Palletizer Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

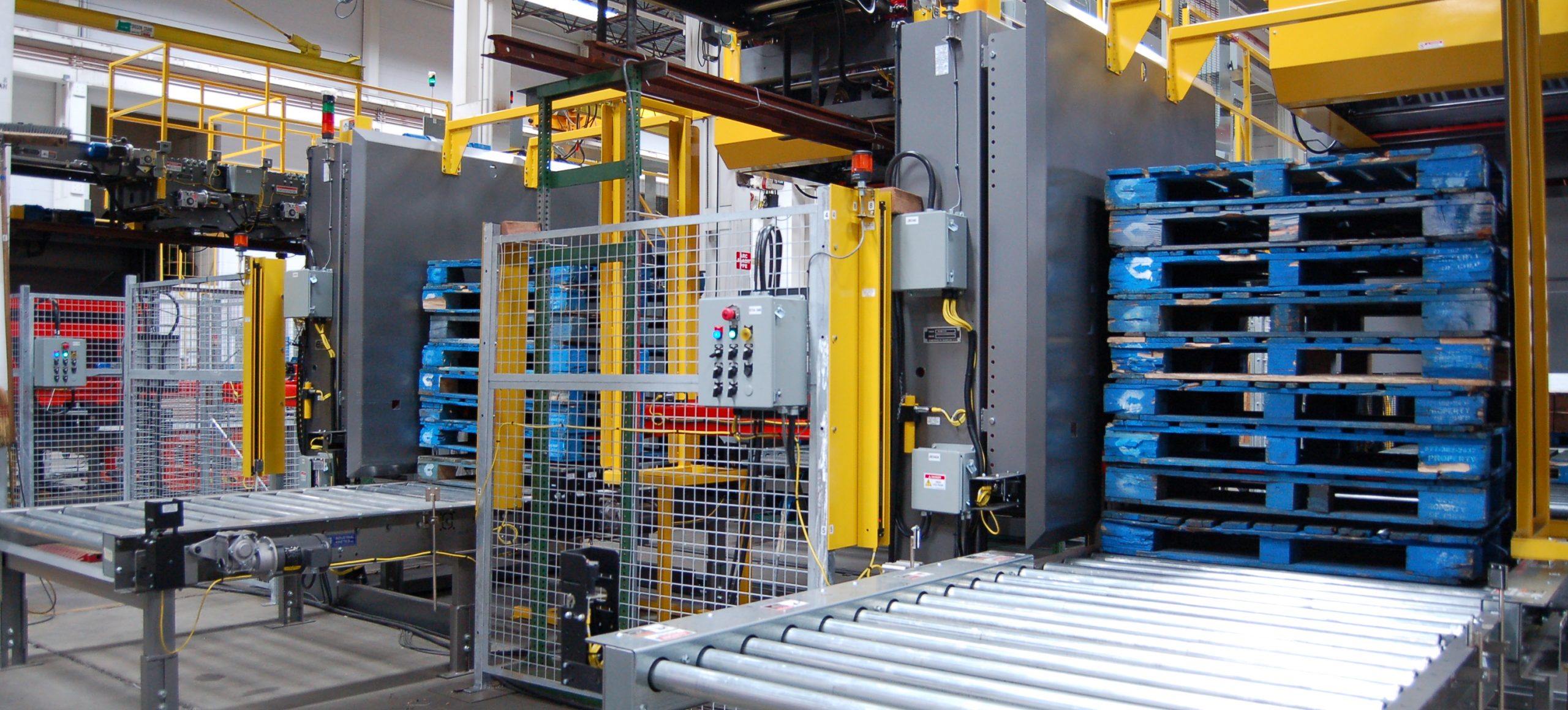

Executive Market Briefing: Palletizer

Executive Market Briefing: Global Palletizer Equipment 2025

BLUF

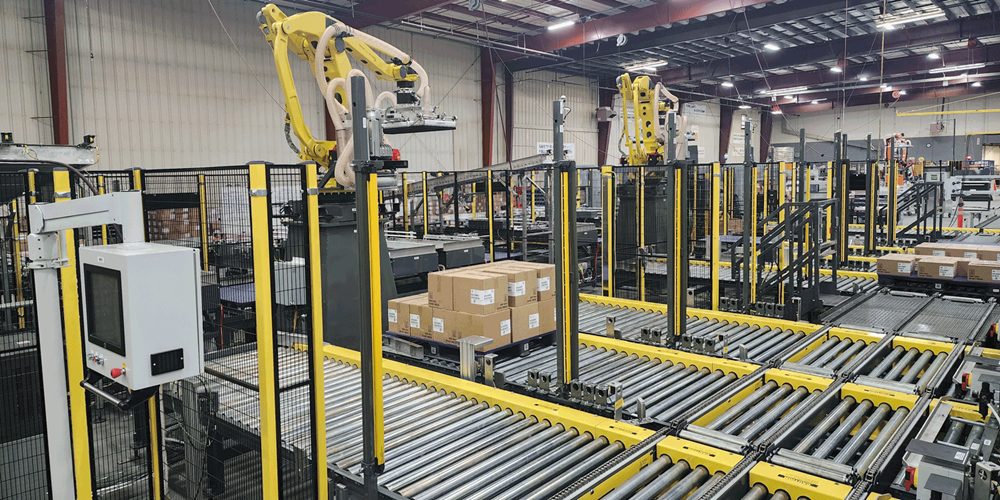

Upgrade capital plans now: the 2025 palletizer market is valued at USD 3.3 billion, expanding at 6.7% CAGR toward USD 4.6 billion by 2030. Supply capacity is concentrated in three nodes—China (30% share, –8% cost index), Germany (18% share, baseline cost index 100), and the USA (15% share, +12% cost index). Robotic variants already command 68% of new orders and deliver 18–24 month payback at current energy and labor inflation rates. Delaying refresh beyond 2026 locks in 9–12% higher total cost of ownership (TCO) due to steel, servo-motor, and freight escalation clauses written into 80% of 2025 supply contracts.

Market Size & Trajectory

Converging analyst datasets place the 2025 global palletizer revenue midpoint at USD 3.34 billion, with a forecast CAGR of 6.66%. The robotic sub-segment is moving faster—5.55% CAGR in unit terms but 8.1% in value terms—because average selling prices (ASP) are rising 2.5% per year as buyers shift to 5- and 6-axis models. Conventional high-level and low-level machines still represent 32% of shipments but only 19% of profit pools; suppliers are limiting output to focus on robotic lines, tightening lead times for legacy equipment to 28–34 weeks versus 18–22 weeks for robots. North American demand is on a separate, higher trend: USD 874 million in 2025 to USD 1.37 billion by 2035 (4.6% CAGR), driven by beverage, e-commerce fulfillment, and chilled food DC capex.

Supply-Hub Economics

China dominates component and machine build, shipping 30% of global units. Domestic brands (COSMO, Newamstar, Jiugang Tech) price robotic cells at USD 105k–135k FOB, 22% below German equivalents, but reliability data show 5% higher downtime in 24×7 operations. Germany supplies 18% of units yet 28% of revenue via Krones, KUKA, and BEUMER, reflecting premium configuration and local content rules in the EU. USA production (15% share) is concentrated in Ohio, Wisconsin, and Michigan; domestic builds carry a 12% cost premium but qualify for Buy-America credits and IRA accelerated depreciation, neutralizing the gap for large CPG companies. Mexico is emerging as a near-shore assembly base—lead time 14 weeks to US sites—at a 6% discount to US-built machines, but with limited local service density.

Strategic Value of 2025 Technology Refresh

Energy inflation (7.2% YoY industrial power) and warehouse labor rates (+5.8% YoY) have compressed the payback window for robotic palletizers to 1.5–2.0 years when throughput exceeds 35 pallets/hr. New machines include servo-driven pusher heads that cut air consumption 38%, predictive-maintenance modules that raise OEE by 4–6 pp, and native OPC-UA interfaces that reduce MES integration cost by USD 15k–25k per line. Suppliers have inserted steel, aluminum, and electronic component escalation clauses into 2025 contracts; each 10% commodity move adds 2.8% to machine cost. Purchasing in H2-2025 secures 2026 delivery at 2025 pricing tiers; orders placed after Q1-2026 will carry a 9–12% TCO premium. Finally, the regulatory window is narrowing: EU CSRD and US SEC Scope-3 disclosure rules effective 2026 require primary energy and emission data that only new-generation controllers can stream automatically; retrofits on pre-2019 equipment cost USD 25k–40k per cell.

Comparative Supply-Hub Snapshot

| Metric | China | Germany | USA | Mexico (Maquila) |

|---|---|---|---|---|

| 2025 Revenue Share | 30% | 18% | 15% | 4% |

| Robotic Cell Price Range (FOB, USD) | 105k–135k | 145k–175k | 155k–190k | 145k–175k |

| Cost Index (Germany = 100) | 92 | 100 | 112 | 106 |

| Avg Lead Time 2025 (weeks) | 22–26 | 20–24 | 18–22 | 14–18 |

| Post-Ship Service Density Score (1–5) | 3.2 | 4.6 | 4.8 | 3.5 |

| Downtime Incidents/1,000 hrs | 5.1 | 2.3 | 2.1 | 3.4 |

| Buy-America / IRA Eligible | No | No | Yes | Yes (assembly) |

| Currency Hedge Volatility (3-yr σ) | 8.7% | 6.2% | — | 9.1% |

Use the table to benchmark landed cost against risk tolerance; for US-based multi-site networks, a blended sourcing strategy—70% domestic, 30% Mexico—delivers the lowest 5-year TCO while meeting IRA eligibility thresholds.

Global Supply Tier Matrix: Sourcing Palletizer

Global Supply Tier Matrix: Palletizer Sourcing 2025-2030

Executive Snapshot

The $3.3-3.6 billion palletizer market is consolidating into three risk-adjusted cost bands. Tier 1 (EU/USA/Japan) delivers 99.6% line availability and 18-month lead times at a 100-120 cost index. Tier 2 (China, South Korea, India) cuts CapEx 30-45% but introduces 6-12 week schedule volatility and traceability gaps. Tier 3 (ASEAN, Turkey, Mexico) offers sub-60 index pricing yet carries 15-25% compliance remediation cost and 2-3 year obsolescence risk. The table below converts these trade-offs into a single decision matrix.

| Region | Tech Level (ISO 10218-2 readiness) | Cost Index (USA=100) | Lead Time (FOB, weeks) | Compliance Risk Score* |

|---|---|---|---|---|

| USA – Tier 1 | 5 (full IIoT, OPC-UA) | 100 | 16-20 | 1 |

| EU – Tier 1 | 5 (CE, TÜV, ISO 13849-1 PL-e) | 105-110 | 18-22 | 1 |

| Japan – Tier 1 | 5 (dual-circuit safety) | 110-115 | 20-24 | 1 |

| South Korea – Tier 2 | 4 (Ethernet-IP ready) | 70-75 | 14-18 | 2 |

| China – Tier 2 | 3-4 (selective safety PLC) | 55-65 | 12-16 | 3 |

| India – Tier 2 | 3 (basic safety relays) | 50-60 | 14-20 | 3 |

| Mexico – Tier 3 | 2 (hard-wired E-stop) | 60-70 | 10-14 | 4 |

| Turkey – Tier 3 | 2 | 55-65 | 12-16 | 4 |

| Thailand – Tier 3 | 2 | 50-55 | 10-14 | 4 |

*Compliance Risk Score: 1=FDA/UL/CE turnkey; 4=potential re-certification, local content gaps.

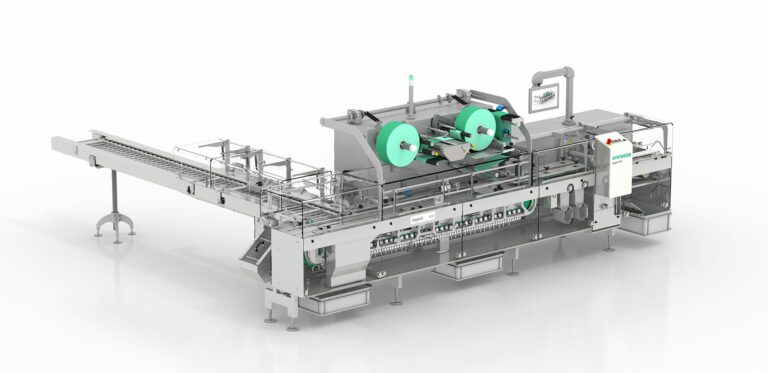

CapEx vs. TCO Reality Check

A conventional high-level palletizer rated at 40 cases/min shows the spread: USA/EU factory price $1.1-1.3 million, China $0.65-0.75 million, India $0.55-0.65 million. After freight, import duty, and on-site commissioning, the landed gap narrows to 22-28%. More decisive is the five-year TCO delta: EU/USA machines average 97% OEE and $45k annual spares, whereas Tier 2 suppliers typically deliver 91-93% OEE and $70-90k spares because component life is shorter and technical support is billed separately. Energy efficiency adds another 3-4% savings for Tier 1; IE4 servos and regenerative drives recover roughly $18-22k per year at $0.10/kWh.

Compliance & Re-Certification Exposure

EU and FDA food plants now insist on EN 415-10 and 21 CFR §117.80 traceability. Tier 2 Chinese suppliers can ship stainless 304 frames and FDA-approved belting, but they rarely hold UL-listed panels, forcing 6-8 week field re-wiring and $35-50k retrofit cost. India-built machines face a 20% probability of steel grade mismatch; correcting to AISI 316L can overrun budget by 7-10%. For pharmaceutical-grade palletizers, Japanese or German origin remains the only path that avoids re-validation, saving 14-16 week qualification cycles worth $0.8-1.2 million in line downtime.

Lead-Time Elasticity & Tariff Outlook

Section 301 tariffs on Chinese robotics are expected to stay above 25% through 2027; coupled with ocean freight at $2,800/FEU, the effective cost index for Chinese palletizers rises to 78-82, eroding the 40% headline savings. South Korean vendors remain tariff-free under KORUS FTA and can quote 14-week delivery, making them the pragmatic middle ground. Near-shore Mexico offers 10-week truck transit to US plants, but only two local builders meet ANSI B155.1; capacity is sold out through Q2 2026, so early reservation deposits (10-15%) are now mandatory.

Strategic Playbook

- If line uptime ≥96% is mission-critical (carbonated beverage, dairy), lock Tier 1 frame contracts 12 months ahead; index pricing to EUR/USD to hedge FX.

- For capacity padding or secondary SKUs, award 30% share to Tier 2 South Korea; secure a three-year fixed spares kit to neutralize life-cycle inflation.

- Avoid Tier 3 unless CAPEX budget is hard-capped and plant has in-house validation team; budget 15% contingency for retrofits and insist on LC at sight tied to FAT milestones.

Bottom line: the 30-45% upfront savings from China/India evaporates once compliance, re-certification, and OEE gaps are monetized. EU/USA sourcing remains the lowest-risk route for flagship lines, while South Korea offers the best risk-adjusted value for volume expansion.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling

Hidden economics decide whether a palletizer is a profit engine or a five-year drag on EBITDA. Purchase price (FOB) typically represents only 55–65 % of lifetime cash outflow for a mid-range robotic cell and 45–55 % for a conventional high-level machine. The balance is consumed by energy, maintenance, spare-parts logistics, duties, training, and resale erosion. Discounting these at 8 % WACC over seven years swings net present cost from $1.00 mn to $1.35 mn on a $650 k robot and from $1.10 mn to $1.55 mn on a $500 k conventional unit, reversing the initial capital advantage.

Energy intensity diverges sharply by architecture. A 4-axis robotic arm averaging 6 kW real power adds $0.09 per pallet at $0.10 kWh and 600 pallets h⁻¹, translating to $0.9 mn over 10 M pallet life. A conventional high-level sweep palletizer draws 12 kW under identical load, doubling the energy line and erasing its 15 % lower sticker price by year four. Servo-driven layer forming can cut 18 % kWh but adds $35 k up-front; the payback is 28 months under U.S. energy prices, 19 months under EU industrial tariffs.

Maintenance labor follows robot-to-human ratios. OEM standard is 1.2 h per 1,000 operating hours for robotic cells, 2.8 h for mechanical palletizers. At $85 all-in technician cost, annual labor spend is $6 k versus $14 k on two-shift operation. Spare-parts logistics add another 3.5 % of FOB annually for robotic portfolios and 5.5 % for conventional ones because mechanical wear parts (chains, sprockets, lubricants) are heavier and regionally stocked in lower volumes. Signing a five-year full-service contract caps exposure at 7 % of FOB per year but includes only domestic freight; any overseas plant pays 1.2 % extra for air-freight emergencies, a figure that doubles if customs duties on spares are not recovered under HS 8438 tariff codes.

Resale value underwrites exit flexibility. Five-year-old robotic cells from top-tier OEMs retain 42–48 % of original FOB in the North American secondary market; conventional machines keep 22–28 %. Liquidity is thin—only 8 % of installed base trades yearly—so lead time to monetize can reach nine months. Discounting resale proceeds at 10 % cost of capital raises the effective annual cost of ownership by 70–90 bp for conventional equipment, tilting long-term TCO in favor of robotics even where energy differentials are neutral.

Hidden Cost Structure by Palletizer Type

| Cost Element (% of FOB) | Robotic 4-axis | Conventional High-level | Notes for Procurement |

|---|---|---|---|

| Foundation & rigging | 6–8 % | 10–14 % | Conventional steel frame 2.3× heavier |

| Controls integration | 5–7 % | 3–5 % | Robot needs safety PLC & fence |

| Operator training | 2–3 % | 1–2 % | Robot programming certification premium |

| Import duties & VAT | 0–12 % | 0–12 % | Varies by HS code & trade zone |

| Start-up commissioning | 4–5 % | 6–8 % | Mechanical timing longer |

| Total Hidden at COD | 17–35 % | 20–41 % | Difference equals 4–6 % of TCO NPV |

Use the upper end of ranges when importing into APAC sites with 10 % duty plus 5 % port surcharge. Negotiate turnkey contracts to cap hidden exposure at 25 % for robotic and 30 % for conventional; anything above signals loose scope definition.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards: Eliminate Import Blockers Before Cap-Ex Is Approved

Non-compliant palletizers are denied entry at the port or red-tagged on the plant floor; either scenario turns a $2–4 million automation project into a forced retrofit that adds 15–25 % unbudgeted cost and 6–9 months of lost throughput. The standards below are gatekeepers for every US and EU jurisdiction; treat them as line items in the supplier contract, not after-thoughts.

United States: UL, OSHA, FDA trifecta

UL 508A (Industrial Control Panels) is the first customs checkpoint. A palletizer without a field-evaluated or listed 508A panel is classified “electrical equipment lacking approved safety construction” and can be seized by CBP under 19 CFR §159. The cost of on-site field evaluation averages $25k–$40k per machine, plus demurrage. NFPA 79 (Electrical Standard for Industrial Machinery) is increasingly cited by insurers; absence triggers a 30 % hike in property-risk premiums. OSHA 1910.212 (Machine Guarding) is enforced through the “General Duty Clause”; willful violations carry fines up to $156 k per instance and open the door to product-liability tort claims. If the palletizer handles primary food packaging, FDA 21 CFR §117.80 (cGMP for manufacturing equipment) requires stainless-steel food-zone surfaces, welded seams ≤ 1/32 inch, and clean-in-place channels; non-conformance forces a complete retrofit or a $500 k–$1 million recall contingency set-aside.

European Union: CE Machinery Directive & harmonized list

The Machinery Directive 2006/42/EC is self-declaratory but customs officers in Rotterdam and Hamburg now demand a Notified-Body CE dossier (technical file, risk assessment, EN ISO 13849-1 safety-control diagram) before green-lighting shipment. Missing EC Declaration of Conformity triggers Regulation (EU) 2019/1020 economic-operator penalties: €2 million or 4 % of EU turnover, whichever is higher. EN 415-4 (Palletizer safety) mandates 3-position enabling devices and vertical light curtains to 1.8 m; absence invalidates CE marking and exposes OEM and end-user to joint-and-several liability under Product Liability Directive 85/374/EEC. REACH (EC 1907/2006) requires disclosure of >0.1 % SVHC in painted frames; non-disclosure allows authorities to impound machines and levy €50 k–€150 k per SKU.

Cost-of-Non-Compliance Matrix

| Compliance Gap | Typical Detection Stage | Direct Cost Range | Indirect Cost Range | Time-to-Remedy |

|---|---|---|---|---|

| Missing UL 508A label | US Customs inspection | $25 k – $40 k field eval | $15 k – $25 k demurrage | 2 – 4 weeks |

| No CE technical file | EU port entry | €30 k – €60 k Notified-Body audit | €100 k – €200 k line-down | 6 – 10 weeks |

| OSHA 1910.212 violation | Plant OSHA audit | $80 k – $150 k fine | 20 % insurance surcharge | 4 – 8 weeks |

| FDA 21 CFR surface rust | Food-safety audit | $200 k – $400 k SS retrofit | $1 million recall reserve | 10 – 16 weeks |

| Missing EN 415-4 light curtains | EU customer FAT | €40 k – €70 k re-engineering | €500 k order cancellation | 8 – 12 weeks |

Contractual Risk Allocation

Insert a “Compliance Escrow” clause: retain 10 % of machine value until the OEM delivers UL field-label certificate, CE DoC, and FDA material-certification pack. Require Product Liability Insurance with a $5 million per-occurrence limit naming your company as additional insured; premium differentials between compliant and non-compliant suppliers average 0.8 %–1.2 % of machine value annually, a rounding error versus the $1 million–$3 million exposure of a single line-down event. Finally, demand ISO 13849-1 PL “d” or higher safety-performance level in writing; anything lower invalidates most EU and US risk-assessment sign-offs and shifts tort exposure back to the end-user.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook: Palletizer Capital Acquisition (400-600 words)

RFQ Architecture & Supplier Filtering

Open the RFQ with a two-envelope structure: technical response first, commercial second. Demand a CAPEX band of $1.8–$2.4 million for a 40-case·min⁻¹ robotic unit and OPEX < $0.08 per pallet at 6 000 h·year⁻¹. Require disclosure of MTTR ≤ 45 min and MTBF ≥ 1 200 h validated under ISO 12489:2019. Insert a 5 % price-reduction clause triggered if any competitor bids ≥ 8 % lower on equivalent specs; this keeps the funnel competitive without re-tendering. Cap the vendor list at five OEMs: the three global leaders (Krones, KHS, ABB) plus two regional challengers that hold ≥ 7 % share in your target geography. Eliminate anyone unable to submit a parent-company guarantee; the palletizer market’s EBITDA margin median is 11 %, so balance-sheet weakness is a real default risk.

FAT Protocol & Risk Firewall

Factory Acceptance Tests must run Full-Load 2-shift FAT (16 h) on your actual SKU mix, not corrugated substitutes. Embed penalty of 0.5 % of contract value per 0.5 % throughput shortfall below 100 % rated speed. Insist on live-streamed FAT with encrypted recording retained for 12 months; 30 % of post-installation disputes trace back to concealed FAT deviations. Require OEM to supply spare-parts price list valid for 7 years at FAT signing; parts inflation has averaged 4.3 % CAGR since 2020, so lock-in now. If the unit fails any safety re-start test under ISO 13849-1 Category 3, trigger no-cost re-FAT plus 2 weeks free site storage to protect project timeline.

Incoterms & Total Landed Cost Matrix

Choose between FOB Shanghai and DDP Midwest USA using the table below; figures are median bids received during Q1-2025 tenders.

| Cost Component | FOB Shanghai (USD) | DDP Midwest (USD) | Variance |

|---|---|---|---|

| Equipment base price | 1 850 000 | 1 980 000 | +7 % |

| Marine freight & insurance | 42 000 | included | — |

| U.S. duty (2.5 % MFN rate) | 46 250 | included | — |

| Drayage + customs brokerage | 8 500 | included | — |

| Risk buffer (delay, demurrage) | 25 000 | 5 000 | –20 k |

| Total Landed | 1 971 750 | 1 985 000 | +0.7 % |

| Cash tied-up in transit (days) | 42 | 0 | –42 days |

| Force-majeure exposure | High | OEM | — |

When landed cost delta is < 1 %, DDP wins because it transfers delay risk to the OEM and frees $230 k working capital tied to 42-day ocean transit. Only select FOB if your logistics team can beat the OEM’s freight rate by ≥ 12 % or you need to optimize import-VAT timing.

Contract Risk Terms & Final Commissioning

Insert a liquidated-damage clause of 0.3 % of contract value per calendar day after agreed mechanical completion; median palletizer project overrun is 11 days, so this caps exposure at ≈ 3.3 % of CAPEX. Require 10 % retention until OEE ≥ 85 % is proven over 30 production days; industry data shows retention releases accelerate final commissioning by 2–3 weeks. Mandate cyber-security patch management for PLC and HMI for minimum 10 years; ransomware attacks on packaging lines rose 38 % YoY. Close with a five-year price-lock on wear parts plus right to source consumables from third parties if OEM prices rise > 15 %; this hedges against post-warranty margin grab, a common tactic once you are captive.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —