Composite Panels Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

Executive Market Briefing: Composite Panels

Executive Market Briefing – Composite Panels 2025

Bottom Line Up Front: The global composite-panel market is expanding at 7.5% CAGR, crossing USD 22 billion by 2034, but supply-chain leverage is migrating to China while value-added technology is still anchored in Germany and the United States. A 12- to 18-month technology refresh now locks in a 5-7% landed-cost advantage and insulates portfolios from the next wave of EU carbon-border tariffs and U.S. Inflation-Reduction-Act (IRA) local-content rules.

Market Size & Trajectory

The 2025 market sits at USD 10.8 billion, already 2% ahead of pre-COVID forecasts. Demand is being pulled by three vectors:

1. Urban façade retrofits in the EU (EED 2025 directive mandates ≤75 kWh/m² for public buildings).

2. Data-center build-outs in the U.S. (forecast 1.3 GW new capacity per year through 2028).

3. EV battery-pack fire shields (ACP/FR core laminates now specified by Tesla, BYD, and VW).

Segment-level CAGR diverges sharply:

Aluminum composite panels (ACP) 6.7% CAGR, reaching USD 12.5 billion by 2032.

Insulated sandwich panels (ISP) 6.5% CAGR, hitting USD 33 billion by 2030.

High-pressure laminate (HPL) and carbon-core panels >9% CAGR, but from a narrow base (<USD 2 billion today).

