.

- ISO 3834‑2 (as applicable): Qualification requirements for fusion welding of metallic materials—ensures weld quality in the frame and swingarm.

- ISO 26221‑2 (as applicable): Noise measurement and limits—used where national/regional limits apply to off‑road noise; confirm applicability to target markets.

- ISO 17025 (for calibration labs): Ensures accurate measurement of dynamometers, torque tools, brake testers, and emissions instrumentation.

Regional considerations:

– U.S.: Off‑highway vehicles are generally exempt from tailpipe emissions certification; verify state‑level noise/sound limits and product labeling requirements.

– EU: CE conformity assessment (self‑declaration or module as applicable) plus RoHS/REACH for materials compliance; ensure national noise limits are met for non‑type‑approved vehicles.

Illustrative Image (Source: Google Search)

Critical‑to‑Quality (CTQ) Map (selected)

| RFZ 140 Feature | Why It Matters | Manufacturing/QC Focus |

|---|---|---|

| 140cc 4‑stroke, air‑cooled single | Reliability and power delivery for off‑road use | Cleanliness of oil/coolant circuits; gasket sealing torque; leak‑down and vacuum checks; dyno timing curve verification |

| 4‑speed manual transmission (N‑1‑2‑3‑4) with kick start | Rider control and durability under load | Gear engagement tests; shift detent verification; kick‑start ratchet/engagement trials |

| Chain final drive | Efficiency and service life | Sprocket runout; chain stretch and wear testing; alignment fixture checks |

| Double‑beam heavy‑duty steel frame | Strength and torsional stability | Weld penetration/penetrant inspection; post‑weld stress relief where specified; dimensional control of head tube, swingarm pivot, and wheelbase (49.2 in) |

| Suspension travel (approx. 13.8 in rear) | Clearance and ride quality | Spring rate verification; damper sealing; ride height and sag checks |

| Ground clearance (13.5 in) | Off‑road obstacle clearance | Frame and swingarm geometry; component packaging review |

| Hydraulic disc brakes (F/R) | Safety under severe use | Brake pad glazing/squeal tests; rotor runout; lever feel and lever stroke validation; pressure/leak testing; final bleed verification |

| Wheel/tire sizes (70/100‑17; 90/100‑14) | Handling and traction | Hub radial/axial runout; rim concentricity; tire pressure setpoints; bead seat integrity tests |

| Seat height (32.5 in) | Rider ergonomics | Ergonomics verification for target riders; seat mounting clearance and torque |

| Wet weight (~196 lb) | Logistics and handling | Component mass balance; assembly weight tracking; packaging fit verification |

| Packaging envelope (approx. 57.5 x 15 x 29.5 in) | Distribution and damage mitigation | Carton design validation; drop/stack testing; protective insert fit checks |

QC Inspection and Testing Plan (indicative)

- Dimensional: Frame/wheelbase/steering geometry against spec; hub and rotor runout; brake calliper piston return.

- Functional: Engine compression/leak‑down; dyno run for power/torque within spec range; transmission engagement and shift quality; kick‑start function; CDI ignition timing.

- Brakes: Pressure build/leak test; minimum lever travel to full lock; fade under repeated stops (if required by internal safety target).

- NVH/Acoustics: Rider area vibration at defined throttle positions; brake squeal propensity; chain noise under varying loads.

- Durability: Sample‑based component endurance for pivot bearings, shock seals, chain/sprockets, and lever pivots.

- Final Audit: Full fit, finish, labeling, torque verification on critical joints (axles, calipers, subframe, triple clamps), and shipment readiness.

Production Control Methods

- Process Control: Torque control (calibrated tools with statistical verification); SPC on high‑frequency joins; First Article Inspections for new tooling/batches.

- Measurement: CMMS and calibrated gauges; brake tester calibration traceable to ISO 17025; dynamometer calibration and correlation to reference units.

- Corrective Action: CAPA workflow; field feedback integration for improvement (e.g., brake pad material tuning, chain/sprocket wear life).

- Continuous Improvement: Yield and rework tracking; internal audit program; supplier PPAP/FAI as applicable for critical components.

This manufacturing and QA framework aligns with international best practices and supports the RFZ 140’s intended use, ensuring repeatable performance and reliability across off‑road conditions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rfz 140’

Practical Sourcing Guide: A Step-by-Step Checklist for RFZ 140

Audience focus: USA and Europe.

Model baseline: Apollo RFZ 140 (also listed as DBZ40).

Use this checklist to validate the model, secure compliance and logistics, and protect value across the lifecycle.

Step 1 — Confirm SKU and Baseline Specs

- Supplier must provide the exact model name (RFZ 140 / DBZ40), SKU/VIN, and latest spec sheet.

- Expected baseline for Apollo RFZ 140:

- Engine: 140 cc, single-cylinder, 4-stroke, air-cooled; 11 HP @ 8000 rpm; 10.2 N·m @ 7500 rpm

- Transmission: 4-speed manual, N-1-2-3-4; final drive chain

- Starting: Kick start

- Ignition: CDI

- Tires: 70/100-17 front; 90/100-14 rear

- Brakes: Hydraulic disc (front/rear)

- Suspension: 30.3 in telescopic forks (non-adjustable); 13.8 in mono-shock (adjustable)

- Frame: Double-beam heavy-duty steel

- Ground clearance: 13.5 in

- Wheelbase: 49.2 in

- Seat height: 32.5 in

- Dimensions (L×W×H): 70 × 30.7 × 46 in

- Shipping dimensions: 57.5 × 15 × 29.5 in

- Weight: Net 168 lb; gross 196 lb

- Fuel capacity: 1.03 gal; oil capacity: 0.24 gal

- Colors: Black, Blue, Green, Red

- Verify any variations by region/supplier. Ensure parts lists and manuals are available.

Step 2 — Fit-for-Use Validation

- Use case: Off-road trail and pit riding; not for use on public roads unless locally permitted and compliant.

- Rider fit: Comfortable for larger teens/adults (seat height 32.5 in, 13.5 in clearance).

- Terrain suitability: Aggressive knobby tires and full suspension for loose dirt, obstacles, and single track.

- Maintenance profile: 4-stroke air-cooled; chain drive; hydraulic disc brakes; kick start. Confirm routine service intervals.

Step 3 — Compliance and Market Approval (USA vs EU)

Table 1 — Compliance snapshot: USA vs EU

| Topic | USA (Off-road use) | Europe (General market) |

|---|---|---|

| Emissions | EPA/CARB: off-road vehicles typically not street-legal; verify with supplier regarding any small-engine compliance. | EU L-category: RFZ 140 likely L1e-B (45 km/h) moped or L3e (45+ km/h) depending on max speed. Road use requires appropriate L-category approval. |

| Noise | Not regulated like on-road vehicles; confirm supplier-provided dB test for buyer risk control. | Noise limits and marking apply under L-category. Verify compliance and labeling. |

| Certification | None required for off-road only use; confirm no on-road claims. | Type approval (e.g., for L3e/L1e-B) or national/individual approval; EC Certificate of Conformity (CoC) required if type-approved. |

| Marking/labeling | Follow OSHA and consumer safety norms; no federal e-mark. | E-marking for type-approved vehicles; reflectors/lights must meet rules for category (varies). |

| Road use | Prohibited unless locally permitted and compliant (EPA, DOT, state). | Allowed only if category-approved and equipped per rule set (lights/reflectors, speed governor if applicable). |

Action:

– USA: Confirm model is sold as off-road-only; specify “not for highway use” in your terms.

– EU: Request CoC with clear category (L1e-B or L3e) and speed capability; verify country approvals and any speed limiters (45 km/h) if intended for road use.

Step 4 — Electrical and CDI Check

- Supplier specification indicates CDI ignition.

- Verify 12V electrical system and charging (if any) — confirm whether a stator/alternator is present; many 4-stroke single cylinders include basic charging for lights/horn. Request wiring diagram if not provided.

Step 5 — Packaging and Shipping Verification

- Standard crate (dimensions provided). Confirm crate strength, tie-down points, and palletization (48 × 40 preferred in USA; EUR-pallet for EU).

- Packing list includes carton count, weights per carton, HS code, and incoterms.

- Transit insurance and claims process documented.

- For USA, consider brokered entry under general merchandise (not typically EPA/CARB entry for off-road). For EU, confirm import category matches the L-category.

Step 6 — Documentation Package

- Commercial invoice, packing list, proforma (for pre-shipment).

- Owner’s manual (English; EU buyers may need local language).

- Parts list and exploded diagrams; maintenance schedule.

- Safety instructions; recommended age/usage notes.

- Warranty terms and service network.

- Certificates: EU CoC (if applicable), dB/noise tests, emissions tests (if any), and country-specific approvals where applicable.

Step 7 — Customs, HS Codes, and Taxes

- HS code: Typically 8711 (Motorcycles; bicycles with auxiliary motor; parts and accessories). Confirm with broker.

- EU: Import VAT and customs duty due at entry; ensure accurate classification and valuation.

- USA: Duty rate per classification; ensure accurate declared value and invoice clarity.

Step 8 — QA and Acceptance on Arrival

- Sample first shipment or a pilot lot.

- Pre-ship photos/videos of engine s/n, VIN (if present), and crate condition.

- On arrival, perform:

- Visual damage inspection of crate and bike.

- Start test (kick start), idle stability, clutch engagement, gear shifts, brake function.

- Tire/wheel integrity and suspension travel.

- Fluid checks (fuel, oil), light check (if equipped).

- Documentation completeness and labeling compliance.

Step 9 — After-Sales and Parts Strategy

- Critical spares: chain/sprockets, tires, brake pads, filters, CDI/ignition components, suspension linkages, cables, grips, levers, forks seals, shock seals, rims/spokes.

- Warranty handling: RMA process, turnaround targets, replacement units vs parts.

- Support channels: Distributor and direct OEM contact information; remote support/FAQ.

Step 10 — Commercials and Contracting

- Incoterms (e.g., FOB/CIF/DAP), payment terms, and pricing validity window.

- Lead time from PO to shipment; minimum order quantity; partials allowed.

- Price breaks by volume; stocking programs; forecast commitment.

- Force majeure and backorder policy; replacement parts priority.

- Brand/IP usage rights if marketing.

Table 2 — Core specification snapshot

| Attribute | RFZ 140 (Apollo DBZ40) |

|---|---|

| Displacement | 140 cc |

| Power / Torque | 11 HP @ 8000 rpm; 10.2 N·m @ 7500 rpm |

| Max speed | ≈ 52 mph (as listed) |

| Transmission | 4-speed manual, N-1-2-3-4; chain drive |

| Starting | Kick start; CDI ignition |

| Brakes | Hydraulic disc (front/rear) |

| Tires | 70/100-17 front; 90/100-14 rear |

| Seat height | 32.5 in |

| Ground clearance | 13.5 in |

| Frame | Double-beam heavy-duty steel |

| Wheelbase | 49.2 in |

| Fuel / Oil | 1.03 gal / 0.24 gal |

| Net/Gross weight | 168 lb / 196 lb |

| Colors | Black, Blue, Green, Red |

If your procurement needs are across USA/EU, align documentation and approvals by market, and treat EU road use and category approvals as non-negotiable gating items.

Comprehensive Cost and Pricing Analysis for rfz 140 Sourcing

Comprehensive Cost and Pricing Analysis for RFZ 140 Sourcing

Context: Apollo RFZ 140 (also marketed as DBZ40). Specs below inform sizing, cartonization, freight class, and duty treatment.

Illustrative Image (Source: Google Search)

What you’re buying (model anchor)

- Apollo RFZ DBZ40

- 140cc single-cylinder 4-stroke, air-cooled

- 4-speed manual, kick start

- Hyd disc brakes f/r; 70/100-17 / 90/100-14 tires

- Steel double-beam frame

- Seat height 32.5 in; wheelbase 49.2 in

- Net 168 lb; Gross 196 lb

- Dimensions (unit): 70 x 30.7 x 46 in

Note: Shipping/carton is typically 57.5 x 15 x 29.5 in, gross 196 lb.

Unit bill of materials (indicative, ex-works)

Use this as a working template. Adjust by supplier quote.

| Subsystem | Typical content | Notes |

|---|---|---|

| Powertrain | 140cc long-block (bore/stroke ~56×57), CDI, carb/EFI, exhaust | Air-cooled; 11 hp claimed |

| Driveline | 4-speed trans, chain, sprockets | Manual clutch/kick |

| Chassis | Double-beam steel frame, swingarm | Cost varies by steel price and weld complexity |

| Suspension | 30.3 in telescopic forks (non-adjustable), rear mono shock (adjustable) | Major cost driver; quality variance is wide |

| Wheels/Tires/Brakes | 17/14 wheels, 70/100-17 / 90/100-14 tires, hydraulic disc calipers/rotors | Tire quality/branding affects landed cost |

| Controls | Bars, levers, cables, switches | Standardization saves cost |

| Electrical | CDI, coil, wiring harness, lighting | Basic harness and DC lighting |

| Cosmetic/Plastics | Seat, plastics, decals | Color SKUs add minor inventory cost |

Manufacturing and assembly labor

Estimates vary by factory and line efficiency.

| Item | Typical range | Driver |

|---|---|---|

| BOM processing (welding/paint/assembly) | $25–$45 per unit | Labor rate, yield |

| PDI (pre-delivery inspection) | $8–$12 per unit | QC checklist depth |

| Packaging | $6–$10 per unit | Corrugate strength, dunnage |

Packaging and handling

Single-unit carton (carton size 57.5 x 15 x 29.5 in; gross 196 lb) sets the bar for LTL freight class and inner-city delivery constraints.

Illustrative Image (Source: Google Search)

| Packaging option | Dimensions (L x W x H) | Gross wt | Pros | Cons |

|---|---|---|---|---|

| Single-unit carton | 57.5 x 15 x 29.5 in | ~196 lb | Retail-ready, easy fulfillment | High dimensional weight; LTL class 250–300 |

| 2-up pack (palletized) | ~60 x 31 x 31 in | ~400–410 lb | Lower DIM per unit | Requires de-pack at warehouse; more pallet damage risk |

| 4-up pack (palletized) | ~60 x 32 x 62 in | ~800–820 lb | Best DIM ratio for FCL/LTL | Needs pallet jack/forklift; handling overhead |

Freight class guidance (domestic US LTL): 250–300. Reclassify at shipment if dims change.

Logistics baseline (EXW China to destination)

| Mode | US West Coast | US East Coast | EU main ports |

|---|---|---|---|

| LCL sea | ~$12–$18 w/m (minimum 1 w/m); 25–35 days transit | ~$18–$28 w/m; 35–45 days | ~€18–€30 w/m; 25–35 days |

| FCL (20’) | ~$2,200–$4,000 port-to-port; 20–30 days | ~$3,000–$5,500; 25–35 days | ~$2,500–$4,500; 25–35 days |

| Air (general) | ~$5–$10/kg; 5–7 days | ~$6–$12/kg; 5–7 days | ~€5–€11/kg; 5–7 days |

Notes:

– Dimensional weight for 1-unit carton: (57.5 x 15 x 29.5)/139 ≈ 185 lb (US), ~92 kg (EU).

– Dimensional weight typically dictates cost; actual chargeable may be near gross due to low density.

FCL load planning (20’ container)

Max floor area ~225–230 ft²; usable length ~19.4 ft. Rough capacity:

– Palletized 4-up (pallet size 48×40 in, height ≤62 in): ~6 pallets per layer x 2 layers = 12 pallets → 48 units.

– 2-up on 48×40 pallets: ~9–10 pallets per layer x 2 layers = 18–20 pallets → 36–40 units.

– 2-up on 48×42 pallets: ~8 pallets per layer x 2 layers = 16 pallets → 32 units.

– 2-up on 48×48 pallets: ~7 pallets per layer x 2 layers = 14 pallets → 28 units.

Landed cost examples (illustrative)

Assumptions:

– EXW unit cost: $1,000 (for illustration only).

– Domestic US drayage: $120 per container; US inland (to Chicago): $1,200–$1,800/container.

– EU terminal/handling: €200–€350 per container; EU inland (to Central EU): €1,200–€2,000.

Illustrative Image (Source: Google Search)

US East Coast, 32 units, 20’ FCL:

– Freight (port-to-port): assume $4,200.

– Domestic: drayage $120 + inland $1,500 → $1,620.

– Per-unit transport ≈ $180. Landed per unit ≈ $1,180 (before duty/VAT).

EU, 48 units, 20’ FCL:

– Freight (port-to-port): assume $3,500.

– Domestic: €200 handling + €1,400 inland → €1,600.

– Per-unit transport ≈ €33. Landed per unit ≈ €1,033 (before duty/VAT).

– EU duty (HS 8711.20): 6.5% on CIF.

– VAT: varies by country (e.g., 19–27%). Illustrative total duties+VAT on €1,100 base: €220–€360.

Shipping method comparison (per unit, same scenario):

| Method | US per-unit transport | EU per-unit transport | Transit |

|—|—|—|—|

| LCL (single-unit carton) | ~$80–$120 | €18–€30 | 25–45 days |

| FCL 20’ (32–48 units) | ~$120–$200 | €33–€60 | 20–35 days |

| Air (charged on ~100 kg) | ~$500–$1,000 | €500–€1,100 | 5–7 days |

Price waterfall (EXW → DDP-like)

| Step | Typical range | Notes |

|---|---|---|

| EXW unit | $900–$1,400 | Driven by engine/suspension spec and quality |

| Packing | $6–$10 | Stronger corrugated, better dunnage = fewer damage claims |

| International freight | See section above | Mode, lane, DIM, and container utilization matter most |

| Duty (US) | 0% (HS 8711.20.00) | Off-road motorcycles; no internal combustion engine duty |

| Domestic delivery | $120–$400 per unit (LTL/US West/East varies) | LTL class 250–300; accessorials add cost |

| Warehousing/handling | $5–$15 per unit per month | Depends on location and storage profile |

US vs EU price dynamics

- Duties: US 0% for off-road motorcycles; EU 6.5%.

- Engine/emissions: US/Europe typically exempt for closed-course off-road; always verify at destination and end-use.

- Product compliance: US and EU labeling/WEEE and country-specific safety standards apply. Budget $1–$5 per unit for labels/small parts.

- Returns/claims: Budget 1–3% of sales for warranty/transport damage; ensure robust packaging and PDI.

Tips to save cost

- Packaging and palletization

- Shift to 4-up pallet packs to reduce dimensional weight by 40–50% for FCL; use 48×40 pallets.

- Reinforce carton edges and top; use corner boards; strap pallets. Fewer claims = lower long-term costs.

- Ocean optimization

- Use FCL whenever unit counts allow. Target 90%+ container fill.

- Consolidate SKUs and colors to minimize dead space.

- Inventory and lead times

- Build quarterly S&OP with suppliers. Pull forward POs ahead of Q4/e-season.

- Safety stock based on demand variability and lane reliability (SD + 0.5*lead time).

- Logistics and routing

- Multi-country strategy: import to LA/Long Beach for US West; Savannah/Newark for US East; Rotterdam/Hamburg for EU. Inland points can be served by 1–2 regional DCs.

- Mix LTL for small lots and FCL for scale. Negotiate accessorials (liftgate, residential, limited access) up front.

- Quality and damages

- Tighten acceptance criteria for powertrain and suspension. Prevent 2–3% rework/damage.

- Implement drop-test for packaging. A 10% reduction in damage can offset a 2–3% packaging spend increase.

- Vendor and payment terms

- Multi-source powertrain and suspension to hedge cost volatility.

- Target 10–20% deposit, 70% on BL, 10% after QA acceptance.

- Retail/e-commerce readiness

- Ensure carton is retail-ready and Amazon/e-commerce compliant (label placement, over-label rules).

- Offer 2-up kits for dealers to lower their inbound freight.

Risk and controls

- DIM weight escalation: Monitor dims/weight; re-bill if class changes.

- Steel/ tire/ fuel cost volatility: Add indexation clauses or quarterly pricing windows.

- Capacity and lead-time reliability: Rolling monthly MFG capacity reports and lane OTIF metrics.

KPIs to track

- Landed cost variance to budget (±3%).

- Container utilization (%): revenue/weight or floor space fill.

- Damage rate (bps of units) and RMA rate.

- Freight cost per unit by lane and mode.

- Lead time adherence (OTIF).

This framework turns Apollo RFZ 140 specs into practical cost and pricing decisions. Adjust unit and freight assumptions to your current quotes and lanes.

Illustrative Image (Source: Google Search)

Alternatives Analysis: Comparing rfz 140 With Other Solutions

Alternatives Analysis: Comparing RFZ 140 With Other Solutions

For mid-size off-road buyers in the USA and Europe, two practical alternatives often appear on shortlists: Apollo DBZ40 (RFZ40) and SSR SE140. The RFZ 140 is positioned as a trail-focused 140 with a manual clutch and 4-speed gearbox, modest seat height, and robust frame/suspension designed for off-road durability.

Comparative specifications

| Attribute | RFZ 140 | Apollo DBZ40 (RFZ40) | SSR SE140 |

|---|---|---|---|

| Intended use | Off-road dirt bike | Off-road dirt bike | Off-road / pit-style |

| Displacement | 140 cc | 140 cc | 140 cc |

| Engine | Single-cylinder, 4-stroke, air-cooled (platform) | Single-cylinder, 4-stroke, air-cooled | Single-cylinder, 4-stroke |

| Power | Not published | 11 HP @ 8,000 rpm | Not published (typical single 4-stroke) |

| Torque | Not published | 10.2 N·m @ 7,500 rpm | Not published |

| Transmission | Not published | 4-speed manual (N-1-2-3-4) | Not published |

| Final drive | Not published | Chain | Chain |

| Starting | Not published | Kick | Kick |

| Ground clearance | Not published | 13.5 in | Not published |

| Seat height | Not published | 32.5 in | Not published |

| Wheel/tire sizes | Not published | 70/100-17 (F) / 90/100-14 (R) | Not published |

| Brakes | Not published | Hydraulic disc (F/R) | Disc (F), drum (R) |

| Suspension travel | Not published | Non-adjustable forks 30.3 in / Rear mono shock 13.8 in (adjustable) | Not published |

| Weight (wet) | Not published | 168 lb (net) | Not published |

| Weight (shipping) | Not published | 196 lb | Not published |

| Warranty | Not published | Not published | 6-month limited |

Notes: RFZ 140 platform specs were not available at time of writing. DBZ40 is commonly marketed as an RFZ 140 variant; specifications above reflect that product page. SSR SE140 specs vary by model year; warranty details per SSR USA.

Head-to-head analysis

RFZ 140 vs Apollo DBZ40 (RFZ40)

– Platform and positioning: The DBZ40 is the RFZ 140’s commercially marketed sibling. Key attributes—manual clutch, 4-speed transmission, chain final drive, kick start—suggest an aligned platform, with RFZ 140 likely carrying similar off-road intent.

– On-trail performance: DBZ40’s 13.5 in ground clearance and 17 in front wheel indicate real trail agility and obstacle clearance typical of trail-focused bikes. If RFZ 140 matches this geometry and tire sizing, expect comparable single-track confidence.

– Serviceability: Shared architecture (single 4-stroke, simple CDI ignition, standard chain/sprocket) implies comparable parts commonality and routine maintenance ease.

– Availability/Support: Apollo has established North American distribution and dealer networks; replacement parts, fluids, and consumables are widely accessible, lowering acquisition-to-service friction for fleet buyers.

– Procurement considerations: If RFZ 140 shares the DBZ40 drivetrain and frame, total cost of ownership (TCO) should mirror the known maintenance profile (oil changes, chain/sprocket wear, brake service). Verify any differences in assembly QA, documentation, or parts support to confirm comparable operating costs.

RFZ 140 vs SSR SE140

– Off-road readiness: SSR’s SE140 is a single-cylinder 4-stroke pit/off-road model with chain drive and kick start. Without published geometry and suspension travel, it is less clear how it performs on sustained single-track compared to trail-specific chassis like the DBZ40/RFZ family.

– Tires and clearance: DBZ40 shows aggressive knobby fitment and high clearance; SSR’s off-road tire spec is not available. Buyers prioritizing technical trail riding should verify wheel/tire and clearance equivalence.

– Weight and ergo factors: Unknowns on SE140 weight/seat height constrain comparison. For fleet ergonomics (dismount/mount ease, size fit), RFZ/DBZ40’s known 32.5 in seat height and 168 lb weight are advantageous.

– Price/value and warranty: With a 6-month limited warranty from SSR USA, the SE140 can present a lower upfront price vs DBZ40. However, warranty scope affects TCO and downtime; ensure clarity on parts coverage and service network responsiveness.

Illustrative Image (Source: Google Search)

Procurement decision guidance

- If the RFZ 140 mirrors DBZ40 performance and component specs, buyers prioritizing real off-road capability and predictable service should favor RFZ 140/DBZ40. Their geometry, clearance, and tire sizing are aligned with trail demands.

- If procurement emphasizes lowest initial cost with minimal off-road technical requirements, SSR SE140 is a valid option. Confirm ride quality, clearance, and parts availability before deployment.

- For B2B deployments in the USA and Europe, prioritize documented warranty terms, spare parts lead time, and regional service coverage to minimize TCO and downtime. Where spec details are not published (RFZ 140, SE140 geometry, weights), request full technical sheets, service manuals, and warranty terms before finalizing.

Essential Technical Properties and Trade Terminology for rfz 140

Essential Technical Properties and Trade Terminology for RFZ 140

RFZ 140 — Key Specs (B2B Quick Reference)

Note: Values shown are from Apollo DBZ40 RFZ 140 literature. Max speed is an approximation.

| Category | Specification |

|---|---|

| Model(s) | Apollo DBZ40 (RFZ 140) |

| Engine | Single-cylinder, 4-stroke, air-cooled |

| Displacement | 140 cc |

| Bore × Stroke | 56 × 57 mm |

| Compression Ratio | 9.8:1 |

| Max Power | 11 hp @ 8,000 rpm |

| Max Torque | 10.2 N·m @ 7,500 rpm |

| Max Speed | ~52 mph (≈84 km/h), typical; verify local conditions |

| Transmission | 4-speed manual (N–1–2–3–4) |

| Starting System | Kick start |

| Ignition | CDI |

| Final Drive | Chain |

| Fuel Capacity | 1.03 gal (≈3.9 L) |

| Oil Capacity | 0.24 gal (≈0.9 L) |

| Brakes (F/R) | Hydraulic disc / Hydraulic disc |

| Tires (F/R) | 70/100-17 / 90/100-14 |

| Suspension (F/R) | Telescopic forks 30.3 in (non-adjustable) / Mono shock swingarm 13.8 in (adjustable) |

| Frame | Double-beam heavy-duty steel |

| Ground Clearance | 13.5 in (≈343 mm) |

| Wheelbase | 49.2 in (≈1,250 mm) |

| Seat Height | 32.5 in (≈826 mm) (some listings also cite ~33 in) |

| Dimensions (L × W × H) | 70 × 30.7 × 46 in |

| Shipping Dimensions | 57.5 × 15 × 29.5 in |

| Net/Gross Weight | 168 lb / 196 lb (≈76 / 89 kg) |

| Colors | Black, Blue, Green, Red (availability varies) |

| Intended Use | Off-road trail; not for public road use unless locally certified |

Engine & Drivetrain

- Air-cooled, 140 cc single with 9.8:1 compression.

- Output oriented for off-road torque: 11 hp @ 8,000 rpm; 10.2 N·m @ 7,500 rpm.

- 4-speed manual gearbox with kick start and CDI ignition; chain final drive.

Chassis, Suspension & Brakes

- Double-beam steel frame for durability; mono-shock rear suspension is adjustable.

- Ground clearance ~13.5 in with a 17 in front wheel aids obstacle traversal and maneuverability.

- Dual hydraulic discs for strong stopping performance off-road.

Dimensions & Mass

- Wheelbase ~49.2 in; seat height ~32.5 in; overall dimensions ~70 × 30.7 × 46 in.

- Net weight ~168 lb; shipping weight ~196 lb.

- Tire sizes: front 70/100-17; rear 90/100-14.

Trade Terminology (B2B)

- MOQ (Minimum Order Quantity): Typically single-unit or pallet-dependent; confirm at inquiry.

- OEM: Manufacturer (Apollo) for base model; OEM parts availability varies by model year; confirm part numbers.

- ODM: Customization options and branding (stickers, colors, decals) subject to supplier confirmation.

- Lead Time: Assembly to shipment typically varies with batch size and inventory; quote on request.

- Incoterms: FOB/CIF/DDP common; destination to be specified.

- Packaging: Crated or otherwise secured for LTL/TL freight; dimension/weight as specified.

- Warranty: Standard manufacturer coverage applies; service network to be confirmed by region (US/EU).

- Certifications/Compliance: Off-road homologation varies; road legality (DOT/EEC) requires local certification. Confirm model year and region.

- After-sales Support: Replacement parts, manuals, and technical service guidance available from the brand/distributor.

- Documentation: Bill of Lading/AWB, commercial invoice, packing list, HS code, and country-of-origin as applicable.

- HS Code: Typical classification is 8711 (motorcycles); final code depends on configuration; verify with broker.

- Origin: Country of manufacture provided by the supplier; confirm at PO stage.

Navigating Market Dynamics and Sourcing Trends in the rfz 140 Sector

Navigating Market Dynamics and Sourcing Trends in the rfz 140 Sector

What drives the RFZ 140 segment

- Adult and family buyers are converging on mid-size 140cc 4-stroke options for trail and trail-plus use. Product positioning is typically “bridge bike”: more power and larger wheels than kids’ 110–125cc, with a lower seat height and manageable torque compared to full-size 250–450cc bikes.

- Availability constraints are common. Example: major US retailers have listed the Apollo RFZ DBZ40 (140cc) as out-of-stock, signaling volatile inventory and longer lead times for importers/distributors.[^2]

- Supply drivers include component lead times (ignition/CDI, hydraulics, disc brakes), tiered packing/shipping constraints, and seasonality. Peak pre-season orders strain factory capacity, then inventory gluts can form post-season.

Product signals that shape sales

- Performance envelope: 11 HP, 10.2 N·m torque, approx. 52 mph top speed; 4-speed manual; kick-start; double-beam steel frame; telescopic fork (non-adjustable) and mono shock (adjustable); chain final drive.[^2]

- Dimensions that define use case:

- Seat height ~32.5–33 in; ground clearance ~13.5 in; wheelbase ~49.2 in.[^2]

- Wheel/tire sizes: 70/100-17 front and 90/100-14 rear; 17-in front improves obstacle clearing and maneuverability on tight single track.[^2]

- Fit for rider profile: retail pages often recommend youth 8–15 and adults 16+; however, the low seat height and tractable torque make it attractive to smaller adults and larger teens.[^2]

Regulatory reality for USA and EU

- USA

- New off-road vehicles sold in California must be CARB compliant with an eVIN. Check whether the specific 140cc model is on CARB’s list or sold via an exempt category (e.g., competition-only).[^3]

- Many 140cc “dirt/pit bikes” are sold as off-highway recreational vehicles outside California; confirm state-level restrictions before shipment.

- Europe

- EU-wide individual approval (WVTA) is required for road use. For off-road/trail-only machines, country-specific requirements may apply (ABE in Germany; similar approvals elsewhere). Confirm noise, lighting, and reflective equipment needs if the product will be used on public paths/roads.

- CE marking, WEEE/RoHS (electrical components), and REACH SVHC compliance remain baseline expectations for responsible market entry.

Sustainability and electrification context

- ICE 140cc bikes remain dominant in price-sensitive segments; electrification is advancing mainly in compact trail/e-bike categories (e.g., 2–4 kW e-motos), not yet in mainstream mid-size ICE price bands. Where available, e-bikes reduce local noise and tailpipe emissions but trade off range and weight.[^1]

- Buyers in both USA and Europe increasingly expect:

- Longer service intervals and durable components (sealed bearings, corrosion-resistant hardware).

- Service parts availability and accessible documentation (manuals, exploded diagrams, warranty terms).

- Packaging and freight optimization (knock-down kits or efficient crate packing) to limit shipping volume and costs.

Sourcing and portfolio strategy

- Keep RFZ 140 in the portfolio to cover the “step-up” buyer and as a hedge against RFZ 110 supply risk. The 140cc platform balances power, manageability, and packaging.

- Build a compliance-first spec for your target markets:

- USA: verify CARB eligibility for California; ensure dealer documentation covers eVIN if applicable.[^3]

- EU: align approvals to intended use (off-road vs road-capable); validate noise, lighting, and labeling; confirm CE/RoHS/REACH.

- Parts and service readiness: pre-buy top-wear items (front/rear tires, chain/sprockets, levers, filters, seals) and critical components (ignition/CDI, shock seals, brake pads). Retail pages show strong interest in supporting documents and support videos.[^2]

- Supplier evaluation checklist

- Compliance capacity for USA/EU road or off-road approvals

- Consistency of packaging dimensions (e.g., shipped crate ~57.5 x 15 x 29.5 in for the Apollo RFZ DBZ40)[^2]

- Lead-time predictability and MOQ flexibility

- Warranty terms and returns handling

Pricing and inventory posture

- Expect price sensitivity in the 140cc segment. Volatility is more about supply timing and parts support than raw engine specs.

- Retail pages routinely show “out of stock” for RFZ 140 models, which impacts conversion and upsell. Mitigate by:

- Providing clear expected restock timelines.

- Bundling accessories (guards, handguards, graphics, tires suited to local conditions).

- Enabling waitlist deposits to manage demand and cash flow.[^2]

Market snapshot: product signals that matter

| Signal | Why it matters | RFZ 140 example |

|---|---|---|

| Power/torque and top speed | Sets trail aggressiveness and rider progression path | 11 HP, 10.2 N·m; approx. 52 mph[^2] |

| Transmission | Affects skill development and trail control | 4-speed manual; kick-start[^2] |

| Wheel sizes and ground clearance | Determines obstacle clearance and handling | 17-in front; 13.5-in clearance[^2] |

| Seat height | Determines accessibility for teens and smaller adults | ~32.5–33 in[^2] |

| Availability | A leading indicator of pricing power and customer churn | Out-of-stock at major US retailer[^2] |

Actionable recommendations

- Lock in a CARB/eVIN compliance path for California-bound inventory; for EU, clarify road-capability and approvals by country.

- Carry pre-assembled SKUs and parts kits to reduce lead-time on critical wear items.

- Use seasonality-aware inventory planning; pre-book factory capacity before peak demand windows.

- Publish service documentation and videos to reduce returns and support burden (buyers expect these assets).[^2]

- Where relevant, pilot or evaluate compact e-bike options to meet tightening noise/emission expectations in sensitive trail areas.[^1]

Sources

[^1]: Apollo RFZ 140 Z40 Dirt Bike — Manual Transmission (17’/14’) tires … (scraper doc page context).

[^2]: Apollo DBZ40 RFZ 140cc Mid-size Dirt Bike — FamilyGoKarts.com (specs, features, availability).

[^3]: Walmart Scraper API — Docs (documentation page context; useful for tracking stock compliance mentions and SKU availability where applicable).

Frequently Asked Questions (FAQs) for B2B Buyers of rfz 140

Frequently Asked Questions (FAQs) for B2B Buyers of RFZ 140

1. What are the core technical specifications of the RFZ 140?

The RFZ 140 features a 140cc single-cylinder, 4-stroke, air-cooled engine producing 11HP at 8000 RPM and 10.2 N.m torque at 7500 RPM. Key specifications include:

| Specification | Details |

|---|---|

| Displacement | 140cc (56 x 57 mm bore x stroke) |

| Compression Ratio | 9.8:1 |

| Transmission | 4-Speed Manual (N-1-2-3-4) |

| Ground Clearance | 13.5 inches |

| Seat Height | 32.5 inches |

| Weight | 168 lbs (net), 196 lbs (gross) |

| Tires | Front: 70/100-17, Rear: 90/100-14 |

2. What is the target demographic for this model?

The RFZ 140 targets two primary segments:

– Youth riders: Ages 8-15 for intermediate to advanced riders

– Adult riders: Ages 16 and up seeking entry-level to mid-range performance

Illustrative Image (Source: Google Search)

The 32.5-inch seat height and manageable 140cc displacement make it suitable for transitioning youth riders and adult recreational enthusiasts.

3. What warranty and support infrastructure is available?

While specific warranty terms weren’t detailed in our reference materials, Apollo typically provides standard manufacturer coverage for B2B partners. Support includes:

– Technical documentation and manuals

– Access to spare parts network

– Training materials for service technicians

– Support hotline for dealer assistance

4. What are the compliance and certification requirements?

Key compliance aspects:

– Emissions: 4-stroke engine typically meets EPA requirements for off-road recreational vehicles

– Safety Standards: Meets standard motorcycle safety requirements for off-road use

– Import Compliance: Suitable for USA and European markets with proper import documentation

Note: Specific certifications vary by region and application. Consult local regulations for commercial operations.

Illustrative Image (Source: Google Search)

5. What are the bulk purchasing and pricing considerations?

Minimum order quantities and volume pricing are available through direct manufacturer contact. Typical B2B pricing structure includes:

– Tiered pricing based on volume

– Seasonal promotional programs

– Warranty extension options

– Parts and accessories bundling

Contact Apollo directly for current B2B pricing and MOQ requirements.

6. What is the shipping and logistics footprint?

Shipping specifications:

– Packaged Dimensions: 57.5″ x 15″ x 29.5″

– Shipping Weight: 196 lbs per unit

– Pallet Configuration: Optimized for container shipping

– Lead Times: Standard production runs with seasonal planning recommended

Container efficiency: Multiple units per container with proper packing configuration.

Illustrative Image (Source: Google Search)

7. What maintenance requirements and parts availability should dealers expect?

Routine maintenance requirements:

– Regular oil changes (.24 gal capacity)

– Chain lubrication and adjustment

– Air filter cleaning/replacement

– Brake system inspection

Parts availability: Apollo maintains a comprehensive parts network with common components readily available, including engine parts, suspension components, and body panels.

8. What competitive advantages does the RFZ 140 offer in the B2B market?

Key competitive differentiators:

| Advantage | Benefit to Dealers |

|---|---|

| Heavy-duty frame construction | Durability reduces warranty claims |

| Adjustable rear suspension | Customer satisfaction and customization |

| Manual clutch transmission | Appeals to traditional off-road enthusiasts |

| Aggressive knobby tires | Ready-to-ride performance without upgrades |

| 13.5″ ground clearance | Superior off-road capability vs competitors |

The RFZ 140 balances performance, durability, and cost-effectiveness, making it suitable for rental operations, dealerships, and recreational businesses targeting intermediate riders.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for rfz 140

Strategic Sourcing Conclusion and Outlook for RFZ 140

The Apollo RFZ 140 (DBZ40) delivers a clear combination of capability and simplicity for mid-size off-road use. For fleet managers, rental operators, and larger dealers, its 140cc air-cooled single, 4-speed manual drivetrain, and 13.5-inch ground clearance enable predictable operations across variable terrain without the complexity and cost of higher-displacement models.

Key purchase drivers

| Attribute | RFZ 140 Insight |

|---|---|

| Engine & Power | 140cc, 11 HP, 4-stroke air-cooled; torque peak ~7,500 rpm for tractable off-road delivery |

| Drivetrain | 4-speed manual, kick start, chain final drive; robust and service-friendly |

| Chassis & Clearance | Double-beam steel frame; 13.5-inch clearance; 49.2-inch wheelbase; 168 lbs net |

| Fit | 32.5-inch seat height; broad youth-to-adult fitment for shared fleets |

| Controls | Telescopic forks (30.3 in) and rear mono shock (13.8 in, adjustable); hydraulic discs front/rear |

| Dimensions | 70 x 30.7 x 46 in; tire sizes 70/100-17 / 90/100-14 |

| Packaging | Shipping 57.5 x 15 x 29.5 in; gross weight 196 lbs |

Operational value

– Lower TCO vs. 250–450cc models due to simpler engine, smaller tires, and reduced insurance/maintenance burden.

– Strong rental suitability: low seat height with 17-inch front wheel supports mixed-skill rider groups.

– Durable suspension and frame mitigate trail damage and downtime.

Risk and compliance

– Confirm U.S./EU emissions/safety conformity and regional road-use limits before purchase.

– Build service parts buffer (filters, brake pads, chain/sprockets) to minimize downtime.

Illustrative Image (Source: Google Search)

Strategic outlook

Demand for mid-displacement trail bikes remains steady across entry-level clubs, rental fleets, and adventure learning programs. The RFZ 140’s design simplicity and fit-to-task capability position it as a dependable, cost-efficient option for multi-rider and rental fleets across the U.S. and Europe.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.