A Vacuum Coating Manufacturer Integrating R&D, Production & Sales

Zhengzhou Tainuo Thin Film Materials Co., Ltd., established in 2005, is a leading manufacturer of laboratory scientific instruments. Our products are widely used in universities, research institutions, and industrial labs across the globe.

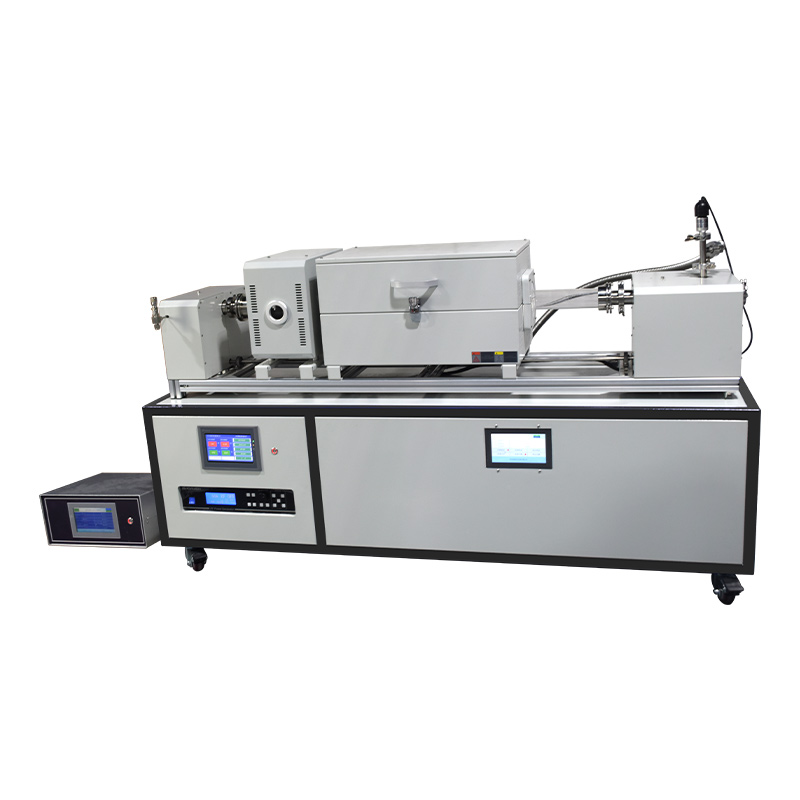

We specialize in magnetron sputtering coating equipment, thermal evaporation systems, plasma coaters, spin coaters, blade coaters, plasma cleaners, and VCD/PECVD vapor deposition systems.