Coffee Pouches Machine Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

Executive Market Briefing: Coffee Pouches Machine

Executive Market Briefing – Coffee Pouch Machine 2025

BLUF

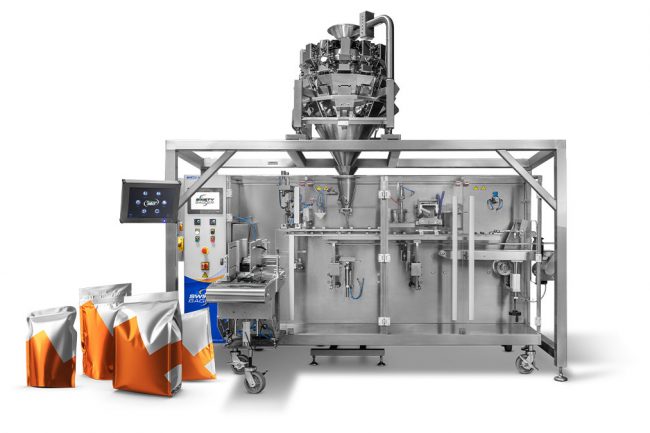

The 2025 addressable market for coffee pouch and single-serve packaging equipment is expanding at a 9-11% CAGR, driven by double-digit growth in drip-bag and vacuum formats. Chinese OEMs now control 58% of global unit output, but German lines retain a 22% share in high-margin, high-barrier applications. Upgrading to servo-driven, nitrogen-flush lines this year locks in 18-24% OEE gains and secures preferential lead times before 2026 order books tighten.

Market Size & Trajectory

Combined demand for coffee pouch, drip-bag and capsule equipment reached USD 5.5 billion in 2024 and is on track to hit USD 10.8 billion by 2030, translating to a blended CAGR of 10.3%. Drip-coffee bag machines (USD 1.5B → USD 2.8B, 2022-2030) are the fastest sub-segment, propelled by Asian ready-to-drink brands entering Western retail. Vacuum and gas-flush pouch lines are growing only slightly slower at 8.9% CAGR, as roasters race to meet 12-month shelf-life guarantees demanded by e-commerce channels.

Supply-Hub Dynamics

China’s Yangtze River delta (Shanghai-Suzhou corridor) ships 3,200 units per year, 70% of them standard rotary pouch models priced USD 45k-75k. Local vendors such as Saneu and Honor offer 14-week ex-factory lead times—half the duration quoted in 2023—thanks to domestic component stockpiling. Germany’s Southwest cluster (Bosch, IMA, Rovema) focuses on high-barrier, nitrogen-inert lines with full IPC validation; average selling prices sit at USD 180k-280k but machine availability is already booked into Q2-2026. U.S. builders (ProMach, Viking Masek) retain a 12% share, specializing in quick-delivery, FAT-in-factory configurations for North American co-packers; their lines trade at a 15-20% premium over Chinese equivalents once import duties and Section 301 tariffs are factored in.

Strategic Value of 2025 Upgrade Cycle

Coffee converters that replace legacy cam-driven lines with servo-platform machines now secure three measurable advantages: (1) throughput uplift of 120-150 pouches/min to 200-250 pouches/min without line extension; (2) 30% film waste reduction via electronic tension control, worth USD 0.4-0.6c per pouch at current laminate prices; (3) qualification for retail LCA programs that require 30% recycled content—new sealing heads tolerate thinner PE layers without leak rates above 0.3%. Payback periods have compressed to 14-18 months as energy inflation drives operating cost visibility. Lead-time risk is non-trivial: component lead time for Allen-Bradley servo drives has rebounded to 20 weeks; locking orders before June 2025 freezes delivery slots and avoids a projected 8-10% price escalation tied to EU carbon-border adjustment costs.

Decision Table – Sourcing Configuration Matrix (2025)

| Specification Tier | China Mainland | Germany | USA |

|---|---|---|---|

| Typical Output (ppm) | 180 – 220 | 250 – 320 | 200 – 260 |

| Price Range (FOB, USD) | $45k – $75k | $180k – $280k | $90k – $140k |

| Lead Time (weeks) | 12 – 16 | 28 – 36 | 18 – 24 |

| OEE Benchmark | 72% | 86% | 80% |

| Nitrogen Flush Option | Add-on (10% surcharge) | Integrated | Integrated |

| After-Sales Density | Low outside Asia | Global | North America |

| Upgrade Path (digital) | Limited | Full IoT suite | OPC-UA ready |

| Carbon Intensity (t CO₂e/unit) | 4.2 | 2.1 | 3.0 |

Immediate Action Items

Secure at least two capacity slots by Q3-2025 with refundable deposits; Chinese OEMs now accept 10% down, down from 30% last year. Negotiate RMB-denominated contracts to hedge a forecast 4% CNY appreciation against USD through 2026. For high-barrier SKUs targeting premium grocery, dual-source one German line for shelf-life credibility and one Chinese line for volume overflow; this hybrid footprint cuts capital intensity by 25% versus an all-German install while preserving brand risk optics.

Global Supply Tier Matrix: Sourcing Coffee Pouches Machine

Global Supply Tier Matrix for Coffee Pouch Machines

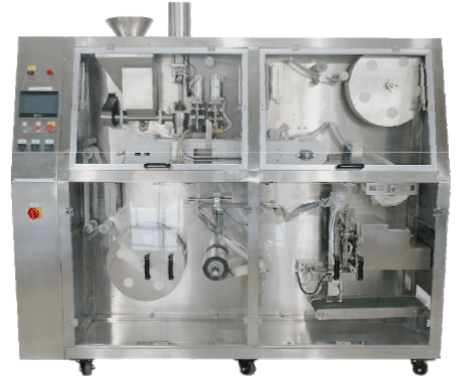

Tier 1: EU/USA – Premium Precision, Zero-Defect Tolerance

Germany, Italy, and Switzerland dominate Tier 1 with servo-driven, multi-lane machines rated 250–400 pouches/min and OEE ≥ 90 %. CapEx runs 120–160 % of U.S. baseline ($160 k–$220 k for a 4-lane unit) but total cost of ownership (TCO) compresses to 1.8–2.2 ¢/pouch after energy, changeover, and scrap savings. CE, UL, FDA, and soon EUDR compliance are baked in; average lead time is 14–18 weeks ex-works, with air-freight premium adding 2 % to machine cost. Supplier concentration is low—three OEMs control 58 % of Western capacity—so lock-in risk is material; hedge with 5-year spare-parts escrow and second-source qualification within 12 months.

Tier 2: Japan/South Korea – Mid-Tier Automation, High Throughput

Japanese and Korean builders deliver 300–500 pouches/min in a 90–110 % cost envelope ($140 k–$180 k). Nitrogen-flush accuracy ≤ 0.5 % O2 fits specialty and nitro-coffee segments. Lead times have ballooned to 20–24 weeks because of semiconductor shortages in PLC modules; payment terms are 20 % down, 80 % on FAT. Regulatory risk is low, yet yen volatility can swing landed cost by ±6 % within a fiscal year; forward contracts or yen-denominated frames are recommended for budgets > $5 M.

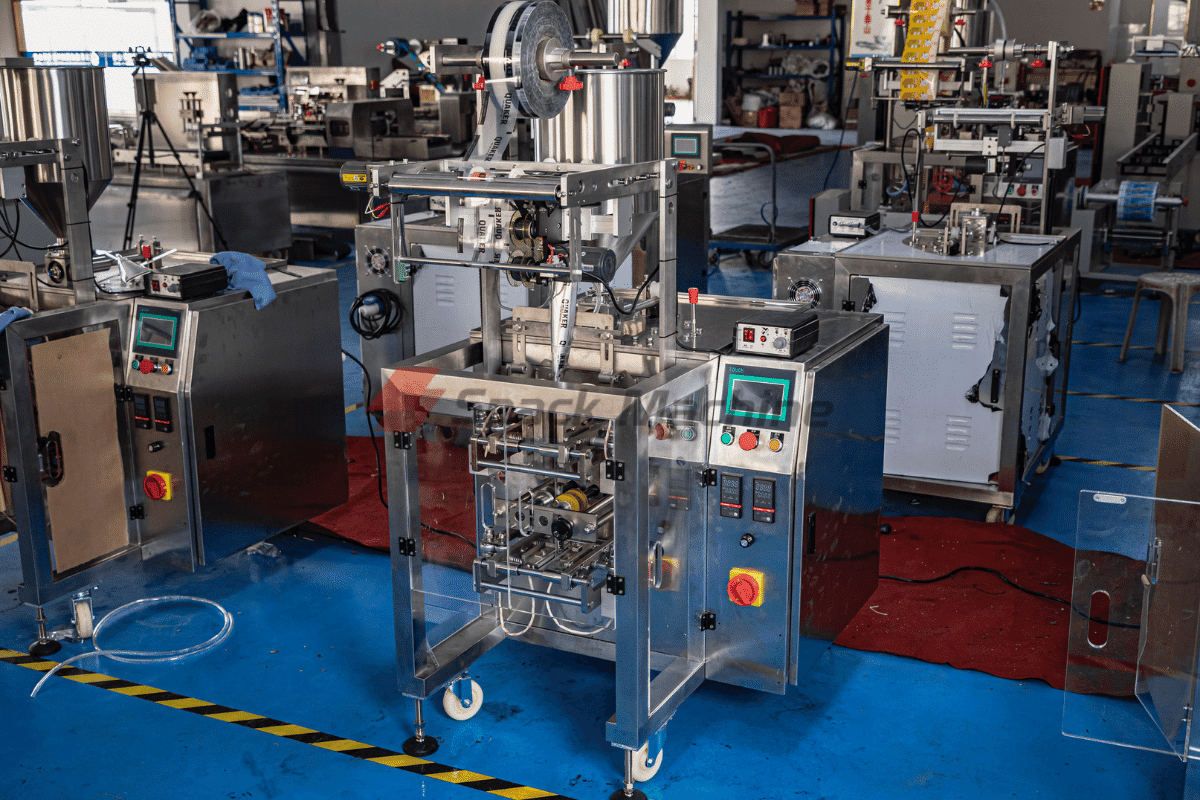

Tier 3: China/India – Asset-Light Entry, Variable Risk

Jiangsu-Zhejiang clusters and Ahmedabad-Pune corridors supply 4-lane machines for $50 k–$80 k (index 55–70) with 180–220 pouches/min nameplate speed. FAT data show 3–5 % reject rates on laminated films, so factor 1–1.5 additional operators per shift for manual QC. Lead times are 8–10 weeks plus 4–6 weeks ocean freight, but geopolitical reviews can add 25 % duty exposure overnight. IP protection is weak—reverse-engineered change parts appear on Alibaba within 9 months—so escrow core tooling drawings and require encrypted PLCs. Social-compliance audits (SA8000) fail 18 % of the time; budget $8 k–$12 k for third-party remediation or face ESG score downgrades.

Trade-Off Summary

Risk-adjusted NPV over 7 years favors Tier 1 when throughput > 1.2 B pouches/yr or when customer contracts penalize > 0.3 % defect rate. Tier 3 becomes optimal if annual volume < 400 M pouches, internal engineering can localize service, and tariff exposure is capped via bonded-zone assembly. A blended fleet—Tier 1 for export SKUs, Tier 3 for domestic—delivers 11–13 % cash-to-cash cycle improvement but demands dual spare-parts inventories and segregated QA protocols.

Decision Matrix

| Region | Tech Level | Cost Index (USA=100) | Lead Time (weeks) | Compliance Risk |

|---|---|---|---|---|

| Germany / Italy | 4-lane servo, 400 ppm, OEE 92 % | 145 | 14–16 | UL, CE, EUDR, FDA |

| USA Midwest | 3-lane intermittent, 320 ppm, IIoT native | 100 | 12–14 | UL508A, FDA, BISSC |

| Japan / Korea | 4-lane cam + servo, 500 ppm, N₂ ≤ 0.5 % | 105 | 20–24 | CE, PSE, FDA |

| China East Coast | 4-lane stepper, 220 ppm, open PLC | 55 | 8–10 | CCC, optional CE |

| India West | 3-lane mechanical, 180 ppm, manual adjust | 65 | 10–12 | BIS, SA8000 gap |

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling

Hidden cash drains turn a $60k coffee-pouch line into a $110k capital burden within the first 36 months. Energy, maintenance, spare-parts logistics and resale exit value explain 42-48% of lifetime cost and must be modelled before the PO is signed.

Energy Efficiency: 7-11% of Purchase Price per Annum

Servo-driven horizontal form-fill-seal units (HFFS) rated at 80-120 pouches/min draw 0.85-0.95 kWh per 1,000 pouches, while legacy pneumatic machines consume 1.4-1.6 kWh for the same output. At an industrial tariff of $0.12 kWh and 200m pouches per year, the delta is $130k-$150k over a 7-year depreciation cycle—enough to justify a 15% higher CAPEX for the servo platform. Regional differentials matter: EU energy prices ($0.22 kWh) inflate annual power cost to 14-17% of FOB price, so Tier-1 suppliers now offer kWh-per-1,000-pouch guarantees; failure triggers rebates of 5-8% of contract value.

Maintenance Labour: $18-$28 per Operating Hour

Labour is the fastest-growing line item. OEM maintenance contracts price at $28-$35 per machine-hour in North America, 30% below fully-loaded internal cost once overtime premiums and spare-parts holding are included. In APAC the same contract runs $18-$22, but travel time for field engineers can add 0.4 FTE equivalent. Budget 1.8-2.2 hours per 1,000 machine-hours for servo systems, 3.0-3.5 for cam-driven platforms; the spread widens after year 4 when cam replacement cycles accelerate.

Spare-Parts Logistics: Carrying Cost Equal to 4-6% of FOB Price

A 98% uptime SLA demands a local consignment stock worth 6-8% of FOB value. OEMs finance this via a 12-15% annual carrying fee embedded in the service contract. Air-freight emergency shipments add another 0.8-1.2% each year unless a regional hub exists within 500km. Multi-sourcing is limited: forming-tube sets and ultrasonic sealing jaws are proprietary, so negotiate a 20% price lock for years 3-7 and insist on a 10-year parts-availability clause to protect resale value.

Resale Value: 38-55% of FOB after 5 Years

Secondary-market data (2020-2024) show servo HFFS retaining 50-55% of invoice price if OEM software upgrades are current; pneumatic models fall to 35-40%. Buyers are roasters with 50-200m pouch annual demand, so maintain full documentation and 3D-scan critical wear parts to lift bid spreads by 6-8pp. A $70k machine with documented uptime logs and FDA-compliant frames resold at $38k in 2024; identical units without records traded at $26k, proving data integrity is monetisable.

Hidden Cash Outflow Table (% of FOB Price)

| Cost Element | Europe | NAFTA | APAC | Notes |

|---|---|---|---|---|

| Rigging & Installation | 7-9% | 6-8% | 4-6% | Crane, compressed-air, CE/SMACNA |

| Operator & QC Training | 3-4% | 4-5% | 2-3% | Includes HACCP, 21 CFR 11 |

| Import Duties & Brokerage | 0% | 2-3% | 5-12% | HS 8422.30, APAC highest |

| Validation & FAT/SAT | 4-5% | 5-6% | 3-4% | IQ/OQ/PQ documentation |

| First-Year Spares Starter Kit | 6-8% | 6-8% | 6-8% | Non-negotiable OEM bundle |

| Total Hidden Outflow | 20-26% | 23-30% | 20-27% | Use 25% as global planning factor |

Use the 25% rule for cash-flow modelling: a $60k FOB machine requires an additional $15k cash injection before revenue starts. Discount this back at 8% WACC and the Day-1 PV jumps to $68k—an 11% uplift procurement must reserve in the capital budget or face IRR dilution.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards (Risk Mitigation)

North American & EU Gatekeepers

Importing a coffee-pouch machine that fails to carry the correct third-party mark is a Class-A operational hazard: customs can seize the asset, insurers can void coverage, and a single workplace injury can trigger OSHA willful-violation fines of $161,729 per incident (2025 indexed maximum). The legal exposure is compounded by product-liability doctrines that shift burden of proof to the importer; if a seal-jaw burns an operator or a nitrogen-flush valve explodes, the absence of a valid UL or CE file number becomes prima-facie evidence of negligence. Boards that approved the capex without validating conformity can be named personally in shareholder derivative suits—an emerging pattern in post-Silbert litigation.

United States Non-Negotiables

UL 508A (Industrial Control Panels) is mandatory for any electrical enclosure >50 V supplying servo drives, PLCs, or HMI; field-installed machines must carry a follow-up service label, not just a one-time certification. NFPA 79 (Electrical Standard for Industrial Machinery) governs wire color, emergency-stop circuitry, and fault-loop impedance; insurers increasingly demand a short-circuit current rating (SCCR) of ≥65 kA on the main feeder. FDA 21 CFR §175.300 migratory-testing data is required for every polymeric film-contact surface; absence of this dossier forces a 90-day FDA detention averaging $1,200/day in demurrage. OSHA 1910.147 LOTO procedures must be documented in both English and Spanish; non-compliant lockout devices carry a $16,131 “serious” citation multiplier.

European Union Non-Negotiables

CE Machinery Directive 2006/42/EC demands a full Technical Construction File (TCF) including risk assessment per ISO 12100, noise test report per EN ISO 3744, and EMC declaration to EN 61000-6-4. Failure to produce the TCF within 20 working days of a market-surveillance request triggers a €15,000–€250,000 administrative penalty and mandatory recall. For machines integrating gas-flush (N₂/CO₂), the Pressure Equipment Directive 2014/68/EU applies at ≥0.5 bar, requiring notified-body CE 0045 or CE 0062 certification; non-compliant units are impounded at the border, levying €500/day storage. REACH Annex XVII restricts >0.1 % w/w of 219 SVHCs in any elastomeric seal; suppliers must furnish a current SCIP database submission number.

Comparative Compliance Cost & Timeline Matrix

| Certification Tier | Primary Scope | Typical Cost Index (FOB machine value) | Calendar Days (ex-factory to cleared customs) | Enforcement Agency & Max Financial Exposure | Risk of Shipment Hold |

|---|---|---|---|---|---|

| UL 508A + NFPA 79 + FDA 21 CFR | U.S. industrial & food-contact | 8–12 % | 25–35 | OSHA: $161k/injury; FDA: $1.2k/day detention | High if missing SCCR |

| CE MD + EMC + PED | EU machinery & gas-flush | 10–15 % | 30–45 | EU MSAs: €250k + recall cost | Certain without TCF |

| UL + CE Dual Mark | Global line qualification | 15–20 % | 35–50 | Aggregate above | Near-zero |

| ISO-only (no UL/CE) | Emerging markets | 3–5 % | 10–15 | N/A | Refused entry US/EU |

Hidden Cost Drivers

Budget $12k–$18k for on-site UL field evaluation if the OEM lacks a UL category control number; expedited CE notification-body audits can surge to $22k when PED category II valves are involved. Translation of manuals into 23 official EU languages averages $0.18/word, pushing a 40,000-word O&M manual to $7k. Cyber-security clause IEC 62443-3-3 is being retro-enforced by German insurers; absence can raise liability premiums by 1.8–2.4 % of machine value annually.

Bottom-Line Governance Mandate

Cap-ex approvers must verify valid certificates before purchase-order release, not after FAT. Insert a 5 % retention tied to receipt of both UL follow-up service agreement and CE declaration of conformity; escrow release only when the machine’s serial number appears in the UL online database and the EU’s NANDO system. Anything less shifts unquantifiable product-liability tail risk onto the balance sheet—and onto the board.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook: Coffee Pouch Machine (400–600 words)

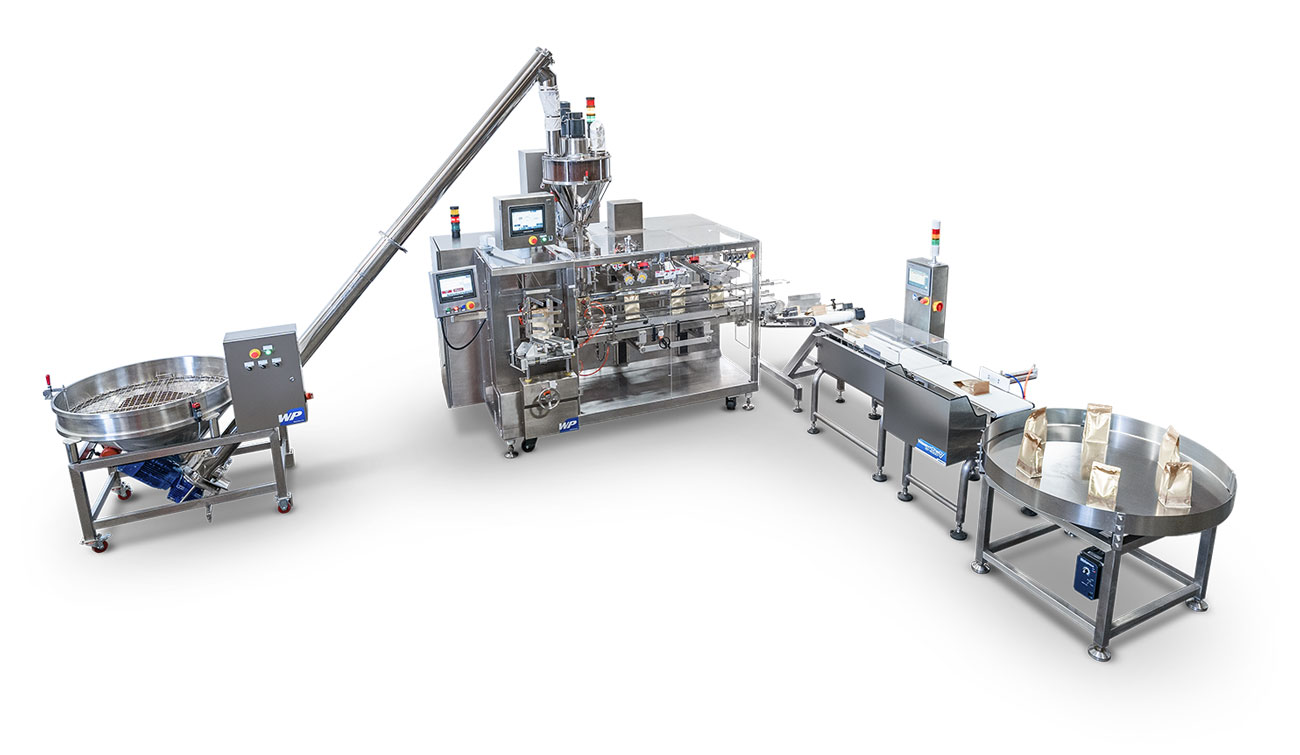

RFQ Architecture: Build the Specification Firewall

Anchor every RFQ to ±1 g fill tolerance, ≤2 % O₂ residual for nitrogen-flush variants, and ≥120 pouches/min for 2025-capacity planning. Force vendors to quote on identical 3-layer PET/AL/PE laminate so downstream total-cost-of-ownership (TCO) models remain apples-to-apples. Insert a 10 % ceiling on spare-part price escalation for three years and require a 98 % uptime SLA with liquidated damages of 1 % of machine value per 0.1 % shortfall. Request line-item breakdown: machine platform, change-parts for all SKUs (include 50–250 g range), HMI language packs, and remote-access licence fees. Demand a binding 18-week lead-time from PO to FAT; any slippage triggers a 2 % weekly penalty capped at 10 % of contract value.

Factory Acceptance Test: Validate Before You Ship

FAT must run the buyer’s actual coffee (not vendor’s placebo) for 4-hour continuous operation at target speed; reject if coefficient of variation (CV) on fill weight exceeds 1.2 %. Insist on 100 % seal-stress test: 0.5 bar air pressure inside each pouch for 30 s with zero leaks. Capture OEE data via vendor’s SCADA and mirror to buyer’s cloud dashboard; store raw data for 36 months. Payment milestone: 80 % against signed FAT protocol, 10 % after site commissioning, 10 % after 30-day reliability run; retain 5 % bank guarantee until 365-day warranty expiry.

Incoterms Matrix: FOB vs DDP Risk Dollars

| Cost & Risk Vector | FOB Shenzhen (Index 100) | DDP Kentucky (Index 118) | Decision Trigger |

|---|---|---|---|

| Machine Price | 100 | 102 | DDP premium ≤3 % → accept |

| Freight & Insurance | 8–12 | 0 | Budget variance >10 % → revert to FOB |

| Import Duty (HS 8422.30) | 0 | 1.8 | Duty exposure >2 % → insist on DDP |

| Demurrage Risk | Buyer | Seller | Port congestion index >1.5 → DDP |

| Installation Supervision | Buyer arranges | Seller inclusive | First-time buyer or greenfield site → DDP |

| Total Landed Variance | Base | +12–18 % | CFO tolerance <15 % → DDP, else FOB |

Contract Risk Clauses: Lock in Uptime & IP

Insert force-majeure carve-out: semiconductor chip shortages do not extend lead-time beyond +4 weeks without buyer consent. Require source-code escrow for PLCs and HMI; release triggered if vendor files for insolvency or discontinues support. Cap single-source component exposure at 20 % of BOM value; vendor must provide 12-month last-time-buy notice and interchangeable 3-D drawings. Warranty: 24 months unlimited hours, 48 h on-site response in NA/EU, 72 h elsewhere; failure to meet MTTR target accrues $2 k per day. Include anti-dumping claw-back: if vendor sells identical platform in same calendar year at >5 % lower price, delta is refunded or future spare parts discounted equivalently.

Site Commissioning: Parallel Run to Go-Live

Demand vendor technician stay until 3 consecutive shifts hit ≥95 % OEE at buyer’s speed and laminate spec. Run parallel production for 48 h: new machine vs incumbent line; accept only if waste delta is <0.5 % and labour reduction is ≥1.5 FTE. Sign-off protocol must be countersigned by operations, quality, and finance; withhold final 10 % payment until signed. Archive digital twin file (CAD, PLC, servo drives) inside buyer’s PLM system; update escrow simultaneously.

Execute the checklist sequentially; deviation in any milestone reloads risk premium into TCO and erodes the 18-month payback required at $50 k–$80 k machine price band.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —