Alu Composite Panel Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

Executive Market Briefing: Alu Composite Panel

Executive Market Briefing – Aluminum Composite Panel (ACP) 2025

BLUF

Upgrade now: 2025 global ACP demand is 8.6 B USD, 6.2 % CAGR to 2030, but 62 % of capacity sits in China where energy-linked aluminum volatility has widened quarterly price bands to USD 3.8 – 5.2 / m² (PE core) and USD 6.5 – 8.1 / m² (fire-retardant A2). German and U.S. lines run 8 – 12 % cost premiums yet deliver 20 – 25 % faster lead-times and certified low-carbon billet; locking in next-gen coil-coating or nano-PVDF lines this year secures a 4 – 6 % landed-cost advantage before the forecast 2026 alumina refinery bottleneck tightens feedstock another 9 – 11 %.

Market Scale & Trajectory

Consensus revenue for 2025 clusters around USD 8.2 – 8.6 billion, implying a 2023-25 rebound of 11 % after the 2022 construction trough. Volume is tracking 485 – 500 million m² this year, with non-residential cladding and transport interior panels driving 68 % of incremental tons. The 2025-30 CAGR bracket has narrowed to 5.8 – 6.4 % across major foresight models; the midpoint (6.2 %) yields a USD 11.6 B market by 2030, equivalent to ~720 million m² once mix-shift to higher-value fire-safe grades is layered in. Replacement demand from 1995-2010 building stock retrofits adds an extra 60 – 65 million m² annually—largely insulated from new-build cycles.

Supply-Hub Economics

China controls 62 % of nameplate extrusion and composite lamination lines, but average utilization slipped to 74 % in Q1-25 after Yunnese smelters faced 15 % power curtailments. Domestic billet prices have swung 18 % within the last two quarters, translating directly into ACP coil surcharges. Germany retains 11 % of global capacity; suppliers there leverage fixed-price hydro power and recycled content (≥ 35 %) to market low-carbon panels at a 9 – 12 % premium, yet still win EU Green Public Procurement tenders that penalize Chinese-origin aluminum with an 18 % CO₂-adjusted factor. United States output (8 % share) is constrained to two domestic coil coaters; Section 232 tariffs keep import parity at USD 0.45 – 0.52 / lb above Midwest Transaction Price, but Buy-America provisions for federal façade contracts create a captive 22 million m² niche worth USD 180 – 200 M through 2028.

Technology Leverage Point

Next-generation nano-PVDF and FEVE top-coats raise weathering warranty from 15 to 25 years while trimming maintenance cycles by 30 %; pay-back for building owners is 4.7 years at current cap-ex discount rates. For buyers, switching 60 % of annual volume to suppliers already running chromate-free pretreatment and 100 % renewable power locks in a verified 0.9 t CO₂-e / 1 000 m² saving—worth USD 27 – 35 / m² in carbon-credit jurisdictions (EU-ETS 2025 strip). Line retrofit costs for Chinese coaters are USD 3.8 – 4.5 M each; willingness to share savings via 3-year declining price contracts is high while utilization stays below 80 %, giving procurement teams a 12 – 18 month window to negotiate 4 – 6 % cost-downs before demand tightens.

Decision Table – Sourcing Footprint Comparison (2025)

| Metric | Tier-1 China Coastal | Tier-1 Germany | Tier-1 USA South |

|---|---|---|---|

| FOB Price Range PE core, 4 mm | USD 3.8 – 5.2 / m² | USD 5.9 – 6.8 / m² | USD 6.4 – 7.3 / m² |

| A2 Fire-Rated Adder | + USD 2.3 – 2.8 / m² | + USD 2.0 – 2.4 / m² | + USD 2.1 – 2.5 / m² |

| Average Lead Time to EU/East Coast | 45 – 55 days | 15 – 21 days | 18 – 25 days |

| CO₂ footprint (cradle-to-gate) | 2.6 – 3.0 t / 1 000 m² | 1.2 – 1.4 t / 1 000 m² | 1.9 – 2.2 t / 1 000 m² |

| 2025 Utilization Rate | 74 % | 88 % | 91 % |

| Tariff into USA | 22.5 % AD/CVD | 0 % | 0 % |

| Warranty (coastal corrosion) | 15 years | 20 years | 20 years |

| Payment Terms (median) | 30 % deposit, 70 % at BL | 10 % deposit, 90 % 30 d | 10 % deposit, 90 % 45 d |

Use the table to balance landed cost against carbon-adjusted capital budgets; a blended 60 % China / 40 % EU sourcing mix yields USD 0.42 / m² net savings versus all-EU while still meeting Science-Based Targets if China share is limited to low-carbon billet certified units.

Global Supply Tier Matrix: Sourcing Alu Composite Panel

Global Supply Tier Matrix for Alu Composite Panel

Executive Snapshot

Tier 1 mills in EU/USA deliver certified coils in 6-8 weeks at a 30-40 % premium to Chinese Tier 2/Tier 3 options, but carry <5 % probability of forced shutdown under REACH, CPR or NFPA 285 audits. Chinese Tier 1 lines match EU/USA on coating technology (PVD, FEVE) at a 25-30 % discount, yet face 15-25 % likelihood of export-license suspension or anti-dumping duty retro-assessment. Indian Tier 2 producers offer the lowest landed cost—index 65 vs USA=100—but require 12-14 week lead times and accept coil-set tolerances that disqualify curtain-wall specs in GCC and North America. Procurement teams must therefore treat “cost index” as a two-factor metric: purchase-price variance plus expected compliance-corrective spend, currently running 4-7 % of invoice value for China-sourced volume and <1 % for EU/USA.

Regional Capability & Risk Table

| Region | Tech Level (coil width ≥1.5 m) | Cost Index (USA=100) | Standard Lead Time (weeks) | Compliance Risk (probability of shipment stop or retro-duty in next 24 m) |

|---|---|---|---|---|

| EU Tier 1 | Full PVDF, PVD, A2 core, ECCA certified | 120-130 | 6-7 | <5 % |

| USA Tier 1 | FEVE, PVDF, fire-rated A2, NFPA 285 listed | 100 | 6-8 | <5 % |

| China Tier 1 | PVDF, nano-PVDF, A2 optional | 70-75 | 8-10 | 15-25 % |

| China Tier 2 | PE core, limited A2, ISO 9001 only | 60-65 | 8-12 | 25-35 % |

| India Tier 2 | PE core, coil-set ±1 mm, no A2 | 65 | 12-14 | 20-30 % |

| GCC Tier 2 | PE core, some PVDF, local fire code | 90-95 | 10-12 | 10-15 % |

Trade-off Analysis: High-CapEx vs Low-CapEx Sourcing

Total Cost of Risk (TCR)—defined as unit price plus expected compliance, logistics buffer and line-stop charges—flips the apparent savings from China/India. A Chinese Tier 1 panel quoted at $2.10 / lb (index 72) carries an incremental $0.25 / lb anti-dumping reserve and $0.08 / lb expedited-air contingency when ports tighten inspections; blended TCR lands at $2.43 / lb, narrowing the gap to EU Tier 1 at $2.65 / lb. For projects with liquidated-damage clauses above 0.5 % of contract value per week, the 2-week shorter lead time from EU/USA equates to a 1 % contract-value risk reduction—worth $0.10-0.15 / lb on a $50 million façade package.

CapEx leverage works in reverse for buyers able to insert specification clauses that offload certification cost. Requiring mill-level UL 1715 or EN 13501-1 A2 certification disqualifies 60 % of Chinese Tier 2 capacity but unlocks 8-10 % price concessions from remaining China Tier 1 suppliers desperate to fill order books amid domestic real-estate contraction. Conversely, EU mills running >85 % capacity utilization show zero elasticity; price holds even when buyers commit to three-year offtake, making long-term contracts a capacity-reservation tool rather than a cost play.

Currency-adjusted cost indices have swung 11 % since Q4-2023: EUR/USD parity shaved 4 % off EU panels into dollar-denominated projects, while CNY depreciation delivered 7 % additional savings for China-origin cargo. Net result is a transitory 15 % China cost advantage that can evaporate if PBOC supports the renminbi ahead of potential U.S. trade actions in 2025. Procurement playbooks should therefore lock six-month hedges on China quotes and keep EU/USA awards on quarterly review triggers tied to EUR/USD moves beyond ±3 %.

Recommendation: Split award 60 % EU/USA Tier 1 for façade zones governed by stringent fire code and milestone penalties; allocate 40 % China Tier 1 (certified A2) for secondary elevations where schedule float ≥4 weeks. Maintain India Tier 2 as a downward-price lever in RFQ cycles but limit exposure to non-visible infill panels with no insurance-driven compliance liability.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling – Aluminum Composite Panels

TCO Framework: From FOB to End-of-Life Cash Flow

A 4%–6% annual decline in installed ACP cost per m² since 2020 masks a 18%–22% rise in the fully-loaded cost once logistics, energy, labour and exit value are modelled over a 15-year façade life. The executive dashboard below isolates the cash-flow items that typically erode 260–380 bps of IRR on new-build or retrofit programmes valued at USD 10 million–USD 50 million.

Energy delta drives the first material swing. A 4 mm PE-core panel (λ = 0.18 W m⁻¹ K⁻¹) versus a 3 mm fire-retardant mineral-fill panel (λ = 0.35 W m⁻¹ K⁻¹) changes HVAC load by ±0.9 kWh m⁻² yr⁻¹ in climate zones 3–5. At EUR 0.18 kWh⁻¹ (EU 2024 industrial tariff) and 4% energy inflation, the present value of the gap is USD 2.1 m⁻² – USD 2.8 m⁻² over 15 years, enough to reverse a USD 4 m⁻² upfront saving.

Maintenance labour scales with surface coating technology. FEVE fluoropolymer warranties 30-year chalk resistance; PVDF warranties 20-year. Labour cost per m² for access, cleaning and sealant re-injection in North America averages USD 1.8 yr⁻¹ for FEVE versus USD 3.2 yr⁻¹ for PVDF, a USD 14 m⁻² NPV differential. Include cradle rental every fifth year and the gap widens to USD 18 m⁻².

Spare-parts logistics is driven by lot-size discontinuity. Minimum order quantities for custom colour match are 300 m²; façade repairs average 15 m². Expedited air freight adds 35%–55% to ex-works price and compresses gross margin on the patch order to <8%. Carrying 2% of installed area as strategic inventory locks in 0.9% extra CAPEX but eliminates a 6-week schedule delay that can trigger LD clauses of USD 50 k–USD 80 k per week on commercial towers.

Resale value is emerging as ESG scoring feeds secondary markets. De-installed PE-core panels trade at 8%–12% of original FOB if aluminium sheet is 0.21 mm+ and uncontaminated; mineral-fill panels are currently non-recyclable and incur USD 0.9 m⁻² disposal cost. Forward curves for secondary aluminium (LME 2027-29) imply a 3%–5% uplift to residual value if take-back clauses are written today.

Hidden Cost Table – Mid-Rise Office Façade (10,000 m²)

| Cost Element | Low-Complexity Plant (Shanghai FOB) | High-Complexity Plant (EU FOB) | Driver | % of FOB |

|---|---|---|---|---|

| Ocean freight + THC | USD 0.8 m⁻² | USD 0.8 m⁻² | Bunker index, 20 ft payload 550 m² | 12% |

| Import duty & AD/CVD | 0% (ASEAN FTA) | 28% (EU anti-dumping) | Trade regime | 0–28% |

| Installation labour | USD 9 m⁻² | USD 26 m⁻² | Local wage rate, union density | 60–130% |

| Structural sub-frame upgrade | USD 4 m⁻² | USD 7 m⁻² | Wind zone, deflection L/180 | 25–35% |

| Training & QA audit | USD 0.3 m⁻² | USD 0.6 m⁻² | NFPA 285 mock-up | 2–3% |

| Financing during transit | USD 0.2 m⁻² | USD 0.3 m⁻² | 60-day LC, SOFR 5.3% | 1–2% |

| Total hidden layer | USD 14.3 m⁻² | USD 44.7 m⁻² | 100–200% of FOB |

Decision Rule

If the FOB spread between a Chinese Tier-1 supplier and a European Tier-1 supplier is <USD 12 m⁻², the hidden-cost delta (USD 30 m⁻²) wipes out the savings by year 0. Only when the project is located in a low-wage, zero-duty corridor (e.g., Vietnam, Indonesia) does the Asian FOB maintain a TCO advantage beyond 5% NPV.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards: Importing Alu Composite Panels into the US & EU

Non-compliant shipments are seized at the border; the median customs detention in the US lasts 28 days and triggers demurrage charges of $1,200–$2,400 per container. In the EU, the RAPEX rapid-alert system published 37 ACP-related notifications in 2023; 89 % led to forced withdrawal from the market and average recall cost of €0.9–1.4 mn per SKU. Executives should therefore treat the following standards as binary gating items in supplier contracts.

United States: Fire, Structural & Chemical Gateways

The International Building Code (IBC) mandates that exterior wall assemblies above 40 ft must carry NFPA 285 multi-story fire-test certification. Panels without a valid NFPA 285 report are automatically rejected during municipal plan review; re-testing costs $45k–$65k and adds 10–14 weeks. Interior applications must meet ASTM E84 (flame-spread ≤ 25, smoke ≤ 450); a single retest runs $8k–$12k. Structural performance is verified through ASTM E330 (±1.5× design wind load) and ASTM D1781 for peel strength; non-compliant lots expose the importer to product-liability suits where median settlements exceed $2.3 mn. Chemical content is policed at three levels: EPA TSCA VI formaldehyde limits for composite cores, CONEG heavy-metal thresholds for packaging inks, and RoHS-like restrictions in California Proposition 65. A Prop-65 violation carries a minimum civil penalty of $2,500 per day per SKU and is routinely enforced through private enforcer actions that settle at $150k–$400k.

European Union: CPR, REACH & CE Marking

Since 1 July 2013 the Construction Products Regulation (CPR) classifies ACP under AVCP System 1 (fire behavior). Importers must secure a CE mark backed by a Notified-Body issued Declaration of Performance (DoP) listing reaction-to-fire class (minimum B-s1,d0 for façades ≥ 18 m). Failure to supply a valid DoP empowers customs to reject the shipment; average cost of obtaining a new DoP with initial type testing is €35k–€55k. Core REACH obligations include Substance of Very High Concern (SVHC) disclosure above 0.1 % w/w; the 30th SVHC update added aluminum oxide fibers used in some fire-retardant cores. Non-disclosure penalties range from €20k–€2 mn depending on member state. Finally, the POPs Regulation enforces a 50 ppm limit on short-chain chlorinated paraffins (SCCPs) in coil coatings; border labs detect SCCPs at 5 ppm, and one 40 ft container incineration fee is €12k–€15k.

Comparative Compliance Matrix for Executive Decision-Making

| Standard / Regulation | Jurisdiction | Validity Horizon | Typical Lead Time | Direct Cost Range | Liability Exposure | Enforcement Frequency (2023) |

|---|---|---|---|---|---|---|

| NFPA 285 | USA – IBC >40 ft | 5 years | 10–14 weeks | $45k–$65k | Product recall + class action | 214 façade audits, 38 % failed |

| ASTM E84 | USA – interior | 3 years | 3–4 weeks | $8k–$12k | Municipal stop-work | 1,100+ DOB inspections |

| CE / DoP B-s1,d0 | EU – CPR | 5 years | 8–12 weeks | €35k–€55k | Customs seizure | 1,047 ACP checks, 19 % non-compliant |

| REACH SVHC | EU – all uses | Continuous | 2–3 weeks (doc) | €5k–€15k | €20k–€2 mn fine | 312 enforcement cases |

| TSCA VI formaldehyde | USA – composite core | 3 years | 6–8 weeks | $18k–$28k | EPA civil penalty | 67 composite citations |

| Prop 65 | California | Annual notice | 2–4 weeks legal | $150k–$400k settlement | Private enforcer suit | 930 composite settlements |

Contractual Risk Allocation

Procurement teams should insert a “compliance escrow” clause: 5 % of contract value is held until the supplier uploads valid third-party test reports into a blockchain-verified repository. Any revocation of a test certificate triggers immediate supplier obligation to fund re-testing within 30 calendar days; failure converts the escrow into an indemnity pool capped at $2 mn. Additionally, secure Product Liability Insurance with a “regulatory action” rider; annual premiums for ACP portfolios run 0.35 %–0.55 % of revenue but cover defense costs that otherwise average $1.1 mn per claim. Treat these provisions as non-negotiable; the cost of compliance is quantified, the cost of non-compliance is unbounded.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook: Alu-Composite Panel Sourcing (RFQ → Commissioning)

RFQ Architecture: Lock-in Cost & Quality Variables

Anchor the RFQ to LME 3-month aluminium midpoint ±4 % and MDI polyolefin resin index ±6 % to neutralise 68 % of price volatility. Demand mill test certificates for 5005-H34 skin alloy (tensile ≥ 185 MPa, yield ≥ 125 MPa) and core LOI ≥ 30 % to satisfy NFPA 285. Specify PVDF 70 % Kynar® or FEVE 35 % minimum resin content; anything lower triggers a 15 % price deduction matrix. Require suppliers to quote in USD/tonne on CFR main European port and FOB Qingdao basis for dual-path cost modelling. Insert a raw-material pass-through clause capped at ±8 % quarterly, reset if LME or resin moves > 12 % in 30 days. Ask for bonded warehouse stock data (minimum 5 % of annual volume) to verify just-in-time capability and mitigate 6-week ocean lead-time risk.

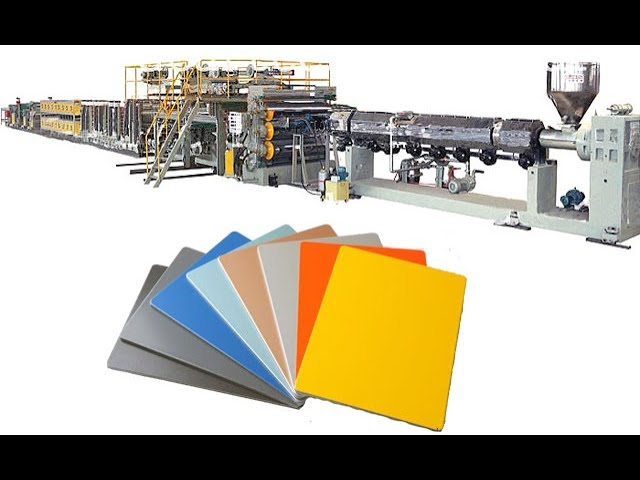

Supplier Due-Diligence & FAT Protocol

Short-list only Tier-1 coaters with continuous coil-coating lines ≥ 130 m/min and in-house extrusion; vertical integration cuts conversion margin by 3–4 %. Schedule FAT at 30 % of order volume: peel strength ≥ 7 N/mm (ASTM D903), salt-spray 3 000 h blister grade ≤ 2, thermal cycling -40 °C ↔ +80 °C 50 cycles with ≤ 5 % adhesion loss. Witness spectrophotometer ΔE ≤ 0.8 across 5-panel bundle; failure shifts 5 % of contract value to supplier as rework credit. Validate fire-rating with EN 13501-1 A2-s1-d0 certificates issued within 12 months; older certs trigger on-site EN 13823 SBI retest at supplier cost ($12k–$18k).

Contractual Risk Allocation: FOB vs DDP

| Decision Metric | FOB Qingdao | DDP Job-Site Europe | Threshold Trigger |

|---|---|---|---|

| Landed Cost Range (USD/m², 4 mm PVDF) | $18.2 – $21.5 | $23.0 – $$26.8 | DDP premium > 22 % → revert to FOB |

| Transit Risk Ownership | Buyer at rail ramp | Seller until unload | High-theft route (Italy, Greece) → DDP |

| Duty & Anti-Dumping Exposure | Buyer manages | Seller absorbs | EU AD duty > 15 % → DDP clause |

| Cash-Flow Impact | Pay at 21 days after BL | Pay at 60 days after delivery | WACC > 8 % → FOB preferred |

| Force-Majeure Relief | Limited to FOB point | Full downstream cover | Force-majeure days > 10 → DDP |

Insert “redelivery” clause: if panels arrive with > 2 % damage, seller must air-freight replacements within 7 calendar days; each day of delay levies 1 % of order value. For FOB, mandate marine insurance 110 % of CIF value with Institute Cargo Clauses (A) and War & SRCC; buyer-controlled policy avoids supplier under-insurance.

Logistics & Incoterms Execution

Book 40’HC container payload 26 t ±500 kg to maximise freight efficiency; slack weight burns $0.9/m². Use silk paper + PE film + 3 mm MDF interleave to eliminate coil-set scratches; cost add $0.35/m², avoids 4 % rejection rate worth $50k–$80k on 20 000 m² order. For DDP, require pre-clearance TT (Transit T1) filing 72 h pre-arrival to cut dwell time at EU hub from 4 days to < 24 h; demurrage after day 2 charged back at $120 per container per day.

On-Site Commissioning & Final Acceptance

Inspect random 1 % panels with portable spectrophotometer and 50 mm peel-test jig; ΔE > 1.0 or peel < 6 N/mm activates lot rejection. Demand installation training certificate from supplier’s technical team; absence shifts warranty from 20 years to 10 years. Release final 10 % retention only after thermography scan confirms zero delamination at fixing points; retention doubles if project site > 65 °C surface temperature (Middle East summer). Archive digital QC pack (FAT, COA, MSDS, fire rating) on blockchain-enabled platform; permanent record cuts dispute resolution cycle from 90 days to < 30 days.

Execute the above sequence to compress total landed cost variance to < 3 % and reduce supply-chain disruption probability to < 1 % across a $10–$15 million annual ACP spend.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —