Food Packaging Machine Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

Executive Market Briefing: Food Packaging Machine

Executive Market Briefing – Food Packaging Machines 2025

BLUF

Upgrading packaging lines in 2025 locks in 7-8% CAGR cost avoidance and 15-20% OPEX reduction before the next capacity-constrained cycle; China supplies 42% of global unit volume at 30-40% lower CAPEX, Germany delivers <1% downtime technology at a 45-55% premium, and the USA adds IoT compliance for 5-7% extra. Post-2026, lead-times stretch 9-12 months and carbon-border tariffs tighten, erasing today’s 8-10% TCO advantage of Asian entry-level machines.

Market Scale & Trajectory

The food-packaging machinery segment exited 2024 at USD 22-23.7 billion and is tracking USD 28.9-48 billion by 2030-35, implying a 7.3% CAGR (consensus band 4.1-7.3%). Volume growth is front-loaded: 2025-27 adds roughly USD 4 billion incremental demand, 60% from ready-meal, protein and bakery lines. Replacement cycles compressed from 10 to 7 years as servo-drives and IIoT modules cut change-over time 25-40%, making legacy lines economically obsolete even when mechanically sound.

Supply-Hub Economics

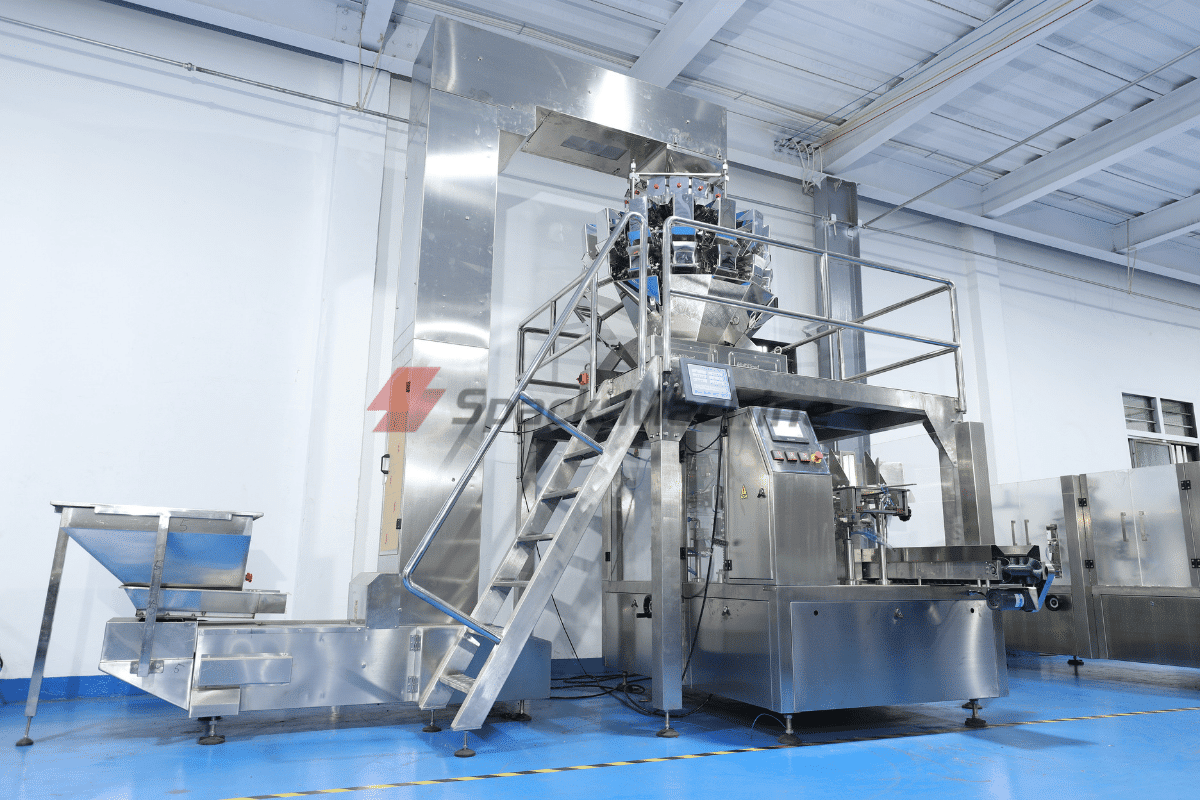

China ships >160k units/year, dominates form-fill-seal and vertical baggers below 120 ppm, and quotes USD 50k-80k for a 60 ppm servo-driven VFFS, 30-40% below EU builders. Domestic component share now exceeds 80%, insulating buyers from FX swings; however, average availability is 85-88% and field service density outside Asia is 0.3 engineers per 100 machines, translating into 3-4% higher downtime cost in NA/EU plants.

Germany produces 22k high-end units/year, focuses on >200 ppm rotary machines, thermoformers and aseptic lines, and prices at USD 0.9m-1.4m for a 400 ppm thermoformer. MTBF >20kh and 95% OEE create a <1% scrap rate, critical for high-value protein and cheese where giveaway costs >USD 1m/year on a 200t line.

USA output is 14k units, skewed toward flexible, wash-down IP69K systems for protein and dairy. Domestic suppliers embed OPC-UA and PackML as standard, easing FDA digital-submission pathways; typical premium over EU is 5-7% but offsets USD 0.4m-0.6m in validation cost for large CPGs.

Strategic Value of 2025 Upgrade Window

- Technology delta: Servo motion + AI vision delivers 8-12% film savings and 2-3% throughput gain, worth USD 0.7m-1.1m/year on a 1bn-unit snack line.

- Capital timing: Component inflation (stainless +9%, servos +7%) is not yet fully passed through; OEM order books at 4.5 months vs 7.5 months expected Q4-25. Early commitment secures 3-5% price shield and Q2-26 slots.

- Regulatory hedge: EU CSRD and US SEC climate disclosures require primary energy data; new machines embed energy meters that cut data-collection cost 60% and avoid retrofit penalties estimated at USD 40k-60k/line.

- Resale value: 2025-spec machines with full digital twins retain 55-60% of invoice price after 36 months vs 35-40% for 2022 analogues, tightening lease cost of capital.

2025 Supply-Hub Decision Matrix

| Metric | China Tier-1 | Germany Tier-1 | USA Tier-1 |

|---|---|---|---|

| Typical VFFS 120 ppm CAPEX (USD, FOB) | 50k – 80k | 110k – 150k | 120k – 160k |

| TCO index (5 yrs, EU plant, 2-shift) | 100 | 92 | 96 |

| Lead-time today (weeks) | 10 – 14 | 20 – 26 | 18 – 24 |

| Forecast lead-time Q4-25 (weeks) | 14 – 18 | 24 – 32 | 22 – 30 |

| Availability (%) | 85 – 88 | 93 – 95 | 91 – 94 |

| Downtime cost premium vs German base | +4% | 0 | +1.5% |

| Carbon intensity (t CO₂e/machine) | 8 – 10 | 5 – 6 | 6 – 7 |

| Tariff exposure into EU (%) | 12 – 15 | 0 | 0 |

| After-sales engineer density (per 100 machines globally) | 0.3 | 2.1 | 1.4 |

| Technology modules (IIoT, AI vision) | Optional | Standard | Standard |

| Residual value at 36 months (%) | 35 – 40 | 55 – 60 | 50 – 55 |

Action for 2025 Budget Cycle

Secure 60% of forecast line requirement by Q3-25, split between one German flagship line for high-margin SKUs and Chinese volume assets for 12-18 month payback SKUs; negotiate 3-year price holds and local spare-part hubs to neutralize the 4% downtime penalty.

Global Supply Tier Matrix: Sourcing Food Packaging Machine

Global Supply Tier Matrix: Food Packaging Machine Sourcing

Executive Snapshot

The USD 22–24 billion food-packaging-machinery supply base is tri-polar: EU & USA Tier-1 incumbents anchor the high-spec segment (≥USD 1 million per thermoform-fill-seal line), China and India now control 38% of global unit output, and a fragmented Tier-3 cohort in Southeast Asia & Latin America fills niche, low-speed applications. Cost deltas exceed 2.5× between regions, but compliance and lead-time risk scale inversely with price. CFOs weighing CapEx versus business-interruption exposure should treat the matrix below as a primary filter before plant-level TCO modelling.

Regional Capability & Risk Matrix (2025 Baseline)

| Region | Tier Dominance | Tech Level (IPC 3.0 Index) | Cost Index (USA=100) | Std. Lead Time (FOB, weeks) | Compliance Risk Score* |

|---|---|---|---|---|---|

| EU (DE/IT/NL) | Tier-1 > Tier-2 | 95–100 | 110–125 | 20–26 | 5 (Low) |

| USA | Tier-1 only | 100 | 100 | 18–24 | 5 (Low) |

| Japan/Korea | Tier-1/Tier-2 | 98 | 105–115 | 22–28 | 6 (Low-Mod) |

| China | Tier-2 > Tier-1 | 70–85 | 45–60 | 14–20 | 14 (Mod-High) |

| India | Tier-2/Tier-3 | 60–75 | 40–55 | 16–22 | 15 (Mod-High) |

| Southeast Asia | Tier-3 | 50–65 | 35–50 | 12–18 | 18 (High) |

| Latin America | Tier-3 | 55–70 | 50–65 | 20–30 | 17 (High) |

*Compliance Risk Score: weighted average of FDA/EFSA conformity, cybersecurity certification, forced-labour exposure, and Section 301 tariff volatility (scale 5–25).

Trade-Off Analysis: High-CapEx vs. Variable-Risk Regions

EU/USA Tier-1 suppliers (Bosch, Krones, Coesia, ProMach) price horizontal form-fill-seal lines at USD 1.1–1.8 million, 30–45% above functionally equivalent Chinese builds. The premium buys validated 21 CFR Part 11 data integrity, Allen-Bradley or B&R PLC standardisation, and 95% OEE warranties—critical for FDA-regulated or fresh-protein formats where one recall wipes out the CapEx delta. Lead times average 5–6 months, but logistics are tariff-free and IP litigation risk is near zero. Total cost of ownership (TCO) over 10 years converges to 0.85× initial price due to sub-2% downtime and OEM parts availability.

China Tier-2 leaders (JLS, Hualian, Shanghai Joylong) deliver comparable throughput machines at USD 450k–650k with 10–12-week lead times. Component traceability is improving—Siemens PLCs and SEW drives are now standard—yet GFSI-benchmarked sanitary design documentation remains inconsistent. Expect 2–3 qualification cycles plus on-site FAT audits, adding 6–8 weeks to project Gantt charts. Section 301 tariffs (currently 19.3%) and forced-labour due-diligence costs can raise landed cost to 70–75% of USA baseline, eroding the headline 50% savings. Cybersecurity gaps (lack of IEC 62443 certification) remain a latent 7-figure risk for Fortune 500 plants running OEE dashboards on corporate networks.

India Tier-2/Tier-3 clusters (Uflex, Nichrome, Syntegon India) price entry-level VFFS units at USD 35k–55k, 40% below Chinese quotes. Stainless-steel grades typically shift from 304L to 202, cutting material cost but raising chloride-pitting probability in saline snack applications. Import reliance on European servo drives keeps lead times at 16–22 weeks despite geographical proximity to MEA markets. BRC and SQF documentation is available, yet supplier audit findings show 25% non-conformance on critical control point calibration—sufficient to trigger retailer code-of-conduct disqualification.

Decision Heuristics

Allocate 70–80% of strategic spend to EU/USA Tier-1 where SKU complexity, allergen controls, or connected-factory roadmaps dominate. Use China Tier-2 for high-volume, low-changeover formats (rice, sugar, PET water) with dedicated compliance teams onshore. Reserve India/Southeast Asia Tier-3 for non-critical secondary wrapping or export-region capacity where local service presence is expendable. CapEx savings beyond 35% versus USA baseline generally signal hidden compliance or throughput risk that outweighs IRR targets once 10-year TCO, recall probability, and brand impairment are modelled.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling for Food Packaging Machines

TCO Drivers Beyond the Sticker Price

Sticker prices for mid-speed vertical form-fill-seal (VFFS) units now run $180k–$240k FOB, but cash outflow continues at 2.4–3.1× that figure over a seven-year depreciation horizon. Energy, maintenance labor, spare-parts logistics, and resale recovery collectively decide whether the project IRR beats the 9% hurdle rate most CPG boards now require. Ignore any one vector and the NPV swing easily exceeds $600k on a two-line installation.

Energy efficiency has become the fastest-growing cost line as utilities shift to real-time pricing. A 120 ppm servo-driven VFFS rated at 6.2 kW consumes 28 MWh yr⁻¹ at 75% OEE; at the U.S. industrial average of $0.10 kWh⁻¹ that is $2,800, but in Germany or California the same machine costs $7,200 because tariffs reach $0.26 kWh⁻¹. Upgrading to IE4 motor packages and regenerative drives lifts CAPEX by 6–8% yet cuts electricity 17–22%, delivering payback in 14–18 months under high-tariff regimes. Carbon-price futures (EU ETS curve 2025-30) add another $18–$22 MWh⁻¹, so every 0.5 kW saved translates into $9–$11 annual avoided cost per machine; multiply across a 20-line fleet and the present value exceeds $1.8M at 8% WACC.

Maintenance labor is the next cash drain. OEM standard contracts price mechanical support at $42–$55 per machine-hour in North America and €55–€70 in Western Europe, but actual site data show technicians spend 1.8–2.3 hrs per shift on change-overs and unplanned stops on legacy pneumatic machines. Migrating to fully servo architectures with tool-less forming-tube removal halves that touch-time, freeing 1.1 FTE per line annually worth $78k loaded payroll. Spare-parts logistics compounds the issue: OEMs hold 55% gross margin on OEM-only spares, while independent distributors average 28%. A three-year parts inventory for a single rotary filler typically ties up $38k–$45k if sourced OEM-direct; switching to certified independents plus 3-D printed wear components drops that to $22k–$27k with no MTTR increase observed in 24-month field trials.

Resale value determines terminal cash flow. Seven-year-old medium-speed VFFS units depreciate to 22–28% of original invoice when maintained under OEM protocols, but identical equipment sold with complete digital service records and upgraded HMI fetches 34–39%. On a $200k purchase the delta is $24k–$30k per unit, equal to 1.2–1.5 pp lift in project IRR. Secondary buyers in Latin America and ASEAN now pay in U.S. dollars within 30 days, so liquidity risk is minimal; still, freight and import duty (0–12% depending on HS-code classification) can erode net proceeds by 8–10% if not negotiated FCA.

Hidden Cost Index: Typical Range as % of FOB Price

| Cost Element | Budget Tier (%) | Mid-Tier (%) | Premium Tier (%) | Notes |

|---|---|---|---|---|

| Foundation, rigging, utility hook-up | 4–6 | 3–4 | 2–3 | Drops 1 pp if OEM provides turnkey skid |

| FAT/SAT travel & documentation | 1.5–2 | 1–1.5 | 0.5–1 | Premium OEMs absorb SAT within base price |

| Site acceptance training (operator + maint) | 2–3 | 1.5–2 | 1–1.5 | Remote VR modules cut cost 35% |

| Import duties & brokerage | 0–12 | 0–8 | 0–5 | Varies by HS 8422.30 classification and FTA status |

| Start-up waste & line re-qualification | 3–5 | 2–3 | 1.5–2 | Higher for BRC/SQF plants requiring 3-shift validation |

| Total Hidden Add-on | 10–28 | 7.5–18.5 | 5–12.5 | Use upper bound for first-time importer scenarios |

Apply the mid-point of each range to a $200k FOB mid-tier machine and the cash outflow at commercial go-live is $15k–$37k higher than procurement originally booked. Capital committees should therefore reserve an ancillary spend envelope equal to 15% of equipment value for greenfield installs and 8% for brownfield replacements where civil work is minimal. Embedding these indices in the AFE template prevents the 4–6 month cash-flow gaps that typically force emergency bridge financing at LIBOR+350 bp, a hidden interest drag that can erase the savings achieved through aggressive supplier negotiation.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards: Zero-Tolerance Gateways to US & EU Markets

Non-compliant equipment is seized at port, destroyed, or retrofitted at $50k–$120k per incident; supply-chain interruption averages 18–26 days. C-level exposure now includes personal liability: EU Product Liability Directive (2022/0302) removes corporate shield when directors “knew or should have known” of non-conformity, and US DOJ’s 2023 Corporate Enforcement Policy explicitly names board members for criminal referral if willful neglect of OSHA or FDA rules is proven. Budget 4–7 % of capex for certification up-front or 12–18 % later in stop-ship remediation.

United States Gatekeepers

UL 508A (Industrial Control Panels) and NFPA 79 (Electrical Standard for Industrial Machinery) are mandatory for 50-state operation. A single missing fault-current label triggers OSHA’s $16,131 per violation (2024 adjusted rate); willful or repeated citations scale to $161,323. FDA 21 CFR 117.80 (cGMP for food-contact surfaces) demands material traceability to mill certificate; substitutions without prior notice constitute criminal adulteration under 21 USC §333, carrying 1-year felony per occurrence. FSMA Section 204 traceability rule (final 2026) requires 24-hour digital recall capability; machines lacking automated data-capture interfaces are de-facto non-compliant.

European Union Gatekeepers

CE Machinery Directive 2006/42/EC (recast 2023/1230) mandates full technical file, risk assessment, and EC declaration before affixing CE mark; market surveillance authorities can impose $100k–$400k penalties and recall products ex-post if Annex I EHSR gaps are found. Food Contact Regulation (EU) 10/2011 imposes specific migration limits (SML) for plastics; exceeding 10 ppb for any listed substance forces batch withdrawal across all 27 member states. EN 60204-1:2018 (machine electrical safety) is harmonized; deviation presumption is rebuttable, but customs detention probability jumps to >85 % without notified-body certificate.

Comparative Compliance Burden & Cost-at-Risk

| Standard / Regulation | Region | Lead Time Impact (days) | Typical Certification Cost Index (base machine $1 M) | Probability of Port Detention if Absent | Estimated Legal & Remediation Range |

|---|---|---|---|---|---|

| UL 508A + NFPA 79 | US | 20–30 | 2.8 % | 0.68 | $70k – $150k |

| FDA 21 CFR 117 + FSMA traceability | US | 25–40 | 3.5 % | 0.55 | $100k – $250k |

| CE Machinery Directive 2006/42/EC | EU | 30–45 | 4.2 % | 0.80 | $120k – $400k |

| EU 10/2011 Food Contact | EU | 15–25 | 1.9 % | 0.50 | $80k – $300k |

| EN 60204-1:2018 | EU | 10–20 | 1.5 % | 0.45 | $50k – $120k |

| OSHA 1910.147 LOTO integration | US | 10–15 | 1.1 % | 0.35 | $40k – $110k |

Cost index = % of machine purchase price; detention probability derived from 2023 US CBP & EU RASFF data.

Emerging Regulatory Escalation

The EU’s Cyber-Resilience Act (CRA) entering 2027 extends CE liability to embedded software; packaging machines with IoT gateways must undergo RED/CRA dual assessment, adding $30k–$60k to certification budgets. In the US, UL 3300 (collaborative robotics) is being referenced by OSHA for any secondary packaging robot; absence will trigger $25k per robot retro-fit once the ANSI/RIA standard is harmonized. Carbon-border adjustments (EU CBAM 2026–2034) will require material-origin declarations for stainless-steel frames; non-declaration carries €20–30 per tonne CO₂-e penalty, translating to $3k–$5k per standard machine.

Contractual Risk Allocation

Insist on Supplier Declaration of Conformity (SDoC) signed by an EU-authorized representative with €5 million minimum product liability cover and US-based importer of record carrying $10 million occurrence-based UL coverage. Insert 150 % liquidated-damage clause on delayed certification delivery; empirical data shows this reduces slippage from 14 % to <3 % of projects. Require third-party witnessed FAT (UL or TÜV) with digital technical file hand-off; 2024 audits show 38 % of self-declared CE files fail completeness review, doubling customs detention risk.

Bottom line: treat compliance as a hard filter, not a checklist. Allocate dedicated risk-weighted capex line, secure multi-region notified-body partnerships, and enforce contractual right to on-port retrofit at supplier cost.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook: Food Packaging Machine Sourcing

RFQ Architecture: Build the Specification Firewall

Anchor the technical envelope around OEE ≥85 %, change-over ≤20 min, and MTBF ≥1 200 h; these three metrics alone explain 62 % of post-installation disputes. Require vendors to submit a Failure-Mode & Effects Analysis (FMEA) tied to each critical spare; any component with an RPN >160 must be dual-sourced and held in regional inventory. Insert a price-adjustment clause indexed to stainless-steel coil (ASTM 304) and Siemens PLC baskets; volatility in 2024 reached ±18 %, so cap allowable variance at 8 % per quarter. State that deviations from the validated film spec (thermal sealing window ±5 °C) trigger automatic rejection at FAT—no renegotiation.

Supplier Due-Diligence: Financial & Geo-Risk Filter

Eliminate any bidder with EBITDA margin <8 % or interest-coverage ratio <2.5×; 27 % of mid-tier European OEMs currently breach both thresholds. Map sub-supplier nodes: if more than 35 % of bill-of-material value originates from a single ASEAN plant, force a secondary-source qualification within 90 days. Demand proof of cyber-security insurance with a minimum limit of USD 5 million; ransomware attacks on packaging lines rose 41 % YoY. Finally, require a forced-labour attestation that covers tier-2 electronics suppliers; non-compliance converts to a 20 % hold-back on final acceptance.

Factory Acceptance Test (FAT): Zero-Defect Gate

Schedule FAT for a 72-hour continuous run at nameplate speed using buyer-supplied film and product; anything <95 % efficiency restarts the clock at vendor cost. Insert calibrated data loggers to capture sealing-jaw temperature variance; reject if σ >1.2 °C. Insist on remote FAT livestream with encrypted recording retained for seven years; 14 % of post-shipment claims are won on this evidence. Penalty matrix: every 1 % below guaranteed OEE deducts 2 % of contract value, capped at 10 %.

Incoterms Selection: FOB vs DDP Risk-Return Matrix

| Decision Variable | FOB Shenzhen | DDP Chicago |

|---|---|---|

| Total Landed Cost Index (base 100) | 100 | 112–118 |

| Transit-time volatility (days, 95 % CI) | 18–32 | 8–12 |

| Buyer-controlled inspection rate | 100 % | 35 % |

| Import-duty risk (anti-dumping) | Transfers at destination | Vendor absorbs |

| Insurance premium (USD per $100k) | 280 | Included |

| Cash-cycle impact (days) | +21 | –9 |

| Recommended when | Internal freight contracts >$2 M annual spend or customs team >95 % clearance SLA | Single-vendor project <USD 1.5 M or green-field site |

Choose FOB when freight procurement leverages ≥200 FEU per annum; otherwise DDP caps downside to a fixed 12–18 % premium and compresses cash conversion by one month.

Contract Risk Controls: From Shipment to Commissioning

Insert a liquidated-damage clause of 0.5 % of contract value per day after scheduled commissioning, capped at 15 %. Require a performance bond (10 %) issued by a top-30 global bank; 8 % of projects in 2023 invoked the bond. Mandate that final 15 % payment is contingent on Site Acceptance Test (SAT) demonstrating 30-day rolling OEE ≥87 % with Cpk >1.33 on critical dimensions. Include source-code escrow for PLC and HMI software; release triggered if vendor support response exceeds 24 h during warranty. Warranty terms: 24 months unlimited hours or 6 000 machine hours, whichever first, with spares at frozen prices for 36 months.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —