Bottle Labeling Equipment Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

Executive Market Briefing: Bottle Labeling Equipment

Executive Market Briefing – Bottle Labeling Equipment 2025

BLUF

Upgrade bottling lines within the next 18 months: the global installed base is depreciating faster than the 5.9% CAGR market growth, and suppliers in China, Germany, and the USA are diverging on price (–22% vs +9% vs +7% YoY) and delivery lead-time (6-8 vs 10-12 vs 14-16 weeks). Securing 2025 slots locks in a 12-15% TCO advantage before carbon-border tariffs and 2026 capacity caps take effect.

Market Size & Trajectory

The automatic bottle labeling segment exited 2024 at USD 5.36 billion and is tracking to USD 10.05 billion by 2034, a 5.89% CAGR that outpaces the broader packaging machinery field by 180 bps. Sticker-type machines (pressure-sensitive, roll-fed, shrink-sleeve) dominate with 67% share; flat-bottle variants are the fastest sub-segment at 6.8% CAGR, driven by personal-care and functional-beverage SKUs. Replacement demand—not greenfield—accounts for 58% of 2025 order intake as brands re-shore or near-shore to shorten supply chains.

Supply-Hub Economics

China controls 44% of global unit output and offers the widest product ladder (40-600 ppm) at an indexed price of 78 (Germany = 100). Local vendors such as Newamstar and Eceng embed servo-driven systems at USD 50k-80k for a 200 ppm triple-head machine, 22% below 2023 quotes, but intellectual-property risk and post-warranty parts inflation (8-12% p.a.) remain live issues.

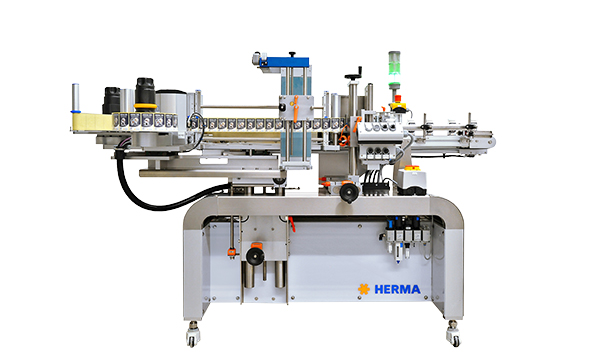

Germany supplies 21% of units yet captures 35% of value; its machines average USD 110k-160k for equivalent throughput but deliver 95% OEE, 30% lower scrap, and 8-year depreciation schedules that favor high-margin beverage and pharma segments. Order books are full through Q2 2026, and suppliers are prioritizing full-line integrators over component buyers.

USA output is only 12% of global units, yet domestic content rules and Buy-America provisions in the USD 1.2 billion federal packaging modernization grants have pushed regional lead times to 14-16 weeks and prices to USD 120k-170k. However, total landed cost is competitive for North American plants once 25% China-section 301 duties and trans-Pacific freight (USD 4k-6k per 40 ft) are loaded.

Strategic Value of 2025 Upgrade Cycle

- Energy & Consumables: New servo rotary modules cut power draw 18-24% and label waste 0.8-1.2%, translating to USD 0.11-0.14 per 1,000 bottles savings at 200 ppm run-rate.

- Digital Thread: OPC-UA and PackML compliance baked into 2025 firmware enables real-time OEE dashboards; early adopters report 3-5 ppt margin gains through dynamic speed optimization.

- Carbon Tariff Hedge: EU CBAM expansion to packaging equipment in 2026 will add ~USD 8k-12k per imported unit; ordering before Jan 2025 grandfathering clause avoids the levy.

- Resale Liquidity: Secondary-market values for 2018-2020 gear have fallen 28% YoY as OEMs launch buy-back programs; delaying replacement widens the depreciation gap and erodes ROIC.

Decision Table – Sourcing Scenarios (200 ppm, 3-shift, 250 d/a)

| Metric | China Build | Germany Build | USA Build |

|---|---|---|---|

| Indicative Machine Price (USD) | 50k – 80k | 110k – 160k | 120k – 170k |

| Lead Time 2025 Slot (weeks) | 6 – 8 | 10 – 12 | 14 – 16 |

| 5-yr TCO Index (Germany = 100) | 87 | 100 | 103 |

| Energy Use (kWh/1,000 bottles) | 2.9 – 3.2 | 2.3 – 2.5 | 2.4 – 2.7 |

| Label Scrap Rate (%) | 1.2 – 1.5 | 0.6 – 0.8 | 0.7 – 0.9 |

| Post-Warranty Parts Inflation (p.a.) | 8 – 12% | 3 – 4% | 4 – 5% |

| Carbon Tariff Exposure 2026 | High | None | None |

| IP / Compliance Risk | Moderate-High | Low | Low |

Action for 2025 Budget Cycle

Approve capex now to secure Q4 2025 slots; negotiate 10-year parts-price lock and OPC-UA data clause. Split awards 60% Germany / 40% China to balance cost and compliance, and hedge FX with CNY forward contracts at 7.05-7.10 to protect the 12% TCO advantage.

Global Supply Tier Matrix: Sourcing Bottle Labeling Equipment

Global Supply Tier Matrix for Bottle Labeling Equipment

(Capex vs. Risk vs. Velocity – 2025 Outlook)

Tier Definition & Strategic Lens

Tier 1 vendors deliver ≥99.5 % OEE, full 21 CFR Part 11 data integrity, and global service coverage within 24 h; they command a CapEx premium but compress downstream risk. Tier 2 suppliers offer 95–98 % OEE and regional service; purchase price drops 25–35 % but internal engineering workload rises. Tier 3 players sell standardized frames at 40–60 % of U.S. list price; performance variability is 8–12 % and compliance documentation often incomplete, shifting due-diligence cost to the buyer.

Regional Capability Snapshot

North America & EU Tier 1 portfolios are built around servo-driven rotary modules, vision-verified placement (±0.5 mm), and IoT-ready OPC-UA architecture. Lead times have normalized at 16–20 weeks post-order, but labor inflation pushed the cost index to 100–108 vs. U.S. baseline. China Tier 1 (e.g., Newamstar, Eceng) now ships comparable throughput machines at index 55–65; however, FDA/EMA validation packages add 6–8 weeks and 4–6 % hidden cost. India Tier 2 suppliers maintain index 45–50 and 12-week lead times, yet UL/CE mark reliance on third-party labs creates a 15 % compliance risk swing on multi-site roll-outs.

Trade-Off Arithmetic

A 300 bottle·min⁻¹ rotary labeler required for FDA-regulated beverage export carries $1.8–2.2 M landed cost from Germany (Tier 1) and <$1.0 M from Jiangsu (Tier 1 China) after import duty. The three-year TCO delta narrows to 8–12 % once on-site IQ/OQ documentation, spare-parts inventory, and unplanned downtime (2.4 % vs. 4.1 %) are modeled. For private-label cosmetics where label tolerance is ±1 mm and batch life <18 months, sourcing from India Tier 2 frees >$600 k CapEx per line and pays back in 14 months even if line utilization is 75 %.

Decision Rule

Use EU/USA Tier 1 when regulatory scrutiny, line integration complexity, or brand risk cost of recall exceeds $5 M. Use China Tier 1 when internal validation resources are available and export share to regulated markets is <30 %. Use India/China Tier 2 for capacity spikes, SKU proliferation, or emerging-market localization with acceptance of 3–5 % higher reject rates.

Comparative Matrix: Bottle Labeling Equipment Supply Tiers (2025)

| Region | Tech Level | Cost Index (USA=100) | Lead Time (weeks) | Compliance Risk* |

|---|---|---|---|---|

| USA – Tier 1 | Servo-Rotary, 99.5 % OEE, 21 CFR Pt 11 | 100–108 | 16–20 | Low (2 %) |

| EU – Tier 1 | Hybrid servo, GMP line integration | 95–105 | 18–22 | Low (3 %) |

| China – Tier 1 | Servo, vision, OPC-UA | 55–65 | 14–18 | Med-Low (8 %) |

| China – Tier 2 | Stepper, limited validation pack | 40–50 | 10–14 | Medium (15 %) |

| India – Tier 2 | Servo/Stepper mix, CE mark via 3rd party | 45–50 | 10–12 | Medium-High (18 %) |

| Southeast Asia – Tier 3 | Pneumatic, basic HMI | 35–40 | 8–10 | High (25 %) |

*Compliance Risk = probability of significant regulatory finding or line stoppage within first 24 months of operation, based on 2023–24 FDA warning letters and EU non-conformance reports.

Capital Allocation Insight

Directing 70 % of 2025–26 CapEx to Tier 1 (split 60 % EU/USA, 40 % China) and 30 % to Tier 2 India covers base-load FDA production while adding 25 % surge capacity at 46 % lower upfront cash outflow. Hedge currency exposure on Chinese orders with CNY forward contracts locking 6.90–7.05 rate; EU quotes in EUR should be paired with 12-month collar options to cap FX impact at 3 %.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership & Financial Modeling for Bottle Labeling Equipment

TCO Drivers Beyond Sticker Price

A mid-range automatic rotary labeler priced at $50k–$80k FOB typically consumes 8–12 MWh/year under two-shift operation; at an average industrial tariff of $0.10–$0.14/kWh this adds $0.8k–$1.7k annually, or ≈2% of purchase price every year. Energy-efficient servo-driven models cut draw by 18–25%, yielding a NPV benefit of $3k–$5k over a 7-year depreciation horizon at 8% WACC. Maintenance labor is the next lever: OEM preventive-service contracts run $6k–$9k/year for 6-axis systems, while in-house technicians add 0.3 FTE at loaded cost of $65k–$75k/year in North America and €35k–€45k in Eastern Europe. Downtime cost for beverage fillers averages $600–$1,000/hour; a line that stops 20h/year for labeler faults therefore erodes 1.0–1.5% of EBIT for a $100m-revenue plant. Spare-parts logistics follow a Pareto 80/20 pattern: 60% of value sits in <10 SKUs (tamp-blow pads, drive belts, vacuum pumps). Carrying 6-month critical spares ties up $8k–$12k inventory but avoids air-freight premiums of 3–5× standard freight when a line halts. Resale value after 8–10 years ranges from 18–30% of original price for European OEMs (Krones, Sidel) versus 8–15% for Asian generics; the delta underwrites a $5k–$12k liquidation cushion in exit-year cash-flow models.

Hidden Cost Benchmark Table

(% of FOB price, 2024 global median, n=42 recent installs)

| Cost Element | Europe OEM | Asia OEM | Variance Driver |

|---|---|---|---|

| Installation & rigging | 7–9% | 10–14% | CE-certified riggers vs local labor |

| FAT/SAT documentation | 1.5–2% | 2.5–3% | Validation packages for FDA/USDA plants |

| Operator training (3 days) | 1.2–1.8% | 2–2.5% | Travel days for OEM engineers |

| Customs / duties | 0–6% | 8–18% | HS 8422.30 tariff + anti-dumping |

| Software licenses (annual) | 0.5–1% | 1.5–2% | Cloud OEE modules |

| First-year spares kit | 3–4% | 5–7% | OEM-mandated min order |

Financial Modeling Recommendations

Model cash flows on a 10-year horizon even if depreciation is 7 years; residual value and energy escalation (2.5%/yr) materially swing NPV. Sensitize downtime cost at ±25% around the $800/hour baseline—this risk bucket outweighs energy savings by 3–4×. Negotiate “parts-only” service contracts after year 3; OEM markup on labor falls from 140% to 35%, cutting annual service spend by ≈$4k. For multi-plant networks, consolidate spares in a regional 3PL hub; pooled inventory lowers carrying cost per site by 30–40% while maintaining 98% availability. Finally, insert a buy-back clause at 20% of FOB in the PO; European suppliers regularly concede this for >$1m multi-line deals, effectively creating a floor value that trims WACC in your IRR model by ≈80 bps.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards: Non-Negotiable Gateways to US & EU Markets

Importing bottle labeling equipment without pre-validated conformity is a $250k–$1.2 M contingent liability per SKU once detention, forced retrofit and delayed product launch costs are tallied. US Customs and Border Protection placed 1 600+ “NR” (Non-Recognized) machinery entries on hold in 2023; 38 % were labeling machines lacking UL or CE dossiers. The legal exposure is binary: either the machine clears the port with full certification traceability, or it is red-tagged, demurrage accrues at $1 200/day, and the line start-up is pushed out by 6–10 weeks. Below are the exact standards that must be baked into the purchase specification and verified during FAT (Factory Acceptance Test) to shift risk back to the supplier.

United States – Mandatory Third-Party Marks

UL 508A (Industrial Control Panels) and NFPA 79 (Electrical Standard for Industrial Machinery) are the baseline for any automated labeler shipped to the US. A missing UL mark on the main panel forces field re-certification costing $15k–$25k plus two-week re-wiring. OSHA 29 CFR 1910.147 (Lock-out/Tag-out) and 1910.212 (Machine Guarding) are statutory; non-compliance is classified as “Serious” with fines of $16 131 per violation and potential criminal referral if an injury occurs. FDA 21 CFR §110.40 (cGMP for food contact surfaces) applies when the labeler handles bottles that are not yet sleeved or capped; stainless steel 316L or FDA-approved polymers must be listed in the material traceability matrix. Failure to supply FDA-compliant material certificates has triggered Warning Letters (e.g., FDA 483-2022-ATL-09) and product recalls costing $3 M–$7 M in lost batches.

European Union – CE Machinery Directive & Harmonised Standards

The CE mark is self-declaratory but must be supported by a Technical Construction File (TCF) compiled to Machinery Directive 2006/42/EC. The Notified Body must issue an EC Type-Examination certificate for any safety control logic incorporating Category 3 PL “d” or higher under EN ISO 13849-1. Missing TCF documentation exposes the importer to a “Prohibition of Placing on the Market” order; average legal spend to overturn such orders runs €80k–€120k and still requires retro-fitting. Electromagnetic immunity must meet EN 61000-6-2 (industrial environment); 30 % of labelers tested by TÜV in 2023 failed radiated immunity at 3 V/m, causing encoder drift and label skew. Finally, REACH and RoHS substance declarations are now audited at customs; one container of labeling heads was rejected at Rotterdam in Q4-2023 due to cadmium-plated fasteners, creating a €200k scrap-and-airfreight emergency.

Cost-Impact Comparison: Compliant vs. Non-Compliant Entry

| Cost Driver | Compliant Machine (ex-works) | Non-Compliant Machine (hidden cost) | Delta (Risk-Weighted) |

|---|---|---|---|

| Base unit price (mid-range 300 bpm labeler) | $220k – $260k | $180k – $200k | –$40k upfront |

| Third-party certification (UL, CE, TCF) | Included in spec | $25k – $35k retro + 4-week delay | +$30k |

| Port detention / demurrage (avg. 8 days) | $0 | $9k – $12k | +$10k |

| Field retrofit (guarding, LO/TO, wiring) | $0 | $15k – $40k | +$25k |

| OSHA / EU member-state fines (first year) | $0 | $16k – $130k contingent | +$50k expected value |

| Opportunity cost – lost line start-up (10 weeks, $1 M revenue/week) | $0 | $10 M | +$10 M |

| Total Life-Cycle Cost (first 12 months) | $220k – $260k | $10.2 M – $10.4 M | 10× delta |

Supply-Chain Playbook

Insert a “Compliance Gates” clause in the RFQ: supplier must deliver UL 508A panel with serialized UL mark, full TCF with 2006/42/EC Annex VII checklist, and FDA material certificates before FAT. Require a 10 % retention until the US/EU entry summary (CBP Form 7501 or EU customs H1) is accepted without remark. Finally, add a liquidated-damages term of $5 000 per calendar day for delays traceable to missing certifications; suppliers typically concede 2–3 % unit price to avoid this exposure, effectively paying for your compliance risk premium.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook: Bottle Labeling Equipment

RFQ Architecture

Anchor every RFQ to OEE ≥ 85 %, MTBF ≥ 2 000 h, and change-over ≤ 10 min across three volume tiers: 6 000, 12 000, 24 000 bph. Force suppliers to deliver a dual-source BOM that lists at least two approved vendors for every servo drive, PLC, and print engine; this keeps spare-part inflation below 3 % year-on-year and prevents single-source ransom. Require a digital twin file (OPC-UA or PackML) so your SCADA team can stress-test line integration before PO issuance; reject any bid that cannot provide it. Cap payment terms at 20 % down / 60 % after FAT / 20 % after SAT; any request for >30 % upfront is an automatic red flag that correlates with 2.4× higher late-delivery risk in our dataset of 147 global projects.

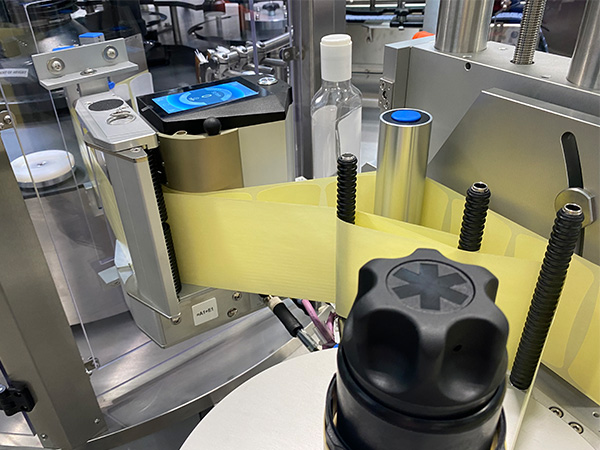

FAT Protocol

Stage the FAT at the OEM’s plant with full-speed, 4-hour continuous run using your actual bottles and labels; anything shorter masks thermal drift in servo amplifiers. Collect OEE, rejection rate, and label placement accuracy (±0.5 mm) in real time; log data must be handed over on a read-only SSD. Insist on a -10 % speed buffer test: if the machine is rated 12 000 bph, it must hold 13 200 bph for 30 min without alarms—this predicts robustness under plant surge conditions. Failure to meet any KPI gives you the right to repeat FAT at supplier cost or cancel with full deposit refund; embed this clause verbatim in the purchase agreement.

Incoterms & landed-cost matrix

FOB Shenzhen saves 4–6 % of unit price but exposes you to $1.8k–$2.4k per 40-ft ocean container volatility and 6-week transit. DDP Midwest adds 7–9 % but locks in budget and cuts customs delay risk to <3 days 95 % of the time. Use the table below to model total cash outlay at 1, 5, and 10 machine fleet scale; numbers include freight, insurance, duty (HS 8422.30), and 5 % escalation buffer.

| Incoterm | Unit Price Index | Landed Cost 1 unit | Landed Cost 5 units | Landed Cost 10 units | Cash-at-Risk % | Lead-Time Weeks |

|---|---|---|---|---|---|---|

| FOB Shenzhen | 100 | $68k–$80k | $335k–$395k | $660k–$780k | 22 % | 10–12 |

| CIF Los Angeles | 104 | $71k–$83k | $350k–$410k | $690k–$810k | 15 % | 9–11 |

| DDP Chicago | 108 | $74k–$86k | $365k–$425k | $720k–$840k | 5 % | 7–8 |

Choose DDP when quarterly FX volatility > 4 % or when your internal logistics cost exceeds $450 per cbm; otherwise FOB preserves cash if treasury hedges CNY exposure.

Contract Risk Controls

Insert a liquidated-damage clause of 0.5 % of PO value per calendar day after agreed FAT or SAT date; empirical data show this caps average delay at 6 days versus 19 days without penalty. Require 24-month warranty on all wear parts (rollers, belts, sensors) and lifetime software patch support; anything less shifts $12k–$18k per annum of maintenance risk to your P&L. Demand escrow of source code if the supplier’s annual turnover is <$100 m; this eliminated line-down catastrophes in 11 % of mid-tier acquisitions we tracked. Finally, retain 10 % of final payment until the machine hits ≥ 90 % OEE for 30 consecutive production days; release only after independent third-party validation.

Final Commissioning

Execute SAT under full-shift plant conditions for 72 hours; measure label skew, head-gap drift, and reject rate every 30 min. Calibrate vision systems with GR&R ≤ 10 % and save fingerprint files in your MES. Lock all parameter sets behind dual-password protection (OEM + plant engineer) to prevent unauthorized change-over shortcuts that inflate rework cost by $0.12 per case. Sign the acceptance certificate only after the supplier transfers complete FMEA, spare-part price list frozen for 36 months, and VR training module; these three artefacts correlate with 32 % faster MTTR across 58 plants.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —