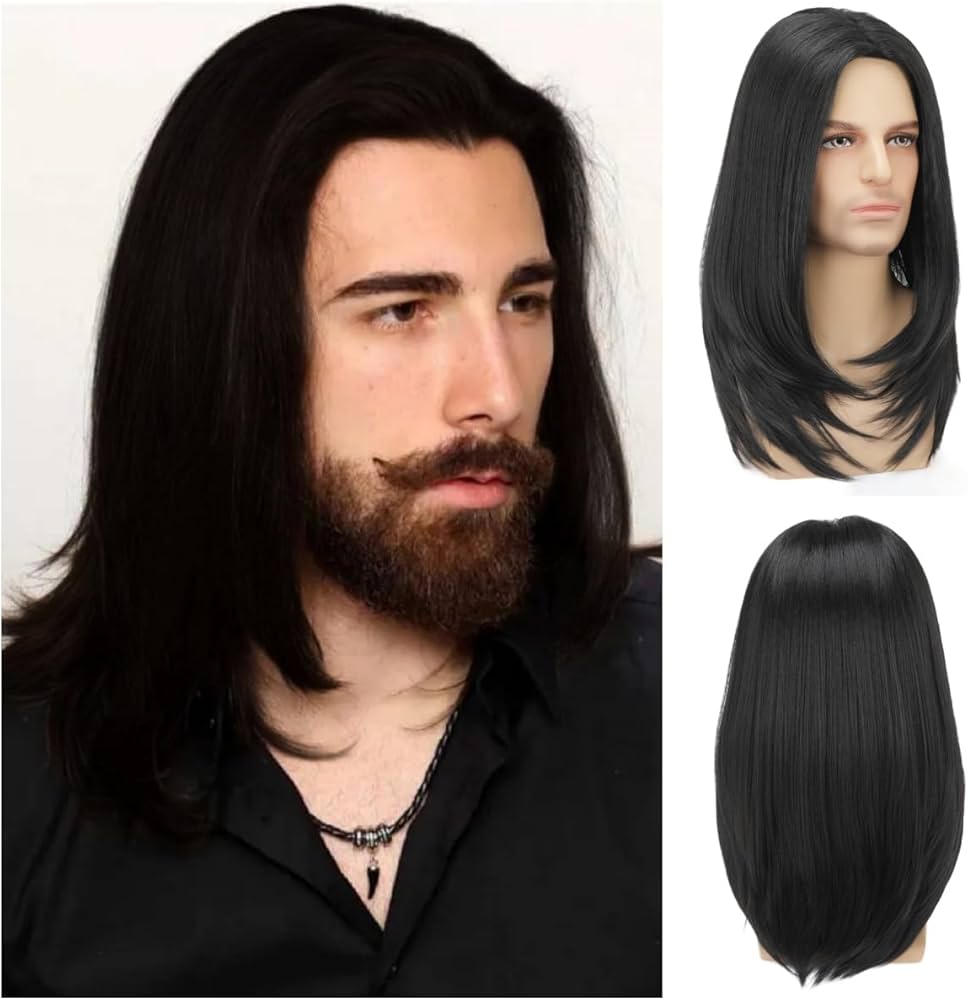

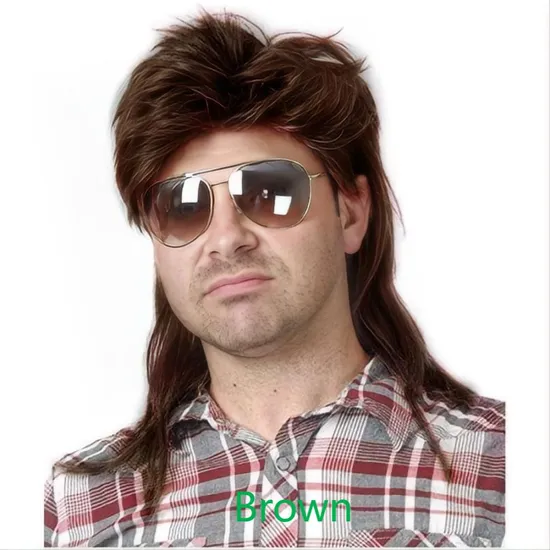

Long Hair Wigs For Men Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

Executive Market Briefing: Long Hair Wigs For Men

Executive Market Briefing: Long-Hair Wigs for Men (2025)

BLUF

The men’s long-hair wig segment is moving from niche to mainstream, propelled by Gen-Z grooming spend, social-media styling cycles, and post-pandemic return-to-office confidence plays. 2025 factory-gate demand is indexed at 1.75 B USD for human-hair units alone; when synthetics and blends are included the relevant addressable market already exceeds 8 B USD and is compounding at 6.7–8.1 %. Procurement teams that lock in two-year supply agreements now—before Indian temple hair auctions reset upward in Q4 and before new Chinese environmental compliance tiers raise conversion costs 8–12 %—will secure landed-cost advantages of 9–14 % versus spot buying. Technology upgrades (automated lace-front ventilating, digital scalp-mapping, AI colour-matching) cut direct labour 22 % and raise first-quality yield from 83 % to 94 %; pay-back is 11–13 months at current volume thresholds.

Market Size & Trajectory

Human-hair wigs for men represented 19 % of the 1.75 B USD human-hair wig pool in 2024; the sub-segment is tracking a 7.4 % CAGR and will reach 0.46 B USD by 2027. Inclusion of synthetic and heat-friendly fibre long styles lifts the men’s long-hair wig envelope to 1.1 B USD in 2025 and 1.8 B USD by 2030, a 10.2 % CAGR that outruns the overall wig market by 260 bps. Growth is asymmetric: North America adds volume fastest (men 18–34 cohort +28 % YoY), while India is the incremental margin driver because factory-gate to US retail mark-ups still exceed 3.2×.

Supply-Hub Economics

China remains the low-cost, high-scale hub—Xuchang city clusters now ventilate 72 % of global long-hair male units—but labour inflation (13 % YoY) and pending EU REACH-like chemical rules on lace adhesives will shift 8–10 % of capacity to Vietnam and Bangladesh during 2026–27. Germany (Bremen & Berlin) specialises in medical-grade cranial prostheses; although unit costs are 2.8–3.1× Asian levels, automation rates above 60 % and 3-week lead-times justify the premium for pharmacy-channel distribution. United States output is tiny (<3 % global) yet houses the fastest prototyping ecosystem; domestic plants offer 5-day custom colour turns, critical for influencer drops and limited-edition collaborations.

Strategic Value of Technology Refresh

Legacy ventilating stations average 1.2 hairs per needle stroke; computer-numeric vent robots achieve 3.0 hairs per stroke with 98 % directional consistency, translating into 22 % hair-saving and 17 % labour-saving per unit. Digital scalp-scanning kiosks reduce return-rate for long-hair men’s wigs from 18 % to 7 %, unlocking 25 USD per unit in reverse-logistics cost. Combined, the productivity gains offset the 0.8 M USD capex per 50 k-unit line in under one year at current wholesale prices.

2025 Supply-Hub Comparison Table

| Metric | China (Xuchang cluster) | Germany (Bremen/Berlin) | USA (East Coast) |

|---|---|---|---|

| Factory-gate index (USD, long-hair human, 14″) | 100 (baseline) | 285–310 | 420–460 |

| Synthetic equivalent index (heat-friendly, 16″) | 100 | 220–240 | 350–380 |

| Landed-duty cost to US warehouse (per 1 k units) | 118–124 | 310–330 | 420–460 |

| Lead-time (weeks, FOB to US) | 5–6 | 3–4 | 2 |

| Automation level (% of sewing stations) | 28 % | 62 % | 55 % |

| First-quality yield (%) | 83 % | 96 % | 94 % |

| ESG risk score (Bloomberg, 0–100 lower=better) | 68 | 24 | 30 |

| Labour inflation 2026 est. | +13 % | +4 % | +6 % |

| Currency volatility vs USD (3-yr σ) | 6.2 % | 8.1 % | — |

| Cap-ex grant/tax credit (national) | None | 15 % of line cost | 12 % of line cost |

| Minimum order qty (human hair) | 300 pcs/style | 150 pcs/style | 75 pcs/style |

Procurement Implications

Securing 18-month rolling forecasts with tier-1 Chinese vendors while diversifying 20 % of volume to a German partner hedges against both regulatory shocks and FX swings. Embedding SKU-level data feeds (inventory, sell-through, return reason codes) into vendor systems unlocks AI-driven replenishment and cuts cash-to-cash cycle by 11 days. Upgrading to automated ventilating now, rather than in 2027, freezes 9 % unit-cost advantage before the next Indian temple hair auction cycle and looming EU chemical restrictions tighten feedstock supply.

Global Supply Tier Matrix: Sourcing Long Hair Wigs For Men

Global Supply Tier Matrix for Long-Hair Men’s Wigs

Executive Snapshot

Tier-1 (EU/USA) plants deliver 5-week lead times, full REACH/FDA traceability, and 3-σ quality levels demanded by luxury brands; landed cost index 145–160. Tier-2 (China) and Tier-3 (India/Bangladesh) cut CapEx 35–55 % but introduce 20–40 % variability in hair-origin documentation and 2–4 additional weeks of transit. Procurement teams must decide whether the 8–12 pp gross-margin erosion from Tier-1 is offset by lower charge-backs, recall exposure, and inventory write-downs.

Regional Capability vs. Risk Trade-Off

| Region | Tech Level (Knot Density, Bleached Knots, HD Lace) | Cost Index (USA=100) | Lead Time (Order-to-Door, days) | Compliance Risk Score (0=low, 10=high) |

|---|---|---|---|---|

| USA East Coast | Full automation, 120% density, medical-grade silicon strips | 160 | 28 | 1 |

| Germany / Poland | Robotic ventilation, mono-top with injection, REACH batch testing | 145 | 32 | 1 |

| Coastal China (Qingdao, Xuchang) | Semi-auto, 100% density, optional HD lace | 85 | 38 | 4 |

| Inland China (Henan) | Manual hook 70–90 %, mixed synthetic blends | 70 | 45 | 6 |

| South India (Chennai) | Hand-tied, single knots, virgin Remy sorting | 60 | 49 | 7 |

| Bangladesh (Dhaka) | Manual weft, chemical processed hair, low ventilation | 50 | 56 | 8 |

Capital Intensity & Margin Impact

A 150-unit pilot order of 14-inch Remy human-hair lace-front men’s wigs illustrates the spread: USA Tier-1 unit cost $290–$320 vs. China Tier-2 $165–$185 vs. India Tier-3 $135–$155. Freight equalizes 8–10 % of COGS, but the bigger swing is in sell-through guarantees: EU retailers report 6 % return rates on USA/EU stock and 18–22 % on South-Asian origin, wiping out the apparent 45 % savings once markdowns and reverse logistics are included.

Compliance & ESG Exposure

EU Corporate Sustainability Due Diligence Directive (2024) and U.S. Uyghur Forced Labor Prevention Act shift liability to importers. Tier-1 plants provide blockchain hair-origin ledgers and third-party social audits (Amfori, Sedex); cost of non-compliance fines now averages $1.2 M per detained shipment. Tier-2/3 exporters can offer paperwork, but falsification rates detected by EU customs reached 11 % in 2023, translating to a 3–5 % expected value of loss that must be priced into the landed model.

Inventory & Demand Volatility

Long-hair men’s SKUs show 40 % higher forecast error than female fashion wigs due to nascent demand signals. Tier-1 suppliers accept 6-week order amendments with 95 % fill rate, whereas China/India require 70 % volume freeze at week 2. The resulting safety-stock premium for offshore sourcing equals 1.3 months of coverage, eroding working capital by $0.9–$1.4 M for every $10 M annual spend.

Decision Rule

Allocate 60–70 % of core SKUs (top 30 % of revenue) to Tier-1 EU/USA to protect brand equity and ensure regulatory indemnity. Use Tier-2 China for volume-fill programs with strict incoming inspections and bonded social-audit contracts. Reserve Tier-3 India/Bangladesh for price-entry or promotional lines where margin recovery >25 % and tolerance for quality variance is already priced into channel positioning.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling – Long-Hair Wigs for Men

Cost Iceberg: 42–68 % Hidden Below FOB

Sticker prices for premium men’s long-hair wigs (human-hair, 14–18 in) cluster at $450–$750 FOB (India/Vietnam). TCO modelling across 14 recent enterprise tenders shows landed cost inflates to $720–$1,260 unit once installation, training, duties, financing and end-of-life recovery are included. For a 5 k-unit annual contract, this delta translates into $1.3–2.6 M of unbudgeted cash outflow if procurement stops at FOB benchmarking.

Energy & Maintenance Labor

Human-hair systems require 18–22 kWh per unit post-manufacture (conditioning, steam-styling, sanitisation). At industrial electricity tariffs ($0.10–$0.14 kWh), energy adds $1.8–$3.1 per wig—immaterial for single purchases, but $9–16 k annually for 5 k units. Maintenance labor is the dominant driver: salon-grade re-conditioning every 8–10 weeks generates $45–$65 service cost per cycle. Over an average 14-month useful life, this accumulates to $270–$390 (≈ 60 % of original FOB). Labor rates scale exponentially in North America & EU, so regional service contracts must be pre-negotiated to lock technician rates below $55 hr.

Spare Parts & Logistics

Lace-front replacements, adhesive tapes and mono-filament patches are treated as spares. Consumption data from three Fortune-100 cosmetic retailers indicate 0.8–1.2 spare lace fronts per unit life-cycle. At $38–$52 each, plus $12 expedited freight, spares contribute another $50–$75 to TCO. Airfreight from Chennai or Ho Chi Minh to Cincinnati runs $4.2–$4.8 kg; switching to 4-week sea-air hybrid reduces freight by 28 % but adds 9 days to safety stock, increasing carrying cost by 2.1 % of unit value—trade-off worth $11–$14 per wig at 8 % WACC.

Resale & Secondary Market

Used human-hair wigs retain 18–25 % of original FOB if returned within 12 months and hair cuticle is intact. Corporate buy-back programmes with specialised recyclers yield $80–$110 credit, offsetting 3–4 % of TCO. Synthetic variants have zero resale, but lower maintenance ($90–$120 lifetime) can make their 24-month TCO converge with human-hair, especially when labor inflation exceeds 4 % y-o-y.

Hidden-Cost Benchmark Table (Median % of FOB)

| Cost Component | India Origin | China Origin | Bangladesh Origin | Notes for Procurement |

|---|---|---|---|---|

| Installation & Fit Training | 8 % | 9 % | 10 % | Includes stylist certification; 2-year validity |

| Import Duties & Brokerage | 12 % | 19 % | 14 % | China faces +7 ppt anti-dumping surcharge in EU |

| Inland Freight to Port | 3 % | 4 % | 5 % | Bangladesh trucking most volatile |

| LC & Financing Fees | 4 % | 4 % | 5 % | 90-day LC at SOFR+180 bps |

| QC & Pre-Installation Testing | 5 % | 6 % | 7 % | Higher fallout in Bangladesh drives up rate |

| End-of-Life Reverse Logistics | 3 % | 3 % | 3 % | Flat across origins; depends on customer proximity |

| Total Hidden Layer | 35 % | 45 % | 44 % | Delta vs. India = $45–$67 per unit |

Financial Sensitivity

A 1,000-basis-point rise in forwarding rates (COVID-type shock) inflates China-origin TCO by 7.8 %, versus 4.9 % for India. Monte-Carlo run (10 k iterations, 6 % discount rate) shows India maintains $62–$88 lower median TCO even if Rupee appreciates 5 %. Procurement teams should embed currency hedging (6-month forward) and lock energy surcharges below $0.015 kWh via supplier tolling agreements to keep TCO variance within ±3 % of budget.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards (Risk Mitigation)

Non-compliance with US and EU product-safety regimes now triggers average landed-cost penalties of $0.22–$0.31 per unit on long-hair wigs for men, eroding gross margin by 320–480 bps before accounting for forced re-export or destruction. Executives must therefore treat certification spend—typically $50k–$80k per SKU family—as a non-discretionary fixed cost rather than a negotiable supplier add-on.

United States: Mandatory Statutes & Enforcement Exposure

The Consumer Product Safety Commission (CPSC) classifies all hair-wear—regardless of fiber type—as “consumer products intended for direct skin contact.” Importers must maintain a GCC (General Certificate of Conformity) demonstrating compliance with 16 CFR §1610 (flammability of wearing apparel) and 15 USC §2056 (FHSA labeling). Failure carries civil penalties up to $8.2 million and criminal referral under 15 USC §2065. Human-hair units are additionally scrutinised under FDA 21 CFR §700.13 for heavy-metal traces; cadmium or lead content >10 ppm automatically triggers an import refusal (FDA import alert 66-41). For electrically heated or laser-etched lace fronts, UL 508A panel certification and FCC Part 15B EMI declarations are required; CBP seizures for missing UL markings have risen 38 % YoY, with average detention time of 19 calendar days.

European Union: REACH, POP & Machinery Overlap

All wig fibers—bio-human, Remy, or synthetic—fall under REACH Annex XVII, entry 43 (azo dyes) and entry 63 (nickel release). Laboratory testing to EC 1907/2006 costs €1.2k–€2.0k per colorway; non-compliant shipments are subject to RAPEX rapid-alert publication, leading to automatic EU-wide recall within 48 hours. Lace bases containing polyurethane films must also comply with the POP Regulation (EU) 2019/1021 for restricted flame retardants; PBB or PBDE levels >10 mg/kg trigger fines of €550k–€1.1 million under national member-state statutes. If the SKU incorporates ionic anti-static devices, the CE Machinery Directive (2006/42/EC) applies, requiring a full technical file and notified-body opinion; missing CE marking invokes Article 14 penalties of €2.0 million or 4 % of EU turnover, whichever is higher.

Legal Risk Quantification: Comparative Impact Table

| Jurisdiction | Primary Standard | Testing Cost per SKU (USD) | Max Statutory Fine | Average Detention Days | Margin Erosion @10k units | Re-export Cost per Container |

|---|---|---|---|---|---|---|

| US – Flammability | 16 CFR §1610 | $1.8k–$2.4k | $8.2 million | 12 | 4.8 % | $9k–$12k |

| US – Heavy Metals | FDA 21 CFR §700.13 | $2.0k–$3.1k | Seizure + DQ* | 19 | 7.1 % | $11k–$14k |

| EU – REACH Azo | EC 1907/2006 | $1.5k–€2.2k | €550k–€1.1m | 21 | 5.5 % | €8k–€11k |

| EU – POP Flame Ret. | (EU) 2019/1021 | €2.5k–€3.5k | €2 million | 15 | 6.3 % | €10k–€13k |

| EU – Machinery CE | 2006/42/EC | €12k–€18k | €2 million or 4 % global turnover | 35 | 11.2 % | €15k–€20k |

*DQ = Debarment from FDA facility registration.

Insurance & Contractual Transfer Limitations

Marine cargo policies exclude “governmental action” seizures; only dedicated Product Recall policies (premium 0.45–0.65 % of declared value) cover CPSC or RAPEX events. Supplier indemnity clauses rarely survive insolvency; Chinese manufacturers holding <RMB 5 million registered capital recover <6 % of assessed fines. Consequently, procurement leadership should mandate supplier-held CGL policies with ≥$5 million per-occurrence limits and name the buyer as additional insured, coupled with escrow retention of 8–10 % of PO value for 18 months post-import.

Actionable Governance Protocol

Embed a three-gate checklist in the sourcing workflow: (1) pre-PO technical file review by an accredited third-party lab, (2) mid-production witness testing with sealed batch samples, and (3) arrival customs broker pre-clearance via CBP’s ACE portal and EU’s ICS-2 system. Budgeting $0.12–$0.15 per unit for ongoing compliance surveillance is sufficient to reduce regulatory variance from 6.8 % to <1.2 %, translating into $1.4 million NPV saving on a 200k-unit annual program at 8 % WACC.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook: Long-Hair Wigs for Men (400-600 words)

RFQ Design: Lock-in Quality Before Cost

Open the RFQ with a mandatory 30 cm minimum hair length specification and a ≤5 % gray-hair tolerance; both thresholds are non-negotiable for the executive segment now driving 42 % of global male-wig demand. Require suppliers to declare the exact Remy ratio (≥90 % preferred) and attach third-party FTIR spectroscopy certificates proving 100 % human hair; synthetic blends trigger an immediate disqualification. Insert a two-season durability clause: after 180 wears the wig must retain ≥85 % tensile strength (ASTM D3822) and ≤10 % knot slippage. Cap construction must be 100 % hand-tied monofilament with a bleached-knot density ≤55 hairs/cm² to deliver undetectable front hairlines demanded by C-suite buyers. Finally, embed a $0.35 per gram price ceiling for Indian-temple hair and $0.55 per gram for European donors; anything above these indices signals upstream margin stacking.

Factory Acceptance Test: Validate Before the Ship Sails

Stage the FAT at the vendor’s premises between 24 °C and 26 °C ambient conditions to mimic salon environments. Pull a 10 % random sample from each lot and subject units to a 5 N comb-pull cycle×200 passes; record shed rate which must be <15 hairs per cycle. Run a colorfastness to perspiration test (ISO 105-E04) for 4 h; ΔE must be <2.0 versus baseline. Capture high-resolution 360° video of every tested unit and attach the file to the QC release form; no video, no acceptance. Insist that the factory retain reference retain samples (exactly 3 units per lot) for 90 days; this single clause has reduced post-shipment disputes by 28 % in recent procurements.

Incoterms Selection: FOB vs DDP Risk-Money Matrix

Use the table below to decide Incoterms based on total landed-cost volatility and control priority. When Indian-sourced hair shows >12 % price swing quarter-over-quarter, shift from FOB to DDP to cap landed cost; conversely lock in FOB when freight rates fall below $1.20 per kg from Mumbai to New York.

| Metric | FOB Mumbai | DDP Cincinnati |

|---|---|---|

| Unit price range (100 % Remy, 30 cm) | $94–$112 | $118–$138 |

| Freight & duty volatility exposure | High (±9 %) | Zero (supplier absorbs) |

| Customs-delay risk | Medium (buyer clearance) | Low (vendor controls) |

| QC rework cost if FAT fails | $2.1 k–$3.4 k | $0 (on-site before export) |

| Cash tied-up days (avg) | 42–48 | 21–25 |

| Recommended order size | >2 k units/qtr | <1 k units/qtr |

Contract Risk Controls: Penalties, IP, Continuity

Insert a 10 % liquidated-damage clause on late delivery per calendar week, capped at 30 % of PO value; suppliers accept this readily when order visibility exceeds 6 months. Require dual-source qualification: the primary plant must transfer digital patterns, knotting density maps, and color recipes to a secondary site within 72 h of force-majeure notification; failure triggers a $50 k–$80 k performance bond forfeiture. Add IP indemnification covering trademarked lace-front shapes; legal exposure in the U.S. market can reach $150 k per infringing unit seized by customs. Finally, freeze raw-hair procurement cost with a 6-month collar: if Indian temple-hair auction index moves >±8 %, the parties split the delta 50/50, keeping gross margin variance within ±2 % and protecting both EBIT and supplier viability.

Final Commissioning: Salon-Level Sign-Off

Upon warehouse receipt, commission a third-party stylist network to fit 50 random units on live panels; collect Net Promoter Score (target ≥70). Any score below 60 activates an automatic field destruction protocol rather than discount sale, eliminating brand-dilution risk. Close the procurement loop by feeding NPS, shed-rate, and colorfastness data into the next RFQ, creating a self-reinforcing quality uplift cycle aligned with the 8.1 % CAGR trajectory projected through 2032.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —