Precision Plastic Injection Molding & Mold Manufacturing

ISO 13485 Certified. Delivering world-class quality, innovation, and reliability in custom plastic molding and product development.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

ISO 13485 Certified. Delivering world-class quality, innovation, and reliability in custom plastic molding and product development.

Your complete source for injection molds, precision plastic molding, and full product development services.

From machining and precision molding to defect-free painting, decoration, and final assembly — we deliver fully integrated solutions tailored to your specifications.

Over 50% of molds produced are supplied to other molders worldwide. We build robust, high-performance molds that exceed shot count warranties and qualify quickly.

Our mission is to exceed customer expectations through innovation, world-class quality, timely delivery, and continuous improvement.

Chief Mold USA will always be a company where growth is based on exceeding our customer's expectations. Our commitment to innovation and product enhancement parallels our commitment to our customers. We strive to manufacture world-class quality custom molding to meet our customer's needs, provide satisfying careers for all our employees, and to earn a fair return in order to allow continuous improvements. Our vision is to be a leading provider of injection molds to the industry, well respected for technical expertise, top quality, timely delivery, and value-added services.

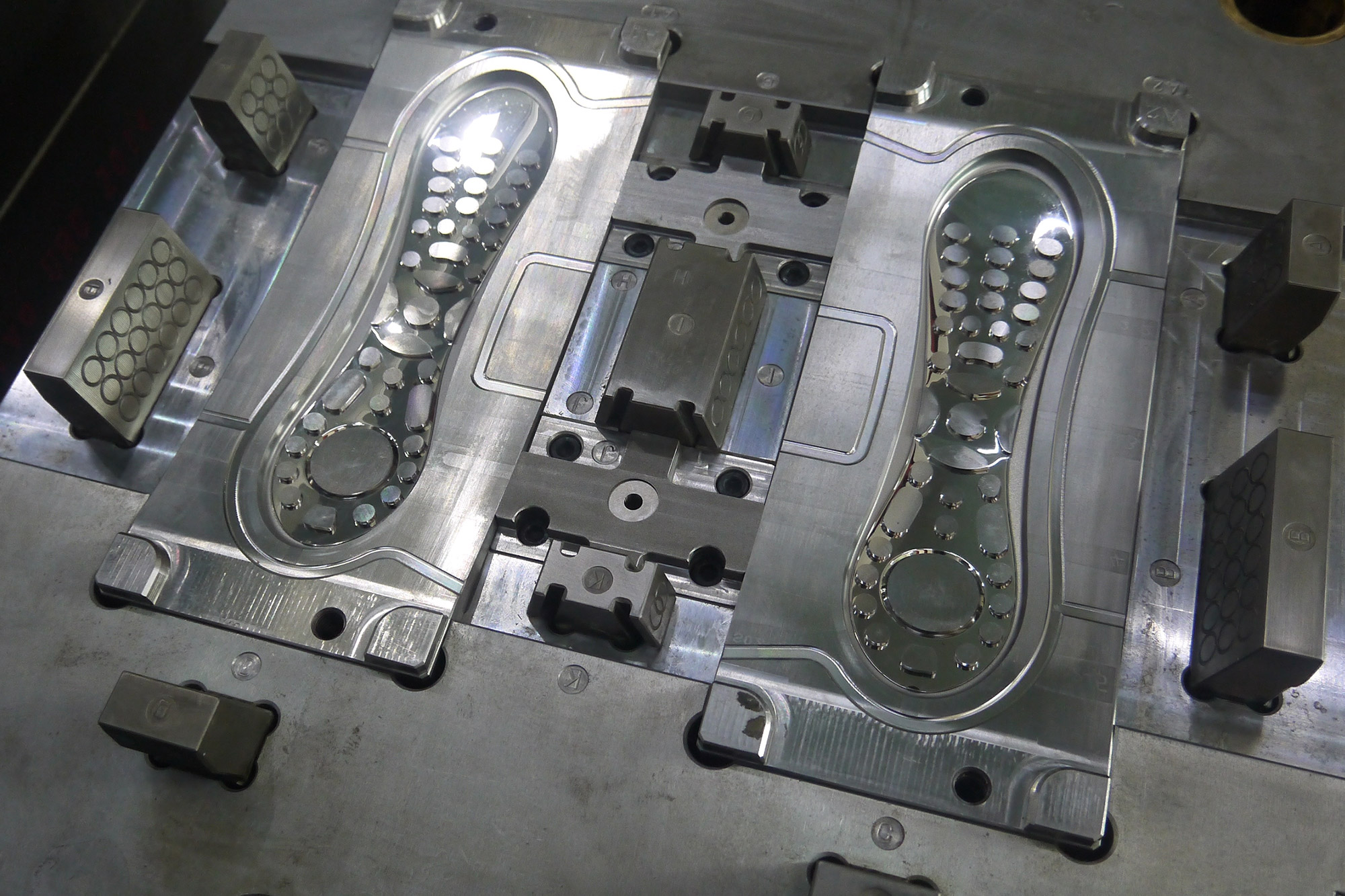

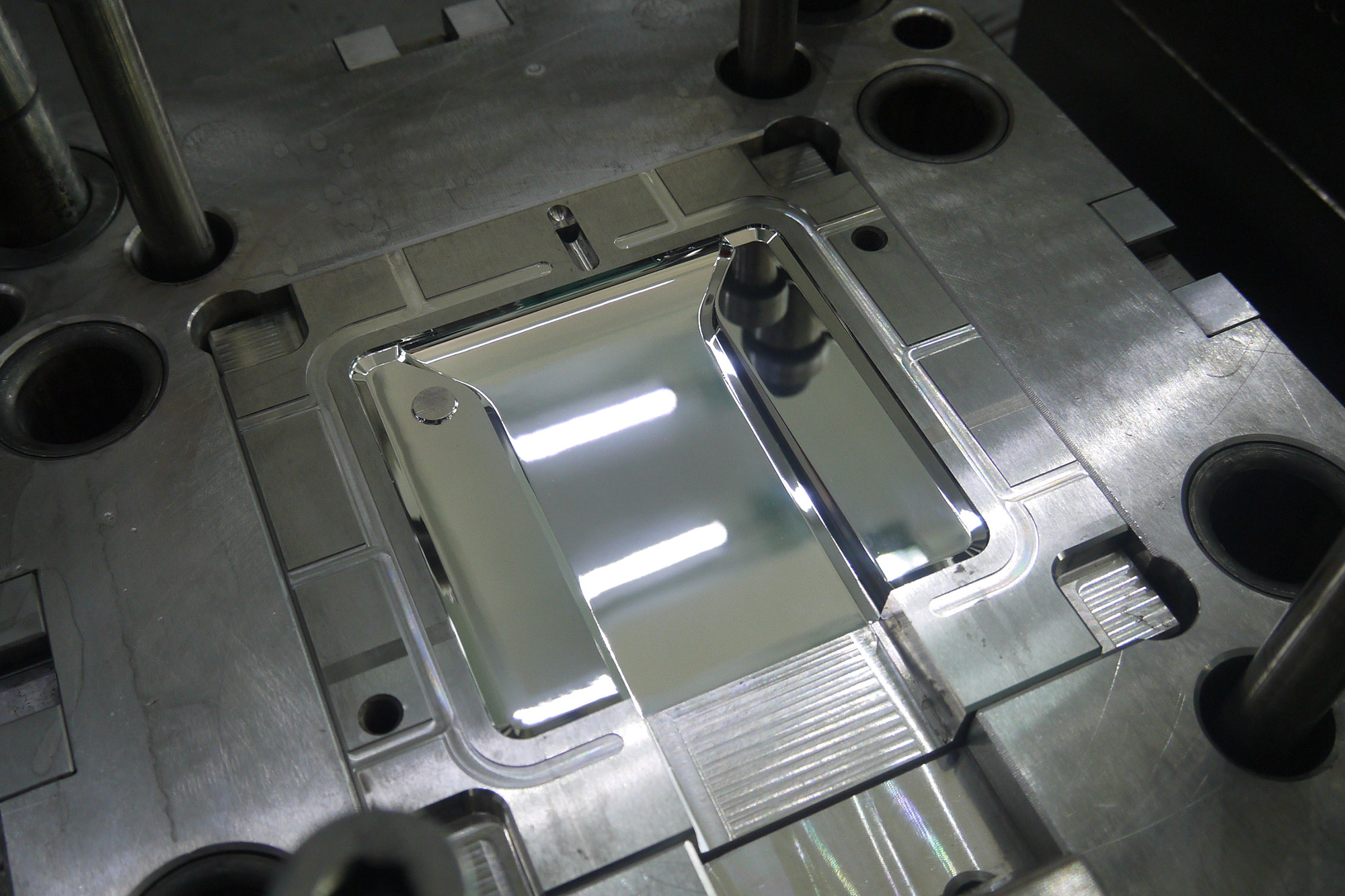

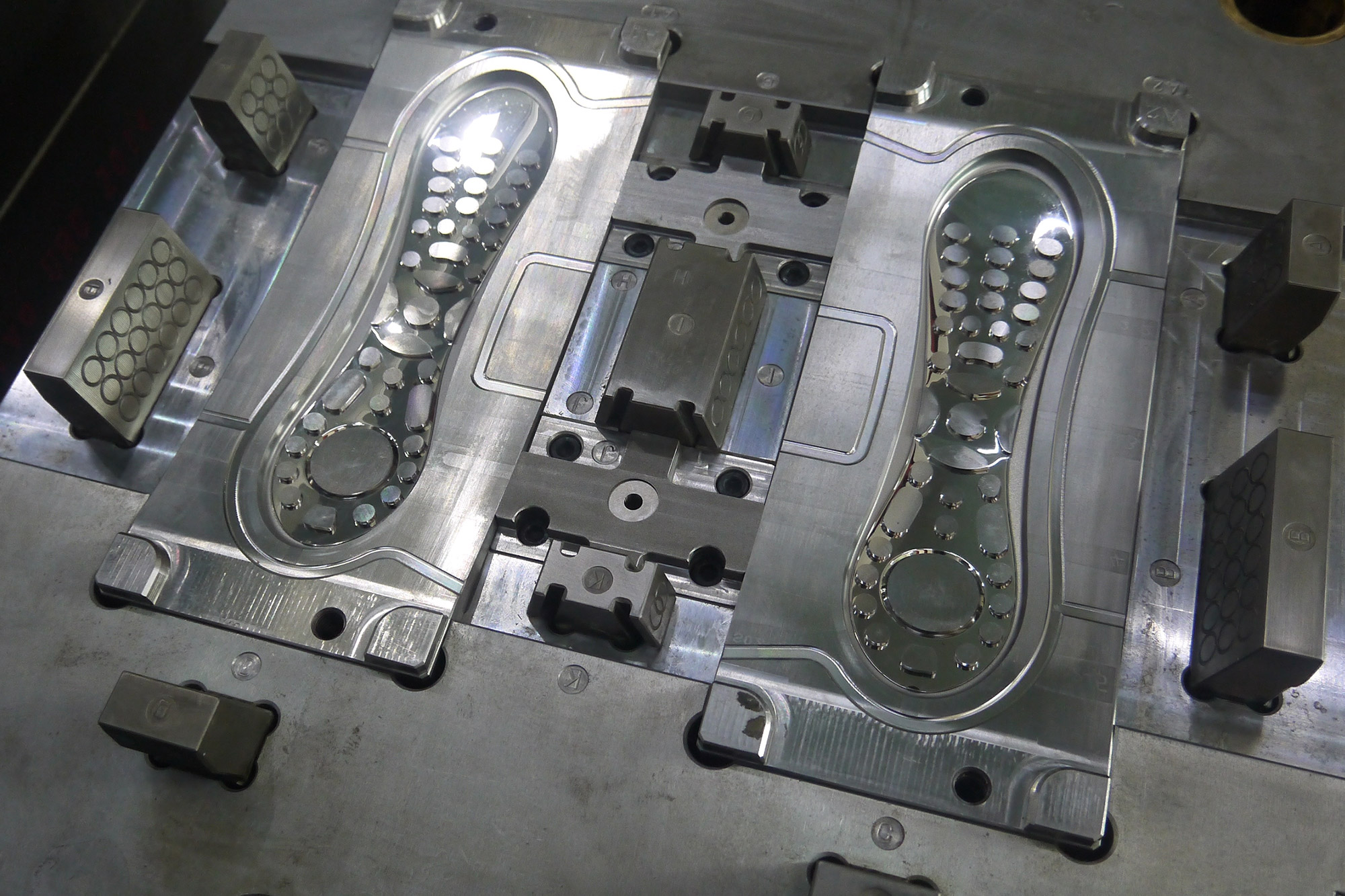

Prototype and full production injection molds built to exact specifications.

IML, IMD, 2-shot, insert molding, and other complex techniques.

High-tolerance plastic injection molded parts per your design.

Painting, silkscreen, pad print, laser etch, NCVM, and VM plating.

Full verification and validation for piece-part qualification.

CPK, FMEA, DOE, Gage R&R, Control Plans, Six Sigma tools.

Heat staking, ultrasonic welding, snap-fit assembly, and packaging.

Operational excellence through structured workplace organization.

Precision plastic injection molds made to your specifications. We offer a variety of technologies to meet design challenges from both industrial and functional perspectives.

Read More →Chief Mold began as a mold maker. Today over 50% of molds produced are for other molders worldwide. We build quality, robust molds that exceed shot counts and qualify quickly.

Read More →We offer painted and plated finishes, multicolor silkscreen, pad print, laser etch, UV protection, IML, IMD, and texturized finishes for premium product appearance.

Read More →Customer-dedicated assembly lines with heat staking, ultrasonic welding, snap-fit features, retail or bulk packaging, and film protection for end-use readiness.

Read More →

High-precision molds for prototype and production use. Built for longevity, accuracy, and fast qualification.

In-Mold Decoration and Lamination for durable, high-gloss graphics integrated directly into the part surface.

Multi-material molding for soft-touch grips, seals, and dual-color components with precise alignment.

Overmolding metal or plastic inserts for strong mechanical bonds and reduced assembly steps.

Non-Conductive Vacuum Metallization for chrome-like finishes without EMI interference.

High-resolution logos, labels, and markings on complex 3D surfaces with excellent durability.

Permanent, high-contrast markings for serial numbers, barcodes, and branding with no consumables.

Clean, fast, and strong joining of plastic components with minimal flash and high repeatability.

It’s important to you and to us knowing that parts delivered meet exacting requirements. Chief Mold begins the verification at the tool level and from First Article through production we ensure that quality remains throughout the life cycle of your production run.

In addition, we have internal labs capable of verifying the most stringent of needs for reliability. Our Quality department maintains complete inspection and testing capabilities including CPK studies, FMEA, Control Plans, Gage R&R, and DOE.

First Article Inspection

Dimensional Verification

Reliability Testing

Six Sigma Tools

For inquiries about mold manufacturing, injection molding, decoration, or assembly services, please visit the official website to get in touch.

Visit Official WebsiteNotice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info