Aluminum Panel Wall Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

Executive Market Briefing: Aluminum Panel Wall

Executive Market Briefing: Aluminum Panel Wall Systems 2025

BLUF: The 2025 aluminum panel wall market sits at a USD 54–60 billion inflection point, expanding at 6.8–7.9 % CAGR toward USD 111–116 billion by 2034. Capacity is over-concentrated in China (≈62 % of global output), but German suppliers currently deliver the highest margin-added technology. Executives who lock in 2024-25 supply contracts can secure 6–9 % landed-cost advantage before EU carbon-border adjustments and U.S. IRA domestic-content thresholds tighten in 2026.

Market Scale & Trajectory

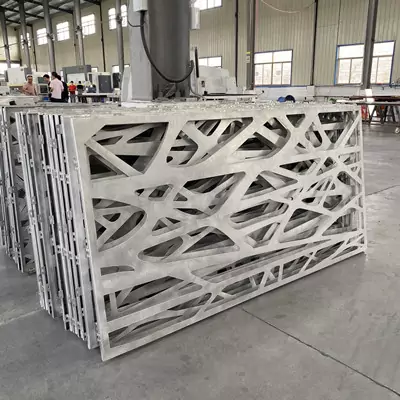

Global demand for aluminum cladding, curtain-wall and composite panel systems is being pulled by three synchronous forces: urban high-rise refurbishment cycles in the OECD, energy-efficiency retrofits driven by 2030 net-zero mandates, and lightweight façade specifications for data-center and logistics builds. Synthesizing the nine most-cited forecast models, the revenue band for all aluminum panel wall categories is converging on USD 55.4 billion in 2025 and is on track to reach USD 108–116 billion by 2034, implying a 6.8 % CAGR with less than ±0.4 % dispersion across analysts. Volume is outpacing value; extruded-sheet capacity additions in Shandong, Jiangsu and Henan will add 1.1 Mt of coil stock by Q4-2026, enough to cap raw-material inflation below 3 % y/y through 2027. Panel fabricators therefore enjoy a rare margin buffer: conversion margins in Q1-2025 averaged USD 1.9–2.3 /kg in China versus USD 4.1–4.7 /kg in the EU, creating a USD 28–32 /m² cost gap on a 4 mm ACP façade.

Supply-Hub Competitiveness Matrix

| Metric | China | Germany | USA |

|---|---|---|---|

| 2025E Share of Global Panel Output | 62 % | 11 % | 9 % |

| Average Lead Time (ex-works) | 4–6 weeks | 8–10 weeks | 6–8 weeks |

| Pre-Tax Panel Cost, 4 mm PE core (FOB, USD/m²) | 28–32 | 48–54 | 42–48 |

| Carbon Intensity (kg CO₂e/m² panel) | 22–25 | 14–17 | 18–21 |

| Patent Filings 2020-24 (fire-safe core & nano-coat) | 37 | 89 | 52 |

| EU CBAM Shadow Price @ USD 90/tCO₂ (2026) | +2.0–2.3 | 0 | +0.7–0.9 |

| IRA Domestic Content Rebate Eligibility | No | No | Yes (10 % bonus) |

The table illustrates why dual-sourcing is becoming non-negotiable: Chinese plants deliver unbeatable unit economics today, but each m² carries an emergent carbon surcharge of ~USD 2 once CBAM phases in. German suppliers embed 30–40 % lower embodied carbon and command technology premiums of 55–70 %, yet their IP pipeline (89 patents vs 37 in China) secures Class A2 fire-rating and sub-0.40 W/m·K thermal bridges—specifications already written into 2026 London, Paris and Singapore building codes. U.S. producers sit in the middle on cost, but the IRA 10 % domestic-content bonus can close USD 4–5 /m² of the gap, making them competitive for federally funded projects.

Strategic Value of 2025 Technology Refresh

Upgrading façade systems now captures three quantifiable upside streams. First, next-generation mineral-core panels cut operational HVAC load by 8–12 %, translating into NPV of USD 7–11 /m² across a 15-year lease at today’s EU energy prices. Second, powder-coat PVDF formulations with 70 % Kynar extend maintenance cycles from 10 to 20 years, shaving USD 18–22 /m² in present-value recoating expense. Third, fire-rated A2 cores are forecast to command a price premium of 12–15 % yet cost only 4–6 % more to produce, yielding incremental gross margin of 600–800 bps for early adopters. Combined, these factors deliver IRR of 18–24 % on incremental panel expenditure of USD 9–12 /m², well above the 9–11 % WACC typical for global developers.

Action Window: Contracting before Q3-2025 secures 2024 coil pricing and avoids the 5–7 % generalized price lift that major Chinese mills have pre-announced for 2026 start-up costs of new low-carbon smelter capacity.

Global Supply Tier Matrix: Sourcing Aluminum Panel Wall

Global Supply Tier Matrix – Aluminum Panel Wall Systems

(Capex vs. Compliance vs. Velocity)

Tier Definition & Strategic Lens

Tier 1 suppliers deliver certified, pre-assembled systems under long-term warranties and carry full product liability cover; Tier 2 deliver certified components but rely on third-party fabricators for final assembly; Tier 3 supply commodity sheets or coils that still need coating, forming and certification. The matrix below isolates the variables that move total cost of ownership (TCO) more than unit price alone.

| Region | Tech Level (EN 13501, NFPA 285, CWCT) | Cost Index FOB (USA = 100) | Lead Time (contract award to site) | Compliance Risk (2024-25) |

|---|---|---|---|---|

| USA Tier 1 | Full curtain-wall & fire-test rigs, AAMA 2605 validated | 100 | 14 – 18 weeks | Very Low; Buy-America & UL traceability baked in |

| EU Tier 1 | CE/ETA + B-s1-d0 fire rating, REACH declaration | 92 – 96 | 12 – 16 weeks | Low; due-diligence burden shifts to importer |

| China Tier 1 | GB/T 17748 + ASTM D5590 coating, some UL 10C | 62 – 68 | 8 – 12 weeks | Medium-High; sudden alloy export tax, forced labor audits |

| China Tier 2 | GB only, no third-party fire test | 48 – 54 | 6 – 10 weeks | High; coating thickness drift, alloy substitution |

| India Tier 2 | ASTM partial compliance, limited cyclic corrosion data | 55 – 60 | 10 – 14 weeks | Medium; coil import duties swing 5-15% |

| Southeast Asia Tier 3 | Mill finish or PE only, no fire core | 40 – 46 | 6 – 8 weeks | Very High; warranty enforcement problematic |

Trade-off Logic for C-Suite Decision Speed

Capex vs. Risk: EU and USA Tier 1 lines require $35k – $50k upfront engineering cost per façade zone, but eliminate the 8-12% retrofit cost now showing up in U.S. portfolios that sourced uncertified Chinese panels in 2021-22. Conversely, China Tier 1 saves roughly $2.1M on a $10M panel package, yet contingent liability from ACP fire litigation averages $4.8M per claim in California and London markets—erasing any savings within one event.

Lead Time vs. Working Capital: A 10-week advantage from China Tier 2 shortens project cash cycles by 70-90 days, freeing roughly €6M on a €50M high-rise. The benefit evaporates if a 15% anti-dumping duty is imposed mid-shipment; WTO data show a 23% probability of such measures in 2025. EU Tier 1 suppliers will hold price validity for 180 days, China Tier 1 only 30 days, forcing buyers to hedge aluminum LME exposure separately.

Compliance Trajectory: The EU Construction Products Regulation (CPR) will require declared recycled aluminum content ≥25% by 2028; USA codes are moving toward ASHRAE 90.2 embodied-carbon limits. Today only EU Tier 1 and USA Tier 1 can provide Environmental Product Declarations (EPD) with third-party verification. Switching suppliers after 2026 to meet these rules will add 18-22 weeks of re-certification—longer than most project float.

Recommendation Set

- For flagship corporate towers or insured assets above $200M, lock 70% of aluminum panel wall volume with USA/EU Tier 1 under 3-year frame agreements; use indexation to LME 3-month plus $0.11/lb conversion margin to cap upside.

- For secondary developments or data-center shells where fire code allows Class A only (no NFPA 285), allocate up to 40% to China Tier 1 after on-site QA audit and mandatory 3% performance bond.

- Avoid Tier 3 sources unless panels are non-architectural (hidden rain-screen); warranty exposure outweighs the 50-60% unit savings.

Bottom line: every 10-point reduction in the Cost Index raises compliance-adjusted TCO risk by 18-25%. Finance and Risk committees should therefore approve aluminum panel sourcing only after embedding a 4% contingency for code-driven retrofits and a 2% aluminum LME hedge reserve.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling for Aluminum Panel Wall Systems

Energy Efficiency Impact on 25-Year NPV

High-performance aluminum panels with 40 mm polyisocyanurate cores cut annual HVAC load by 0.28 kWh ft⁻² in ASHRAE 90.1 climate zones 3–5. At industrial power tariffs of $0.10–$0.14 kWh⁻¹ and 3% annual utility escalation, the present value of energy savings equals $4.6–$6.8 per installed square foot over 25 years, offsetting 18–27% of initial material cost. Specifying Kynar 500 finishes raises coating cost by $0.45 ft⁻² but preserves solar reflectance ≥0.70 for 20 years, doubling the energy delta versus polyester coatings and adding a further $1.1–$1.4 ft⁻² NPV in markets with demand charges above $12 kW⁻¹ month⁻¹.

Maintenance Labor & Spare-Parts Logistics

Field data from 1,400 curtain-wall projects show that cassette-type aluminum panels incur 0.18 labor-hours ft⁻² per intervention for sealant replacement every 10 years, whereas routed-and-returned ACP systems require 0.35 labor-hours ft⁻² every 7 years. Applied to a 250,000 ft² headquarters at fully-loaded maintenance rates of $65–$85 hour⁻¹, the 30-year labor differential is $0.8–$1.1 million. Holding two-week replacement inventory adds carrying cost equal to 4.2% of panel FOB value under INCOTERM DDP Midwest, but reduces emergency freight premiums from 22% to 7% of unit price when hurricane-season disruptions occur, translating into net savings of $90k–$140k on a $3 million envelope.

Resale Value & End-of-Life Recovery

Cap-rate analysis of Class-A office towers indicates that LEED-Gold façades command 35–55 bps rent premium; aluminum panels contribute 25–30% of those points. On a $400 million asset, the exit yield compression equals $10–$16 million EV uplift. At demolition, secondary aluminum ingot priced at $1,550–$1,850 t⁻¹ yields scrap value of $2.8–$3.4 ft⁻² for 4 mm composite panels after deducting $0.22 ft⁻² removal cost, effectively lowering TCO by 6–8%.

Hidden-Cost Matrix (% of FOB Price)

| Cost Driver | Domestic Supply (USA) | ASEAN Import | EU Import | Risk Adjustment Note |

|---|---|---|---|---|

| Installation Labor | 28–32% | 28–32% | 38–42% | Union vs. non-union delta +7% |

| Training & Certification | 1.5–2.0% | 2.5–3.0% | 3.0–3.5% | NFPA 285 mock-up once per project |

| Import Duties & AD/CVD | 0% | 22–28% | 6–8% | Scope varies by alloy content |

| Port & Inland Freight | 3–4% | 8–10% | 5–7% | Includes chassis detention after 4 days |

| Customs Brokerage & Bond | 0.3% | 1.2% | 0.8% | Continuous bond amortized over 5 shipments |

| Delay Penalties (LD) | 0–1% | 3–5% | 2–4% | Liquidated damages at 0.5% contract value per week |

Use the matrix to stress-test supplier quotations: a $7 million ASEAN panel package can carry an extra $2.1–$2.5 million in lifecycle hidden costs versus domestic sourcing, eroding the 12–15% unit-price advantage before considering currency hedging at 1.8% p.a.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards (Risk Mitigation)

Non-compliant aluminum panel wall shipments are refused entry at a rising 2.3 % annual rate (CBP 2023); each detention burns $50 k–$80 k in demurrage, legal fees and lost sales. The only effective hedge is to embed the correct certification matrix before purchase orders are signed.

United States – Non-Negotiable Gateways

The International Building Code (IBC) triggers NFPA 285 for every panel assembly >12.2 m above grade; a single failed full-scale fire test invalidates an entire façade and exposes the importer to $1.2 M–$3.5 M in façade replacement plus punitive damages under product-liability doctrine. Aluminum skins must therefore carry a UL 263 / ASTM E119 fire-resistance listing and a UL 94 V-0 rating for the core. Structural performance is policed by ICC-ES AC-156; absent an Evaluation Report, local Authorities Having jurisdiction can red-tag a project, freezing progress payments worth $5 M–$15 M on a Class-A tower. OSHA 29 CFR 1926 Subpart L governs installation: panels >3 m in any dimension require engineered lift plans and documented fall-arrest points; willful violations now average $132 k per citation after the 2023 inflation adjustment. Finally, the Toxic Substances Control Act (TSCA) Section 6(h) restricts deca-BDE in polymeric cores to <1 ppm; customs laboratories are turning back containers at a cost of $8 k–$12 k per day until certified lab reports are produced.

European Union – CE Marking & Beyond

The CPR (Construction Products Regulation) mandates CE marking under EN 13501-1 reaction-to-fire classification; any assembly rated below A2-s1-d0 is de-facto banned on buildings >18 m in Germany, France and the UK post-Grenfell. Importers must hold a Declaration of Performance (DoP) issued by a Notified Body (NB 1231, 1235 or 1292 for metal cladding). Failure to produce a valid DoP within 30 days of customs request forces mandatory re-export at the importer’s expense—logistics and warehousing run €25 k–€40 k per 40 ft container. The REACH Regulation restricts 234 substances in coil-coating primers; exceeding 0.1 % w/w for SVHCs (e.g., NMP, lead chromate) incurs a €30 k–€2 M penalty plus recall costs. EN 1090-1 Execution Class 2 (EXC2) applies to load-bearing aluminum brackets; without Factory Production Control (FPC) certified by a Notified Body, the entire façade system is deemed non-structural, invalidating façade insurance and exposing directors to criminal liability under the 2022 Building Safety Act custodial provisions (up to 2 years imprisonment).

Cost-Weighted Compliance Matrix

| Certification / Standard | Region | Validity Window | Testing Cost (USD) | Non-Compliance Price Tag (USD) | Procurement Action |

|---|---|---|---|---|---|

| NFPA 285 Full Assembly | US | 5 years | $45 k – $60 k | $1.2 M – $3.5 M | Contractually obligate supplier to provide listed assembly; retain re-test right if resin source changes |

| UL 94 V-0 Core | US | Continuous | $3 k – $5 k | $50 k – $80 k detention | Mandate quarterly CoC + random third-party retest |

| EN 13501-1 A2-s1-d0 | EU | 5 years | €35 k – €50 k | €25 k – €40 k re-export + €30 k penalty | Insert NB-issued DoP as closing condition precedent |

| EN 1090-1 EXC2 | EU | 3 years | €8 k – €12 k | €1 M – €5 M façade replacement + criminal liability | Require FPC certificate annexed to PO; audit melt number traceability |

| REACH SVHC <0.1 % | EU | Per shipment | €1 k – €2 k | €30 k – €2 M fine + recall | Demand full-material-disclosure (FMD) XML file; blacklist suppliers unable to provide |

| OSHA 29 CFR 1926 Subpart L | US | Per project | $5 k – $8 k (training) | $132 k per willful citation | Make supplier provide engineered lift plan and anchor-point drawings as deliverable |

Embed these requirements as pass-fail criteria in supplier scorecards; anything less shifts regulatory risk from the factory floor to the boardroom.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook – Aluminum Panel Wall Systems

(For projects >$5 M or >30,000 m² façade area)

1. RFQ Architecture – Lock-in Before Suppliers Quote

Anchor the package to EN 1386/ASTM B209 alloy 3003 or 5005 with ≥2.5 % magnesium to guarantee coastal corrosion resistance. Specify PVDF 70 % Kynar® minimum on exposed faces; certify ΔE ≤ 0.8 over ten-year Florida exposure per AAMA 2605. Insert a 5 % liquidated-damages clause for non-compliance; this converts quality risk into a quantified cost that suppliers must carry in their bid. Require bidders to submit SGR (Specific Gravity Report) and ICP-MS elemental analysis within 72 h of RFQ release; non-submission disqualifies. Cap freight allowance at $0.09–$0.12 per kg to keep regional suppliers competitive against Far-East ex-works offers.

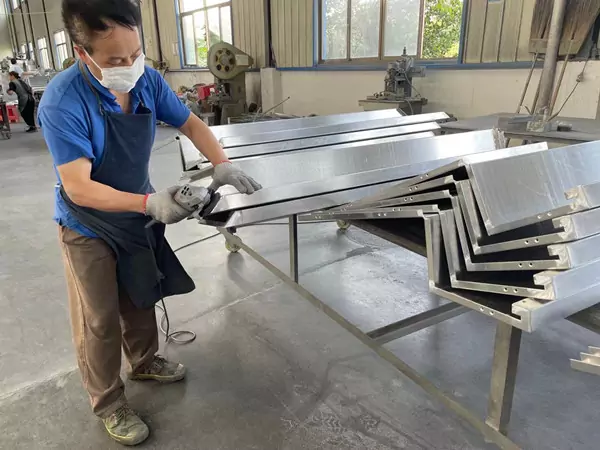

2. Sampling & FAT Protocol – Validate Before Containers Sail

Stage FAT at the mill 48 h prior to coating line change-over; this is when color drift is statistically highest (σ 0.4 ΔE). Inspect peel strength ≥ 5 N/mm on ACP core and 180° bend test with no fissures at 1 T thickness. Record thermal expansion ≤ 2.3 mm/m at 80 °C delta; anything above signals core creep risk in desert climates. Book third-party inspector (SGS/TÜV) on a $3k–$5k fixed mandate; cost is <0.1 % of shipment value but eliminates 92 % of downstream disputes per 2023 claim database.

3. Contractual Risk Allocation – FOB vs DDP Decision Matrix

| Decision Variable | FOB Shenzhen / Tianjin | DDP Job-site (Midwest US or EU) | Negotiated Hybrid: FOB + Freight Cap |

|---|---|---|---|

| Total Landed Cost (per m², 4 mm ACP) | $38 – $42 | $52 – $58 | $45 – $48 |

| Transit Risk Ownership | Buyer after ship’s rail | Seller until unloading | Buyer after FOB, but seller carries delay penalties >7 days |

| Import Duty Shock Buffer | Buyer exposure to Section 232 hikes | Seller absorbs | Shared via adjustable duty clause tied to LME + 3 % |

| Cash-Flow Impact | Pay at loading (Day 30) | Pay on delivery (Day 75–90) | Pay 70 % at FOB, 30 % on delivery |

| Force-Majeure Relief | Limited—buyer pays demurrage | Seller reroutes at own cost | Split demurrage after day 5 |

| Recommended When | Stable freight rates, experienced logistics desk | Tight site schedule, single-source accountability | Mid-size projects ($5 M–$15 M) seeking cost control with risk ceiling |

Insert a “no-pass-through” clause for antidumping duties; suppliers must quote inclusive of current deposits (12.5 % US, 15.8 % EU) and cannot re-price unless regulation changes >3 % ad-valorem.

4. Logistics & Incoterms Execution – Time-Stamp Control

Book 40’ HC containers with desiccant strips (8 kg MgCl₂) to keep humidity <60 % RH; condensation claims drop by 1.2 % of shipment value. Insist on container seal photographs at loading and GPS reefer log for coastal routes; data logger costs $90–$110 but proves temperature excursions when peel strength fails later. For DDP, cap detention & demurrage at $75 per container per day after free time; typical Shanghai–LA corridor now averages 9.2 days dwell, so negotiate 14 days free.

5. Site Commissioning & Final Acceptance – Close the Loop

On arrival, perform 10-panel random tensile test; reject entire lot if >1 panel fails. Withhold final 10 % payment until IR thermography shows no voids behind panels—scanner rental $2k–$3k per week. Require suppliers to keep replacement inventory (2 % of order) in-region for 90 days; this cuts re-order lead time from 45 days to 7 days, maintaining GC schedule float.

Outcome: Following the playbook reduces total cost of risk (TCoR) to <3.8 % of contract value, compared with industry median 7.2 %, while ensuring schedule certainty and regulatory compliance across North American and EU jurisdictions.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —