About Jinrong

Established in 1987, Jinrong has become an expert beverage machinery manufacturer in China, providing equipment for optimal drink processing, filling and packaging solutions for customers.

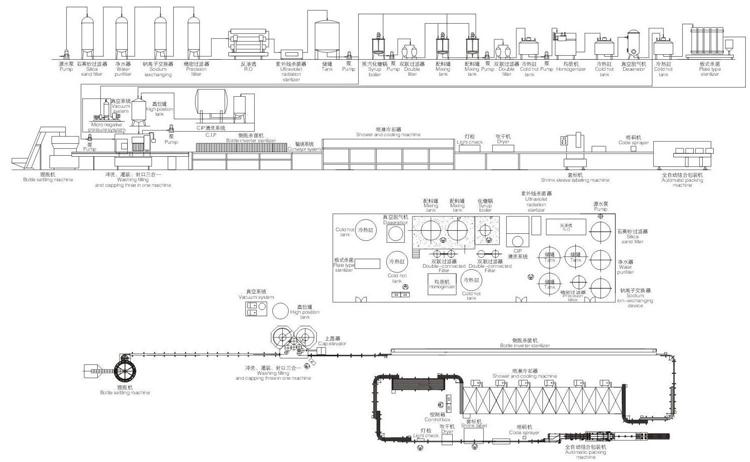

Our diversified product portfolio includes water purification systems, drink pretreatment systems, PET blow molding machines, bottle unscramblers, beverage mixers and capping line bottle packaging systems.

With a focus on continuous improvement, we are always looking to develop new equipment to increase our market competitiveness and we have obtained ISO9001 and CE certificates.