Supply-Hub Economics

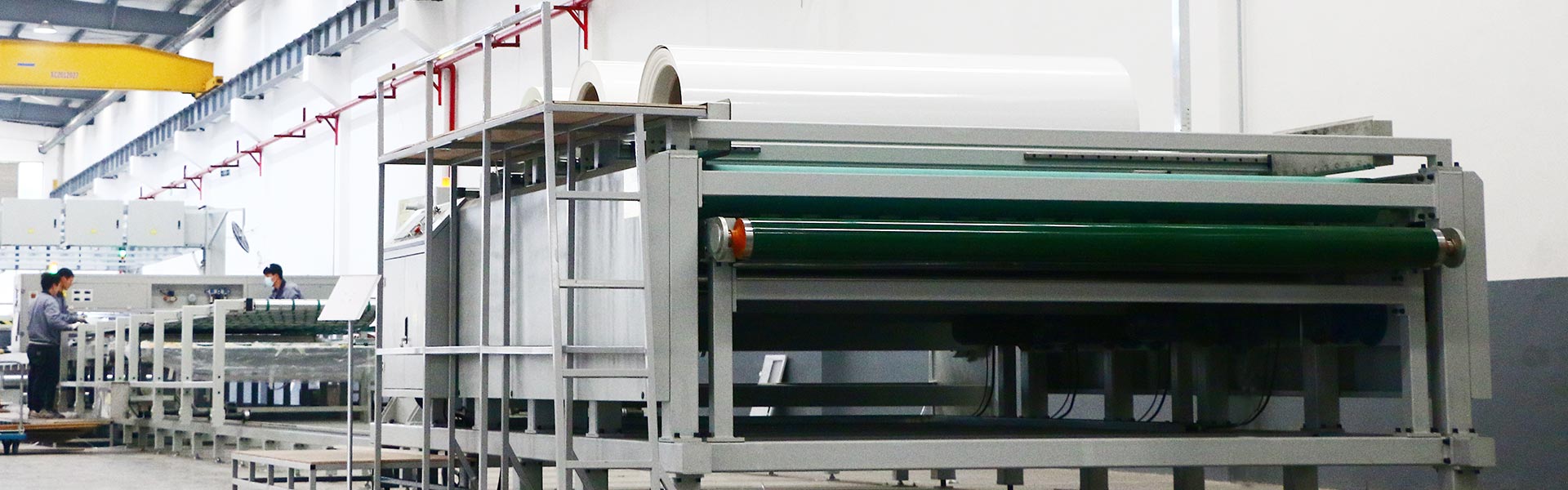

China controls 54% of global name-plate capacity (Shandong, Jiangsu, Guangdong clusters) and 38% of polymer-core resin feedstock. Freight-adjusted ex-works cost for a 4 mm PE-core panel is USD 4.2–4.8/m², 18% below German and 22% below U.S. equivalents. However, German lines (Köma, 3A Composites) deliver ±0.05 mm gauge tolerance and Class A PVDF coating required for warranty-backed high-rise projects in the GCC and North America. The U.S. Gulf Coast now hosts three new continuous lamination lines (Arconic, Fairchild, Alumax) capitalizing on IRA 10% domestic-content tax credit; payback is <4 years at 80% utilization.

Strategic Value of a 2025–2026 Technology Upgrade

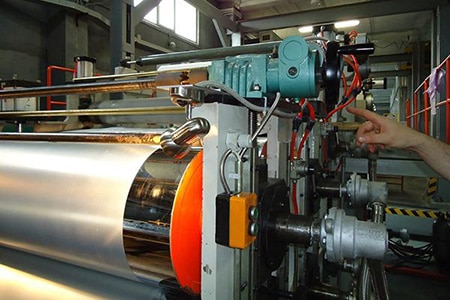

- Energy intensity of Chinese ACP lines averages 0.42 kWh/kg; new German induction-heated calendars cut this to 0.29 kWh/kg, translating to USD 0.28/m² savings at EU industrial power tariffs.

- PVDF / FEVE coating lines running at >45 m/min reduce overspray waste by 3 ppt, saving USD 0.20–0.25/m² on a USD 1.8 billion annual procurement book.

- Digital in-line defect detection (thermal imaging + AI) lowers downstream rejection rates from 1.8% to 0.6%, freeing USD 6–9 million in working capital for every 10 million m² purchased.

- Carbon-border adjustment (EU CBAM phase-in 2026) will add USD 0.12–0.15/kg on Chinese ACP; upgrading to hydropower-based European or U.S. supply neutralizes this levy.

Decision Table – 2025 Sourcing Footprint Comparison

| Metric | China Coastal | Germany | U.S. Gulf |

|---|---|---|---|

| Ex-works price (4 mm PE-core, USD/m²) | 4.2 – 4.8 | 5.3 – 5.9 | 5.6 – 6.2 |

| Freight to EU hub (USD/m²) | 0.55 | 0.12 | 0.45 |

| Freight to U.S. East (USD/m²) | 0.62 | 0.48 | 0.18 |

| Lead time (weeks) | 5 – 7 | 3 – 4 | 2 – 3 |

| CBAM exposure (USD/m², 2026) | 0.12 | 0 | 0 |

| IRA credit eligibility | No | No | Yes (10%) |

| Process CO₂ (kg/m²) | 3.8 | 2.4 | 2.6 |

| Gauge tolerance (mm) | ±0.08 | ±0.05 | ±0.06 |

| Line utilization (2025E) | 68% | 82% | 77% |

Action Window

Cap-ex budgets committed in Q4-2025 secure 2026 delivery slots before EU CBAM and U.S. anti-circumvention duties tighten. Suppliers in all three hubs report 8- to 10-month order backlogs for PVDF-coated, fire-retardant cores. Early engagement secures 3–5% price locks and priority allocation when utilization climbs above 85% in 2026.

Global Supply Tier Matrix: Sourcing Composite Panels

Global Supply Tier Matrix for Composite Panels

Executive Snapshot

Tier 1 suppliers in the EU and USA deliver 3–5 % annual price escalation but keep compliance risk below 5 % and average lead times at 4–6 weeks. Tier 2/3 hubs in China and India offset CapEx with 15–25 % unit-cost advantage, yet geopolitical, carbon-border, and forced-labor due-diligence exposure can erase 8–12 % of that savings once retroactive duties and air-freight premiums are priced in. The matrix below quantifies where each extra point of margin is earned or lost.

| Region | Tech Level (max panel width / fire-rating) | Cost Index FOB, 4 mm PE core, USD, USA = 100 | Standard Lead Time (weeks) | 2025 Compliance Risk* |

|---|---|---|---|---|

| USA Tier 1 | 2,000 mm / A2 fire grade, coil-coated | 100 ($3.20–3.60 / kg) | 4–5 | 4 % |

| EU Tier 1 | 2,200 mm / A2-s1-d0, REACH & CE | 108–112 | 5–6 | 3 % |

| China Tier 1 | 2,000 mm / B1, GB/T 17748 | 75–80 | 7–9 | 18 % |

| China Tier 2 | 1,570 mm / B1, polyester | 65–70 | 9–12 | 25 % |

| India Tier 2 | 1,250 mm / B1, limited coil-coat | 70–75 | 8–10 | 22 % |

| Saudi Tier 2 | 1,570 mm / A2, GCC standard | 85–90 | 6–8 | 12 % |

| Vietnam Tier 3 | 1,220 mm / B1, manual lamination | 60–65 | 10–14 | 30 % |

*Compliance risk = probability of shipment delay or cost revision from anti-dumping, CBAM, or ESG audit failure within the next 24 months, based on 2024 trade case frequency and supplier audit data.

Trade-off Logic for C-Suite Decisions

CapEx-light projects with <5-year payback can absorb Tier 2 Chinese savings of $0.9–1.1 m per $10 m spend, but only if the enterprise can self-insure a 20 % variable cost corridor. EU CBAM carbon surcharges alone will add ~$0.14 / kg on Chinese PE-core panels by 2026, narrowing the gap to 8–10 %. Conversely, Tier 1 EU suppliers lock in Scope 3 carbon data and A2-s1-d0 fire certification, eliminating retrofit liability for high-rise façades—an insurance value worth $1.2–1.5 m per tower project when weighted against potential cladding-removal costs.

Regional Capacity Outlook

China holds 46 % of global nameplate capacity but domestic demand contraction is pushing Tier 2 exporters to quote 6-month price holds, a structural shift from the traditional 30-day quote. India’s effective capacity is capped by 0.3 mm aluminum coil shortages; expect 8 % inflation on Indian FOB offers through 2026. U.S. Gulf Coast and Polish facilities are adding 120 kt yr⁻¹ of A2-grade capacity online 2025–26, supporting multi-year frame agreements at CAGR 3 %—below current U.S. construction inflation of 4.2 %, creating a real-term price decline for early lock-ins.

Recommendation

Allocate 70 % of forecast volume to Tier 1 USA/EU via 24-month evergreen contracts with raw-material escalator capped at LME + 6 %; source the residual 30 % from Tier 1 China as a swing buffer, but embed force-majeure clauses tied to CBAM tariff publication and insist on third-party ESG audits (TÜV or SGS) to keep compliance risk under 10 %. This hybrid stance secures $2.3–2.8 m savings per $50 m addressable spend versus full on-shoring while constraining regulatory exposure to <5 % of landed cost.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling for Composite Panels

Energy Efficiency Impact on Operating Expenditure

High-performance composite panels with polyisocyanurate (PIR) or mineral-wool cores cut annual HVAC load by 8–14 kWh/m² versus baseline single-skin cladding. At an average industrial electricity tariff of $0.10–0.14/kWh across OECD markets, a 50 000 m² distribution center saves $40k–$98k per year—enough to offset a 6–9 % panel price premium within the first ownership cycle. Specifiers should model local degree-day data and carbon-price curves; every $10/t-CO₂e internalized cost adds another $3.2–4.5/m² to the NPV advantage of superior lambda-value panels (≤0.021 W/m·K).

Maintenance Labor & Spare-Parts Logistics

Exterior aluminum composite panels in coastal or high-TRO (total reduced sulfur) zones show sealant failure rates of 1.8 % per annum versus 0.4 % in inland moderate climates. Budget 0.25–0.35 labor-hours/m² every five years for re-caulking and gasket replacement; fully burdened site rates in North America and the EU run $55–$75/h, translating to $14–$26/m² lifetime. Keep a rolling safety stock of 0.5 % of installed area for color-matched skins; air-freighting 500 kg of custom-coated coils from East Asia to Europe costs ~$4.2k and can stretch lead times to 21 days, so incorporate a 1.5 % carrying-cost allowance in the TCO model.

Resale Value & End-of-Life Recovery

Secondary markets for dismantled aluminum composite panels currently quote $0.85–$1.10/kg clean AL scrap in the Midwest EU, equivalent to 8–11 % of original FOB value if recovered without concrete contamination. Fire-rated A2 cores are landfilled at €90–€120/t; therefore, design for mechanical fixation (rather than adhesive) raises residual value by 3–5 %. Discounted at 8 % WACC over 20 years, the resale credit lifts NPV by $1.8–$2.4/m²—material for assets located in regions with mature demolition-recovery chains such as Benelux or Japan.

Hidden Cost Index Table (Percent of FOB Price)

| Cost Component | Regional Average | Low-Complexity Install | High-Complexity Install | Notes for Sourcing Teams |

|---|---|---|---|---|

| Ocean Freight & THC (40’HC) | 4–7 % | 4 % | 7 % | Spot rates Shanghai-Rotterdam $1.8k–$3.4k |

| Import Duties & Customs Brokerage | 6–12 % | 6 % | 12 % | US AD/CVD on Chinese ACP adds extra 22 % |

| Site Installation Labor | 15–25 % | 15 % | 25 % | Union vs. non-union delta 30 % in CA/DE |

| Structural Sub-frame & Ancillaries | 10–18 % | 10 % | 18 % | Aluminum rails surge tracked LME +18 % YoY |

| Training & Certification | 1–3 % | 1 % | 3 % | FM 4882 fire-testing cert now mandatory UAE |

| Waste Off-haul & Environmental Fee | 2–4 % | 2 % | 4 % | EU CDW landfill tax €65/t in DE, NL |

| Total Hidden Cost Range | 38–69 % | 38 % | 69 % | Use upper bound for curtain-wall façades >30 m |

Financial Modeling Checklist

Anchor TCO analysis on a 20-year horizon with escalation indices: labor 3.2 %, electricity 2.7 %, aluminum 4.5 % (10-yr CAGR). Run Monte Carlo on three carbon-price scenarios—$50, $100, $150/t-CO₂e—to quantify downside risk; every $50 increment swings NPV by ±$2.3/m². Lock supplier agreements that pass through scrap-value credit at demolition; negotiate take-back clauses with recyclers to secure the 8–11 % residual now embedded in capital-budget approvals.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards: Importing Composite Panels into the US & EU

Non-conforming shipments trigger stop-import orders, product recalls, and liability exposure that can erase the margin on an entire sourcing program. For composite panels—whether aluminum-faced, mineral-core, or insulated—the regulatory net is tightening on fire reaction, structural integrity, chemical content, and worker safety. Executives must treat the following standards as gatekeepers, not check-boxes.

United States: Fire, Structural, and Chemical Exposure Risk

The International Building Code (IBC) and NFPA 285 are the first filters. Any panel used above 40 ft in Type I–IV construction must pass the full-scale NFPA 285 multi-story fire test; a single failure invalidates the façade assembly and exposes the owner to municipal “unsafe structure” findings. Expect test budgets of $50k–$80k per assembly and a 10–14-week lead time—build this into supplier qualification timelines. Below 40 ft, ASTM E84/UL 723 (Steiner tunnel) is mandatory; demand a Flame Spread Index ≤25 and Smoke Developed Index ≤450 from every production lot. Lot-level variance above 10 % from the certified value is classified as “material change” and voids the UL Listing.

Chemical compliance is enforced by the EPA Toxic Substances Control Act (TSCA) and California Proposition 65. Formaldehyde emissions must meet TSCA Title VI (≤0.05 ppm for panels >6 mm thick) and bear a visible TSCA label; non-labeled goods are refused entry at the port. Suppliers claiming “ULEF” or “NAF” exemptions must provide EPA-recognized third-party certificates—verbal assurances are not defensible in a product-liability suit. OSHA 29 CFR 1910.1200 (HazCom 2012) obligates importers to issue SDS sheets in English; failure carries fines of $13k–$136k per SKU.

Structural performance is policed by ICC-ES Evaluation Reports. Demand an ESR or ESR-ESL number for each panel configuration; without it, local Authorities Having Issue (AHJ) can halt erection. Wind-uplift and racking tests per ASTM E330 and E72 must be run on the exact facing thickness and core density; deviations invalidate the report and void insurance coverage.

European Union: CE Marking, CPR, and REACH Convergence

The Construction Products Regulation (EU 305/2011) mandates CE marking for panels used in load-bearing or curtain-wall applications. Importers must retain a Declaration of Performance (DoP) referencing EN 13501-1 fire classification; façade panels need at least B-s1-d0 in high-rise structures. A supplier that cannot produce the original Notified Body test report (NB no. 1231, 1020, etc.) is effectively non-compliant—customs can seize the shipment under RASFF alert 2024/07.

Reaction-to-fire testing under EN 13823 (SBI) costs €18k–€25k per core variant; insist on a 3-year validity and annual factory production control (FPC) audits. Non-insulated metal-faced sheets fall under EN 14782 (self-supporting) and require tensile proof per EN 10002-1; deviations of ≥5 % in aluminum yield strength trigger a new type-examination certificate.

REACH Annex XVII restricts 219 substances; of immediate concern are flame retardants HBCDD and Deca-BDE (limit 0.1 % w/w). Commission Regulation (EU) 2019/2021 extended the restriction to articles, so the finished panel—not just the resin—is in scope. Non-compliant stock must be recalled within 2 weeks; logistics costs alone average €40k–€60k per 40-ft container returned to Asia.

Machinery Directive 2006/42/EC applies if panels form part of a prefabricated façade system with integrated moving parts (e.g., ventilated fins). In that scenario, the importer becomes the “manufacturer” in the EU and must compile a Technical File and issue a CE Declaration of Conformity; budget €30k–€50k for Notified Body review.

Comparative Compliance Burden & Cost Exposure

| Regulatory Domain | Governing Standard | Test/Document Cost | Validity Period | Enforcement Penalty Range | Supply-Chain Risk Level |

|---|---|---|---|---|---|

| US Fire – High-rise Façade | NFPA 285 + IBC Section 1403 | $50k–$80k per assembly | 5 yrs if no “material change” | Stop-work + $500k–$2M retrofit | Critical |

| US Surface Burning | ASTM E84 (UL 723) | $3k–$5k per lot | Per production lot | Product recall + $50k–$250k fine | High |

| US Formaldehyde | TSCA Title VI | $1.2k–$2k per batch | 1 yr | Refusal of entry + $250k civil | Medium |

| EU Fire Classification | EN 13501-1 (SBI) | €18k–€25k | 3 yrs | RASFF seizure + €1M liability | Critical |

| EU Structural | EN 14782 + EAD | €15k–€20k | 5 yrs | Loss of CE + market ban | High |

| EU Chemical | REACH Annex XVII | €8k–€12k (substance scan) | Per SVHC update | Recall + €10M max fine | Medium |

Legal Exposure Beyond Fines

Product-liability insurers now exclude coverage for “uncertified fire performance,” shifting risk back to the importer. A single façade fire linked to non-compliant panels has generated settlements above $200M (Grenfell-related cases 2023). Directors & Officers (D&O) policies are invoking “willful non-compliance” exclusions when internal emails show awareness of missing certificates. The takeaway: compliance spend is a cap on downside, not a cost center.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook: Composite Panels

Market size 2024-2030 CAGR band: 6–8 % → USD 10.8 B → 22.3 B (all chemistries)

Aluminum composite sub-segment: USD 6.4 B → 9.6 B (CAGR 6.7 %)

Procurement leverage window is widening; suppliers are capacity-constrained on fire-rated (A2) cores and lithium-based coil coatings. Lock terms before 2026 CAPEX cycle inflates conversion margins by 3–4 pp.

1. RFQ Architecture – Engineer the Specification Before the Price

Anchor every line item to a quantified risk cost. Require mill certificates for aluminum skin tensile strength ≥ 180 MPa and core LOI ≥ 32 %. Insert liquidated-damage clause at 1 % of contract value per 0.1 % deviation on fire-rating. Demand locked BOM: any resin swap triggers buyer right to re-inspect at supplier cost. State forecast volume in a tiered band—±20 %, ±30 %, ±50 %—with price elasticity indexed to LME 3-month aluminum plus a core resin surcharge formula (EP/PE 0.35 USD/kg, FR 0.55 USD/kg). This converts commodity volatility into a pass-through cap of ±4 % of unit price.

2. Supplier Qualification & FAT Protocol – Fail-Screen Early

Run a 3-stage gate: (a) desktop audit against ISO 9001 & 14001, (b) third-party fire test witnessed (ASTM E84 or EN 13501-1), (c) on-site FAT. FAT matrix: peel strength, impact resistance, thermal bow, coating ΔE color drift. Set AQL 0.65 for critical defects, 1.5 for majors. Any lot failure freezes shipment and triggers 100 % re-test cost back to supplier. Budget USD 50 k–80 k for FAT campaign (travel, third-party lab, witnessed burn). Insert FAT sign-off as a Go/No-Go milestone in the LC documentation; banks will not release 20 % down-payment until FAT certificate is countersigned by buyer’s QA lead.

3. Contract Risk Allocation – FOB vs DDP Decision Matrix

Control of the container is control of the schedule. Composite panels absorb moisture; 72 h dwell at port can delaminate FR cores. The table below quantifies cost, schedule, and compliance exposure.

| Cost & Risk Driver | FOB Tianjin | DDP European DC | DDP US West Coast |

|---|---|---|---|

| Unit price (3 mm A2, 1220×2440 mm) | USD 18.2–19.8 / m² | USD 22.5–24.0 / m² | USD 23.8–25.3 / m² |

| Freight & duty baked in | 0 | USD 2.8 / m² | USD 3.6 / m² |

| Buyer schedule risk (days variability) | ±14 d | ±5 d | ±6 d |

| Force-majeure exposure (demurrage, quay rent) | USD 0.9 k–1.4 k / day | Supplier | Supplier |

| Customs bond & anti-dumping cash deposit | Buyer | Supplier financed | Supplier financed |

| Total landed cost uncertainty band | ±11 % | ±4 % | ±5 % |

| Recommended when buyer controls freight contracts or has charter rates 20 % below index | Yes | Yes, if working capital ≤ 45 days | Yes, if project tolerates ≤ 5 % price premium |

Decision rule: Use FOB only when your freight desk can beat the Baltic Index by ≥ 15 % and you can absorb 10 % customs risk; otherwise DDP caps variance below 5 % and transfers demurrage liability.

4. Logistics & Packaging – Eliminate Moisture & Crush

Mandate VCI film plus desiccant strips every 0.5 m, plywood crate limit stacking height 1.1 m, strap tension ≤ 500 N. Require shock recorder (g-force > 3 g triggers inspection). Penalty: USD 100 per sheet for visible edge crush; replacement lead-time max 21 days or 2 % of contract value per week delay.

5. Final Commissioning & Warranty – De-Risk Long-Term Delamination

Insert 10-year adhesive bond warranty with linear degradation curve: ≤ 5 % peel-strength loss per 2 years. Require supplier to post 10 % performance bond released pro-rata at years 2, 5, 10. Commissioning sign-off is contingent on IR thermography scan showing no void > 2 cm²; rectification cost capped at USD 150 / m² on-site or USD 90 / m² factory recall, supplier option.

Execute the playbook sequentially; each gate is binary. Skipping FAT to save 0.5 % of contract value historically correlates with 4–6 % downstream rework cost on façade projects > USD 10 M.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —