Amp Grille Cloth: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Amp Grille Cloth

High‑volume guitar cabinet builders and restorers face a deceptively complex decision when choosing amp grille cloth: the material must deliver brand‑authentic aesthetics, reliable acoustic transparency, and steady supply across regions with different standards and lead times. This guide is built for teams in the USA and Europe who need to standardize SKUs, simplify procurement, and ensure consistent finishes.

What this guide covers

– Technical considerations: weave patterns, durability, and how they relate to appearance and airflow.

– Spec normalization: converting widths between imperial and metric; brand‑specific styles (Fender, British/Marshall, Mesa, Vox, Ampeg) mapped to standard roll widths (26–58 in / 66–147 cm).

– Availability and pricing: practical ranges based on current listings (e.g., ~$14.50–$65.95; widths 26–58 in).

– Procurement and logistics: MOQs, lead times, regional suppliers, and shipping policy implications.

– Selection framework: a decision matrix aligned to brand fidelity, availability, and total cost of ownership.

Use the guide as a step‑by‑step path—from understanding weave families and spec conversion to comparing brands, verifying availability, and finalizing vendor options—so your team can make fast, confident decisions without sacrificing brand accuracy or operational reliability.

Top 10 Amp Grille Cloth Manufacturers & Suppliers List

1. Black grill cloth – Speakerbuildersupply.com

Domain: speakerbuildersupply.com

Registered: 2007 (18 years)

Introduction: 1–5 day deliveryFeatures: This grill cloth is the same stuff used by many leading manufacturers on guitar amps and speaker cabinets.Missing: top grille suppliers…

2. GRILL CLOTH – Mojotone

Domain: mojotone.com

Registered: 1996 (29 years)

Introduction: Free delivery over $99Shop premium guitar grill cloth in vintage and modern styles. Durable materials for enhanced sound projection and a professional finish….

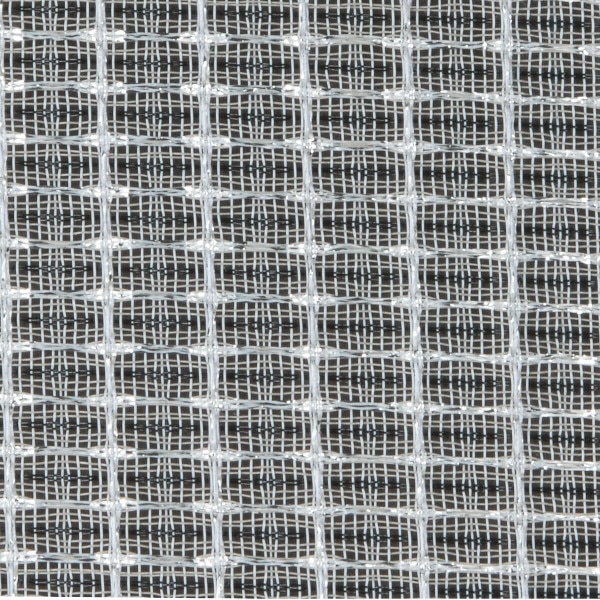

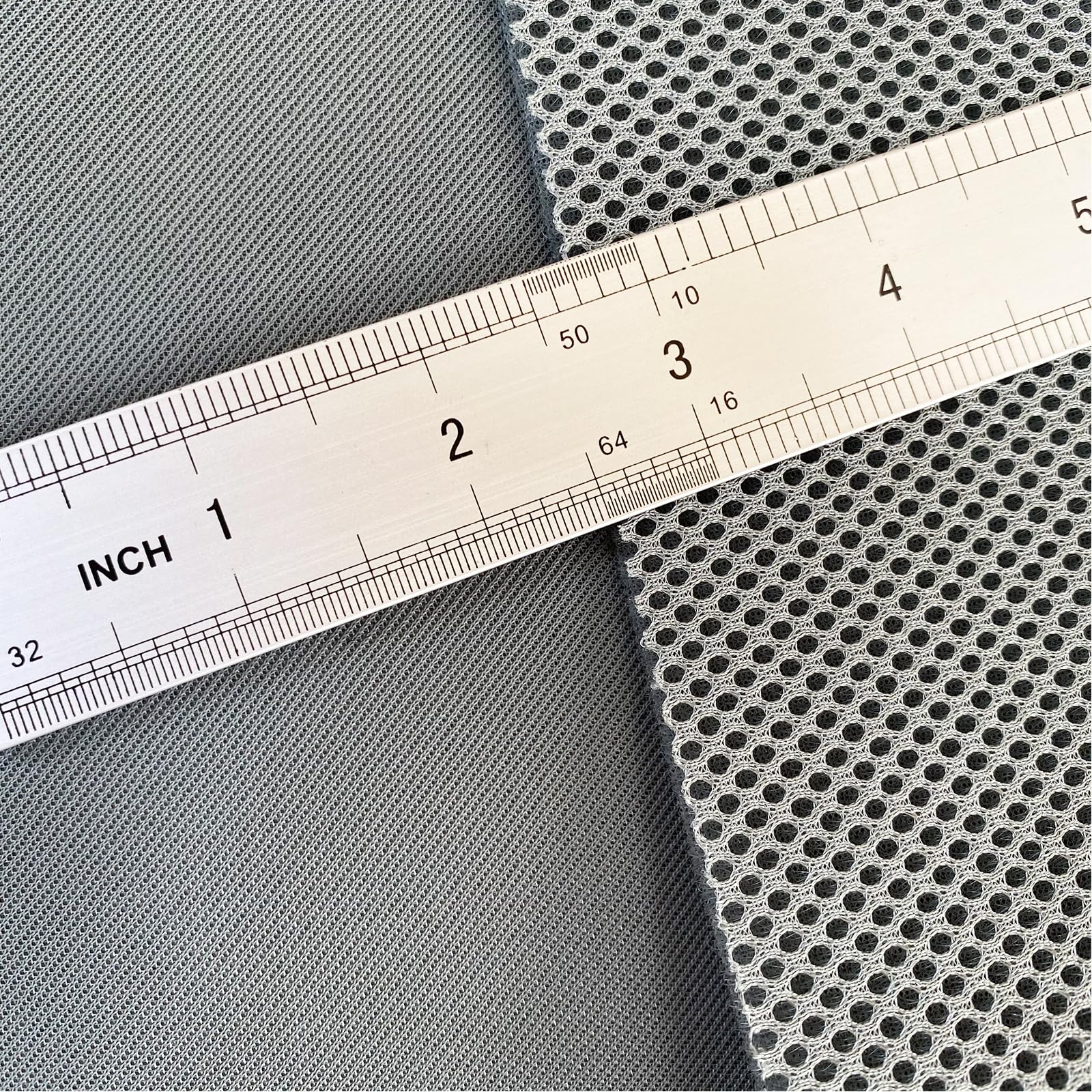

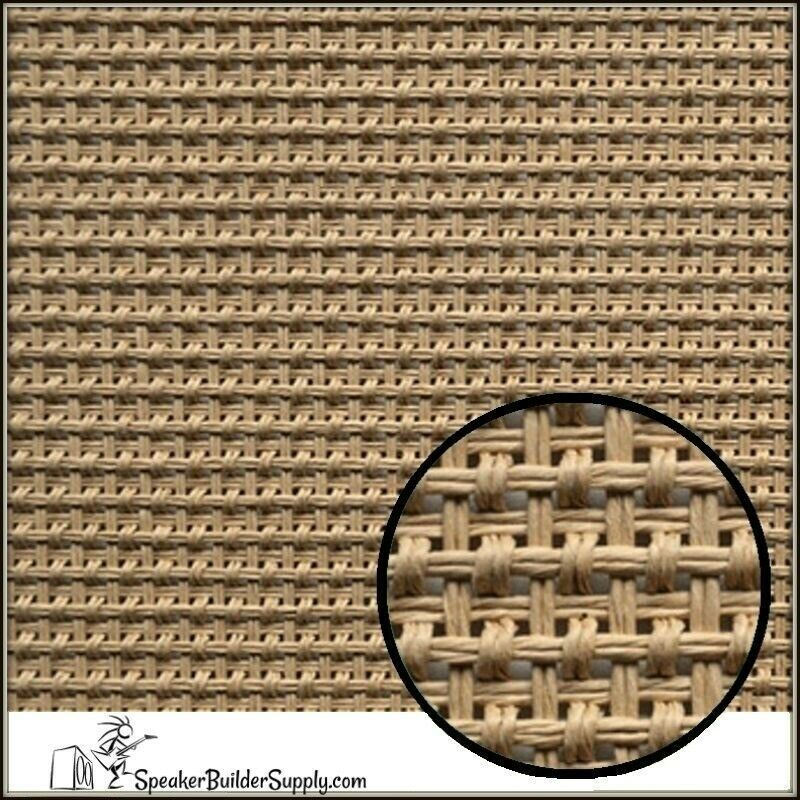

Illustrative Image (Source: Google Search)

3. Best Sources for Grill Cloth? – The Gear Page

Domain: thegearpage.net

Registered: 2003 (22 years)

Introduction: Real vintage grille cloth is very difficult to find IME — as mentioned above, mojotone is a great source for acceptabe reproductions of grille cloth, tweed, ……

4. P3000 Series Grill Cloth 72

Domain: acoustonegrillecloth.com

Registered: 2000 (25 years)

Introduction: SPEAKER AND AMPLIFIER GRILL LINE. EXCELLENT TRANSMISSIBILITY. Sound absorptionwhen laminated or applied in front of a sound absorbent material. Suitable for ……

5. Best website for high quality speaker grille cloth – Facebook

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: What is the best website for high quality yet relatively inexpensive speaker grille cloth? … Amazon or eBay. Depending on how much you need you ……

6. Grill Cloth – Tube Amp Doctor

Domain: tubeampdoctor.com

Registered: 2000 (25 years)

Introduction: Grill Cloth TAN & BROWN (made in USA) used by Fender® for the brown tolex models: Vibroverb, Princeton, Deluxe, Concert, Tremulox, Reverb 6G15 and some blonde ……

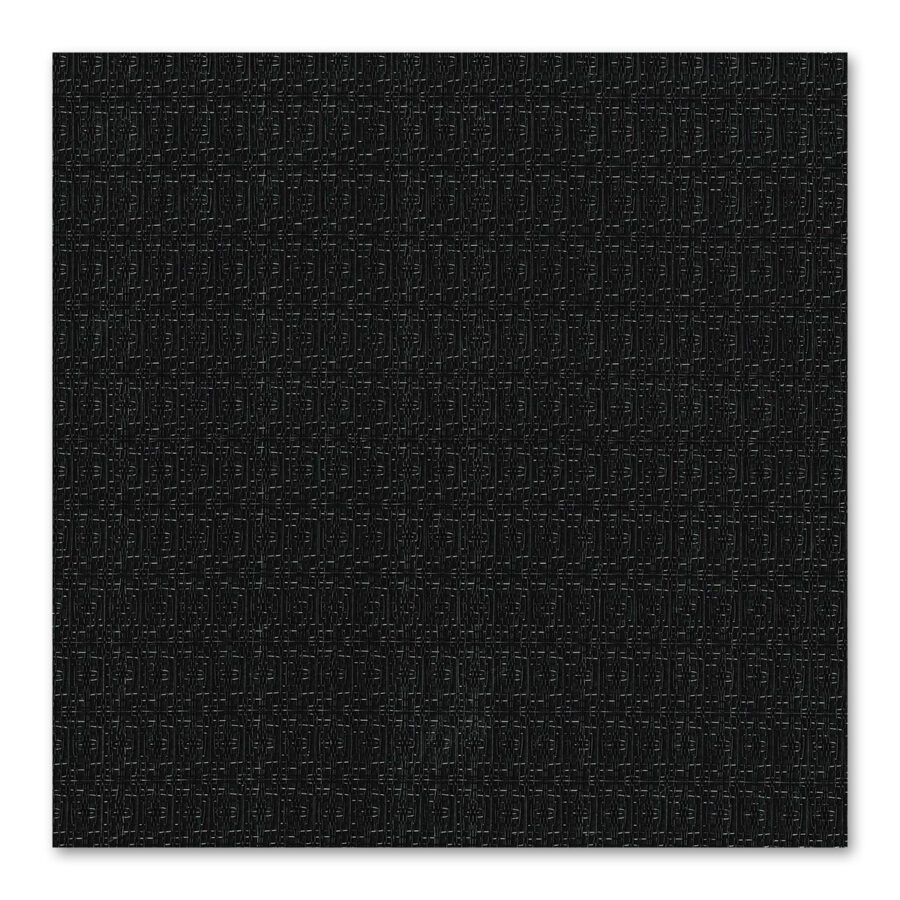

Illustrative Image (Source: Google Search)

7. Buy Speaker Grill Fabric | Large Acoustical Fabric.

Domain: studio-productions-inc.com

Registered: 2004 (21 years)

Introduction: Chameleon™ Acoustical Grill Cloth in Large and Small Sizes. Big 188″ Wide Grill Cloth(or Small too!) Get Grille Cloth Quickly, Even Large Size Grilles….

8. Grille Cloth | Midwest Speaker Repair

Domain: midwestspeakerrepair.com

Registered: 2001 (24 years)

Introduction: Free deliveryPremium Acoustically Transparent Speaker Grille Cloth! Mellotone’s 100% polyester fabric and Acoustone’s high-tech yarns of vinyl-coated fiberglass make a ……

Understanding amp grille cloth Types and Variations

Understanding amp grille cloth Types and Variations

Grille cloth type affects acoustic transparency, perceived frequency response, and visual identity. For B2B procurement, the right choice combines a consistent weave that preserves speaker performance, a reliable width for standardized cabinetry, and aesthetic alignment to brand or model lineage.

Summary table: grille cloth types, features, applications, pros/cons

| Type | Features (width, weave, colorways) | Applications | Pros | Cons |

|---|---|---|---|---|

| Fender Style (incl. Mojotone equivalents) | 26–36″ widths; checker and tweed patterns; oxblood, black/white/silver, aged variants | Fender and Fender-inspired combos and 1×12/2×12 cabinets; classic and boutique builds | High brand recognition; familiar palettes; consistent widths for repeatable installs | Some patterns cost more (aged); limited British/Marshall authenticity |

| British Style (Marshall-inspired) | 32″ widths; black, black/tan; small-weave cane and diamond variants; limited sparkle | Marshall-inspired stacks; UK-voiced builds; vintage Marshall re-creations | Authentic look; reliable 32″ coverage; cane variants offer warmer tone | Often 32″ only (less flexible for wider cabs); availability can vary |

| Mesa Style | 32″ widths; small-weave cane (black) | Mesa/Boogie-inspired combos and 1×12/2×12; tighter British-leaning tonality | Balanced airflow; durable; easy-to-handle width | Limited colorway choice; narrower than some Fender/UK patterns |

| Vox Style | ~46″ widths; black diamond weave | AC30 and Vox-inspired 2×12/4×12 cabs; wider baffles and vintage Brits | High acoustic transparency; wide width simplifies large baffles | Price premium; single-weave focus may limit colorways |

| Mojotone Specialty Weaves | 48″ MojoWeave; 58″ cane; unique diamond and sparkle variants; black/red and classic oxblood | Custom builds, modern cabinets, and high-coverage baffles | Extra-wide options (48–58″) for fewer seams; unique aesthetics | Specialty pricing; availability varies by SKU |

Fender Style (incl. Mojotone equivalents)

- Features: Typical 36″ widths; 26″ available on select SKUs. Checker and tweed patterns with colorways such as oxblood (with or without gold stripe), black, black/white/silver (including aged), and wheat/beige. Pricing in listings ranges approx. $19.50–$38.50 depending on width and finish.

- Applications: Fender and Fender-inspired cabinets and combos; widely used for 1×12 and 2×12 builds; good fit for boutique builds requiring classic visuals.

- Pros: Strong brand alignment; familiar aesthetic for resale and end-user expectations; standardized 36″ width aligns with common baffle sizes.

- Cons: Some aged or multi-color patterns carry a price premium; less relevant to British-branded builds.

British Style (Marshall-inspired)

- Features: Typically 32″ widths; colorways include black and black/tan; small-weave cane and diamond patterns. Listings show prices approx. $24.50–$36.00.

- Applications: Marshall and Marshall-inspired stacks; vintage re-creations and UK-voiced builds.

- Pros: High authenticity; robust weave; 32″ width aligns with many British-style baffles.

- Cons: Often 32″ only, which can be limiting on larger baffles; color options are narrower than Fender’s range.

Mesa Style

- Features: 32″ widths; small-weave cane (black). Listings show price approx. $32.54.

- Applications: Mesa/Boogie-style combos and cabinets; tone-forward builds seeking a balanced, tighter pattern.

- Pros: Balanced acoustic properties; durable; convenient 32″ roll width for common baffles.

- Cons: Limited color choices; may not match broad aesthetic requirements outside Mesa lineage.

Vox Style

- Features: Black diamond pattern; approx. 46″ width (e.g., “Vox Black Diamond Cloth – 46″ w”). Listings show price approx. $52.45.

- Applications: AC30 and Vox-inspired 2×12/4×12 cabinets; baffles requiring wider coverage.

- Pros: High acoustic transparency; wide width reduces joins on large baffles.

- Cons: Higher price point; limited colorway variability compared to Fender/British options.

Mojotone Specialty Weaves

- Features: Wider roll options and unique designs. Examples include MojoWeave (48″, approx. $18.95), Cane Grill Cloth (58″, approx. $45.14), British Brown Diamond (30″ × 36″, approx. $50.39), and Black & Tan with Gold Sparkle (36″, approx. $65.95).

- Applications: Custom cabinet builds, modern aesthetics, and scenarios where roll width or distinct look are primary needs.

- Pros: Extra-wide formats minimize seams; unique patterns offer differentiation.

- Cons: Specialty pricing and SKU-dependent availability.

Implementation guidance:

– Match roll width to baffle size (e.g., 36″ for Fender, 32″ for British, ~46″ for Vox, 48–58″ for Mojotone specialty).

– Consider acoustic transparency vs. aesthetic: diamond and cane patterns favor high-frequency clarity; checker/tweed can add a perceived midrange warmth in tone stacks.

– For replacement projects, specify brand/style and target width to reduce ambiguity during ordering.

Key Industrial Applications of amp grille cloth

Key Industrial Applications of Amp Grille Cloth

Amp grille cloth enables OEM brands and service providers to deliver reliable sound projection, component protection, and authentic aesthetics. Typical use-cases include speaker cabinets and amplifier head shells, live-sound and install enclosures, broadcast monitors, and retail display fixtures. Buyers in the USA and Europe prioritize brands and visual authenticity, acoustic transparency, durability and FR compliance, and cost efficiency at scale.

Industry applications and detailed benefits

| Industry / Application | Detailed benefits |

|---|---|

| Pro audio and live-sound manufacturing | Acoustic transparency preserves frequency response while protecting drivers; high-tenacity weaves resist tearing and abrasion under touring stress; brand-consistent grille patterns (e.g., Fender, Marshall, Vox, British style) support identity and resale value; FR-treated options help meet venue and venue-rental safety standards; wide rolls (e.g., 46–48″) optimize cutting efficiency for large panels. |

| Musical instrument and amplifier manufacturing (OEM) | Authentic aesthetics (e.g., Fender, Ampeg, Vox, Mesa styles) with consistent colorways and stripe options; reliable fit across standard 26–36″ widths for amp heads and combos; durable weaves with dust/stain resistance help maintain showroom finishes; premium finishes support perceived quality in prosumer and professional lines. |

| Custom cabinet fabrication | Flexible formatting across 26–58″ widths simplifies fitting curved or angled baffles; lightweight weave installs without compromising cabinet rigidity; aged and classic weaves deliver period-correct styling; tear-resistant materials support repeatable CNC workflows with low rework. |

| Audio service, repair, and re-cone centers | Easy-to-cut patterns reduce labor and turnaround; availability in legacy patterns improves restoration authenticity; protective cloth reduces dust ingress during repairs; low MOQs and stocked SKUs streamline service part logistics for repeat repairs. |

| Commercial installation (hospitality, retail, education, worship) | Neutral and black/tan weaves complement interior designs; durable construction resists scuffs in high-traffic spaces; FR options support regional safety codes; visual consistency across rooms simplifies procurement and maintenance; 32–36″ widths are practical for wall-mounted and freestanding installs. |

| Broadcast, studio, and monitoring | Tight weaves reduce light bleed through grilles on studio monitors and camera-facing panels; low reflectance aesthetics (e.g., black/oxblood) support broadcast environments; uniform weave supports predictable acoustic behavior across monitor fleets; robust materials maintain finish under frequent handling. |

| OEM replacement parts and refurbishment | Direct pattern matches to popular brands reduce mis-spec risk; priced for economical refurbs; fast shipping and stocked widths enable just-in-time replenishment; FR-rated variants align with replacement compliance needs. |

| Live event staging and rental houses | Tear-resistant construction withstands setup/teardown cycles; neutral tones and brand patterns match rental fleet aesthetics; 32–48″ widths balance coverage with manageable handling; FR-treated options help satisfy venue safety requirements; easy cleaning preserves professional appearance across bookings. |

| E-commerce and retail display | Crisp brand-aligned weaves elevate packaging and demo displays; in-stock availability and consistent quality improve e-commerce fulfillment and storefront uptime; aged and sparkle options add merchandising differentiation. |

Notes for USA/Europe buyers:

– Availability spans vintage-to-modern styles (Fender, Ampeg, British, Mesa, Vox, Mojotone) with widths commonly 26–58″.

– FR (flame-retardant) variants are available from select vendors; confirm certifications to regional codes where required.

– Brand-style cloths should be specified by pattern rather than for end-user marketing claims.

3 Common User Pain Points for ‘amp grille cloth’ & Their Solutions

3 Common User Pain Points for ‘Amp Grille Cloth’ & Their Solutions

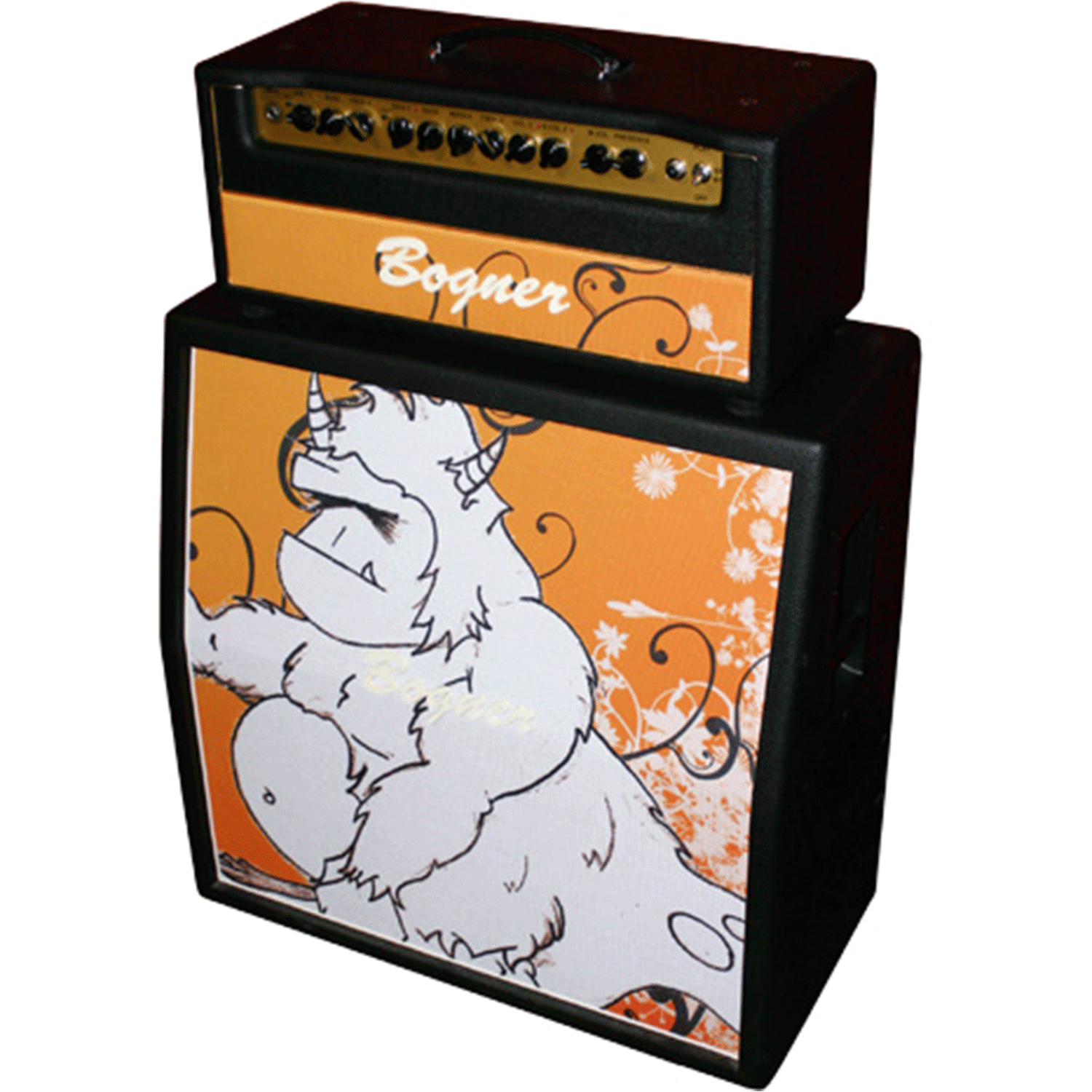

Pain Point 1: Brand Authenticity and Visual Fit

Scenario: A boutique amp builder needs an exact “Fender” look for a heritage reissue and a “Marshall” small-weave black for UK-styled cabs.

Problem: Mismatched styles and widths (colors, weave density, and panel size) lead to re-work, delayed builds, and brand credibility issues.

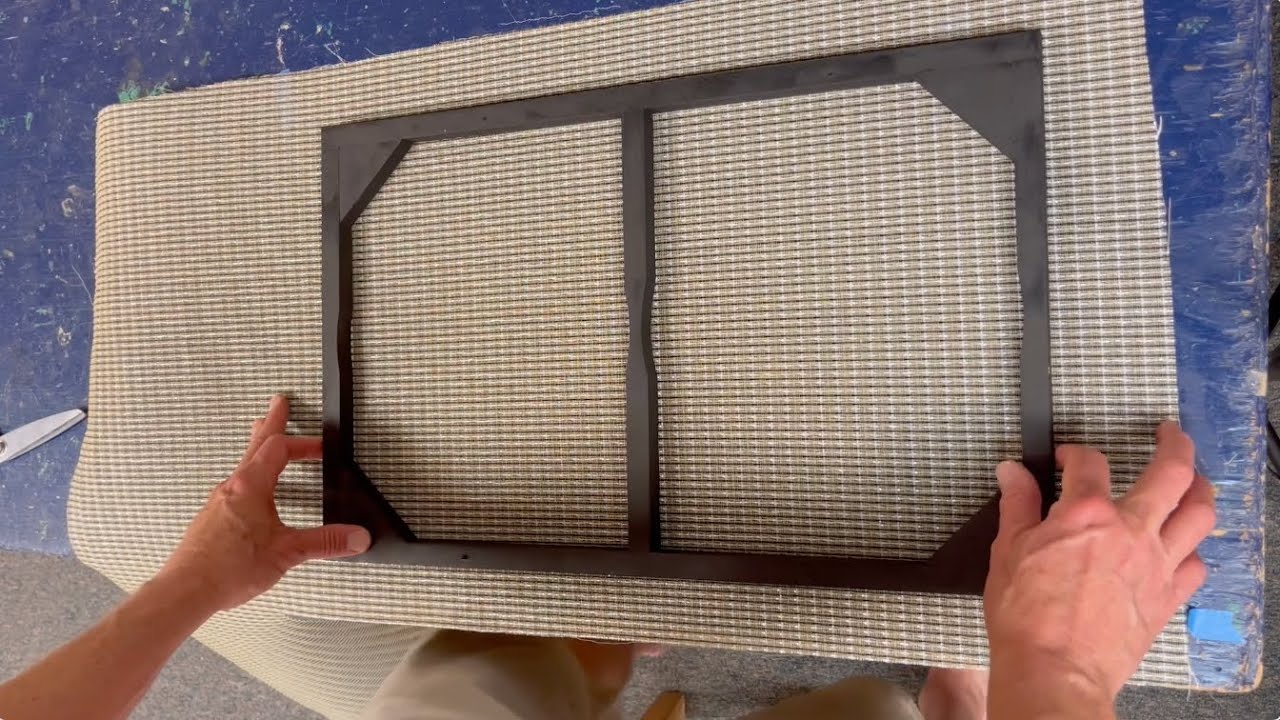

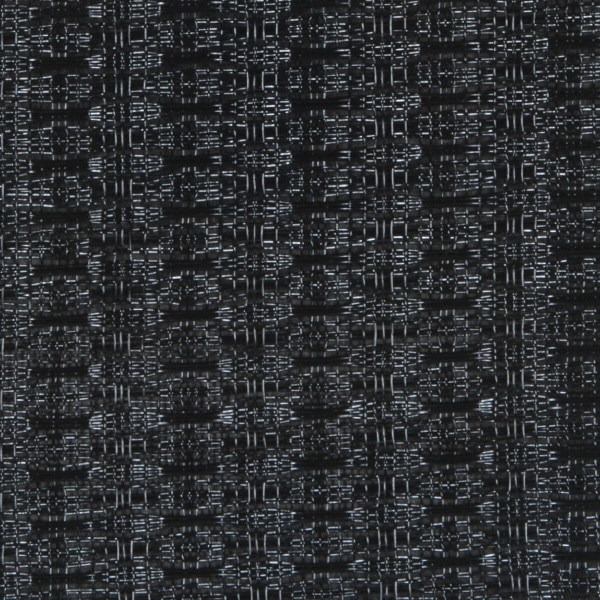

Illustrative Image (Source: Google Search)

Solution:

– Source from brand-mapped families to control aesthetics (e.g., Fender Style, British Style, Mesa Style, Vox Style).

– Specify width up front: Fender Style commonly 36″ (e.g., Fender Style Black/White/Silver, Fender Style Oxblood variants), British/Marshall 32″ (e.g., British Style Black 32″W, British Style Small Weave Cane).

– Match dye lots within a style; avoid mixing patterns across families.

– Pull pre-shipment swatches or small runs for color/shine verification before mass production.

– Pin pre-cut panels to baffles to confirm fit before fabric laydown.

– Use brand-coded SKUs to minimize picking errors.

Example SKUs by style:

| Brand/Style | Color/Pattern | Width | Example (Mojotone) | Status |

|——————-|——————————————–|——-|—————————————————–|————|

| Fender Style | Black/White/Silver | 36″ | Fender Style Black/White/Silver Grill Cloth | In stock |

| Fender Style | Oxblood w/ Gold Stripe | 36″ | Fender Style Oxblood w/ Gold Stripe Grill Cloth | In stock |

| British Style | Black (Marshall Replacement) | 32″ | British Style Black Grill Cloth | In stock |

| British Style | Small Weave Cane | 32″ | British Style Small Weave Cane Grill Cloth | In stock |

| British Style | Black and Tan | 32″ | British Style Black and Tan Grill Cloth | In stock |

| Mesa Style | Small Weave Cane (Black) | 32″ | Mesa Style Small Weave Cane (Black) | In stock |

| Mojotone | Oxblood with Silver Stripe | 36″ | Mojotone Oxblood with Silver Stripe 36″W | In stock |

| Vox Style | Black Diamond | 46″ | Vox Black Diamond Cloth – 46″ w | In stock |

| Ampeg Style | Black/Silver | 36″ | Ampeg Style Black/Silver Grill Cloth | In stock |

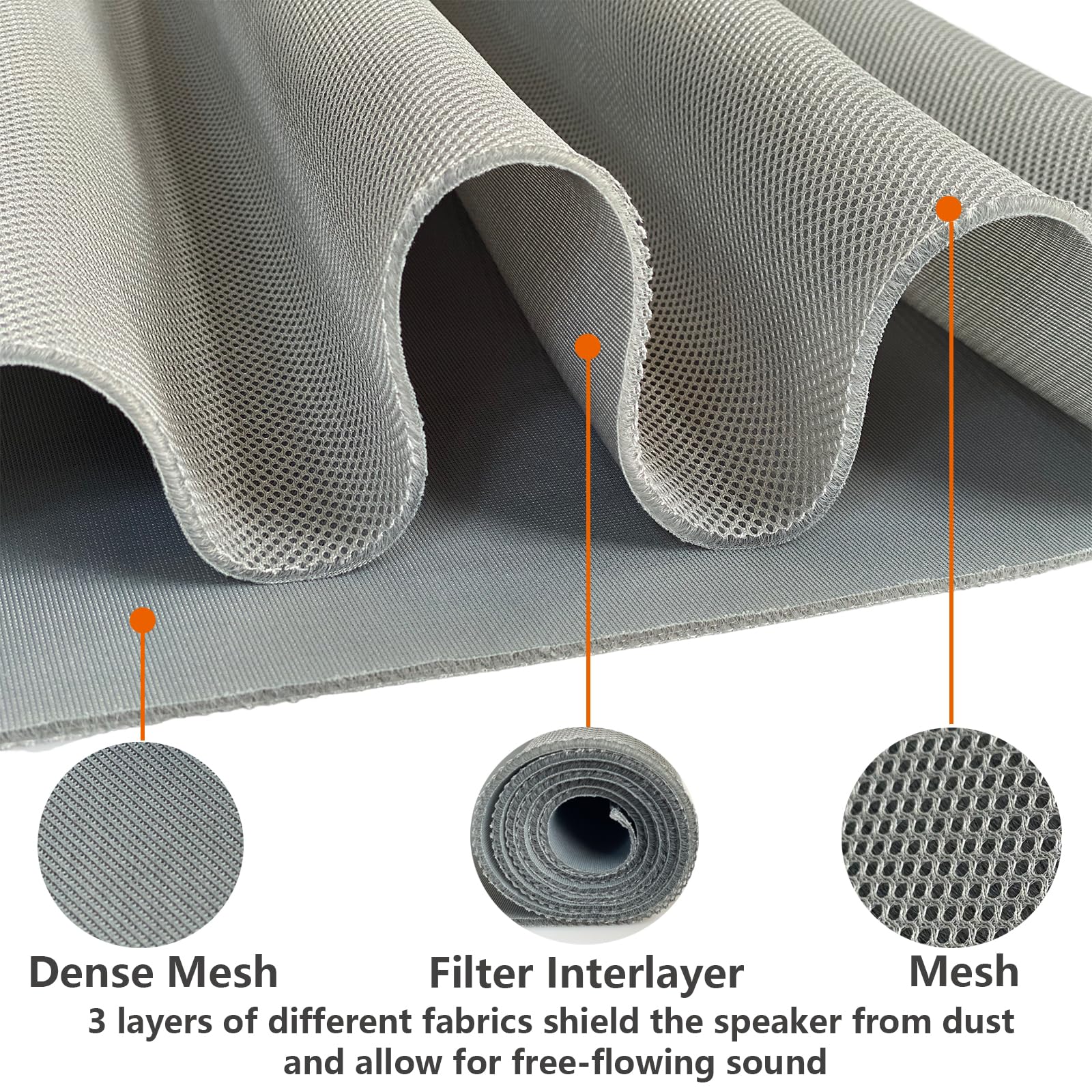

Pain Point 2: Acoustic Transparency vs. Durability

Scenario: A rental house re-grilles 50 cabs per quarter and wants clean projection with rugged panels for road use.

Problem: Weaves that look authentic can be too tight (muffled highs) or too fragile (snagging, tears); inconsistent weave density across panels creates uneven projection.

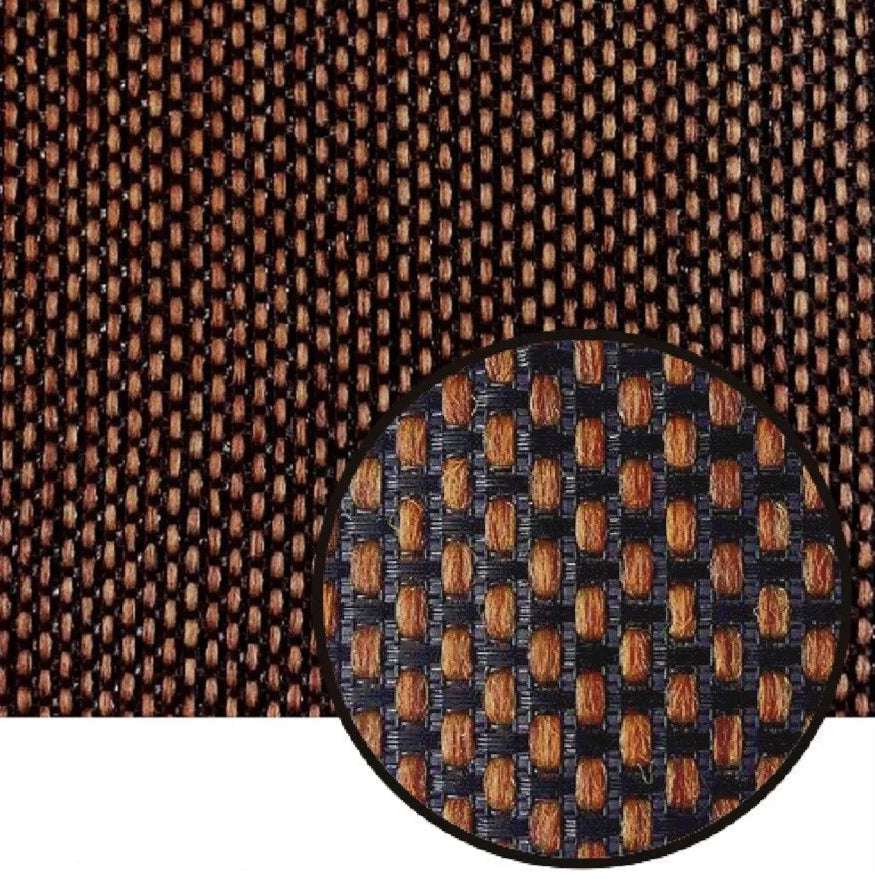

Illustrative Image (Source: Google Search)

Solution:

– Prioritize small-weave or cane-based panels where projection matters:

– British Style Small Weave Cane (32″W) and Mesa Style Small Weave Cane (Black) are engineered for tighter weave with adequate air flow.

– Vox Black Diamond (46″W) offers a classic diamond pattern with projection considerations.

– If prioritizing tear resistance and cost, use MojoWeave Black/Red (48″W), which balances durability with open-ness at a lower price.

– Keep weave density consistent within a production batch; order by brand/style codes to avoid mix-and-match variability.

– Size baffle panels to minimize seams; use the fabric’s listed width efficiently to reduce waste and seaming (e.g., 36″ for Fender, 32″ for British, 48″ for MojoWeave).

– Avoid heavy surface coatings or backing layers that dampen highs; specify uncoated, open-weave constructions where possible.

Example acoustic/durability choices:

| Style | Weave Type | Width | Intended Use | Notes |

|————————|——————–|——-|————————————–|——————————–|

| British Style | Small Weave Cane | 32″ | Marshall-style cabs | Balanced openness/durability |

| Mesa Style | Small Weave Cane | 32″ | Mesa-style cabs | Tighter weave, crisp highs |

| Mojotone MojoWeave | Open Weave | 48″ | Budget durability / long runs | Good tear resistance |

| Vox Style | Diamond Pattern | 46″ | Vox-styled cabs | Classic aesthetic |

Pain Point 3: Lead Times, Width Variability, and Stock Availability

Scenario: A European distributor runs monthly production slots and needs predictable supply for 36″ Fender and 32″ British styles.

Problem: Width variability by brand (36″ vs. 32″ vs. 46″–48″), intermittent “Back Soon” status, and inconsistent stock windows disrupt scheduling and create excess waste from offcuts.

Illustrative Image (Source: Google Search)

Solution:

– Lock a width standard per product line to avoid re-engineering baffles and offcuts:

– 36″ for Fender (Fender Style panels).

– 32″ for British/Marshall/Mesa styles (British/Mesa panels).

– 48″ for MojoWeave.

– Purchase by brand-coded SKUs with explicit width in the spec to simplify picking and reduce miscuts.

– Check availability filters for “In stock” vs. “Back Soon”; plan procurement buffers around known stock windows.

– Consider combining shipments (orders over $99) and consolidate SKUs to improve shipping efficiency and reduce landed cost.

– For tight deadlines, pre-commit to the smaller, commonly stocked widths (32″ and 36″) and avoid long-lead specialty weaves if avoidable.

Representative widths:

| Brand/Style | Common Widths (in stock examples) |

|——————-|——————————————|

| Fender Style | 36″ (e.g., Oxblood, Black/White/Silver) |

| British Style | 32″ (e.g., Black, Small Weave Cane) |

| Mesa Style | 32″ (Small Weave Cane) |

| Mojotone MojoWeave| 48″ |

| Vox Style | 46″ (Black Diamond) |

This approach minimizes rework, preserves sound, and stabilizes supply across USA and Europe operations.

Strategic Material Selection Guide for amp grille cloth

Strategic Material Selection Guide for Amp Grille Cloth

Purpose

– Align grille cloth selection with build method, use case, brand positioning, and regulatory environment.

– Provide material-level decision criteria and a side-by-side product comparison for North American and European buyers.

Illustrative Image (Source: Google Search)

Selection criteria by material

– Acoustic transparency (openness)

– High openness: cane/“small weave” and diamond patterns.

– Moderate: classic Fender/Marshall/Vox weaves.

– Lower (more coverage): dense “aged” styles and metallic sparkle options.

– Durability (wear, UV, tear resistance)

– Highest: polyester and poly/nylon woven textiles.

– Moderate: cane-based cloths.

– Varies widely: metallic/acid-dye finishes may fade; consider UV exposure in stage lighting.

– Pattern fidelity and brand matching

– High fidelity to classic aesthetics (oxblood, black/tan, diamond).

– Match cabinet brands via style designations (Fender Style, British/Marshall Style, Mesa Style, Vox).

– Dimensional stability and ease of installation

– Woven textiles are stable and easy to cut/staple.

– Cane can be brittle and more tear-prone at folds; handle with care.

– Fire-retardant and chemical compliance

– US/EU: ensure FR properties and REACH/RoHS for dyed or metallized finishes; request test reports from supplier.

– Cost-to-width ratio (yarding and waste)

– Larger widths (48″) minimize seams and waste on big baffles; 32″ and 26″ suit narrow baffles and vintage designs.

Material profiles (typical industry characteristics)

– Classic Fender Style (polyester textile)

– Pros: robust, consistent drape, brand-authentic patterns, good acoustic transparency.

– Cons: UV and dye fade over time under intense stage lighting.

– Use: production builds, touring, and studio cabinets where cost control and durability matter.

– British/Marshall Style (cane/rayon-based open weave)

– Pros: iconic look and high acoustic openness; vintage-correct for Brit tones.

– Cons: lower tear strength; prone to brittleness with age and humidity; handling sensitivity at folds.

– Use: boutique builds, restorations, and heritage models; specify handling protocols.

– Vox Diamond (textile, diamond weave)

– Pros: high pattern visibility; classic mid-century modern aesthetics; good openness.

– Cons: textile dye may fade; ensure FR and compliance for EU if required.

– Use: Vox-branded builds and vintage-correct restorations.

– Ampeg/Luxe “sparkle” weaves (textile with metallic/acid-dye overlay)

– Pros: unmistakable stage identity; visible sparkle under light.

– Cons: metallic overlays can reduce acoustic openness; potential for dye fade; ensure compliance if metallized.

– Use: high-visibility stage rigs and premium finishes; consider acoustic impact on speaker.

– Mojotone MojoWeave (poly-blend textile)

– Pros: modern durability and flexibility; available in wider width for efficient material usage.

– Cons: contemporary look may not match strict vintage period correctness.

– Use: custom builds and touring-ready cabinets requiring robustness and width efficiency.

Width selection by cabinet size

– 26″: vintage single-12″ speaker baffles; minimizes waste with narrow cutouts.

– 32″: common for 1×12″ and compact 2×12″ cabinets; manageable seaming.

– 36″: standard for most modern 2×12″/4×12″ baffles; balanced coverage and waste.

– 46″/48″: ideal for 4×12″ and large baffles; wide cloth reduces panel joins and improves panel stability.

– 58″: bulk runs and oversized baffles; optimized for manufacturing efficiency and minimal waste.

Application scenarios and recommendations

– Vintage restoration (Fender/Vox): choose classic Fender Style (36″) or Vox Black Diamond (46″) for brand-correct aesthetics; consider 32″ if baffle width dictates.

– British Marshall tribute: British Style Cane (32″) for authenticity; handle gently during install; specify FR if required by venue.

– Stage touring/rental: MojoWeave (48″) or Mesa Small Weave (32″) for durability and coverage; use 36″/48″ to minimize seams.

– Boutique custom: Mojotone sparkle options or British Small Weave; balance acoustic openness with finish.

– Budget OEM: MojoWeave (48″) or Fender Black (36″) for cost and reliability.

Illustrative Image (Source: Google Search)

Compliance checklist

– Fire performance (US/EU venue codes; specify FR-treated cloth where required).

– REACH/RoHS (especially for metallized/sparkle or acid-dye finishes).

– UV resistance (for stages with intense lighting).

– Acoustic openness (consider speaker dispersion needs).

Cost benchmarks and availability notes

– Premium/vintage-correct patterns (sparkle, diamond) command higher prices per yard and may be in limited stock.

– Wider widths (48″/58″) generally reduce total cloth consumption and labor for large baffles, improving cost-to-build despite higher price per yard.

Comparison table (Mojotone offerings)

| Style | Material (typical) | Weave | Width (in) | Price (USD) | Stock status | Acoustic openness | Durability | Notable notes |

|---|---|---|---|---|---|---|---|---|

| Fender Style Black/White/Silver | Polyester textile | Classic Fender | 36 | 24.95 | In stock | Moderate–High | High–Very High | Production-friendly; good value |

| British Style Black (Marshall) | Cane-based | Open small weave | 32 | 36.00 | In stock | High | Moderate | Heritage look; handle gently |

| Fender Style Oxblood w/ Gold Stripe | Polyester textile | Classic Fender | 36 | 29.39 | In stock | Moderate | High | Vintage-correct patterning |

| Fender Style Aged Black/White/Silver | Polyester textile | “Aged” pattern | 36 | 38.50 | In stock | Moderate | High | Visual aging; may affect UV perception |

| Salt and Pepper | Polyester/Blend textile | Salt-and-pepper | 32 | 32.95 | Back soon | Moderate | High | Neutral tone; check dye fastness |

| Fender Style Black | Polyester textile | Classic Fender | 36 | 24.50 | In stock | Moderate–High | High–Very High | Value; broad compatibility |

| Fender Style Beige Brown (Wheat) | Polyester textile | Classic Fender | 36 | 31.50 | Back soon | Moderate | High | Neutral vintage aesthetic |

| British Style Black and Tan | Cane-based | Open small weave | 32 | 24.50 | In stock | High | Moderate | Cost-effective cane option |

| MojoWeave Black/Red | Poly-blend textile | Modern open weave | 48 | 18.95 | In stock | Moderate–High | High | Wide roll minimizes seams |

| Mesa Style Small Weave Cane (Black) | Cane-based | Open small weave | 32 | 32.54 | In stock | High | Moderate | Touring-friendly open weave |

| Fender Style Oxblood | Polyester textile | Classic Fender | 36 | 26.24 | In stock | Moderate | High | Stripe-less oxblood variant |

| Mojotone Oxblood w/ Silver Stripe | Polyester textile | Classic Fender | 36 | 14.50 | In stock | Moderate | High | Value stripe option |

| British Style Small Weave Cane | Cane-based | Open small weave | 32 | 32.54 | In stock | High | Moderate | Heritage small-weave alternative |

| Fender Style Beige Brown w/ Gold Stripe | Polyester textile | Classic Fender | 26 | 19.50 | In stock | Moderate | High | Narrow baffle specialist |

| Fender Style Aged Blue/White/Silver | Polyester textile | “Aged” pattern | 36 | 28.34 | In stock | Moderate | High | Subtle blue/white blend |

| Cane Grill Cloth | Cane-based | Open | 58 | 45.14 | In stock | High | Moderate | Wide cane; reduces seams |

| British Brown Diamond | Polyester textile | Diamond | 30×36 (panel) | 50.39 | Back soon | High | Moderate | Panel format; heritage pattern |

| Ampeg Style Black/Silver | Polyester textile | Classic open | 36 | 44.00 | In stock | Moderate–High | High | Stage-distinctive black/silver |

| Vox Black Diamond Cloth | Polyester textile | Diamond | 46 | 52.45 | In stock | High | Moderate | Classic Vox diamond weave |

| Mojotone Black & Tan w/ Gold Sparkle | Polyester textile | Sparkle overlay | 36 | 65.95 | In stock | Lower–Moderate | Moderate | Premium look; comply with REACH/RoHS |

Selection shortcuts by build intent

– Value and scale: MojoWeave 48″; Fender Black 36″.

– Heritage correctness: British Cane 32″; Vox Diamond 46″.

– Visibility and branding: Ampeg Black/Silver 36″; Mojotone Sparkle 36″.

– Acoustic openness with cost control: Mesa Small Weave 32″.

Illustrative Image (Source: Google Search)

Procurement notes

– Confirm FR status and REACH/RoHS for dyed/metallic finishes where applicable.

– Verify weave lot-to-lot consistency for brand-matched batches.

– If working in meters, convert yards to meters (yd × 0.9144) and plan for panel seaming.

This guide positions material decisions to deliver the right balance of acoustic performance, durability, brand fidelity, and regulatory compliance for both US and European markets.

In-depth Look: Manufacturing Processes and Quality Assurance for amp grille cloth

In‑depth Look: Manufacturing Processes and Quality Assurance for Amp Grille Cloth

This section outlines typical manufacturing steps and quality assurance (QA) practices for amp grille cloth used in guitar and keyboard amplifier cabinets. Production follows the four-stage workflow below, aligned to ISO-based quality management to ensure consistent performance, appearance, and acoustic properties.

Process Overview

- Prep: Define specifications, source materials, and validate fabric and treatments.

- Forming: Weave/knit base cloth, dye/finish, slit to width, and apply acoustic tests.

- Assembly: Integrate cloth into finished grille panels; cut, hem, attach to frames.

- QC: Verify appearance, dimensional stability, mechanical performance, and compliance.

Step 1 — Prep

- Specification definition: Specify style (e.g., Fender, British, Mesa, Vox), weave type (plain, twill, basket), dye method (yarn-dyed or piece-dyed), and finish options (aging, stripes, sparkles).

- Material sourcing: Polyester and cotton are common substrates; flame-retardant (FR) options are available. Yarn type (staple or filament), tex, and finish level are selected for durability and acoustic transparency.

- Dimensional planning: Target widths (26″, 32″, 36″, 46″, 58″) and cut-length planning per cabinet design. Allow for seam allowances and hem allowances.

- Compliance planning: Define regional performance targets (US/EU) for flammability (e.g., NFPA 701 for US) and chemical compliance (e.g., REACH/SVHC for EU).

- Documentation: Create work instructions and a Bill of Materials (BOM). Record lot numbers, dye lots, and finishing recipes.

Step 2 — Forming

- Fabric formation:

- Warping and beaming: Align warp yarns, manage tension, and set reed/fill counts.

- Weaving/knitting: Produce base cloth to target thickness, openness, and strength. Control beat-up to achieve consistent openness and air permeability suitable for sound projection.

- Dyeing and finishing:

- Pretreatment: Desize, scour, or heat-set as required to stabilize geometry.

- Dyeing: Apply dyeing/printing processes compatible with the substrate and specified color.

- Finishing: Heat setting, calendaring (optional), anti-curling treatment, stain/UV resistance (where applicable). Note that flame-retardant treatments, if required, are typically applied during finishing.

- Slitting and winding: Slit to final widths (e.g., 26″, 32″, 36″, 46″, 58″). Inspect selvedges, correct bow/skew, and ensure roll continuity.

- Acoustic validation:

- Air permeability and open area targets: Match weave/weight to maintain acoustic transparency without excessive fiber shedding.

- Verify via ISO 9237 or equivalent methods at the fabric roll stage.

Step 3 — Assembly

- Cutting: Nest panels for minimal waste; ensure accurate panel dimensions and cut edge quality.

- Hemming: Apply stitched or thermally bonded hems per specification to prevent fraying.

- Attachment options: Stapling, hook-and-loop (Velcro), clips, or frame-integrated systems. Validate pull-off and peel forces suitable for field replacement.

- Pattern alignment: For aged/worn effects and stripes/sparkles, align pattern direction and spacing across the cabinet to maintain visual consistency.

Step 4 — QC

- Systems and audit: Operate under ISO 9001-aligned quality management; conduct internal audits and management reviews.

- Incoming inspection:

- Verify yarn batch, finish recipe, and color match against the master. Check certificates of compliance for FR and chemical compliance (US/EU).

- In-process controls:

- Dimensional checks (thickness, open area, air permeability).

- Visual inspection: color consistency, shade, defects, pattern alignment.

- Final inspection:

- Mechanical performance: Tensile strength and seam strength (ISO 13934); Tear resistance (ISO 13937); Bursting strength (ISO 13938).

- Dimensional stability: Dimensional change/shrinkage (ISO 5077).

- Abrasion/wear: Martindale abrasion or Taber abrasion as agreed with customers (ISO 12947).

- Color fastness: Crocking/rubbing (ISO 105-X12), light fastness (ISO 105-B02), and wash/fastness where relevant (ISO 105-C06).

- Acoustic: Air permeability/open area (ISO 9237).

- Flammability: NFPA 701 (US) or applicable EU test; ISO 3795 can support internal risk screening.

- Environmental/health: REACH/SVHC compliance for EU (materials not exceeding thresholds).

- Sampling and AQL:

- Employ AQL inspection levels per accepted sampling plans (e.g., MIL‑STD‑414/105E principles). Define critical, major, and minor defect classes (e.g., 1.0–2.5% depending on severity).

- Nonconformance and traceability:

- Quarantine and root cause analysis. Maintain lot traceability and rework standards.

Key ISO/Industry References

| Domain | Standard/Guidance | Typical Application |

|---|---|---|

| Quality Management | ISO 9001 | Quality system, audits, continuous improvement |

| Air Permeability | ISO 9237 | Acoustic transparency and sound projection |

| Strength — Tensile | ISO 13934‑1/‑2 | Fabric and seam strength |

| Strength — Tear | ISO 13937 | Resistance to tearing |

| Strength — Burst | ISO 13938 | Resistance to bursting pressure |

| Dimensional Stability | ISO 5077 | Shrinkage/dimensional change |

| Abrasion (Martindale) | ISO 12947 | Durability/abrasion resistance |

| Color Fastness — Rubbing | ISO 105‑X12 | Crocking resistance |

| Color Fastness — Light | ISO 105‑B02 | Resistance to light fading |

| Color Fastness — Washing | ISO 105‑C06 | Wash fastness (where applicable) |

| Flammability Screening | ISO 3795 | Supplementary screening for ignition |

| Flammability — US Market | NFPA 701 | US regulatory compliance for drapery/decorative fabrics |

| Environmental — EU Market | REACH/SVHC | EU chemical compliance (materials under thresholds) |

Notes:

– Numeric thresholds for air permeability, tensile/tear strength, and abrasion cycles are defined per customer specification and acoustic/brand requirements.

– For EU markets, confirm compliance with applicable national fire safety regulations in addition to the flammability standards listed above.

Illustrative Image (Source: Google Search)

Process Capability (What to Control)

- Air permeability/open area: Verified against target to ensure sonic neutrality and minimal obstruction.

- Dimensional stability: Manage shrinkage and skew to maintain fit on frames and consistent pattern alignment.

- Mechanical robustness: Tensile and tear strengths set to avoid damage during installation and field replacement.

- Color integrity: Crocking and light fastness tuned to handle repeated handling and varying light conditions.

Compliance Across Regions (US/EU)

- US: NFPA 701 for FR when specified; comply with applicable US environmental rules for chemicals in finishes (where applicable).

- EU: REACH/SVHC; confirm national fire-retardancy regulations for consumer electronics enclosures. Coordinate with downstream amp OEMs for end-of-life packaging compliance where required.

Practical QA Checklist (Summary)

- Incoming: Yarn lot, finish recipe, color standard; FR and chemical compliance certificates.

- In-process: Thickness, open area, air permeability; visual defect tracking; seam consistency.

- Final: Strength tests (tensile, tear, burst); dimensional stability; abrasion; color fastness; NFPA 701/ISO 3795; air permeability/open area; AQL sampling acceptance.

- Release: Lot traceability, inspection records, and customer-agreed specifications documented and approved.

This workflow delivers repeatable performance and appearance for amp grille cloth while meeting US/EU regulatory expectations through ISO-based QA and targeted flammability standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘amp grille cloth’

Practical Sourcing Guide: A Step-by-Step Checklist for Amp Grille Cloth

Step 1: Define the Exact Specification

- Determine the brand/style of grille cloth (e.g., Fender, British/Marshall, Mesa, Ampeg, Vox, Mojotone) and colorway (e.g., black/white/silver, oxblood, salt and pepper, diamond patterns).

- Choose the required width (e.g., 26″ W, 30″ W, 32″ W, 36″ W, 46″ W, 48″ W, 58″ W).

- Note finish/finish level (e.g., standard vs aged/vintage).

- Identify shipping markets (USA and Europe) and lead-time targets.

- Plan minimum order quantities (MOQ) and reorder frequency aligned with your production schedule.

Step 2: Verify Fit and Form-Factor

- Confirm the weave and pattern are appropriate for your speaker cabinets (open vs closed back).

- Match the width to your baffle cutouts; avoid width gaps that compromise coverage.

- If matching an existing brand aesthetic (e.g., British Style or Fender Style), use style labeling to simplify procurement.

Step 3: Evaluate Supplier Options

- Request catalog availability, in-stock status, and lead times for target widths and styles.

- Confirm shipping to USA and Europe; confirm order thresholds and freight arrangements.

- Discuss volume pricing, MOQ, and payment terms (e.g., net-terms, financing options if available).

Step 4: Validate Quality and Acoustics

- Request physical samples before bulk orders.

- Check weave consistency, color uniformity (especially important for aged/vintage looks), edge finishing, and durability.

- Validate acoustic transparency vs visual aesthetics; ensure the grille cloth does not interfere with sound projection.

Step 5: Secure Pricing and Order Structure

- Build a bill of materials (BOM) listing brand/style, width, and colorway by cabinet model.

- Align unit costs and order values with shipping thresholds to optimize freight.

- Prepare POs with exact SKUs, widths, and quantities to minimize returns and reorders.

Step 6: Logistics and Shipping (USA & Europe)

- Confirm transit times and carrier coverage to both regions.

- Ensure proper packaging for roll widths to avoid creasing.

- Track shipments and set lead buffers for critical production windows.

Step 7: Incoming Quality Control (QC) and Documentation

- Inspect shipment for correct width, style, and colorway.

- Verify in-stock product availability matches invoiced items.

- Document lot or roll numbers for traceability and future reorders.

- Retain small sample swatches for future reference.

Step 8: Pilot Build and Final Approval

- Run pilot builds on one or two cabinets to confirm fit, cutout alignment, and visual consistency.

- Capture notes for installation procedures and fabric handling.

- Approve for full production based on pilot outcomes.

Step 9: Reorder and Lifecycle Management

- Monitor roll consumption vs build rate to set reorder triggers.

- Track price variations across styles; maintain backup options for long-lead items.

- Keep an updated sourcing profile for USA and Europe markets to streamline future requests.

Glossary for Faster Vendor Communication

- Style: Fender, British (Marshall), Mesa, Ampeg, Vox, Mojotone.

- Weave/Pattern: Small weave cane, diamond, oxblood with stripe, black/white/silver, salt and pepper.

- Width: 26″, 30″, 32″, 36″, 46″, 48″, 58″.

- Finish: Standard vs aged/vintage.

Quick Reference: Width and Style Examples (Mojotone Catalog)

| Style/Catalog Label | Example Widths | Example Price (USD) | Notes (Finish/Aging) |

|---|---|---|---|

| Fender Style Black/White/Silver | 36″ W | $24.95 | Standard |

| British Style Black | 32″ W | $36.00 | Marshall Replacement |

| Fender Style Oxblood w/ Gold Stripe | 36″ W | $29.39 | Standard |

| Fender Style Aged Black/White/Silver | 36″ W | $38.50 | Aged/Vintage |

| Salt and Pepper | 32″ W | $32.95 | Back Soon status noted |

| British Style Black and Tan | 32″ W | $24.50 | Standard |

| MojoWeave Black/Red | 48″ W | $18.95 | Wide roll for larger baffles |

| Mesa Style Small Weave Cane (Black) | 32″ W | $32.54 | Standard |

| Mojotone Oxblood with Silver Stripe | 36″ W | $14.50 | Value option |

| British Small Weave Cane | 32″ W | $32.54 | Standard |

| Cane Grill Cloth | 58″ W | $45.14 | Extra-wide roll |

| British Brown Diamond | 30″ x 36″ | $50.39 | Back Soon status noted |

| Ampeg Style Black/Silver | 36″ W | $44.00 | Standard |

| Vox Black Diamond Cloth | 46″ W | $52.45 | Standard |

| Mojotone Black & Tan w/ Gold Sparkle | 36″ W | $65.95 | Premium/Highlighted |

| Fender Style Beige Brown (Wheat) | 36″ W | $31.50 | Back Soon status noted |

Notes:

– Prices are example points from the Mojotone catalog; actual prices may vary with availability and promotions.

– Shipping note: $5 shipping on orders over $99 (USA market reference). Confirm logistics for EU shipments directly with the vendor.

Final Checklist

- Specification finalized (style, width, finish).

- Samples approved (aesthetic and acoustic).

- Pricing and MOQs confirmed for USA and Europe.

- Shipping terms and schedules aligned to production.

- QC plan and documentation ready for incoming inspections.

- Pilot builds completed successfully.

- Reorder triggers and supplier documentation updated.

Comprehensive Cost and Pricing Analysis for amp grille cloth Sourcing

Comprehensive Cost and Pricing Analysis for Amp Grille Cloth Sourcing

Market price anchors (reference: Mojotone)

The table below maps representative retail prices per square foot to help benchmark procurement and retail pricing across common styles and widths. Conversions assume 36 in = 1 linear yard; 1 yd2 = 9 ft2.

| Style | Typical width | Panel size | Retail price (Mojotone) | $/ft² | $/yd² |

|---|---|---|---|---|---|

| Fender Black | 36″ | 36″ × 36″ | $24.50 | 2.72 | 24.50 |

| Fender Beige Brown w/ Gold Stripe | 26″ | 26″ × 36″ | $19.50 | 2.50 | 22.50 |

| British Small Weave Cane | 32″ | 32″ × 36″ | $32.54 | 3.39 | 30.50 |

| Mesa Style Small Weave Cane (Black) | 32″ | 32″ × 36″ | $32.54 | 3.39 | 30.50 |

| British Brown Diamond | 30″ | 30″ × 36″ | $50.39 | 5.60 | 50.40 |

| Vox Black Diamond | 46″ | 46″ × 36″ | $52.45 | 3.18 | 28.60 |

| Ampeg Style Black/Silver | 36″ | 36″ × 36″ | $44.00 | 4.89 | 44.00 |

| MojoWeave Black/Red | 48″ | 48″ × 36″ | $18.95 | 1.32 | 11.87 |

Use these anchors to:

– Validate competitor positioning (US/EU retail).

– Construct SKU-level price ladders (entry, mid, premium).

– Model margin and contribution by style.

Illustrative Image (Source: Google Search)

Cost drivers and structural pricing model

| Dimension | Key drivers | Typical ranges (indicative) |

|---|---|---|

| Materials | Yarn type (cotton, polyester, acrylic), weave complexity, dye/finish | $0.25–$0.85 per ft² (economy to premium) |

| Conversion | Knitting/weaving + dyeing/finishing + slitting, defect allowance | $0.15–$0.30 per ft² (plus ~8–12% quality loss on dyed material) |

| Packaging | Tube/roll, poly wrap, labels | $0.02–$0.05 per ft² |

| Overhead/QA | Factories, storage, QC, sampling | $0.03–$0.06 per ft² |

| Logistics (retail/e-commerce) | Small-parcel shipping, order handling | Often “free shipping” thresholds; real cost ~$5–$12 per order if broken out |

| Logistics (B2B) | Full-roll LTL/TL, EU freight, duties (EU), customs broker, inbound handling | DDP USA: ~3–6% of ex-factory for LTL; EU: ~12–18% DDP with duties/VAT |

Indicative total landed cost (TLC) targets by sourcing tier (ex-works to DLC):

– Retail/wholesale (single rolls): $3.00–$6.00 per ft²

– Wholesale (case packs, 5–20 rolls): $2.00–$4.50 per ft²

– Direct import OEM (MOQ 500–1,500 m; 3–6 weeks): $1.00–$2.60 per ft²

Notes:

– TLC includes conversion, packaging, overhead, and freight/duties (where applicable).

– Exact benchmarks vary by pattern, width, and region (US vs EU DDP).

Labor and value-add impact

- Cut-to-size service: adds $0.10–$0.20 per ft² (labor + scrap).

- Edge handling/hemming: adds $0.05–$0.15 per ft².

- Pattern matching across panels: may raise waste by ~10–20%.

- Pre-packing kits (multiple pieces per SKU): adds $0.03–$0.06 per ft².

How to price wholesale and retail (US/EU)

Recommended margin ladder per piece, calibrated to Mojotone retail anchors:

– Wholesale to retailer: 30–50% margin on wholesale ex-factory.

– Retail: 50–100% markup on wholesale.

Worked example (36″×36″ Fender Black):

– Cost model (mid case): $1.25 ex-factory + $0.20 conversion + $0.10 overhead + $0.05 packaging = $1.60 per ft².

– Wholesale at $1.60 per ft²: suggest $3.20–$4.00 per ft² to distributor/retail (50–100% markup), yielding $28.80–$36.00 per panel.

– Retail price target: $36.00–$48.00 per panel (competitive vs $24.50–$44.00 Mojotone range).

Illustrative Image (Source: Google Search)

For higher-end patterns (diamond/cane), budget higher materials and conversion costs; expect retail prices at $50–$65 per 36″×36″ panel.

Unit economics per cabinet (typical 14″×18″ amp grille)

- Panel size: 252 in² = 1.75 ft².

- Single-roll retail cost: $35–$65 per panel (see $/ft² table).

- Wholesale mid: $10–$20 per panel.

- Import mid: $6–$12 per panel.

- Replacement ROI: using mid wholesale, save $1,750–$3,650 per 250 cabinets vs retail, even after sampling and setup costs.

10 ways to save cost

1) Standardize widths and formats (26″, 32″, 36″, 46″). Avoid one-off widths unless necessary.

2) Bundle SKUs and pre-buy peak colors. Target 3–6 months’ coverage; carry cost often <5% vs 10–20% savings.

3) Switch to 500–1,000 m MOQ where feasible. Price drops 20–40% vs fragmented orders; amortize sampling/tooling.

4) Consolidate into LTL/TL (full container for EU). Target 90–95% container fill; DDP freight can fall from >15% to 8–12% of ex-factory.

5) Cut waste by panel nesting. For a 14″×18″ aperture, use 26″ material for most cabs; 32″ only when needed.

6) Pre-screen suppliers: verify dye-house capability, color-fastness tests, and abrasion specs to reduce rework/defect costs.

7) Use neutral pack and generic labeling for stock; apply brand labels at the DC to cut SKU proliferation.

8) Offer “plain” variants (mono-color) at lower price points, reserve premium weaves for flagship lines.

9) Reduce expedited freight; build safety stock for 2–3 weeks during peak to avoid airfreight premiums.

10) In the EU, favor EU-based converters or suppliers with bonded warehouses to avoid repeated import duty on small drops.

US vs EU procurement notes

- US: DDP domestic rail/truck typically 3–6% of ex-factory for 5–20 roll orders; 2–4% for full containers.

- EU: DDP including import duty/VAT often 12–18% for 3–10 roll LTL; 8–12% for FCL consolidated shipments.

- Consider regional warehousing for EU to minimize cross-border VAT and duty friction.

Sample margin ladder (36″×36″ panels)

Use the cost model to set margins that align with your brand positioning.

| Style | Anchor retail (Mojotone) | Suggested wholesale | Suggested retail (US) | Suggested retail (EU incl. VAT) |

|---|---|---|---|---|

| Fender Black | $24.50 | $30–$40 | $42–$58 | €45–€62 |

| Mesa/British Cane | $32.54 | $34–$42 | $48–$66 | €52–€72 |

| Vox Black Diamond | $52.45 | $45–$60 | $62–$88 | €68–€95 |

| Ampeg Black/Silver | $44.00 | $38–$48 | $54–$72 | €58–€78 |

| Mojotone Black & Tan w/ Sparkle | $65.95 | $58–$78 | $78–$118 | €85–€128 |

Note: EU retail includes VAT; exclude VAT when comparing ex-tax US prices. Adjust by freight, currency, and channel strategy.

Illustrative Image (Source: Google Search)

Risk and hidden costs checklist

- Defect rate and rework: 2–5% typical on first runs; build a quality buffer.

- Pattern repeat and alignment waste: +10–20% on designs requiring matching.

- Duty and VAT (EU): HS code specifics and rules of origin matter; validate DDP landed cost early.

- Shipping damage/claims: factor 0.3–0.7% incident rate on small-parcel shipments.

- Sampling cycles: expect 1–3 rounds at $50–$250 per sample; cap and schedule in project plan.

- Inventory carrying cost: set at 8–14% annualized; offset via improved fill rate and reduced spot buys.

Quick decision framework

- Need 1–20 panels: buy from US distributor; cost parity with wholesale is strong given free shipping thresholds and short lead time.

- 50–500 panels/year: engage a wholesale distributor; target case-pack pricing and better freight.

- 500+ panels/year or 3+ core SKUs: quote direct import OEM for 20–40% cost reduction with DDP US/EU, while protecting lead times via buffer stock.

This analysis provides the numbers and levers you need to set target landed costs, choose the right sourcing tier, and protect margin across US and EU channels.

Alternatives Analysis: Comparing amp grille cloth With Other Solutions

Alternatives Analysis: Comparing Amp Grille Cloth With Other Solutions

Amp grille cloth remains the preferred trade-off for most cabinet builds and restorations. When different form factors, environments, or cost targets apply, two alternatives are commonly evaluated: open-frame speaker mesh and perforated metal grilles.

Key specifications at a glance

| Option | Acoustic transparency | Speaker protection | Durability & impact resistance | Aesthetic flexibility | Weight | Cost band | Availability | Maintenance | Typical use cases |

|---|---|---|---|---|---|---|---|---|---|

| Amp grille cloth | High open-weave allows sound to pass with minimal obstruction. Reason: Maintains tonality and projection while diffusing dust. | Moderate protection against dust and light impacts. Reason: Soft material cushions but won’t stop forceful contact. | Good, depending on weave; less resilient than metal. Reason: Fabric can fray with heavy use. | Extensive patterns/colors; easy to match brand styles. Reason: Flexible look across Fender, Marshall, Vox aesthetics. | Low. Reason: Lightweight material reduces cabinet mass. | $–$$ per yard. Reason: Prices vary by width and pattern. | Broad. Reason: Multiple vendors stock variants and widths. | Easy to clean; replaceable. Reason: Non-rigid panels swap quickly. | Vintage restoration, touring rigs, cost-conscious builds, tonal purity focus. Reason: Balanced acoustic and visual needs. |

| Open-frame speaker mesh | Very high open area; minimal effect on tone. Reason: Large openings reduce diffraction. | Strong protection for drivers. Reason: Rigid mesh resists punctures and fingers. | High impact resistance; may dent but not tear. Reason: Metal wireframe tolerates shocks. | Limited weave patterns; primarily utilitarian. Reason: Functional aesthetic rather than heritage styling. | Low–medium. Reason: Thinner gauge metal still adds some mass. | $$ per panel. Reason: Depends on frame and finish. | Moderate. Reason: Less common in boutique retail; available in pro supply channels. | Requires corrosion care and occasional tightening. Reason: Tighteners and hardware can loosen over time. | Portable PA/touring, outdoor/exposed setups, durability priority. Reason: Defends drivers while preserving sound. |

| Perforated metal grille | Lower acoustic transparency due to hole pattern. Reason: Fine perforations impede high frequencies more than cloth or mesh. | Very high protection and tamper resistance. Reason: Rigid, theft-deterrent surface. | Excellent; handles heavy handling and weather. Reason: Metal resists shocks and wear. | Limited patterns; robust “industrial” look. Reason: Branding often via panels or logos. | Medium–high. Reason: Thicker plate adds significant weight. | $$$ per panel. Reason: Fabrication, finish, and fastening drive cost. | Specialized/industrial supply. Reason: Custom tooling and finishes required. | Occasional rust/paint touch-up; hardware upkeep. Reason: Exposed environments cause wear. | Security-sensitive installs, outdoor/fixed venues, branding/panelized grilles. Reason: Protection and visibility trump full acoustic transparency. |

Analysis: when each option fits

- Choose amp grille cloth when tonal accuracy and appearance are paramount, and budgets are constrained. Reason: It preserves cabinet tone with broad aesthetics at lower cost.

- Select open-frame speaker mesh for portable touring or exposed environments where driver protection and minimal tonal impact are critical. Reason: It balances strong protection with near-transparent acoustics.

- Opt for perforated metal grilles for security-first or weather-prone installations, accepting some acoustic penalty. Reason: It offers the highest protection and durability at the cost of weight and tone coloration.

Practical selection guidance

- For EU projects needing compliance with EN 45545-2 for railway interiors or NFPA 701 for North American venues, confirm flame-retardant certifications before specifying cloth. Reason: Not all grille cloths meet transport flammability standards.

- If brand-authentic appearance (Fender, Marshall, Vox) is required, grille cloth offers the richest stylistic fit. Reason: Heritage patterns and colors are readily available across standard widths.

- For serviceability and logistics, cloth panels are faster to remove/replace on the road. Reason: Non-rigid installations reduce labor during field repairs.

- Consider a hybrid approach: cloth fronts for tone-sensitive cabinets, perforated panels for high-visibility branding or security needs. Reason: Aligns performance to each cabinet’s role and environment.

Quick decision checklist

- Prioritize acoustic transparency and heritage looks: choose amp grille cloth. Reason: Best balance of sound quality and brand aesthetics.

- Prioritize driver protection in demanding venues: choose open-frame mesh. Reason: Strong defense with minimal tonal effect.

- Prioritize security and durability in fixed or outdoor installs: choose perforated metal. Reason: Highest robustness and tamper resistance.

In most B2B scenarios, amp grille cloth remains the default—balanced, cost-effective, and brand-aligned—while open-frame mesh and perforated metal serve as targeted alternatives for protection-first or environment-specific requirements. Reason: They trade acoustic purity for security and robustness in well-defined use cases.

Essential Technical Properties and Trade Terminology for amp grille cloth

Essential Technical Properties and Trade Terminology for Amp Grille Cloth

Amp grille cloth must deliver stable appearance, predictable acoustic behavior, and reliable handling in OEM and service environments. The section below consolidates the core technical properties and the trade terminology commonly used in the US and Europe to specify, source, and evaluate these materials.

Illustrative Image (Source: Google Search)

What determines performance

- Acoustic openness and airflow: determines how much sound passes through without obstruction; higher openness correlates with lighter perceived tonal damping from the grille.

- Weave structure and porosity: affects both visual grain and acoustic transparency; diamond and basket weaves are common on vintage-style cloths.

- Mechanical durability: tensile strength, tear resistance, and abrasion resistance resist rips, wear at speaker openings, and handling damage.

- Dimensional stability: shrinkage control keeps installed panels true to cabinet openings across climates.

- Color fastness: maintains visual integrity under heat, UV exposure, and cleaning; critical for “aged” or “sparkle” finishes.

- Flame behavior and compliance: ensures materials meet venue or jurisdiction requirements when installed in public spaces.

- Finish and substrate compatibility: coatings, treatments, and edge bonding do not release volatiles (REACH-compliant) and do not interfere with finishes.

- Cuttability and seamability: stable cut edges without excessive fraying; machine stitchability where needed.

- Width availability: standard widths enable efficient yield planning for common grille sizes (32″, 36″, 46″, 48″, 58″).

Common technical properties and why they matter

| Property | Why it matters | Typical US/EU specs or notes |

|---|---|---|

| Acoustic openness (light transmittance) | Predicts tonal transparency; more open cloth allows more direct sound. | Often not published for cloth; where transparency is critical, specify higher openness and verify by sample. |

| Weave type | Controls pattern grain, acoustic passage, and visual authenticity. | Diamond, basket, twill; diamond and basket are prevalent on classic-style cloths. |

| Fiber composition | Influences durability, heat stability, and finish integrity. | Jute/cotton blends for classic look; polyester for durability; fiberglass for open-mesh “cane.” |

| Yarn/thread count or gauge | Affects tear resistance and acoustic balance. | Not standardized; request warp/weft counts for batch consistency. |

| Tensile strength | Resistance to pulling forces during installation and use. | Specify per ASTM D5034 (US) or ISO 13934-1 (EU). |

| Tear resistance | Prevents rips from corners and cutouts. | Specify per ASTM D1424 (US) or ISO 13937 (EU). |

| Abrasion resistance | Withstands handling, cleaning, and speaker-edge wear. | Specify per ASTM D4966 Martindale (US) or ISO 12947 (EU); minimum target per application. |

| Dimensional stability/shrinkage | Prevents cabinet fit issues. | Wash or heat test: ≤2–3% typical target for installation tolerance. |

| Color fastness | Prevents fading under heat/UV and from cleaning. | Specify per ISO 105-B02 (light) and ISO 105-X12 (rub/cold water). |

| UV resistance | Slows color change with exposure. | Note exposure conditions and material choice. |

| Flame behavior/compliance | Meets venue and market requirements. | FR versions available; see certifications table. |

| Chemical and VOC profile | Avoids reactions with cabinet finishes; safe for enclosed spaces. | REACH compliance (EU), RoHS (EU) for non-metallic components; ask for supplier declaration. |

| Finish effects | Preserves specialty appearances (aged, sparkle, stripe). | Verify adhesion, rub fastness, and finish color match across batches. |

| Cuttability/seaming | Reduces fraying; improves handling speed. | Ask for cut-edge stability and recommended stitch type/tension. |

| Width options | Drives yield and panel planning. | Common widths: 26″, 30″, 32″, 36″, 46″, 48″, 58″. |

Market-standard sizes and cuttable units

| Width (inches) | Typical applications | Notes for sourcing |

|---|---|---|

| 26–32″ | Vintage-style British/Marshall-style openings; compact cabinets. | Use width ≥30″ when panels include angled corners. |

| 36″ | Fender-style, Ampeg-style panels; 1×12 combos. | Widely available; suitable for long runs and service stock. |

| 46″ | Vox-style “black diamond” patterns; larger speaker arrays. | Check weave density for acoustic balance. |

| 48″ | Modern cabinets and custom builds needing extra width. | Better yield on large flat panels; verify roll lengths. |

| 58″ | Oversized panels; multi-speaker cabs with seamless coverage. | Verify roll lengths and seam recommendations. |

Acoustically relevant weave styles

| Weave style | Typical look | Acoustic tendency |

|---|---|---|

| Diamond | Classic vintage lattice; balanced grain. | Balanced acoustic permeability; widely used. |

| Basket (herringbone or Oxford-style) | Fine, tight interlace; contemporary look. | Slightly less open than diamond; smoother tone visually. |

| Cane/open mesh | High airflow and visibility; often fiberglass. | Very high acoustic transparency; strong, open structure. |

Certifications and compliance (US/EU)

| Certification/standard | Region | What it addresses | Typical acceptance/use |

|---|---|---|---|

| NFPA 701 (flame resistance of textiles) | US | Flame propagation of fabric drapes. | Stage, venue, and rental requirements; specify when needed. |

| CPAI-84 (A/B/C types) | US | Flame-retardant treated fabrics for tents/awnings. | Used as a baseline for FR performance in similar fabrics. |

| ISO 3795 (flammability) | EU | Burning behavior of textiles (laboratory). | General indicator of flame spread; paired with local codes. |

| California TB 117-2013 | US | Flammability of upholstered furniture components (legacy label). | Historical reference; check current local requirements. |

| EN 13773 (class-based flame propagation) | EU | Classification for textiles in public spaces. | Venue-specific acceptance; verify class required. |

| REACH compliance | EU | Chemical safety for articles placed on the EU market. | Required for EU sales; supplier declaration recommended. |

| RoHS compliance | EU | Restriction of hazardous substances in electrical components (e.g., hardware). | If metallic hardware, studs, or fasteners are included. |

Trade terms and business parameters

| Term | Meaning | Region/notes |

|---|---|---|

| MOQ (Minimum Order Quantity) | Minimum yardage or rolls to qualify for a specific price tier. | Typical per width/style; confirm with supplier. |

| SKU/Part No. | Supplier’s unique identifier for each style and width. | Use in POs, inventory, and cut tickets. |

| Width | Finished usable width. | Specify after seam allowance if edges will be bound. |

| Roll length | Linear yards or meters per roll. | Confirm upcharge for cut-to-length orders. |

| Unit of sale | Yards or meters; sometimes “piece.” | US: yards common; EU: meters; clarify invoicing unit. |

| Lead time | Time from PO to ship date. | Include supplier’s cut and finish queues. |

| Cut stock vs. roll stock | Pre-cut pieces vs. continuous rolls. | Reduces handling for standard cabinet sizes. |

| Die-cut or CNC cut | Precision cutting for complex apertures. | Ask for tooling cost amortization on larger runs. |

| Edge finishing | Overlock, tape, or bonded edges to control fraying. | Specify stitch type and thread if sewing is used. |

| Seam/panel joining | Recommendation for overlap, butt seam, or hidden seam. | Critical for visual continuity across joints. |

| Aging (distressed) | Controlled appearance changes (fading, speckle distribution). | Ask for sample approval to lock appearance tolerance. |

| Stripe/sparkle patterns | Decorative overlays or woven patterns. | Verify adhesion and rub fastness on coated variants. |

| Price tiers | Volume discounts by total yardage. | Request breakpoints; typical small orders ≥10–25 yd. |

| Freight terms | FOB/FCA/EXW; LTL/FTL. | Include dimensional weight for wide rolls. |

| Tariff/HS codes | Customs classification; duty implications. | Provide codes to purchasing for landed cost. |

| IncoTerms | Shipping responsibility boundaries. | Define point of risk transfer and insurance. |

| Payment terms | Net, COD, 2% 10, etc. | Common: Net 30 for approved accounts. |

| Warranty | Material performance assurance. | Stipulate replacement scope, not labor. |

| Return policy | Defects, batch variance, uncut stock. | Require photo evidence and RMA within defined window. |

| SDS/MSDS | Safety data sheet when coatings or chemicals present. | Ask for latest version. |

| Compliance documentation | REACH, RoHS, flame certificates, origin. | Provide on request for EU and venue buyers. |

| REACH compliance | EU regulation on chemical substances. | Supplier declaration and material data requested. |

| RoHS compliance | EU regulation on hazardous substances in electronics. | Only applicable if metals or hardware included. |

| California Prop 65 | State-level chemical exposure warning requirement. | Labeling may apply; include on SDS when required. |

Market examples (Mojotone product listings)

| Brand/style | Width | Status | Price (USD) | Observations |

|---|---|---|---|---|

| Fender Style Black/White/Silver | 36″ W | In stock | $24.95 | Classic vintage pattern; standard width for Fender-style panels. |

| British Style Black | 32″ W | In stock | $36.00 | Marshall-style replacement width. |

| Fender Style Oxblood w/ Gold Stripe | 36″ W | In stock | $29.39 | Decorative stripe overlay; verify color matching across batches. |

| Salt and Pepper | 32″ W | Back Soon | $32.95 | High-demand vintage look; availability impacts lead time. |

| British Style Black & Tan | 32″ W | In stock | $24.50 | Classic British aesthetic; width aligns with vintage cabs. |

| Mesa Style Small Weave Cane (Black) | 32″ W | In stock | $32.54 | Open-mesh look; good acoustic transparency. |

| Ampeg Style Black/Silver | 36″ W | In stock | $44.00 | Coarser weave; confirm panel opacity vs. tone preferences. |

| Vox Black Diamond | 46″ W | In stock | $52.45 | Diamond pattern at wider width; ideal for Vox-style coverage. |

| British Brown Diamond | 30″ x 36″ | Back Soon | $50.39 | Non-standard dimensions; consider cutting yield. |

| Mojotone Black & Tan w/ Gold Sparkle | 36″ W | In stock | $65.95 | Sparkle effect; verify rub fastness on coated finishes. |

| MojoWeave Black/Red | 48″ W | In stock | $18.95 | Wide roll for modern builds; competitive per-width price. |

| Cane Grill Cloth | 58″ W | In stock | $45.14 | Oversized width for large, seamless panels. |

Notes on units and invoicing

– US sellers frequently price and sell in yards; EU buyers typically receive meter-based invoices. Confirm invoicing unit, minimum increment (e.g., 1 yard vs. 10 cm), and whether half-rolls are accepted.

Practical guidance for buyers

- Always request a sample for both acoustic and visual acceptance, especially for aged or sparkle finishes.

- Where venue requirements apply, specify flame certificates in your RFQ and verify any laundering or heat exposure limits.

- Confirm dimensional stability with a controlled wash/heat test before committing to production cut lists.

- Define seam allowances and edge finishing in your specification to avoid rework and edge fray.

- Lock a multi-year color standard by approving a physical master set and maintaining supplier batch records.

This consolidated view of technical properties and trade terms supports reliable purchasing decisions and consistent installation outcomes in both US and European markets.

Navigating Market Dynamics and Sourcing Trends in the amp grille cloth Sector

Navigating Market Dynamics and Sourcing Trends in the Amp Grille Cloth Sector

Amp grille cloth sits at the intersection of heritage tone, cabinet differentiation, and pragmatic economics. While it appears simple, the market is shaped by brand lineage, acoustic considerations, and evolving supply chains. For USA and Europe-based buyers—cabinet OEMs, repair shops, custom modders, and distributors—the current environment rewards disciplined specification, diversified sourcing, and clear sustainability commitments.

Demand drivers and product segmentation

- Brand style alignment

- Fender, Vox, British Style (Marshall), Mesa, Mojotone, and Ampeg drive clear style segments that carry premium perceived value. Buyers often seek drop-in replacements to match brand aesthetics or to restore classic cabs, driving a stable, repeat SKU business.

- Acoustic and durability trade-offs

- Materials and weave density influence airflow and projection. While exact acoustic metrics vary by source and method, open weaves generally deliver higher airflow, whereas tighter weaves may alter high-frequency detail. Durability hinges on fiber type, weave construction, and finishing; heavier weights and specialized coatings improve longevity in high-heat environments.

- Availability status as a purchasing signal

- Items listing “Back Soon” indicate constrained stock or extended lead times; this matters for production planning and for managing customer expectations on restoration work.

Illustrative product-level view from a leading supplier:

Illustrative Image (Source: Google Search)

| Supplier | Style/Brand reference | Width (in) | Availability (as listed) | Price (USD) |

|---|---|---|---|---|

| Mojotone | Fender Style Black Grill Cloth | 36 | Available | 24.50 |

| Mojotone | British Style Black Grill Cloth (Marshall Replacement) | 32 | Available | 36.00 |

| Mojotone | Mesa Style Small Weave Cane (Black) | 32 | Available | 32.54 |

| Mojotone | Vox Black Diamond Cloth | 46 | Available | 52.45 |

| Mojotone | MojoWeave Black/Red Grillcloth | 48 | Available | 18.95 |

| Mojotone | Fender Style Beige Brown (Wheat) Grill Cloth | 36 | Back Soon | 31.50 |

| Mojotone | British Brown Diamond Grill Cloth | 30 x 36 | Back Soon | 50.39 |

Materials, finishes, and sustainability considerations

Polyester and nylon dominate on durability and cost. Cotton and blends can be used for their hand and visual character but may not consistently meet flame-retardancy or abrasion requirements without additional finishing. Sustainability is now an explicit criterion rather than an afterthought.

- What buyers should assess

- Chemical compliance: EU Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) and restricted substances in apparel are increasingly referenced by EU buyers; US buyers often require California Proposition 65 conformity. Confirm test reports and declarations of conformity.

- Flame-retardant (FR): Requirements vary by region and application. If the cloth is installed near heat sources (amp vents, vents near tube sockets), ensure FR compliance and clear labeling. Specify performance levels (e.g., BS 5852 in the UK/EU or appropriate US standards).

- Recycled content: Recycled polyester is feasible and may be specified where sustainability policies require it. Validate the proportion and certification (e.g., Global Recycled Standard).

- Waste and trim reduction: Consider roll lengths to minimize offcuts and packaging weight. For overseas procurement, target formats that reduce dead stock.

- Acoustic implications

- Weave type and density influence airflow. Typical categories—small weave cane, diamond, MojoWeave—signal specific visual and potentially acoustic characteristics; confirm with prototypes when tuning cabs for tone.

Comparative materials view (typical characteristics):

| Material | Strengths | Acoustic tendencies | FR options | Sustainability pathway |

|---|---|---|---|---|

| Polyester | High tensile strength, abrasion resistance, low moisture uptake | Stable airflow when woven open; controlled HF response | FR finishes available; durable in frequent handling | Recycled polyester (rPET) feasible; standard industrial recycling routes |

| Nylon | Good abrasion resistance and elasticity | Similar to polyester with slightly more stretch; care needed to maintain tension | FR finishes and inherent heat-resistant variants possible | Recycled nylon available; verify quality consistency |

| Cotton / natural blends | Distinct hand and look; vintage appeal | Softer visual character; may vary in airflow depending on weave | FR finishing required for proximity to heat | Organic cotton and controlled dyeing for reduced impact |

| Acrylic | Good colorfastness; used in vintage weaves | Similar airflow if woven open; UV stability | FR options available | Recycled acrylic limited; consider provenance and end-of-life planning |

USA vs. Europe: procurement and compliance

- Buying behavior

- USA: Wider availability of brand-matching styles and “drop-in” rolls; price competition is stronger; buyers often use availability status to schedule jobs and manage stock turns.

- Europe: Stronger emphasis on REACH, Proposition 65 (for export), CE-marking for related hardware assemblies, and supplier audit trails. Style fidelity matters, but compliance and traceability can be decisive criteria.

- Shipping, MOQ, and currency

- Domestic USA shipments from major suppliers often benefit from free or low-cost shipping thresholds; overseas airfreight adds cost and lead times. European buyers frequently face minimum order quantities (MOQs) and longer replenishment cycles, encouraging small buffer stocks of critical styles.

- Aesthetic preferences

- USA buyers tend to favor vibrant oxblood and classic Fender patterns; European buyers often emphasize classic British diamond patterns and Vox black diamond aesthetics, with a preference for heritage reproduction authenticity.

Sourcing strategies that work now

- Define standards upfront

- Brand style taxonomy (e.g., Fender/Vox/Marshall/Mesa/Ampeg) avoids ambiguity across suppliers and regions.

- Specify width, weight, construction, and FR requirements. Do not leave weave “open”—provide swatches and weave counts.

- Qualify suppliers with a scorecard

- Use data (not just quotes) to select partners:

Supplier evaluation scorecard

| Criterion | Indicators | Typical pass threshold |

|---|---|---|

| Compliance & traceability | REACH, Proposition 65 declarations; SDS on finishes; audit readiness | All documentation in place; no critical non-conformities |

| FR performance | Lab reports aligned to relevant standards | Verified FR for intended use cases |

| Style fidelity | Swatch-match accuracy against approved samples | Visual match within acceptable delta-E thresholds |

| Lead time reliability | On-time delivery > 95% | ≥ 95% |

| Price transparency | Clear MOQ tiers, currency handling, freight included | Competitive within 5–10% of market benchmark |

| Sustainability | Recycled content (where applicable), responsible dye processes | Quantified claims with third-party verification |

- Mitigate supply risk

- Dual-source critical styles; hold a two- to four-week buffer for high-demand items and anything marked “Back Soon.”

- Use alternates only with pre-approved swatch matches to avoid field rework.

Pricing, lead times, and inventory implications

From a large catalog snapshot (27 of 31 products, indicative range):

Illustrative Image (Source: Google Search)

| Attribute | Observation |

|---|---|

| Price (USD) | Approximately $14.50 to $65.95 across listed styles |

| Widths (in) | Common widths: 26, 30, 32, 36, 46, 48; special sizes: 58 (limited availability) |

| Availability status | “Back Soon” appears on select SKUs, signaling temporary constraints |

| Brand/style alignment | Fender, Vox, British Style (Marshall), Mesa, Mojotone, Ampeg form discrete clusters |

Operational implications:

– Price spreads reflect brand matching, pattern complexity, and width. Buyers can optimize by selecting standard widths where feasible (e.g., 36″) and confirming acoustic performance before locking into specialized widths.

– Availability flags (“Back Soon”) signal replenishment risk—plan work orders accordingly and maintain alternates.

– For Europe, include freight and compliance costs in total landed cost comparisons; domestic USA buyers benefit from consolidated shipments and low shipping thresholds.

Sustainability levers with business impact

- Material choices

- Specify recycled polyester where acceptable to meet procurement sustainability targets.

- Request dye and finishing disclosures to avoid restricted substances and optimize impact.

- Operational efficiency

- Align roll widths with common cabinet sizes to minimize waste and cutting time.

- Consolidate shipments to reduce freight emissions and packaging material.

- Circularity and durability

- Favor high-abrasion-resistant weaves for cabs handled frequently (touring, rental), reducing replacement frequency.

- Explore take-back programs or partnerships for end-of-life textile recovery where practical.

Where brand style meets sound: a practical note

Style categories (e.g., Fender, Vox, British Style, Mesa, Mojotone, Ampeg) are a shorthand for aural and visual expectations. While weave type alone won’t “fix” tone, it influences airflow and projection characteristics. Confirm with real-cab testing before locking in large-volume purchases—particularly for custom builds where pattern density could subtly alter perceived brightness and openness.

Bottom line for buyers

- Treat grille cloth as a specification-led purchase—do not rely on names or patterns alone. Set clear standards for width, weave, durability, FR, and style fidelity.

- Use availability and pricing data to inform planning; monitor “Back Soon” signals and hold buffers for mission-critical styles.

- In the USA, price and speed are decisive; in Europe, compliance, traceability, and sustainability documentation carry equal weight.

- Evaluate recycled content and FR requirements early. They can materially change supplier choices and landed cost.

By blending brand-aligned aesthetics with rigorous material, compliance, and sustainability criteria—and by using data-driven supplier selection—B2B buyers can navigate today’s market dynamics and keep both tone and supply chain healthy.

Frequently Asked Questions (FAQs) for B2B Buyers of amp grille cloth

Frequently Asked Questions (FAQs) for B2B Buyers of Amp Grille Cloth

1) What widths and roll lengths are available?

Most styles ship in standard widths to match common cabinet formats. Typical widths include 26″, 30″, 32″, 36″, 46″, 48″, and 58″. Rolls are sold by the yard. Note the specific width on each product page and specify exact width when ordering.

Illustrative Image (Source: Google Search)

| Product (example) | Width | Price |

|---|---|---|

| Mojotone Oxblood with Silver Stripe | 36″ | $14.50 |

| British Style Black Grill Cloth (Marshall Replacement) | 32″ | $36.00 |

| Vox Black Diamond Cloth | 46″ | $52.45 |