Our Products & Solutions

High-precision plastic components and molds for diverse industrial applications.

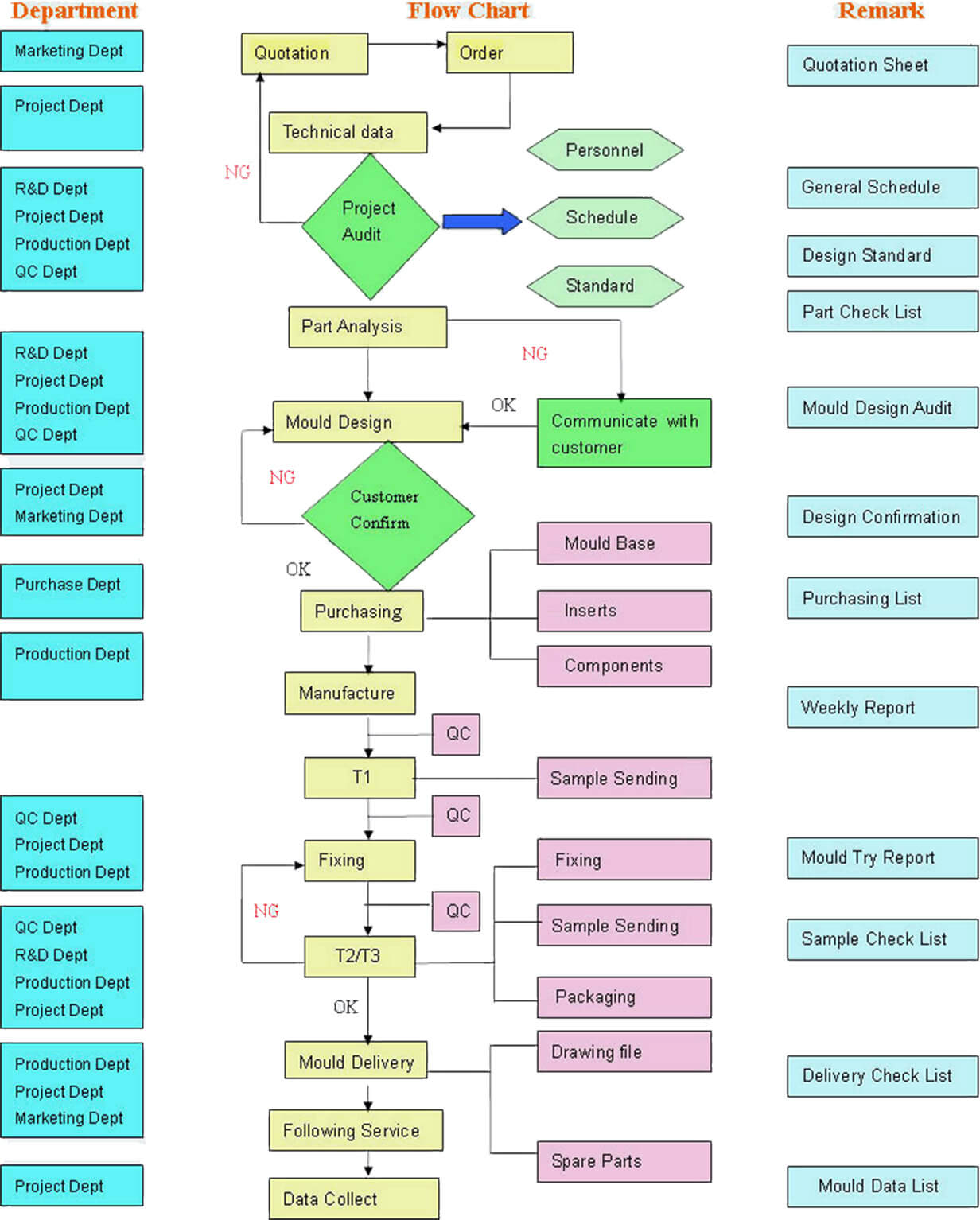

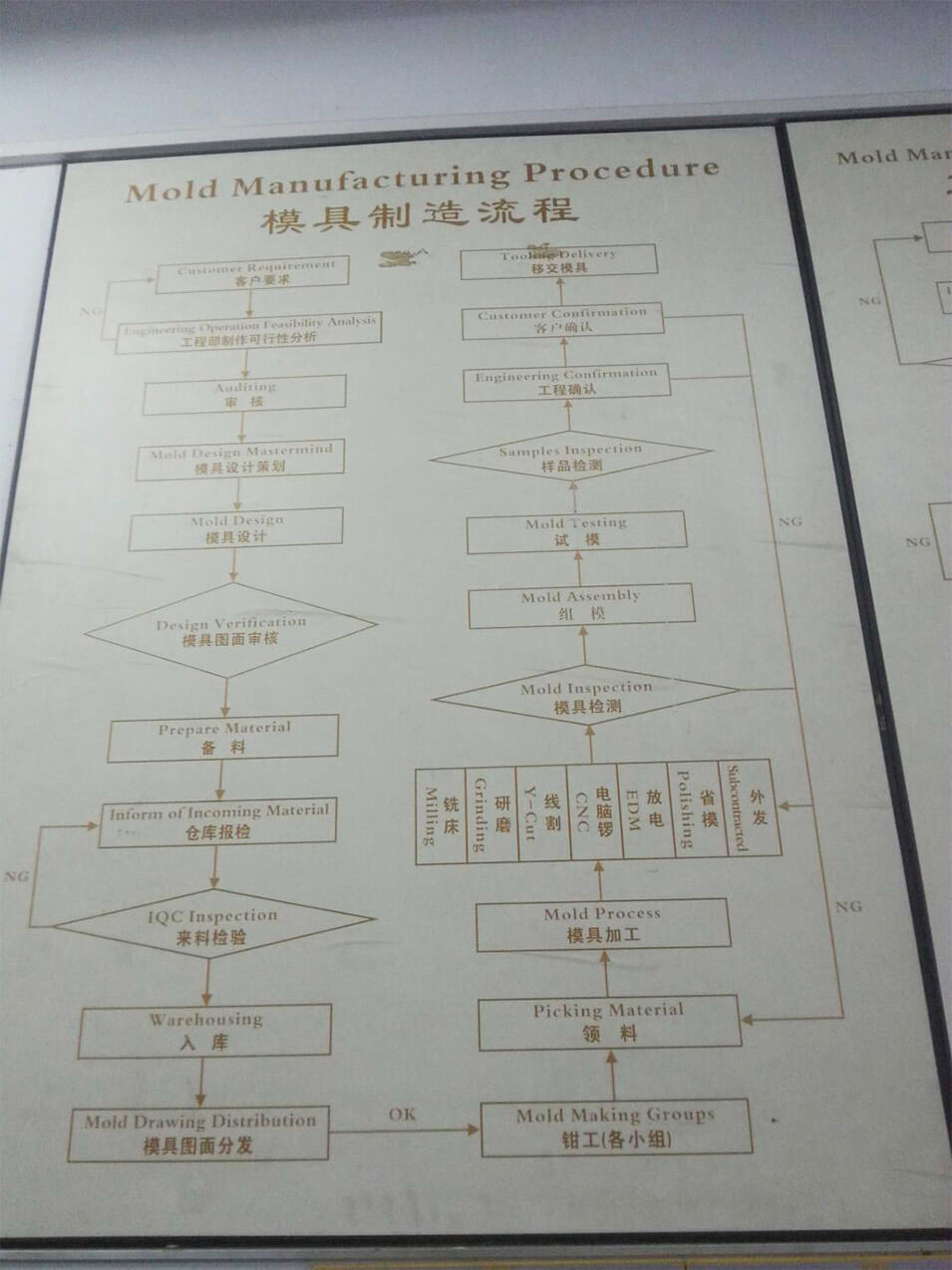

Plastic Injection Molds

Custom-designed molds for thermoplastics, including hot runner, multi-cavity, and thin-wall solutions.

Injection Molded Parts

High-quality plastic components for automotive, medical, electronics, and consumer goods.

Two-Color Plastic Parts

Dual-material and dual-color injection molded components for ergonomic and aesthetic applications.

Mold Inserts & Components

Precision-machined inserts, cavities, cores, slides, and lifters for reliable mold performance.

Die Casting Molds & Parts

Aluminum and zinc die casting molds and components for durable metal parts.

Silicone & LSR Molds

Liquid Silicone Rubber (LSR) and rubber molds for medical, automotive, and consumer applications.

Thermoset Molds

Molds for SMC, BMC, and phenolic resins used in electrical, automotive, and industrial sectors.

Hardware & Accessories

Custom fasteners, brackets, and plastic hardware for integration into final assemblies.