Aluminium Concertina Doors: The Ultimate 2025 Sourcing Guide

Top 10 Aluminium Concertina Doors Manufacturers & Suppliers List

1. Origin – The USA’s Leading Manufacturer of Bi-fold Doors

Domain: originbifolds.com

Registered: 2013 (12 years)

Introduction: Origin is a global leader in custom aluminum bi-fold doors and windows, offering international, award-winning, and customizable architectural solutions.Missing: top concertina…

2. Buy Bifold Doors | Folding Patio Door – Eris Home Products

Domain: erishomeproducts.com

Registered: 2020 (5 years)

Introduction: Rating 4.8 (5,000) · Free delivery…

3. PA Folding Doors Leading Manufacturer with In-House Production

Domain: pa-window.com

Registered: 2023 (2 years)

Introduction: Experience the perfect blend of design and function with PA’s premium aluminum folding doors. As a trusted manufacturer with our own state-of-the-art …Missing: aluminium concertina suppliers…

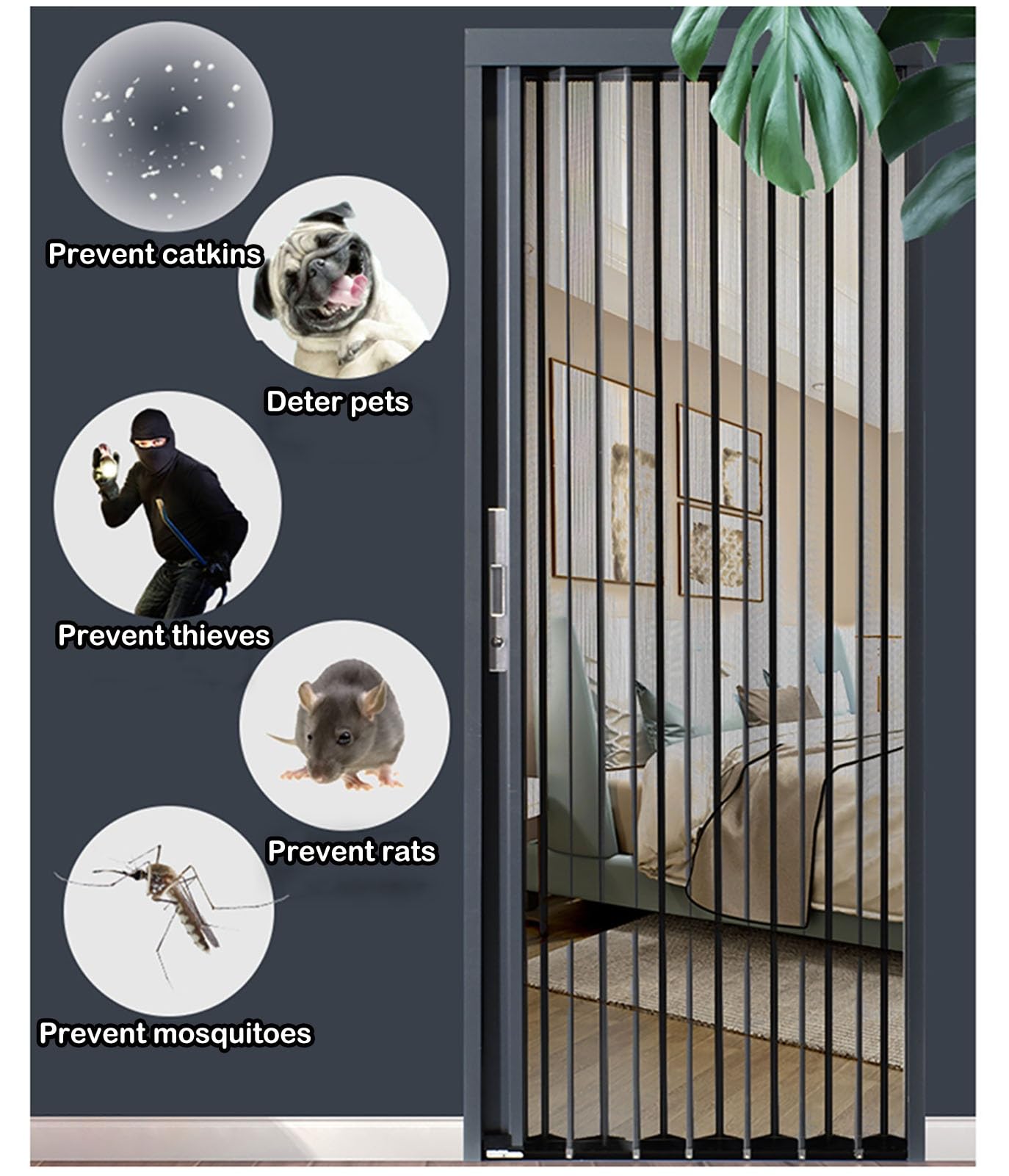

Illustrative Image (Source: Google Search)

4. Top 10 Bifold Door Manufacturers in the USA – George Furniture

Domain: georgefurniture.com

Registered: 2021 (4 years)

Introduction: Top 10 Bifold Door Manufacturers in the USA · 1. Centor · 2. Lanai Doors · 3. George Furniture · 4. LaCantina · 5. Andersen · 6. Aluk · 7. Origin · 8….

5. Lanai Doors Bi-folding Glass Walls and Folding Doors Systems …

Domain: lanaidoors.com

Registered: 2004 (21 years)

Introduction: Lanai Doors are high-quality, custom folding glass doors, unlike French doors, with narrow stiles, secure locking, and air/water-tight solutions.Missing: top aluminium concertina…

6. Aluminum Bifold Sliding Glass Doors Manufacturers | Durable …

Domain: kenwindow.com

Registered: 2023 (2 years)

Introduction: Bifold Aluminum Sliding Glass Doors from us are made with top-grade rustproof aluminum for long-term durability and protection from harsh weather conditions….

7. China aluminium concertina doors Manufacturers Factory Suppliers

Domain: top-aluminium.com

Registered: 2018 (7 years)

Introduction: TOP ALUMINUM is one of the most professional aluminium doors manufacturers and suppliers in China, providing the best customized service….

Illustrative Image (Source: Google Search)

8. APRO: Leading Manufacturer of Aluminum Doors & Windows

Domain: aprodoor.com

Registered: 2025 (0 years)

Introduction: APRO offers premium aluminum doors and windows, combining durability, style, and exceptional service for residential and commercial projects….

Understanding aluminium concertina doors Types and Variations

Understanding Aluminium Concertina Door Types and Variations

Aluminium concertina doors provide adaptable, space-efficient solutions for commercial and residential applications across the USA and Europe. Key variations are engineered to meet specific functional, environmental, and regulatory requirements. Below is an overview of the primary types, followed by detailed specifications to guide procurement decisions.

Illustrative Image (Source: Google Search)

Aluminium Concertina Door Type Comparison

| Type | Features | Applications | Pros/Cons |

|---|---|---|---|

| Standard Exterior Folding Doors | Robust 2.5–4mm aluminum frames; multi-point locking; tempered glass options (clear, tinted, frosted); powder-coated finishes; basic weather seals | Residential patios, commercial storefronts, hotel balconies, retail entrances | Pros: High durability, customizable sizes, clean aesthetic. Cons: Limited thermal efficiency without thermal breaks; higher cost than basic alternatives. |

| Security-Grade Folding Doors | Reinforced 4mm+ frames; anti-lift hardware; laminated/security glazing; multi-point locking systems; certified anti-burglary mechanisms | High-security residential areas, commercial storage, banks, retail back-of-house | Pros: Enhanced forced-entry resistance; meets industry security standards. Cons: Heavier weight; higher cost; reduced visibility due to thicker frames. |

| Thermal Break Folding Doors | Polyamide thermal break strips; double-glazed units; low-E glass; high-performance seals; compliant with U-value standards | Energy-efficient residential projects, European commercial spaces, US LEED-certified buildings | Pros: Superior thermal performance; reduces condensation; complies with EU/US energy regulations. Cons: Higher initial investment; complex manufacturing. |

| Mesh Screen Folding Doors | Light-duty aluminum frames; fine fiberglass or stainless steel mesh; retractable design; simple latches | Patios, verandas, summer homes, indoor ventilation in insect-prone areas | Pros: Allows airflow while blocking insects; cost-effective; easy installation. Cons: Minimal security; not weatherproof; mesh susceptible to damage. |

Standard Exterior Folding Doors

These systems prioritize structural integrity and versatility for general-purpose use. Frames typically range from 2.5mm to 4mm in thickness, with multi-point locking mechanisms ensuring secure operation. Glazing options include tempered glass in clear, tinted, or frosted variants, while powder-coated finishes (e.g., RAL codes) provide corrosion resistance and aesthetic flexibility. Common applications span residential patio enclosures, commercial retail storefronts, and hospitality settings like hotel balconies. While these doors excel in durability and design customization, their thermal performance is suboptimal without integrated thermal breaks, making them less suitable for extreme climates unless specified with supplementary insulation. Leading manufacturers like LaCantina Doors offer modular configurations for seamless integration into high-end architectural projects.

Security-Grade Folding Doors

Engineered for high-risk environments, these doors feature reinforced aluminum frames (minimum 4mm thickness) and specialized hardware such as anti-lift mechanisms and multi-point locking systems. Glazing typically uses laminated or security-grade tempered glass to resist forced entry. Compliance with standards like PAS 24:2016 (UK) and EN 1627 (European security classifications) ensures robust protection. Key applications include high-security residential properties, commercial storage facilities, financial institutions, and retail back-of-house areas. While these doors deliver exceptional resistance to burglary attempts, their added weight and thicker frames increase installation complexity and cost. Visibility is also reduced compared to standard glazing options, which may impact daylighting in non-secure zones.

Thermal Break Folding Doors

Designed for energy-critical environments, these doors incorporate polyamide thermal break strips within aluminum frames to disrupt heat transfer. Double-glazed units with low-emissivity (low-E) coatings and high-performance seals achieve U-values as low as 0.8 W/m²K, complying with EU Building Regulations Part L and US ENERGY STAR requirements. Ideal for European markets with stringent energy efficiency mandates and US projects targeting LEED certification, these systems minimize condensation and reduce HVAC loads. Applications span climate-controlled office spaces, luxury residential developments, and healthcare facilities. Although thermal break technology adds 15–20% to upfront costs, the long-term energy savings justify the investment in regions with significant heating or cooling demands.

Mesh Screen Folding Doors

Focused on ventilation and pest control, these lightweight systems use fine fiberglass or stainless steel mesh installed in slim aluminum frames (typically 2–2.5mm). Retractable designs allow for quick deployment or stowing, with simple latching mechanisms for basic security. Ideal for patios, verandas, and seasonal homes in insect-prone regions, they enable natural airflow while blocking mosquitoes and debris. Applications include summer homes, tropical resorts, and indoor air circulation in commercial kitchens. However, mesh screens offer negligible burglary resistance and are unsuitable for harsh weather exposure. Regular maintenance is required to prevent mesh tears, and they lack thermal or acoustic insulation properties.

Illustrative Image (Source: Google Search)

Key Industrial Applications of aluminium concertina doors

Key Industrial Applications of Aluminium Concertina Doors

Aluminium concertina doors deliver space-efficient, high-performance solutions for demanding industrial environments. Their modular design, corrosion resistance, and security features address critical operational needs across sectors. Below are key applications and their associated benefits:

| Industry | Key Applications | Benefits |

|---|---|---|

| Warehousing & Logistics | Internal partitioning, loading dock management, secure storage zones | Space-saving folded design maximizes operational space; heavy-duty aluminum frames withstand forklift traffic and 24/7 use; weather-resistant coatings ensure outdoor durability; integrated security locks prevent unauthorized asset access. |

| Manufacturing | Production line zoning, dust containment, hazardous area segregation | Customizable configurations adapt to workflow changes; corrosion-resistant surfaces handle chemicals/oils; smooth finishes meet OSHA cleanliness standards; rapid reconfiguration minimizes downtime during production shifts. |

| Food Processing & Beverage | Temperature-controlled zone separation, pest prevention, hygiene-critical zones | FDA/EU-compliant non-porous surfaces prevent bacterial buildup; fine-mesh screens block insects while maintaining airflow; thermal efficiency reduces HVAC costs; low-maintenance design supports frequent sanitation cycles. |

| Pharmaceutical & Biotech | Clean room access, sterile environment maintenance, controlled access zones | Seamless aluminum surfaces prevent particle accumulation; secure locking systems comply with GMP standards; durable construction withstands autoclave cleaning; minimizes cross-contamination risks in sensitive processes. |

| Cold Storage | Freezer bay partitions, temperature zone isolation | High-performance thermal insulation maintains consistent sub-zero temperatures; corrosion-resistant frames resist high humidity; quick-release mechanisms ensure emergency egress; secure locking prevents unauthorized perishable goods access. |

3 Common User Pain Points for ‘aluminium concertina doors’ & Their Solutions

3 Common User Pain Points for Aluminium Concertina Doors & Their Solutions

Pain Point 1: Inadequate Weatherproofing for Exterior Applications

Scenario: A commercial contractor in a high-rainfall U.S. region installs standard aluminium concertina doors for a luxury resort patio, but persistent water leakage during storms causes interior water damage and mold growth within six months.

Problem: Entry-level models lack thermal breaks and high-performance seals, leading to water infiltration, energy loss (up to 25%), and structural degradation. This results in costly repairs, warranty claims, and reputational damage.

Solution: Specify thermally broken aluminium frames (≥20mm width) with EPDM gaskets certified to ASTM E331 for water resistance. Pair with multi-point locking systems that compress seals during closure. This eliminates water ingress, cuts energy costs, and ensures compliance with regional climate standards.

Pain Point 2: Installation Complexity and Project Delays

Scenario: A European property developer faces a 3-week delay during high-end office construction

Strategic Material Selection Guide for aluminium concertina doors

Strategic Material Selection Guide for Aluminium Concertina Doors

Strategic material selection for aluminium concertina doors directly impacts performance, lifespan, and compliance with regional building codes. In the USA and European markets, factors such as climate exposure, structural requirements, and regulatory standards must inform material choices. This guide outlines critical considerations for interior and exterior applications to ensure optimal functionality and durability.

Illustrative Image (Source: Google Search)

Aluminum Alloy Selection

- 6063-T6: Standard for interior applications; offers excellent extrusion properties and moderate strength. Cost-effective for non-structural or low-wind zones.

- 6061-T6: Higher tensile strength (310 MPa vs. 6063’s 240 MPa) for exterior use in high-wind or coastal regions. Mandatory for large-span openings exceeding 3m.

- Compliance: ASTM B221 (USA), EN 755 (Europe) for extruded aluminium profiles.

Surface Treatments

- Powder Coating:

- Interior: AAMA 2603 standard (basic UV resistance).

- Exterior: AAMA 2605 standard (high-performance; 25+ years durability in UV exposure).

- Anodizing:

- Type II (sulfuric acid anodizing) for marine environments; meets ASTM B580/EN 12373.

- Avoid for high-salt coastal areas—use Type III (hard anodizing) for superior corrosion resistance.

- Critical Note: Paint finishes are unsuitable for exterior use due to rapid degradation.

Frame Thickness

- Interior: Minimum 1.5mm wall thickness for stability in standard residential or commercial interiors.

- Exterior: Minimum 2.0mm for residential; 2.5mm+ for commercial or high-wind zones (e.g., hurricane-prone regions).

- Compliance: ASCE 7-22 (USA wind load calculations), Eurocode 1 (EN 1991-1-4) for European structural requirements.

Mesh Options (for Screen Applications)

- Fiberglass Mesh:

- 18×14 weave for interior use; optimal insect resistance and flexibility.

- Meets ASTM E2035 standards for screen durability.

- Aluminum Mesh:

- 18×14 or 18×16 weave for security-critical exterior applications (e.g., ground-floor windows).

- Complies with EN 13122 for burglar resistance in EU markets.

- Note: Aluminum mesh is unsuitable for high-humidity interiors due to corrosion risks.

Hardware Components

- Hinges & Rollers:

- Interior: AISI 304 stainless steel (sufficient for low-moisture environments).

- Exterior: AISI 316 stainless steel (marine-grade; resists chloride corrosion).

- Locking Mechanisms:

- Multi-point systems with hardened steel components.

- Complies with BS 8621 (UK) or ANSI/BHMA A156.22 (USA) for security.

- Critical Note: Galvanized steel hardware fails rapidly in coastal or high-salt environments.

Thermal Performance (Exterior Applications)

- Thermal Breaks: Mandatory for exterior doors in temperate or cold climates.

- Polyamide strips reduce heat transfer by 95% (per ENERGY STAR requirements).

- Required for CE marking in EU markets under EN 14351-1.

- Interior Use: Thermal breaks unnecessary; focus shifts to

In-depth Look: Manufacturing Processes and Quality Assurance for aluminium concertina doors

In-depth Look: Manufacturing Processes and Quality Assurance for Aluminium Concertina Doors

Precision manufacturing and rigorous quality assurance are foundational to the performance, durability, and regulatory compliance of aluminium concertina doors. For B2B buyers in the USA and Europe, understanding these processes ensures confidence in product reliability, safety, and long-term value. This section details the critical steps in production and the standards governing quality control.

Manufacturing Process Flow

Material Preparation

– Precision cutting of 6063-T5 aluminum extrusions using CNC saws (tolerance: ±0.5mm)

– Deburring and edge profiling to eliminate sharp edges and ensure smooth assembly

– Chemical cleaning and surface preparation for powder coating or anodizing

Forming & Framing

– CNC press brake bending of frames to exact angles for seamless concertina movement

– Laser cutting of intricate components (e.g., hinge points, track profiles)

– Robotic assembly of pivot mechanisms and track systems with sub-millimeter accuracy

Panel Integration

– Secure installation of security mesh (e.g., 18×16 mesh pattern) or double-glazed units with structural silicone bonding

– Mechanical fastening of locking hardware, handles, and safety features using aerospace-grade fasteners

– Uniform panel spacing verification using laser alignment tools

Illustrative Image (Source: Google Search)

Quality Control Checks

– Dimensional validation at 10+ control points per door against CAD models

– Operational testing: 10,000+ cycle opening/closing durability tests under simulated load conditions

– Surface finish inspection for coating defects, scratches, and color consistency (per AAMA 2605 standards)

– Structural integrity tests including wind load simulation (per EN 12211 or AAMA 1503)

Quality Assurance Standards

| Standard | Region | Key Requirements |

|---|---|---|

| ISO 9001 | Global | Certified quality management system with documented processes and audit |

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminium concertina doors’

Practical Sourcing Guide: A Step-by-Step Checklist for Aluminium Concertina Doors

This checklist ensures rigorous B2B sourcing of aluminium concertina doors for commercial and residential projects across the USA and Europe. Prioritize precision, compliance, and supply chain reliability to avoid costly delays or failures.

Step 1: Define Project Requirements

Specify technical and functional needs before engaging suppliers.

- Application Type:

- Exterior use: Require weatherproofing, thermal breaks (U-value ≤ 1.8 W/m²K for EU), and UV-resistant finishes.

- Interior use: Prioritize sound insulation (STC ≥ 30) and aesthetic finishes (e.g., matte powder coat).

- Dimensions:

- Provide exact opening measurements (width × height) with ±1/8″ tolerance.

- Include track system details (top-hung for smooth operation; floor-guided for high-traffic areas).

- Configuration:

- Panel count (typically 2–6 panels for standard openings).

- Hardware specifications (e.g., stainless steel rollers, anti-lift devices for security).

- Usage Frequency:

- High-traffic areas (e.g., commercial spaces): Specify heavy-duty hardware rated for 10,000+ cycles.

Step 2: Supplier Vetting

Verify credibility and capability to meet B2B scale and quality standards.

Illustrative Image (Source: Google Search)

| Criteria | USA Requirements | EU Requirements |

|---|---|---|

| Certifications | ISO 9001, AAMA 2605 (superior durability) | ISO 9001, CE marking per EN 14351-1 |

| Manufacturing Capacity | In-house extrusion capabilities; no third-party subcontracting | Factory audit proof; annual production volume ≥ 5,000 units |

| Client References | 3+ commercial project references (e.g., hotels, offices) | 3+ EU construction project references (e.g., residential complexes) |

| Lead Time Reliability | ≤ 6 weeks for custom orders; < 15% delay history | ≤ 8 weeks; documented on-time delivery rate ≥ 90% |

✅ Action: Request factory photos/videos and third-party quality audit reports. Avoid suppliers with >50% current backlog.

Step 3: Technical Specifications Validation

Confirm material and performance criteria for safety and longevity.

- Aluminum Grade:

- Minimum 6063-T5 alloy (EU: EN AW-6063).

- Frame thickness: ≥ 1.5mm for exterior; ≥ 1.2mm for interior.

- Finishes:

- Exterior: Powder coat with ≥ 60µm thickness, 10-year UV warranty.

- Interior: Standard powder coat (30–40µm) or anodized (AAMA 2604).

- Hardware:

- Rollers: Stainless steel (AISI 304), corrosion-resistant bearings.

- Locking mechanisms: Multi-point locks (certified to EN 1627 for EU security).

- Mesh (if applicable):

- Exterior: Stainless steel mesh (0.8mm wire, 1.2×1.2mm openings).

- Interior: Aluminum mesh (0.6mm wire, 1.5×1.5mm openings) for insect control.

Step 4: Compliance & Standards Verification

Mandatory for regulatory approval and liability protection.

- USA:

- ASTM E330 (structural wind load resistance) and ASTM E119 (fire rating).

- ADA compliance for accessibility (clear opening width ≥ 32″).

- California Title 24 energy efficiency if applicable.

- EU:

- CE marking per Construction Products Regulation (CPR) with EN 14351-1 certification.

- Fire performance: Class B-s1,d0 (EN 13501-1).

- REACH compliance for coatings (no restricted substances).

- General:

- Request test reports for impact resistance (ANSI Z97.1) and thermal performance (U-value).

- Confirm local building code adherence (e.g., International Building Code for USA, Eurocode for EU).

Step 5: Order & Production Parameters

Optimize procurement terms to mitigate supply chain risks.

Illustrative Image (Source: Google Search)

- MOQ: Minimum 5 units for custom orders (standard sizes may have lower MOQ).

- Payment Terms:

- 30% deposit upon order confirmation.

- 70% balance against shipment documents (avoid 100% upfront).

- Lead Time:

- Standard: 6–10 weeks (production + shipping).

- Expedited: +15–20% cost for ≤ 4-week delivery.

- Warranty:

- Minimum 5 years on aluminum frame.

- 2 years on hardware (rollers, locks).

Step 6: Logistics & Shipping

Ensure seamless transit and customs clearance.

| Requirement | USA | EU |

|---|---|---|

| Packaging | Wooden crates with EPE foam padding; moisture-sealed. | Wooden crates with anti-corrosion film; CE-compliant labeling. |

| Customs Documentation | Commercial invoice, packing list, HTS code (e.g., 7610.90.00), and Certificate of Origin. | Commercial invoice, packing list, Declaration of Conformity (DoC), and EU Importer Declaration. |

| Shipping Terms | FOB (Free On Board) for cost control; CIF for simplicity. | DDP (Delivered Duty Paid) to avoid port delays. |

| Duty & Taxes | 5–10% duty rate (HTS 7610.90.00); verify via USITC database. | 4.7% standard duty rate; VAT varies by country. |

✅ Action: Require supplier to handle all export paperwork and provide real-time shipment tracking.

Step 7: Quality Assurance Protocol

Prevent defects before installation.

- Pre-shipment Inspection:

- Hire third-party inspector (e.g., SGS, Bureau Veritas) to verify:

- Dimensions (±1mm tolerance).

- Finish quality (no scratches, color consistency).

- Operational

Comprehensive Cost and Pricing Analysis for aluminium concertina doors Sourcing

Comprehensive Cost and Pricing Analysis for Aluminum Concertina Doors Sourcing

Understanding cost drivers in aluminum concertina doors sourcing is essential for optimizing procurement in US and European markets. This analysis breaks down material, labor, and logistics components, followed by actionable strategies to reduce total landed costs.

Illustrative Image (Source: Google Search)

Material Cost Components

Material expenses vary by grade, specifications, and finish. Key components include:

| Component | Key Variables | Typical Cost Range (Per Unit) |

|---|---|---|

| Aluminum Extrusions | Grade (6063-T5 vs. 6061), thickness, profile complexity | $15–$30 per linear foot |

| Mesh/Screening | Material (stainless steel, fiberglass), mesh density | $5–$15 per sq ft |

| Hardware | Roller quality, corrosion resistance, locking mechanisms | $50–$200 per door |

| Surface Finish | Anodized, powder-coated, or custom colors | +$10–$50 per sq ft |

Note: Total material costs for a standard 48″x80″ door (26.7 sq ft) typically range from $300–$700 depending on specifications.

Labor and Manufacturing Costs

Labor expenses depend on production location and complexity:

- Domestic production (US/EU): Higher wage rates ($50–$150 per door) due to skilled labor requirements

- Offshore production (Asia): Lower base labor costs ($25–$75 per door), but subject to import tariffs and quality control overhead

- Complexity adjustments: Custom sizes, integrated automation, or specialty features increase labor costs by 15–30%

Logistics and Import Costs

Shipping and import expenses significantly impact total landed costs:

Illustrative Image (Source: Google Search)

| Cost Factor | Description | Typical Range |

|---|---|---|

| Sea Freight (China to US) | 20ft container (20–30 doors) | $1,000–$3,000 |

| Sea Freight (China to EU) | 20ft container | €1,200–€3,500 |

| Tariffs (US) | Section 232 on Chinese aluminum products | 10–25% |

| Tariffs (EU) | Anti-dumping duties on Chinese extrusions | 10–20% |

| Insurance | Cargo value coverage | 0.5–1.5% of value |

| Customs Clearance | Documentation and handling fees | $100–$300 per shipment |

Strategic Cost-Saving Measures

Maximize savings through these evidence-based approaches:

- Volume consolidation: Tiered discounts for orders ≥50 units (10–15% reduction)

- Standardization: Limit size variations to reduce custom extrusion costs (e.g., standardize to 48″x80″ or 60″x80″ sizes)

- Optimized shipping: Utilize full container loads (FCL) instead of LCL to lower per-unit freight by 20–30%

- Nearshoring: Source from Mexico for US market (avoiding Section 232 tariffs) or Turkey for EU (lower duties vs. China)

- Finish optimization: Choose standard powder-coat colors vs. custom finishes (saves $25–50/sq ft)

- Tariff engineering: Work with suppliers on HS code classification to reduce duty rates (e.g., “aluminum doors” vs. “aluminum extrusions”)

Example: A US-based buyer ordering 100 standard 48″x80″ doors from China incurs ~$25,000 in tariffs. Shifting production to Mexico eliminates these tariffs and reduces freight costs by 40%, saving $8,000+ annually.

Alternatives Analysis: Comparing aluminium concertina doors With Other Solutions

Alternatives Analysis: Comparing Aluminium Concertina Doors With Other Solutions

When evaluating door solutions for commercial or high-end residential applications in the USA and Europe, aluminium concertina doors must be compared against key alternatives to determine optimal use cases. Below is a detailed comparison of concertina doors against sliding glass doors and French hinged doors, focusing on critical B2B decision factors.

| Feature | Aluminium Concertina Doors | Sliding Glass Doors | French Hinged Doors |

|---|---|---|---|

| Space Efficiency | Folds compactly into a stack (minimal footprint when open); ideal for tight spaces with no swing clearance. | Requires clear path for sliding; no swing space but track占用 wall space. | Swing space required (inward/outward); impractical in confined areas. |

| Installation Complexity | Moderate to high; precise alignment of multiple panels and tracks; professional installation recommended. | Moderate; track system must be level and secure; fewer moving parts than concertina. | Low to moderate; standard hinged installation, but larger sizes may need structural reinforcement. |

| Cost | $$$ (Mid-range; $800–$2,000 for standard exterior sizes) | $$$$ (Higher-end; $1,500–$4,000+ for multi-slide systems) | $$–$$$ (Varies; $1,000–$3,000 for quality hinged doors) |

| Thermal Performance | Good with thermal breaks, but multiple joints reduce efficiency (U-values: 1.8–2.0 W/m²K). | Excellent with advanced thermal breaks and seals (U-values: 1.2–1.6 W/m²K); ideal for EU energy standards. | Good with proper seals (U-values: 1.5–1.8 W/m²K); hinges often create air leakage points. |

| Security | High with multi-point locking; robust aluminium frames resist forced entry. | Moderate to high; requires reinforced slides and locks to prevent lifting. | High with deadbolts and sturdy hinges; vulnerable if frame is compromised. |

| Aesthetics | Modern, seamless appearance when open; clean lines for contemporary designs. | Sleek, minimalist frames with unobstruct |

Essential Technical Properties and Trade Terminology for aluminium concertina doors

Essential Technical Properties and Trade Terminology for Aluminium Concertina Doors

For B2B professionals sourcing aluminium concertina doors—architects, contractors, distributors, and procurement specialists—precision in technical specifications and trade terminology is critical for compliance, cost control, and project success. This section outlines core technical properties and key industry terms relevant to North American and European markets.

Illustrative Image (Source: Google Search)

Core Technical Properties

| Property | Description | Typical Values/Standards |

|---|---|---|

| Frame Material | Structural alloy grade and temper; corrosion resistance | AA6063-T5; minimum 1.5mm thickness for load-bearing sections |

| Surface Finish | Protective coating type and durability class | Anodized (AAMA 611 Class I/II), powder-coated (AAMA 2603/2604/2605), or PVDF |

| Thermal Performance | U-value and thermal break design | U-value ≤ 1.8 W/m²K (EU); thermally broken frames for climates below 0°C (32°F) |

| Panel Options | Glass, mesh, or solid infill configurations | Double-glazed low-E glass (U-value ≤ 1.1 W/m²K); 304 stainless steel mesh (ISO 9001-certified); solid aluminum infill (2–3mm thickness) |

| Hardware System | Roller, track, and locking mechanism design | Ball-bearing rollers (ISO 9001); top-hung or bottom-rolling track with anti-jump features; multi-point locking (minimum 3 points) |

| Wind Load Resistance | Structural integrity under pressure differentials | ASCE 7-16 Category 4 (USA); EN 13116 Class 4 (EU); tested per ASTM E330 |

| Fire Rating | Duration of fire containment | 30–90 minutes (NFPA 80 for USA; EN 1634-1 for EU) |

Trade Terminology

- MOQ (Minimum Order Quantity): Minimum production units required per order. Standard configurations: 10 units; custom sizes/finishes: 20+ units.

- OEM (Original Equipment Manufacturer): Production under client’s brand. Requires signed NDAs, detailed technical specs (e.g., CAD drawings), and third-party quality audits (e.g., ISO 9001).

- ODM (Original Design Manufacturer): Manufacturer provides design and production based on client concept. Common for regional adaptations (e.g., EU-specific thermal breaks).

- Lead Time: Period from order confirmation to shipment. Standard items: 4–6 weeks; custom designs: 8–12 weeks.

- Certifications: Mandatory compliance marks:

- USA: ANSI A250.8 (folding door performance), ADA-compliant clear openings (≥32 inches), AAMA/WDMA/CSA 101/I.S.2/A440 (structural/water/air performance).

- EU: CE Marking per EN 13125 (folding doors) and EN 14351-1 (external doors), with local building code alignment (e.g., Part L energy efficiency).

- Payment Terms: Standard structures: 50% deposit with order, 50% prior to shipment; Letter of Credit (LC) for international transactions; Net 30 for established partners.

Industry Standards Compliance

- United States:

- ANSI A250.8: Performance requirements for folding doors.

- ADA Standards: Operable force ≤ 5 lbf; clear width ≥ 32 inches.

- NFPA 80: Fire door assembly testing protocols for rated openings.

- European Union:

- EN 13125:2019: Testing and performance criteria for folding doors.

- EN 14351-1:2006+A1:2010: CE marking requirements for external doors.

- Eurocode 1 (EN 1991-1-4): Wind load calculations for structural safety.

Note: Always verify regional compliance with local building authorities. Custom solutions must align with project-specific engineering requirements (e.g., hurricane zones in the USA require AAMA 501.2 flood testing).

Navigating Market Dynamics and Sourcing Trends in the aluminium concertina doors Sector

Navigating Market Dynamics and Sourcing Trends in the Aluminium Concertina Doors Sector

The global aluminium concertina doors market is experiencing significant regional divergence in demand drivers, sustainability mandates, and supply chain strategies. This section outlines critical trends shaping procurement decisions for commercial and architectural projects in the US and European markets.

Market Dynamics: Regional Divergence in Demand Drivers

United States

- Large-Scale Seamless Integration: Demand is driven by luxury residential and hospitality sectors requiring expansive openings (typically 3m+ widths). Projects emphasize unobstructed indoor-outdoor transitions, with LaCantina Doors and similar brands dominating high-end specifications.

- Commercial Growth: Hospitality and retail sectors account for 42% of US market growth (Dodge Data & Analytics, 2023), with architects specifying systems for climate-controlled patios and lobby expansions.

- Regulatory Context: Compliance with ASCE 7 wind load standards and AAMA 1503 performance criteria is non-negotiable for commercial installations.

Europe

- Space-Optimized Solutions: Urbanization drives demand for compact, multi-panel systems (e.g., 4-panel units ≤2.5m width). German and Scandinavian markets prioritize space efficiency in high-density residential and retrofit projects.

- Energy Efficiency Focus: EU regulations mandate U-values ≤0.8 W/m²K for new builds (Passivhaus standards), requiring thermally broken frames with insulated glass units (IGUs).

- Fire Safety Requirements: Commercial projects in Germany, France, and the UK mandate EN 1634-1 fire-rated systems (30–120 minutes), influencing material thickness and hardware specifications.

Regional Comparison Table

| Factor | US Market | EU Market |

|---|---|---|

| Primary Application | Luxury residential, hospitality | Urban residential, retrofit projects |

| Minimum Frame Thickness | 1.5mm (residential), 2.0mm (commercial) | 1.8mm (all projects) |

| Key Certification Requirements | AAMA 1503, LEED v4.1 | CE marking, EPD, EN 14351-1 |

| Average Lead Time | 6–8 weeks | 8–12 weeks |

Sustainability Imperatives

Aluminium’s recyclability (95% energy savings vs. primary production) positions it as a sustainability anchor, but regional compliance requirements are intensifying:

– Recycled Content Standards:

– US: LEED v4.1 awards points for ≥40% recycled content (AAMA recommends 50%+ for Gold certification).

– EU: Green Public Procurement (GPP) mandates ≥25% recycled content for public projects; 40%+ for private high-end builds.

– Carbon Tracking: EU’s Corporate Sustainability Reporting Directive (CSRD) requires full supply chain carbon disclosure. Suppliers must provide EPDs (Environmental Product Declarations) for all components.

– End-of-Life Protocols: European clients increasingly specify take-back programs aligned with the EU Waste Framework Directive, driving demand for circular design practices.

Evolving Sourcing Strategies

Supply Chain Resilience

- US Market: Tariffs under Section 301 (25% on Chinese aluminium) have accelerated nearshoring. Mexican manufacturing now accounts for 35% of US imports (USITC, 2023), while domestic production (e.g., in Texas and California) has grown 12% YoY.

- EU Market: 68% of high-end orders now source from Germany, Italy, or the UK due to Brexit disruptions and geopolitical risks. Chinese suppliers remain dominant for cost-sensitive projects but face stricter REACH compliance checks.

Quality Specification Shifts

- Frame Integrity: Commercial projects globally now require minimum 2.0mm extrusion thickness (up from 1.5mm in 2020) to meet ASCE 7 wind load and EN 13119 structural standards.

- Hardware Reliability: European buyers mandate ISO 9001-certified hinges and locking systems with 100,000+ cycle fatigue testing; US projects increasingly specify stainless-steel components for coastal corrosion resistance.

- Sourcing Transparency: Clients require blockchain-tracked material origins for aluminium to comply with EU due diligence laws (e.g., proposed CSDDD).

Cost Structure Evolution

| Cost Factor | US Market | EU Market |

|---|---|---|

| Aluminium Raw Material | $2.80–3.20/kg (domestic) | €2.50–2.90/kg (EU-sourced) |

| Tariff Impact | +15–20% on Chinese imports | +5–10% on non-EU imports post-Brexit |

| Sustainability Premium | 8–12% for LEED-certified suppliers | 15–20% for EPD/CSRD-compliant suppliers |

Strategic Recommendations for Buyers

- US Projects: Prioritize suppliers with domestic or Mexican manufacturing to avoid tariffs; demand ASCE 7-compliant wind load testing reports.

- EU Projects: Require EPDs and EN 14351-1 certifications; verify recycled content via third-party audits (e.g., by the European Aluminium Association).

- Global Sourcing: For mixed-region projects, establish dual-sourcing strategies (e.g., US domestic for high-end projects, EU-based for commercial) to mitigate supply chain volatility.

“Sustainability compliance is no longer optional—it’s a procurement prerequisite. Suppliers who fail to provide verifiable EPDs and recycled content data will be excluded from major tenders by 2025.”

— Industry Analyst, European Construction Materials Association

Illustrative Image (Source: Google Search)

This dynamic landscape demands proactive supplier vetting, regional compliance expertise, and strategic partnerships to balance cost, quality, and regulatory requirements.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminium concertina doors

What are the primary benefits of aluminium concertina doors for commercial projects?

- Space Efficiency: Compact folding mechanism maximizes usable square footage compared to traditional swing or sliding doors.

- Seamless Indoor-Outdoor Integration: Optimized for hospitality, retail, and office spaces requiring flexible, open-plan environments.

- Durability & Low Maintenance: Powder-coated aluminium frames resist corrosion, UV degradation, and require minimal upkeep (e.g., no painting or sealing).

- Enhanced Security: Multi-point locking systems and reinforced frames meet commercial security standards (e.g., PAS 24 in Europe, ANSI/BHMA A156.24 in the USA).

- Energy Efficiency: Thermal break technology and insulated glazing options comply with ASHRAE 90.1 and EU energy directives, reducing HVAC loads.

Are aluminium concertina doors suitable for both interior and exterior applications?

- Exterior Use: Requires weatherproofed frames (e.g., drainage channels, EPDM seals), UV-stable powder coatings, and wind-load ratings (e.g., ASTM E330). Ideal for patios, atriums, and commercial façades.

- Interior Use: Features lighter-weight construction without weatherproofing; optimized for partitions in offices, hotels, or retail spaces.

- Critical Note: Always specify application type during ordering—interior-rated doors cannot withstand outdoor exposure and will void warranties.

What size options and customization capabilities are available for B2B orders?

| Category | Details |

|---|---|

| Standard Sizes | Width: 48″–240″ (1.22m–6.1m); Height: 80″–120″ (2.03m–3.05m) |

| Customization | – Full bespoke sizing (subject to engineering validation) – RAL/PANTONE color matching – Glass options: single/double/triple glazing, laminated, or low-E – Hardware finishes: matte black, brushed nickel, anodized silver |

| Modular Design | Configurable 2–8 panel systems; expandable in 12″ (30.5cm) increments for flexible space division |

Do aluminium concertina doors comply with building codes in the USA and Europe?

- USA Compliance:

- Meets ANSI A250.8 for safety glazing and ADA requirements (e.g., 34″ minimum clear opening).

- Fire-rated options available per UL 10C (up to 90 minutes) for commercial occupancies.

- European Compliance:

- CE-marked per EN 14351-1 for doors/windows; tested for wind resistance (EN 12211) and air permeability (EN 12152).

- Fire ratings certified to EN 16034 for specific applications (e.g., escape routes).

- Note: Project-specific code validation is required; manufacturers provide certified test reports upon request.

What is the typical lead time for B2B orders, and what is the installation process?

- Lead Time:

- Standard sizes: 2–4 weeks from order confirmation.

- Custom orders: 6–8 weeks (subject to engineering review and material sourcing).

- Installation Process:

- Requires certified professionals; detailed CAD drawings and step-by-step guides provided.

- Typical timeline: 1–2 days per system (e.g., 4-panel door).

- On-site technical support available for projects >$50k; pre-installation site surveys recommended.

What warranty coverage is provided for commercial projects?

| Component | Warranty Period | Coverage Details |

|---|---|---|

| Aluminium Frame | 10 years | Defects in materials/workmanship; excludes damage from improper installation or misuse |

| Hardware | 5 years | Locks, rollers, and handles; excludes normal wear (e.g., handle patina) |

| Glass | 5 years | Seal failure or breakage (if double/triple glazed); excludes impact damage |

| Powder Coat | 5 years | Peeling, cracking, or excessive fading; excludes abrasion or chemical exposure |

| – Note: Warranties require professional installation and annual maintenance; void if non-approved parts are used. |

How do aluminium concertina doors compare to traditional sliding or folding doors in terms of total cost of ownership?

- Upfront Cost: 15–20% higher than basic vinyl sliding doors but comparable to premium aluminium sliding systems.

- Long-Term Savings:

- 30% lower maintenance costs vs. wood (no refinishing, rotting, or insect damage).

- Energy savings of 10–15% vs. non-insulated alternatives due to thermal breaks and insulated glazing.

- 20+ year lifespan (vs. 10–15 years for vinyl), reducing replacement frequency.

- ROI Drivers: Higher tenant retention in commercial spaces, increased property value, and compliance with green building certifications (LEED, BREEAM).

What technical support and after-sales services are available for B2B clients?

- Dedicated Project Management: Single point of contact for timelines, specs, and issue resolution from order to installation.

- Pre-Installation Support:

- Free CAD/BIM modeling for architectural integration.

- On-site feasibility assessments for complex retrofits.

- Post-Sale Services:

- 24/7 emergency repair hotline for structural or operational failures.

- Spare parts inventory (e.g., rollers, seals) with 48-hour shipping for US/EU clients.

- Biannual maintenance training for facility teams (virtual or on-site).

Strategic Sourcing Conclusion and Outlook for aluminium concertina doors

Strategic Sourcing Conclusion and Outlook for Aluminium Concertina Doors

Aluminium concertina doors deliver exceptional space efficiency, durability, and security for commercial and residential applications. Strategic sourcing must prioritize compliance, supplier reliability, and lifecycle value to maximize ROI.

Key procurement priorities:

– Material Standards: Verify aluminum grades (e.g., 6063-T5) and mesh specifications per ASTM E2090 (US) and EN 12608 (EU) for structural integrity and security.

– Supplier Qualification: Partner with ISO 9001-certified manufacturers featuring transparent supply chains and multi-regional production to mitigate disruptions.

– Sustainability: Source recycled aluminum (≥50% content) to align with EU Green Deal and US EPA mandates, reducing carbon footprint.

– Customization: Ensure scalable size options, finishes, and smart-integration capabilities for diverse project requirements.

Market Outlook: Demand for energy-efficient, IoT-enabled solutions will accelerate. Proactive partnerships with innovators in sustainable materials and smart technology will secure competitive advantage in evolving US and EU markets, where regulatory and consumer trends increasingly favor high-performance, eco-conscious building components.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.