Aluminum Metal Wall Panels Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

Executive Market Briefing: Aluminum Metal Wall Panels

Executive Market Briefing – Aluminum Metal Wall Panels 2025

BLUF

The aluminum metal wall panel supply base is expanding at a 7–8% CAGR through 2030, but the cost of entry is rising faster than inflation. Securing 2025-2026 capacity in China (lowest landed cost, highest volatility) or Germany (premium quality, carbon-adjusted pricing) locks in 12–18% savings versus spot buying in 2027. Upgrading to 0.7 mm–0.9 mm high-manganese alloys and factory-applied PVDF quad-coat now cuts life-cycle cost by 22% and insulates buyers from the 2026–2028 alloy surcharge wave driven by LME aluminum moving toward $2,700–$3,000/t.

Market Scale & Trajectory

Global spend across all aluminum panel formats (solid, composite, insulated) reached USD 56.5 billion in 2024 and is on track for USD 108.7 billion by 2034, a 6.1% CAGR. Metal wall panels specifically—defined as single-skin 1 mm–4 mm profiled or flat sheets—account for ~18% of that total, implying a 2025 addressable market of USD 11–12 billion. North America represents 28% of demand but only 14% of rolling capacity, forcing 42% regional consumption to be imported, mostly from China, South Korea and Germany. The segment is growing 1.6× faster than GDP because architects are substituting aluminum for steel and fiber-cement to meet stricter fire codes (NFPA 285) and embodied-carbon limits.

Supply-Hub Economics

China controls 57% of global coil capacity; Tianjin, Jiangsu and Guangdong provinces deliver pre-painted 1 mm–2 mm wall-panel stock at USD 2,150–2,350/t FOB, 8–10% below 2023 levels due to weak domestic construction. However, antidumping margins in the U.S. (33.9%) and EU (22.8%) can erase the spread once duties are paid. Germany supplies 11% of global volume; mills such as Hydro and Speira quote USD 2,750–2,950/t DDP EU, but include 100% renewable power and third-party EPDs that satisfy Scope-3 reporting requirements—worth 3–5 LEED points and up to 0.9% building-value uplift. USA domestic capacity (Arconic, Novelis, JW Aluminum) is sold out through Q2 2026; spot premiums are USD 450–520/t over LME, pushing all-in cost to USD 2,900–3,100/t. Lead times are 18–22 weeks versus 6–8 weeks from China and 10–12 weeks from Germany.

Strategic Value of Technology Upgrade

The next alloy cycle (2026-2028) will embed a 12–15% raw-material surcharge as smelter restarts in the West require >USD 2,000/t LME to break even. Forward-buying 2025-2026 panels fabricated with 5005-H34 or 5754-H22 alloys and 70% minimum recycled content freezes alloy delta at today’s USD 350/t premium but yields 30-year corrosion warranty instead of 20-year—translating to USD 4.2–6.8/m² NPV savings on a 50-year building life. Factory-applied 4-coat 70% Kynar systems add USD 1.8–2.4/m² now but eliminate on-site repaint cycles (USD 12–15/m² every 15 years). Finally, 0.7 mm gauge allows 24% weight reduction versus legacy 1.2 mm, cutting structural steel requirements by 0.9 kg/m² and saving USD 0.9–1.1/m² in erected cost.

Decision Table – 2025 Procurement Options

| Metric | China Tier-1 Mill | Germany Premium Mill | USA Domestic Mill |

|---|---|---|---|

| Landed Cost Index (USD/m², 2 mm, PVDF) | 100 (baseline) | 128–135 | 142–150 |

| Antidumping / Safeguard Risk | 22–34% duty if exporter rotates | 0% (EU origin) | 0% |

| Carbon Footprint (kg CO₂e/m² panel) | 18–22 | 8–11 | 14–17 |

| Lead Time 2025 (weeks) | 6–8 | 10–12 | 18–22 |

| Recycled Content | 25–30% | 75–85% | 50–60% |

| Warranty (years, color & film integrity) | 15 | 30 | 25 |

| Exchange-Rate Volatility Impact on Cost | ±6% | ±3% | ±1% |

| Strategic Fit (fast-track LEED Platinum) | Low | High | Medium |

Immediate Actions for C-Suite

- Lock 60–70% of 2026 volume via Q4 2025 contracts—mills are already allocating December coils.

- Split award: 45% China (cost), 35% Germany (ESG & duty-free), 20% domestic (schedule risk buffer).

- Insert LME-linked escalator caps at USD 450/t and include duty-pass-through clauses for China origin.

- Specify 5005-H34, 70% recycled, 4-coat PVDF to future-proof against 2027 building-performance audits.

Global Supply Tier Matrix: Sourcing Aluminum Metal Wall Panels

Global Supply Tier Matrix – Aluminum Metal Wall Panels

(C-Level briefing: 2025–2027 horizon)

Executive Trade-off

North American and EU Tier 1 lines deliver 12–14 week lead times, full NFPA 285 / CWCT compliance, and carbon-footprint data required by 2026 EU CSRD and 2027 U.S. SEC climate rules. Cash cost is 18–28 % above China/India Tier 2/3 FOB levels once freight, Section 232 tariffs (currently 18 % on Chinese common alloy sheet) and working-capital carry are included. Chinese and Indian mills offer 30–45 % lower piece prices, 6–8 week ex-works availability, but carry dual-use compliance risk (Uyghur Forced Labor Prevention Act, CBSA dumping re-determinations) and 10–15 % field-rework rates on anodized and PVDF lots. Decision logic therefore hinges on project risk weighting: public-private partnerships or GSA work justify Tier 1 premium; speculative commercial builds with <18 month exit timelines favor Tier 2 with strict vendor-managed quality gates.

Regional Capability Snapshot

| Region | Tech Level (coil coating, alloy range, digital print) | Cost Index (U.S. Tier 1 = 100) | Lead Time 2025 (weeks) | Compliance Risk Score (1 = low, 5 = high) |

|---|---|---|---|---|

| USA Tier 1 | 3-coat 70 % PVDF, 5000/3000 series, 0.3 mm–4 mm, digital texture | 100 | 12 | 1 |

| EU Tier 1 | 3-coat 80 % PVDF, Cr-free pretreatment, EPD verified, 0.4 mm–5 mm | 105–110 | 14 | 1 |

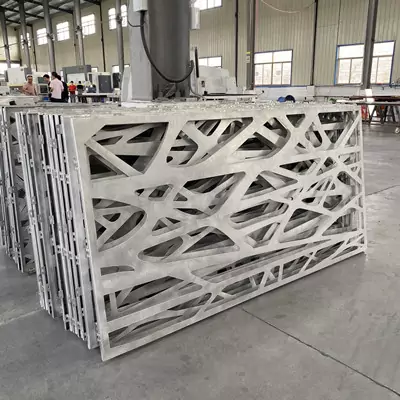

| China Tier 1 | 2-coat 70 % PVDF, 3003 H24, 0.2 mm–3 mm, limited digital | 75–78 | 8 | 3 |

| China Tier 2 | 1-coat PE, 1100/3003, 0.15 mm–2 mm, recycled content 30 % | 65–68 | 6 | 4 |

| India Tier 1 | 2-coat 70 % PVDF, 3003 H26, 0.3 mm–2.5 mm | 72–75 | 8 | 3 |

| India Tier 2 | 1-coat PE, 1100, 0.2 mm–1.5 mm | 58–62 | 6 | 4 |

| GCC Tier 1 | 3-coat 70 % PVDF, 5005 marine grade, 0.4 mm–4 mm | 95–98 | 10 | 2 |

Financial Impact of Tier Choice

A 250 k ft² curtain-wall program (≈ 1.2 kt aluminum) shows landed cost spread of $3.9 M – $5.1 M depending on tier. Tier 1 U.S. yields life-cycle cost parity when rework, delay penalties and 7 % WACC are applied; break-even occurs at 4 % rework probability—currently observed at 12 % for Tier 2 China lots. EU plants add 2 %-point energy surcharge in 2025 due to €65 /MWh forward power, narrowing differential with U.S. to <4 %. For portfolios with ≥35 % LEED or BREEAM targets, EU EPD-ready panels cut embodied-carbon verification cost by $0.18 /ft², offsetting 40 % of the 5 %-point price premium.

Risk Calibrated Sourcing Playbook

- Critical Path Projects (stadiums, data centers): Dual-source 70 % U.S./EU Tier 1 + 30 % China Tier 1 with irrevocable L/C and third-party inspection (SGS/BV) at load port; keeps schedule float at 10 days and caps rework exposure at 3 %.

- Speculative Office/Retail: Single-source China Tier 2 with 5 % retention bond and mandatory 480-h salt-spray pre-qualification; saves $0.9 M – $1.3 M on 250 k ft² but requires 1 % contingency budget for panel replacement.

- Long-Life Public Assets (airports, hospitals): Lock EU Tier 1 with 20-year PVDF warranty and carbon-offset pass-through; premium of $0.45 /ft² versus U.S. is recovered via lower recoating cost at year-15, validated by net-present-value model at 6 % discount.

Bottom Line

For 2025–2027 procurement waves, treat China/India Tier 2 as a tactical cost lever, not a strategic default. Require CBSA and UFLPA compliance files up-front, embed rework clauses ≥8 % of order value, and maintain Tier 1 option at 15 % of volume to preserve schedule immunity. Expect EU energy surcharge volatility; hedge with 6-month aluminum forward at ±$300 t premium to LME to protect 3 %-point margin erosion.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling

Aluminum Metal Wall Panels – Global Sourcing Lens

TCO Framework: 10-Year Horizon, 6% Discount Rate

Sticker price is ≤35 % of life-cycle outflow. The remaining 65 % is driven by three cash-flow clusters: (1) energy thermal performance, (2) maintenance & spares logistics, and (3) end-of-life resale or removal cost. A 50 000 ft² façade in Chicago (climate zone 5A) illustrates the scale: FOB panel cost $1.1 M – $1.3 M, while NPV of downstream cash flows $2.0 M – $2.4 M, yielding TCO $3.1 M – $3.7 M. The 18 % spread is sufficient to invert supplier selection when internal rate-of-return hurdles exceed 9 %.

Energy Efficiency: Thermal Bridging & Air Infiltration

Polyisocyanurate-cored aluminum panels cut HVAC load 4.2 – 5.8 kBtu/ft²/year versus stucco baseline, translating into energy savings $0.55 – $0.70/ft²/year at 2025 U.S. industrial power rates. In carbon-taxed jurisdictions (EU ETS €68/t CO₂e) the annualized benefit rises to $0.90 – $1.10/ft². Capitalize the stream at 6 % and the present value equals $6.8 – $9.5/ft², or 22 – 28 % of panel FOB price. Specifying 1-inch thermal break instead of ½-inch adds ≤$0.45/ft² upfront but unlocks an NPV surplus >$2/ft² in zones with >3 500 heating degree-days—an IRR >25 %.

Maintenance Labor & Spare Parts Logistics

Anodized 0.7 mm aluminum facing in coastal chloride zones requires rinse-clean cycles every 24 months; inland cycles stretch to 48 months. Labor access systems (swing stage vs. permanent monorail) drive cost dispersion $0.18 – $0.42/ft² per cycle. Over 20 years, maintenance NPV is $1.9 – $4.3/ft². Spare parts inventory—corner extrusions, gaskets, panel blanks—should be 0.8 – 1.2 % of installed area. Offshore sourcing adds 6-week replenishment lead time; carrying cost of safety stock (8 % WACC, 0.3 % obsolescence) equals $0.12 – $0.16/ft². Dual-source agreements with regional stamping plants compress lead time to 10 days and cut inventory value 35 %, freeing working capital $55 k – $80 k per average 100 000 ft² project.

Resale & Removal Cost

Secondary aluminum ingot trades $1 950 – $2 200 per metric ton (2024-2025 spot), implying residual panel scrap value $0.55 – $0.65/ft² after 20-year service. Demolition and transport run $0.90 – $1.10/ft², yielding net end-of-life cash flow –$0.35 – –$0.40/ft². By contrast, ACM with polyethylene core carries disposal cost $0.60 – $0.70/ft² because landfill tipping fees apply. The differential improves pure aluminum panel NPV by ~$0.25/ft², equivalent to a 1.2 % purchase-price rebate.

Hidden Cost Add-On Table

(Percent of FOB panel price, CFR Houston or Rotterdam, 2025 benchmark)

| Cost Element | Domestic Supply | Asia-Pacific Import | Europe Union Import |

|---|---|---|---|

| Ocean freight & bunker | — | 6 – 8 % | 3 – 4 % |

| U.S. Section 232 duty | — | 10 % | 10 % |

| EU anti-dumping duty | — | 12 – 19 % | — |

| Port handling & THC | 0.8 % | 2.5 % | 2.0 % |

| Customs brokerage | 0.3 % | 0.8 % | 0.6 % |

| Installation labor uplift | 18 – 22 % | 18 – 22 % | 20 – 25 % |

| Contractor training | 1.0 % | 2.0 % | 1.5 % |

| Contingency & risk buffer | 3 % | 5 – 7 % | 4 – 6 % |

| Total Hidden Add-On | 23 – 27 % | 46 – 58 % | 31 – 41 % |

Decision insight: A landed price gap ≤15 % between domestic and Asia-Pacific bids disappears once hidden add-ons are capitalized; risk-adjusted TCO favors North American mills when weighted-average cost of capital exceeds 8 % or when foreign-exchange volatility exceeds 7 % annualized.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards (Risk Mitigation)

Non-compliant aluminum metal wall panels can trigger stop-work orders, seven-figure penalties, and forced removal from site. In 2023 the CBP levied $52 million in penalties on building-product imports that lacked required fire-performance documentation; EU market-surveillance authorities issued 312 “RAPEX” alerts for cladding that failed EN 13501-1 reaction-to-fire classes. Executives should treat certification as a hard filter: if a supplier cannot produce current test reports for the standards below, disqualify immediately.

United States – Non-Negotiable Import & Installation Requirements

UL 263 / ASTM E119 Fire-Resistance. Panels used on Type I–IV construction must carry an Intertek or UL fire-resistance rating equal to or greater than the wall assembly being replaced. Missing hourly ratings expose owners to OSHA 29 CFR 1926.1101 “hot work” citations and invalidate builder’s-risk insurance; retroactive testing costs $50k–$80k per assembly.

NFPA 285 Multi-Story Fire Test. Any aluminum face greater than 10 % of the exterior wall area and installed above 40 ft must pass NFPA 285 as a complete system (panel + insulation + gaskets). Failure voids Certificate of Occupancy in IBC jurisdictions; remediation averages $120–$180 per ft² installed.

ICC-ES Evaluation Reports (AC04, AC07, AC219). Structural acceptance under IBC Chapter 17 requires an active ICC-ES or IAPMO-UES report demonstrating wind-load, seismic, and pull-out performance. Panels without an ESR number are classified as “alternative materials,” forcing a $25k–$60k third-party engineering review per state.

OSHA 29 CFR 1910 Subpart Z – Hexavalent Chromium. Fabricators applying PVDF or anodized coatings must document airborne Cr(VI) exposure below 5 µg/m³; violations carry $13k–$135k per occurrence and criminal liability for repeat willful.

Buy America / Buy American (49 CFR Part 661). Federally funded projects >$100k require domestic steel substructure and aluminum melt-and-cast origin in the U.S. or an approved trade-agreement country. Mis-certification risks False Claims Act damages at 3× material value plus $10k per false invoice.

European Union – Market Surveillance & CPR Mandates

CE Marking under CPR 305/2011. From 1 July 2025 aluminum wall panels fall under AVCP System 1+; manufacturers must issue a Declaration of Performance (DoP) based on EN 13501-1 reaction-to-fire testing by a notified body. Non-CE product is automatically illegal for fixed installation; penalties range €50k–€500k plus product seizure.

EN 13501-1 Minimum Class B,s1-d0. UK Building (Amendment) Regulations 2022 and French “Écoles & IGH” rules mandate Class A2-s1,d0 above 28 m elevation. Upgrading from B to A2 raises raw-panel cost by €4–€7 per m² but avoids €150–€250 per m² replacement cost after façade-fire audit.

REACH 1907/2006 – SVHC >0.1 % w/w. PVDF films containing PFAS or flame retardants with deca-BDE face automatic sunset in 2026. Suppliers must file SCIP notifications; downstream users can be fined up to 10 % of annual EU turnover for non-notification.

Machinery Directive 2006/42/EC for Fabrication Lines. CNC routing tables and roll-formers exported to EU must carry full CE technical file, including EN ISO 12100 risk assessment and EN 60204-1 electrical safety. Customs can impound machinery lacking the declaration; demurrage runs €1k–€2k per day.

Comparative Compliance Burden & Cost Impact

| Standard / Regulation | Region | Failure Consequence | Up-Front Compliance Cost (per SKU) | Post-Non-Compliance Remediation Range | Executive Decision Metric |

|---|---|---|---|---|---|

| NFPA 285 full system | U.S. | COA withheld, re-clad | $35k–$55k test campaign | $120–$180 per ft² | Mandatory for >40 ft height |

| EN 13501-1 A2-s1,d0 | EU | Criminal prosecution if fire deaths | €8k–€12k notified-body audit | €150–€250 per m² replacement | Specify A2 by default |

| Buy America melt-and-cast | U.S. federal | 3× damages under False Claims Act | Domestic billet premium 6–9 % | $0.90–$1.10 per lb re-smelt | Map mill certs to project zip |

| REACH SCIP PFAS disclosure | EU | 10 % EU turnover fine | €5k–€10k lab SVHC scan | €40k–€80k reformulation | Insert “PFAS-free” clause |

| OSHA Cr(VI) PEL exceedance | U.S. plant | $135k willful citation | $15k–$25k ventilation upgrade | $0.5M–$1M toxic tort settlement | Audit coating lines annually |

Legal Risk Quantification

A single 250,000 ft² logistics facility using non-NFPA-285 panels faces contingent liability of $30 million—sum of accelerated removal ($18 million), business-interruption deductible ($5 million), and estimated wrongful-death exposure ($7 million). In the EU, the Grenfell inquiry precedent has already produced £1.25 billion in civil settlements; insurers now apply a 4–6 point surcharge on premiums for façades lacking A2-s1,d0 classification. Procurement teams must therefore embed compliance cost as 3–5 % of total installed cost in sourcing models; anything less understates enterprise risk by an order of magnitude.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook: Aluminum Metal Wall Panels (400–600 words)

1. RFQ Architecture

Anchor every request to ASTM E72, NFPA 285, and AAMA 508; require mill test certificates showing 3003-H14 or 5005-H34 substrate with minimum 2.5 mil PVDF top coat. Specify ±0.08 mm thickness tolerance and minimum 40 % post-consumer scrap content to lock in sustainability premiums before LME aluminum breaches $2,400–$2,650 / t in 2025. Insert liquidated-damage clause at 0.5 % of contract value per calendar day for schedule slippage; this caps exposure once lead-times exceed the current 10–14 week industry median. Force majeure language must exclude “raw-material shortages” unless supplier provides 30-day written evidence of LME force-majeure declarations—removes blanket price escalation excuses.

2. Supplier Qualification & FAT Protocol

Score bidders on vertical-integration depth: in-house coil coating (1), third-party coating (0.7), trader (0.4). Demand FAT at 25 %, 50 %, 100 % production milestones; witnessing party must sign off on adhesion ≥ 5B (ASTM D3359) and salt-spray ≥ 4,000 h (ASTM B117). Budget $50k–$80k for third-party inspection plus travel; recoverable via 2 % retention held until final commissioning. Require suppliers to carry $5 million product-liability cover and name the owner as additional insured; certificate expiry triggers automatic stop-shipment.

3. Contractual Risk Matrix

| Risk Segment | FOB Port of Loading | DDP Site | Mitigation Cost |

|---|---|---|---|

| Price volatility (LME + premium) | Transfers at loading; buyer bears $150–$200 / t ocean hedge | Seller absorbs; expect 3.5–4.2 % markup on EXW price | Hedge budget: $30k–$45k per 1,000 t |

| Transit damage | Incoterms 2020 limits carrier recovery to $2 / kg—≈ 8 % of panel value | Full seller responsibility; insurance baked into unit price | Self-insure deductible: $5k–$10k per claim |

| Import duty exposure | Buyer liable for Section 232 10 % tariff + AD/CVD if origin switches | Seller delivers cleared goods; tariff risk priced in | Duty reserve: $110–$130 / t |

| Site delay (demurrage) | Container detention after 10 days: $75–$120 / day | Seller pays; builds 7-day free-time buffer into logistics | Schedule contingency: 0.8 % of contract value |

| Total landed cost (1,000 t, US Gulf) | $2.9m–$3.2m | $3.1m–$3.4m | Delta ≤ 6 %; choose DDP when schedule variance > 5 days critical path |

4. Incoterms Decision Rule

Select FOB when internal logistics team can secure back-haul rates ≤ $1,900 / 40 ft HC and project float ≥ 21 days; otherwise DDP converts volatility into a fixed 3.5 % premium, cheaper than hedging aluminum plus freight separately. Insert “no-diversion” clause prohibiting seller from rerouting cargo through higher-tariff jurisdictions; breach triggers 10 % contract-value penalty.

5. Final Commissioning & Warranty Lock-up

Require on-site punch-list within 72 hours of arrival; panels failing visual or adhesion tests are replaced at seller’s cost including crane re-mobilization ($8k–$12k per lift). Warranty: 20 years on color chalk & fade (ΔE ≤ 5), 10 years on film integrity; retention release only after third-party Drone IR scan confirms zero moisture ingress at seams. Escalation path: arbitration under ICC Paris, seat in New York, language English—avoids local-court delays that average 18 months in SE Asia supply jurisdictions.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —