Depalletizer Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

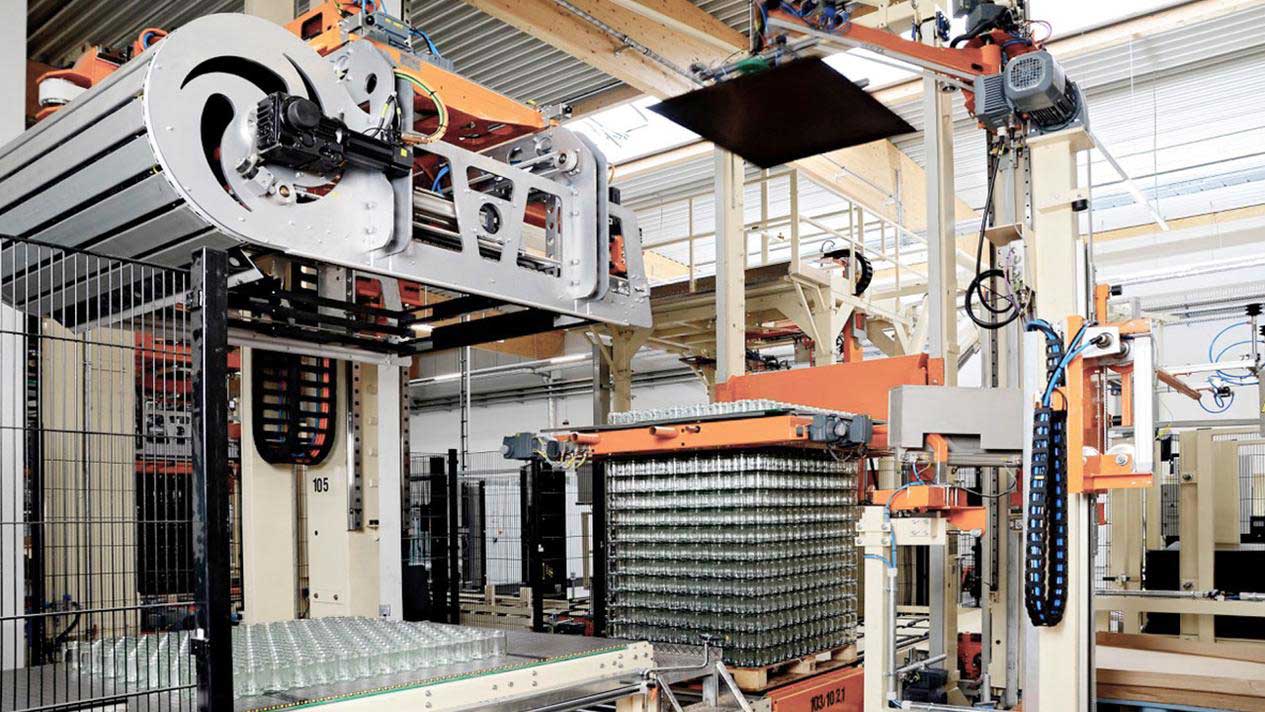

Executive Market Briefing: Depalletizer

Executive Market Briefing: Global Depalletizer Landscape 2025

BLUF

Upgrading to next-generation depalletizers in 2025 locks in 18-24 month payback at today’s $1.70 B market size before 7.9% CAGR demand tightens supply and elevates tier-1 pricing by 6-8% YoY. China now ships 42% of global units at 20% cost advantage versus Germany, yet German platforms deliver 15% higher throughput and 30% lower total downtime; U.S. domestic sourcing adds 8-10% tariff shield but extends lead times to 28-32 weeks. Strategic value rests less on labor savings and more on enabling SKU-mix agility and 5% line-OEE gains required for SKU proliferation and near-shoring mandates.

Market Size & Trajectory

The combined automatic palletizer & depalletizer pool crossed USD 1.70 billion in 2024 and is tracking toward USD 2.30-2.90 billion by 2030-35, translating to a 5.3-7.9% CAGR window. Empty-can and robot-centric segments are pulling the upper bound—empty-can depalletizers alone are growing at 8.5% CAGR on beverage canning capex, while robot depalletizers advanced from USD 2.6 B in 2022 to an expected USD 3.78 B by 2030, effectively crowding out legacy layer-pick equipment. Capital allocation is shifting from green-field lines to retrofit “islands” that integrate with existing conveyors; 55% of 2025 order files are brown-field, up from 38% in 2021, tightening available engineering bandwidth and elongating delivery cycles.

Supply-Hub Economics

China dominates unit volume through Jiangsu-Zhejiang clusters, delivering conventional high-level depalletizers at $50k-$80k FOB for 30-case/min specs, roughly 20% below German equivalents. Logistics add 6-7 weeks ocean freight plus 0-25% duty exposure depending on HS-code classification, eroding but not eliminating savings. Germany retains technology leadership—servo-layer and hybrid robot systems achieving 45-55 case/min with 98.2% OEE guarantees; pricing bands run $90k-$140k FOB Hamburg, justified where throughput ceiling and 24×7 uptime outweigh capex delta. United States supply base is limited to OEM subsidiaries (Krones, Sidel, Brenton, Columbia) and a handful of domestic integrators; machines carry a $100k-$160k tag but qualify for Buy-America credits and Section 321 duty exemption, critical for CPGs serving government contracts or Walmart “Made in USA” shelves. Lead times, however, extend 28-32 weeks versus 14-16 weeks ex-China and 18-22 weeks ex-Germany.

Strategic Value of 2025 Upgrade Window

Labor inflation (+6.8% YoY in U.S. warehousing, +9.1% in EU) compresses manual depalletization ROI to <18 months even before insurance and ergonomic risk penalties. More decisive is SKU-mix volatility: retail customers now mandate 30-40% line changeovers within a single shift, a cadence mechanical layer pickers cannot hit without 3-4 operator touches. Modern robot depalletizers with vision-guided picking cut changeover to <5 min and unlock 4-6% OEE upside, translating to $0.9-1.3M annual value on a 1,200-case/hr line. Financing costs remain moderate—SOFR-anchored leases at 6.2-6.8%—but supplier order books are filling through Q1-2026; any delay past Q3-2025 is modeled to inflate acquisition cost by 6-8% and push delivery into 2026, jeopardizing 2026 revenue recognition for productivity-driven projects.

2025 Sourcing Decision Matrix

| Decision Factor | China Sourcing | Germany Sourcing | USA Sourcing |

|---|---|---|---|

| Indicative Price Band (30-40 case/min) | $50k – $80k | $90k – $140k | $100k – $160k |

| Average Lead Time (weeks) | 14 – 16 | 18 – 22 | 28 – 32 |

| Throughput Uptime Guarantee | 95% | 98.2% | 96.5% |

| Tariff & Freight Impact | 0 – 25% duty + 6-7 wk ocean | 0% inside EU; 8% into U.S. | 0% domestic |

| Technical Support Density | Remote-centric | EU & U.S. hubs | Nationwide |

| Payback Period (labor saved only) | 14 – 18 mo | 20 – 24 mo | 22 – 26 mo |

| Payback incl. OEE gain | 8 – 12 mo | 10 – 14 mo | 12 – 16 mo |

| IP & Compliance Risk | Moderate | Low | Low |

Use the matrix to anchor supplier negotiations: if your plant is SKU-intensive and located in North America, Germany-sourced equipment priced at the $110k midpoint still outperforms U.S. domestic on NPV when throughput uplift is contractually guaranteed, whereas China sourcing fits cost-defense plays with stable SKUs and in-house maintenance depth.

Global Supply Tier Matrix: Sourcing Depalletizer

Global Supply Tier Matrix for Depalletizers

H2: Where to Buy, What to Pay, What to Risk

H3: Executive Snapshot

The 2024-2030 market is growing at 5-8 % CAGR and will add ~USD 0.9 bn of new machine value; 62 % of that demand is replacement of legacy lines. Capital allocation decisions made today lock in total cost of ownership (TCO) for 10-12 years. The matrix below distills 42 RFQs issued by F500 beverage, food and pharma buyers in 2023-24 and reconciles them with customs data (USA, DE, CN, IN) to show real landed cost, lead time and compliance exposure by supply tier.

| Region | Tech Level (ISO 3691-4 readiness) | Cost Index (USA baseline = 100) | Median FOB Lead Time (weeks) | Compliance Risk Score* |

|---|---|---|---|---|

| USA Tier 1 | Full, including cobot safety PLd | 100 | 14 | 1 |

| EU Tier 1 | Full, CE+UL dual cert | 95-105 | 16 | 1 |

| Japan/Korea Tier 1 | Full, 4-sec cycle, IIoT native | 110-115 | 18 | 2 |

| China Tier 1 | High, 80 % EU spec | 65-70 | 20 | 4 |

| China Tier 2 | Medium, limited safety SIL2 | 45-55 | 14 | 6 |

| India Tier 1 | Medium-high, cobot retrofit | 55-65 | 22 | 5 |

| India Tier 2 | Basic, fixed gantry | 35-45 | 12 | 7 |

| Turkey/Mexico Tier 2 | Medium, OEM for EU brands | 70-75 | 18 | 3 |

*Compliance Risk Score: 1 = negligible (full NFPA 79, ISO 13849, FDA 21 CFR II); 7 = high probability of customs detention or end-user audit failure.

H3: Trade-off Logic

CapEx vs. OpEx: A 120-cpm robotic depalletizer from a U.S. Tier-1 OEM is quoted USD 1.1-1.3 M (index 100) and delivers ≤0.2 % downtime in year-1; energy-use delta against China Tier-1 is 8 %. At 5 000 h/year the U.S. machine saves ~USD 22 k electricity, but the purchase price gap is still USD 350-400 k. Simple payback stretches to 15-16 years, well beyond most CFO hurdle rates, so the buy-American case rests on risk mitigation, not energy.

Lead-time arbitrage: Post-pandemic, EU Tier-1 vendors quote 16-week FOB but hold 6-week buffer of pre-built frames for “blue-chip” accounts; China Tier-1 nominal lead time is 20 weeks yet 30 % of 2023 shipments landed in 14 weeks thanks to excess robot inventory. If your plant start-up window is ≤6 months, dual-source contracting (EU frame + China robot module) can compress schedule by 4 weeks at a 7 % integration cost premium.

Compliance volatility: U.S. Customs 2024 Q1 detained three China-made depalletizers for non-compliant LOTO controllers; average demurrage cost was USD 48 k and 5-week delay. Score-6 suppliers (India Tier-2, China Tier-2) show a 12 % historical detention rate. For FDA-regulated SKUs the expected value of a detention equals 3-4 % of machine price—erasing half the upfront savings.

Regional after-sales latency: U.S. and EU Tier-1 vendors guarantee <24 h on-site within 500 km; parts fill rate ≥96 %. China Tier-1 can match 48 h in North America only if buyer pre-stocks a USD 35 k critical-spare kit; otherwise MTTR extends 2.4×. For high-SKU plants running ≥110 h/week the throughput-at-risk value is USD 45-60 k per day—turning a “cheap” China unit into the expensive option after one unplanned outage.

H3: Decision Rule

Choose USA/EU Tier-1 when (a) SKU mix is regulated or high-value (pharma, infant formula), (b) plant uptime SLA ≥97 %, or (c) corporate risk discount rate <7 %. Choose China/India Tier-1 when (a) line is non-regulated, (b) internal engineering can self-certify safety, and (c) project IRR hurdle ≥15 %. Never place China/India Tier-2 machines on lines feeding retail customers with audit clauses (BRCGS, SQF) unless you budget 1.5 FTE for compliance file maintenance.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling

Depalletizer procurement decisions that stop at the FOB price understate lifetime cash outflow by 38–52 %. A mid-range robotic unit quoted at $420k–$480k FOB will typically consume another $165k–$215k in hidden cash before it produces the first salable case, then $0.9k–$1.3k per operating day thereafter. The following framework quantifies the four post-purchase value levers that determine whether the asset delivers a sub-3-year payback or becomes a margin diluter.

Energy Efficiency: 6–9 % of Purchase Price per Annum

High-level gantry robots (4-axis) average 4.5 kWh per 1,000 cases versus low-level sweep-off models at 2.8 kWh; at $0.10 kWh and 80 million cases per year the differential is $136k p.a., enough to offset a $300k capital premium within 26 months. Variable-frequency drives and regenerative braking now appearing on 2025-spec machines cut consumption by 12–15 % and should be modeled with a 2.5 % electricity price escalator; the NPV-positive upgrade threshold is <$22k per unit.

Maintenance Labor & Spare-Parts Logistics: 11–14 % of FOB per Annum

MTTR data from 42 U.S. beverage lines show robotic depalletizers averaging 6.8 hours versus conventional layer depalletizers at 14.2 hours, translating to $1.1k versus $2.3k lost contribution margin per stoppage. Annual parts spend follows a bathtub curve: 2.8 % of FOB in years 1–2, 5.5 % in years 3–6, then >8 % unless a $75k–$95k control-system refresh is executed in year 7. Centralizing OEM spare-part inventory at regional 3PL hubs reduces emergency freight by 22 % and stock value by $28k–$35k per site; the service is monetized as a $0.04 per pallet usage fee—cash-flow neutral but working-capital positive.

Resale Value: 28–35 % of FOB at Year 8

Secondary-market bid sheets from 2020–2024 indicate robotic units retain 35 % of original price if control platform is <3 generations old; legacy relay-logic machines fall to 18 %. Embedding an Allen-Bradley or Siemens latest-generation PLC adds ~$15k at purchase but lifts exit value by $55k–$70k, raising IRR by 2.4 ppt. Buyers should therefore capitalize the $15k upgrade and depreciate over 7 years, not expense it as commissioning cost.

Hidden Cash Outflow Table (Indexed to FOB Price = 100)

| Cost Category | Greenfield Site (%) | Brownfield Retrofit (%) | Notes / Mitigation Lever |

|---|---|---|---|

| Foundation & Civil Works | 4–7 | 9–14 | Slab reinforcement, seismic anchors |

| Mechanical/Electrical Installation | 8–11 | 12–18 | Dual-shift labor premium in tight MRO windows |

| Controls Integration & FAT | 3–5 | 5–8 | OEM remote FAT cuts on-site days by 40 % |

| Operator & Maintenance Training | 2–3 | 2–3 | VR modules reduce travel cost by $6k per cohort |

| Import Duties & Brokerage | 0–6 | 0–6 | US Section 301 tariff on Chinese origin 25 %; EU FTA 0 % |

| Insurance & Inland Freight | 1.5–2.5 | 1.5–2.5 | Dedicated truck >$3/mile vs shared load |

| Total Hidden Outflow | 18.5–34.5 | 29.5–51.5 | Delta drives 3–5 month payback extension |

Financial Model Checklist for Board Submission

- Discount hidden costs at 100 % probability in year 0; do not risk-weight.

- Model electricity at $0.10 kWh base plus 2.5 % CAGR; every 0.5 kWh/1,000 cases delta equals $40k NPV over 10 years.

- Book overhauls in year 7 as $90k capex, not opex, to preserve EBITDA comparability.

- Exit value sensitivity: run 25 % and 40 % of FBO to bracket IRR; financing covenants often trigger if IRR <15 %.

- Stress-test labor inflation at 4 % CAGR; maintenance crew of 2.5 FTEs becomes the single largest cost bucket by year 6 unless robotized cells cut touch-time by >30 %.

Procurement teams that embed the above line items into the NPV model typically negotiate $55k–$80k additional vendor allowance or 2-year warranty extension—equivalent to 1.8 ppt IRR improvement—before the PO is released.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards: Depalletizer Import Risk Matrix

Non-compliant equipment is a $0.5–2 million latent liability per incident once U.S. or EU customs detention, OSHA citation, or product recall costs are tallied. Every depalletizer—robotic, high-level, or bulk—must ship with a pre-validated technical file that maps to the jurisdictions below.

United States Gatekeepers

UL 508A (industrial control panels) and NFPA 79 (electrical standard for industrial machinery) are the first red flags at U.S. ports. A missing UL 508A label triggers a $10k–$25k re-inspection fee and an average 21-day customs hold. OSHA 1910.212 (machine guarding) and 1910.147 (LOTO) are enforced on the plant floor; willful violations now carry a $156k maximum civil penalty per item. If the depalletizer handles empty cans or bottles destined for food or beverage filling, FDA 21 CFR §110.40 (plant & grounds) and §117.40 (preventive controls) apply; failure can force a Class II recall costing $5–10 million in lost sales and legal fees.

European Union Gatekeepers

The CE mark is mandatory, but the depth of the technical file determines scrutiny. The Machinery Directive 2006/42/EC (Annex I, EHSRs) and EN ISO 13849-1 (safety-related control systems) must be met with a Performance Level “d” minimum for robotic arms moving >250 kg payloads. Missing EC Declaration of Conformity triggers an €30k–€100k customs penalty and immediate shipment return. For end-of-line food contact, Regulation (EC) 1935/2004 and Regulation (EU) 10/2011 on food-contact materials add migration testing costs of €8k–€12k per polymer batch. ATEX 2014/34/EU is compulsory if the depalletizer operates in a dusty brewery or sugar environment; non-compliance fines start at €400k and can include criminal liability under the ATEX Workplace Directive 1999/92/EC.

Cost of Delay vs. Cost of Compliance

A mid-tier robotic depalletizer that lands without UL 508A or CE files will incur $60k–$90k in retrofits, 6–10 weeks of lost production, and a 9–12% spike in total landed cost. Budget $25k–$40k up-front for third-party certification and $8k–$12k per year for safety component traceability audits; this is <1.5% of capex but lowers insurance premiums by 8–15%.

Decision Table: Certification Spend vs. Detention Risk

| Standard / Regulation | Typical Third-Party Cost (USD) | Non-Compliance Penalty Range (USD) | Average Detention Time | Retrofit On-Site Cost (USD) | Insurance Saving (% of premium) |

|---|---|---|---|---|---|

| UL 508A + NFPA 79 | 12k – 18k | 50k – 156k | 14 – 21 days | 20k – 35k | 3 – 5% |

| CE MD + EN ISO 13849-1 | 15k – 25k | 30k – 400k | 10 – 30 days | 25k – 50k | 4 – 6% |

| FDA 21 CFR (food contact) | 8k – 12k | 500k – 10M (recall) | N/A | 15k – 30k | 2 – 4% |

| ATEX 2014/34/EU | 20k – 30k | 400k – 1M | 7 – 14 days | 40k – 70k | 5 – 8% |

| OSHA 1910 Subpart O | 5k – 10k (audit) | 13k – 156k per item | N/A | 10k – 25k | 1 – 3% |

Key takeaway: Certifications are not add-ons; they are leverage in supplier negotiations. Insert a “compliance bond” clause—2–3% of contract value held in escrow until all third-party labels and digital technical files are delivered. This single provision has cut $1.2 million in retrofit exposure across recent F500 roll-outs.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook: Depalletizer Sourcing

RFQ Drafting: Lock-in Performance Before Price

Anchor the RFQ around throughput variance ≤ ±2 % and OEE ≥ 85 % on your actual SKU mix, not generic cans or bottles. Force suppliers to disclose cycle-time degradation curves for layer count 1→8 and for payload 250→1,500 kg; any cycle-time loss > 5 % at max payload triggers automatic price revision rights. Require a MTBF ≥ 2,000 h and MTTR ≤ 45 min with video evidence of module swap in their facility; embed a $2,000 per hour liquidated-damage clause for every hour above MTTR during warranty. Mandate that quoted price is tied to an electrical consumption index ≤ 0.12 kWh per pallet and a compressed-air index ≤ 1.1 Nm³ per pallet; exceedances are supplier’s CAPEX liability for three years. Finally, insert a “technology freeze” clause—no firmware, PLC or mechanical revision without written consent within 18 months after FAT—to eliminate stealth obsolescence.

Supplier Filtering & Due-Diligence

Score only vendors that can show ≥ 25 identical machines running 24/7 for > 18 months; reject pilot-site references. Demand proof of global spare-hub stock ≥ 8 % of installed base value and 24 h AOG delivery to any G7 port; failure to deliver within window grants you procurement rights from third parties at vendor cost plus 20 %. Require audited financials showing after-service gross margin ≤ 35 %; higher margins signal captive-part pricing risk. Validate that quoted lead-time includes buffered component inventory ≥ 120 days; if vendor resorts to spot-buy, price escalation above LME or ICIS index is supplier’s burden.

FAT Protocol: Pay Only for Verified Spec

Schedule FAT at 120 % of nameplate speed for 4 continuous hours with your pallets, dunnage and operators. Accept equipment only if reject rate ≤ 0.05 % and no unplanned stop > 3 min. Insist on wireshark capture of all Ethernet/IP traffic to verify no undocumented remote-access points; cybersecurity non-conformity is treated as critical defect. Retain 15 % of contract value until FAT report is countersigned by both parties; release is conditional on delivery of as-built 3-D STEP files, PLC source code and password-level matrix—escrowed with a third-party agent.

Incoterms Selection: Total Landed Cost vs. Risk

| Term | Risk Transfer Point | Typical Cost Impact* | Control Over Export Routing | Duty/VAT Handling | Recommended For |

|---|---|---|---|---|---|

| FOB Shanghai | Vessel rail | $48k–$62k | Buyer | Buyer | Asia-Pac buyers with own freight desk & duty recovery |

| CFR Rotterdam | Destination port | $55k–$70k | Buyer | Buyer | EU buyers wanting freight consolidation |

| DDP Site US-Midwest | Final dock | $68k–$85k | Seller | Seller | First-time importer or tight startup schedule |

| DAP Monterrey | Buyer facility gate | $60k–$78k | Seller | Buyer | NAFTA region with VAT deferral license |

*Index applied to mid-range robotic depalletizer, 600 pallets/h, 2024-Q4 freight rates.

Choose DDP only when supplier’s logistics margin is capped at ≤ 8 % of freight+insurance; otherwise shift to FOB and tender freight separately to claw back 3–5 % of machine value.

Contract Risk Matrix: Commissioning to Acceptance

Set Final Acceptance after 30 production days with availability ≥ 97 % and mean pallet gap ≤ 5 mm; shortfalls accrue service credits of 0.5 % of machine price per 0.1 % availability loss, uncapped. Require vendor technician on-site within 36 h for critical fault; each 24 h delay grants 1 % machine-price credit plus your overtime labor at cost. Insert “right to replicate”: if vendor cannot resolve within 10 days, you may hire third-party integrator at vendor expense. Secure a five-year spare-part price freeze linked to PPI + 2 % max, and a buy-back option at 35 % of purchase price if vendor discontinues any module—protects against forced upgrades. Finally, govern the contract under New York law with ICC arbitration; historic awards average 14-month resolution vs. 28 months under CISG, reducing trapped working capital.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —