High Precision

Shaft Couplings &

Ball Screw Support Units

Engineered for performance, durability, and precision in industrial automation, CNC machinery, robotics, and motion control systems.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Engineered for performance, durability, and precision in industrial automation, CNC machinery, robotics, and motion control systems.

COUP-LINK is a leading manufacturer of high-precision mechanical components for industrial automation and motion control systems. With a focus on innovation, quality, and technical excellence, we deliver reliable solutions trusted by engineers worldwide.

COUP-LINK, part of Guangzhou LINK Automation Equipment Co., Ltd., specializes in the design and production of precision couplings, ball screw support units, motor brackets, and linear modules.

Our products are widely used in CNC machines, robotics, semiconductor equipment, packaging machinery, and automation lines where high torque transmission, zero backlash, and misalignment compensation are critical.

We combine advanced materials, precision machining, and rigorous testing to ensure every component meets international standards.

ISO Standards Compliant Manufacturing

Engineers with 10+ Years Experience

Advanced CNC & Assembly Lines

Showcasing Innovation Worldwide

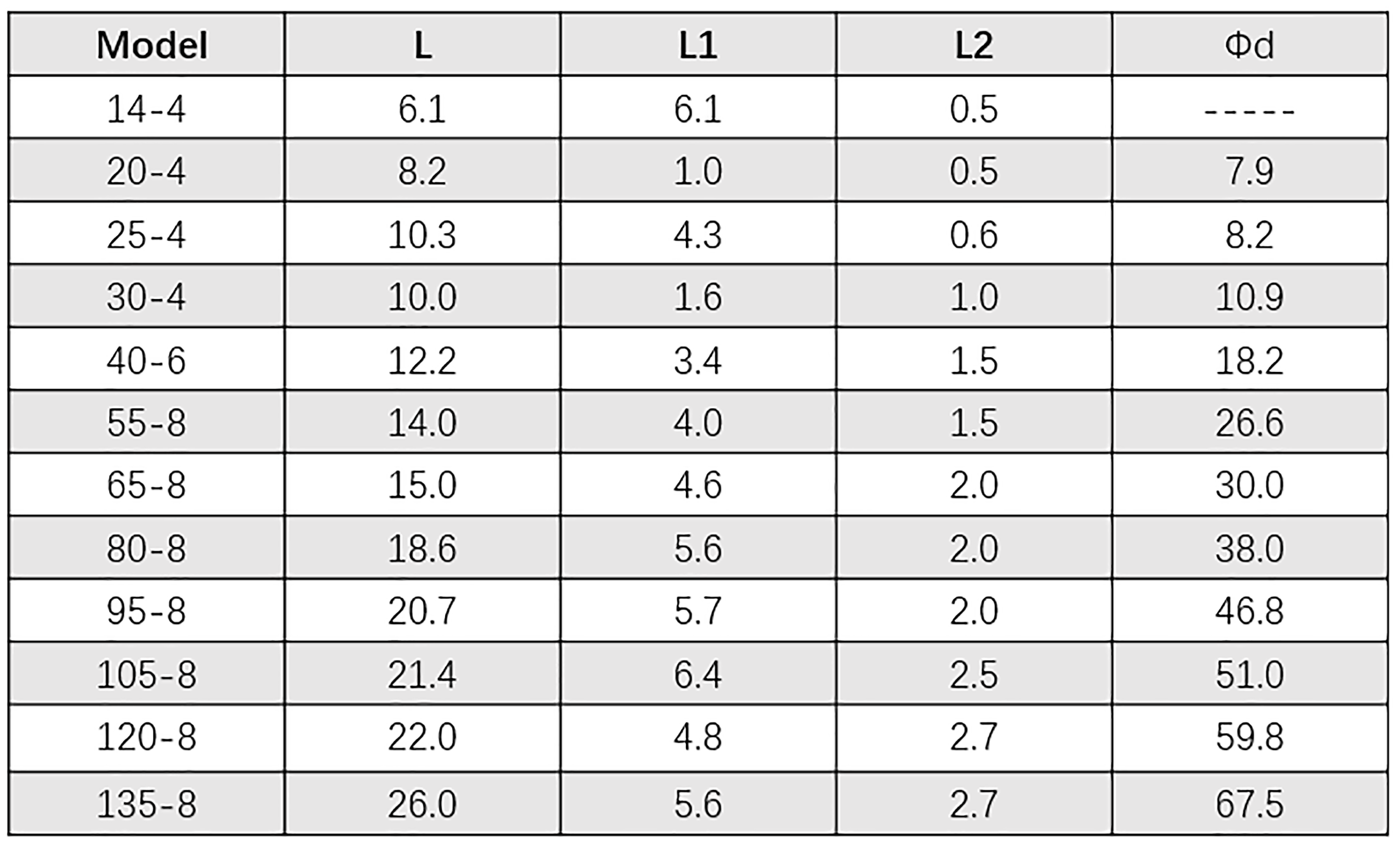

Precision-engineered components designed for reliability, performance, and long service life in demanding industrial environments.

Zero backlash, high torsional stiffness, ideal for servo motors and precision motion systems.

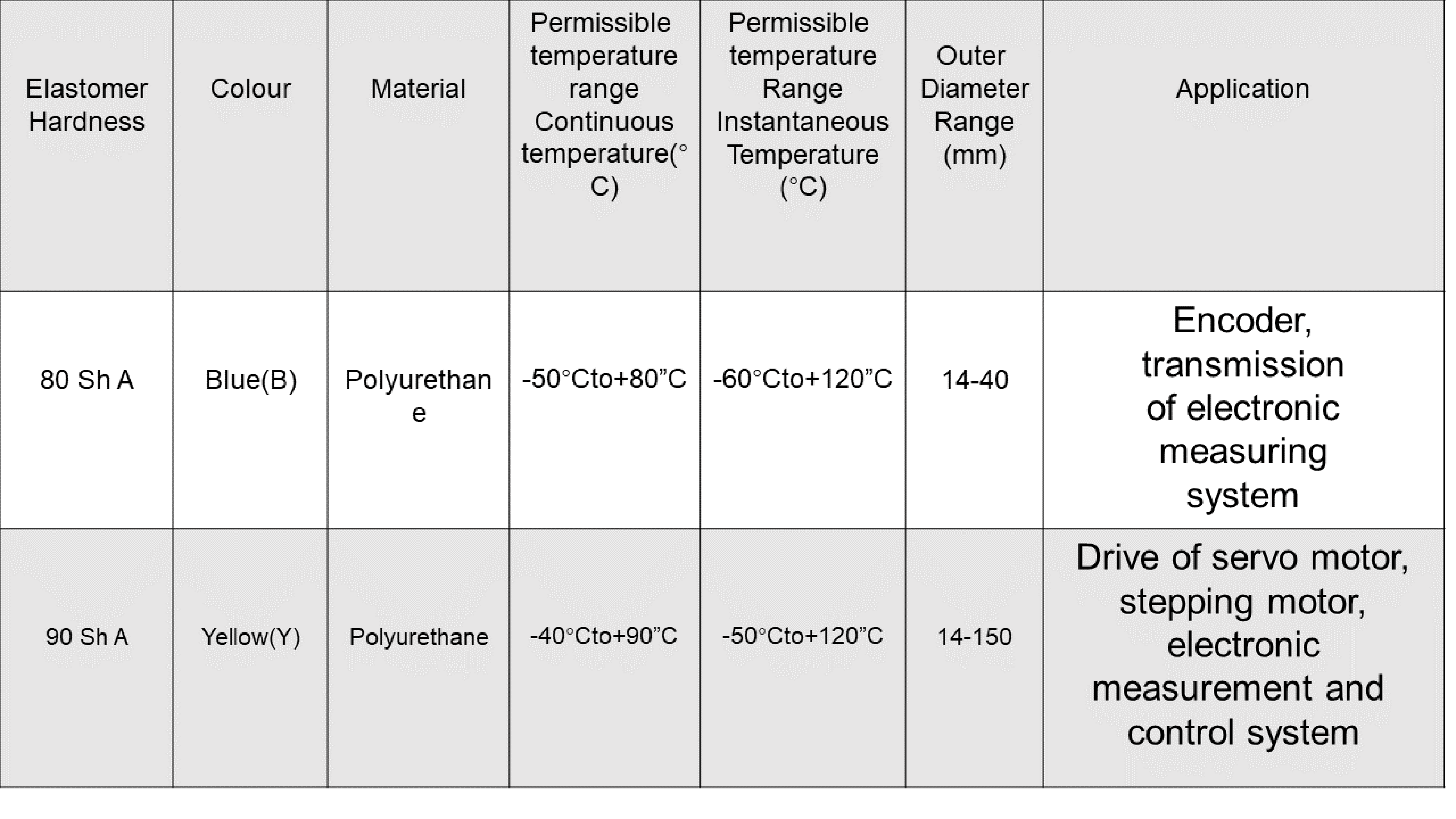

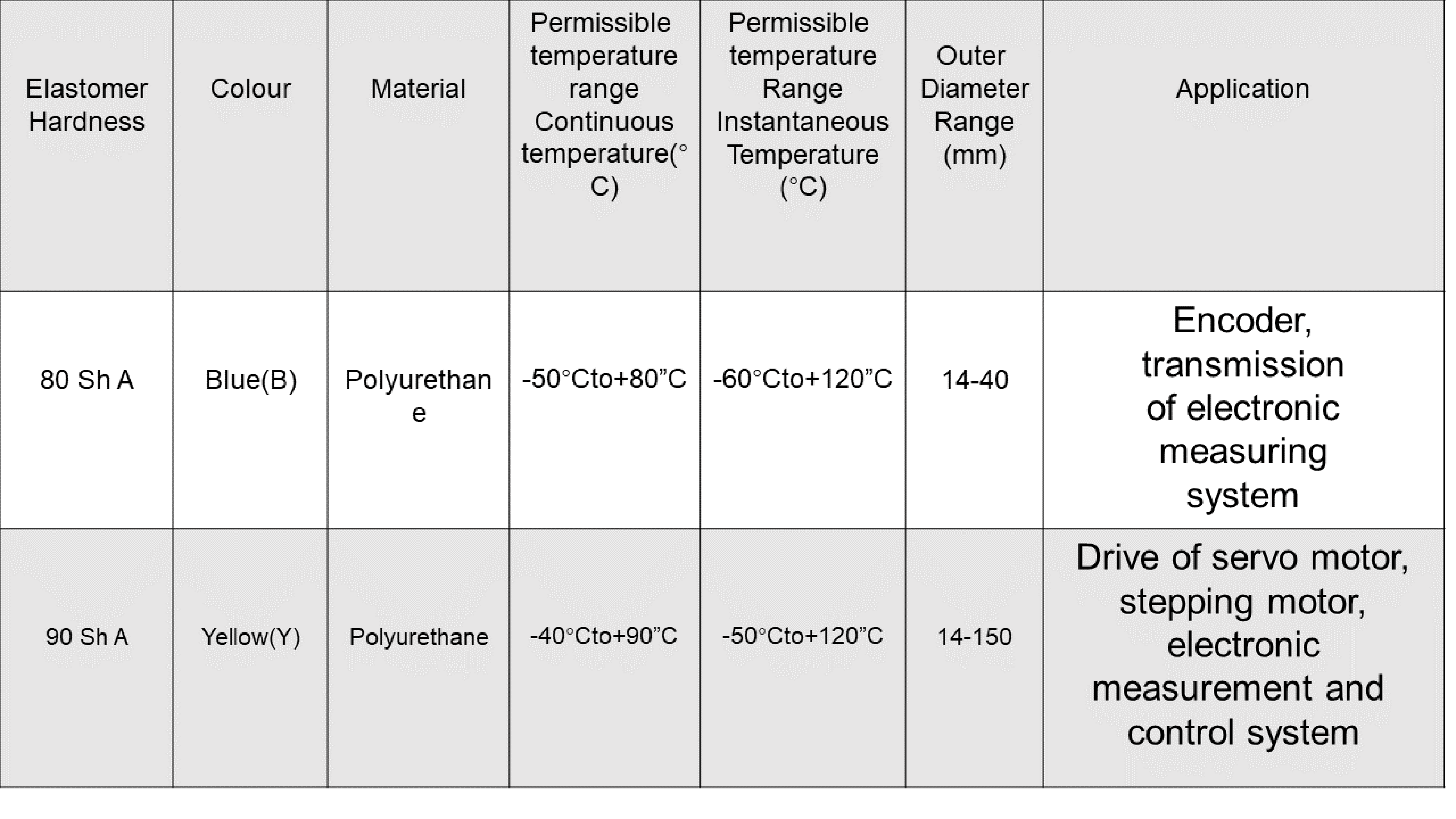

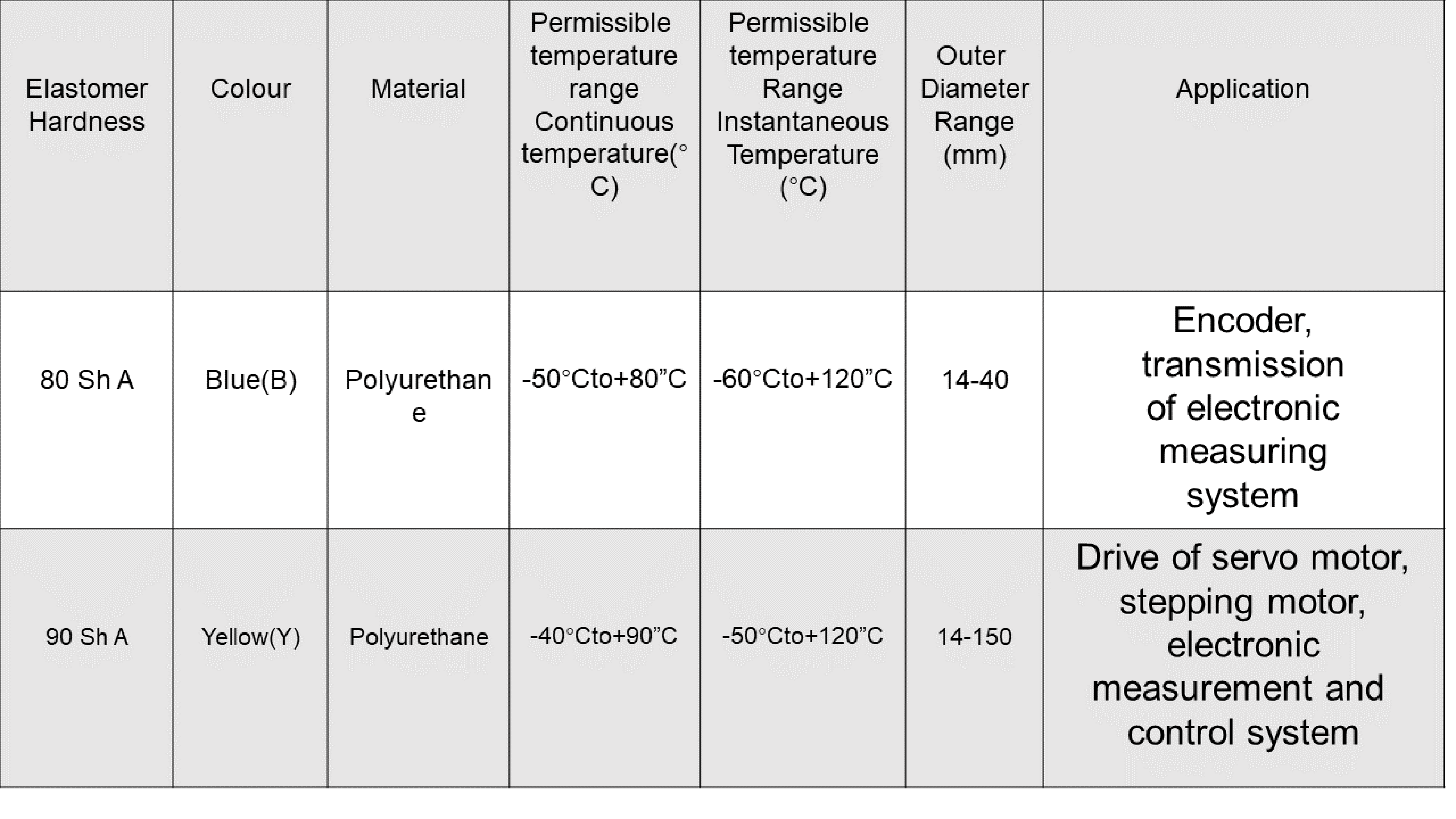

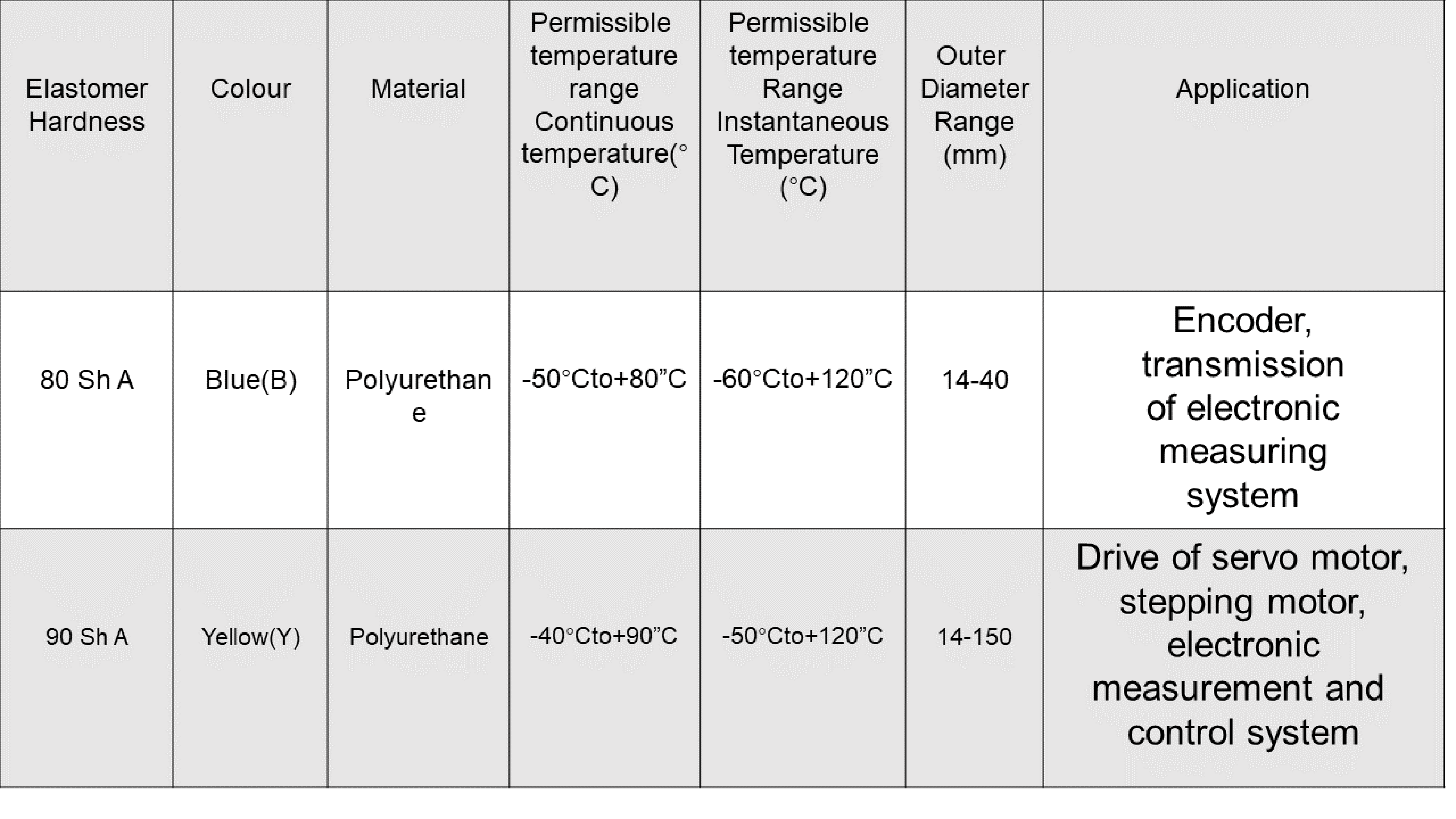

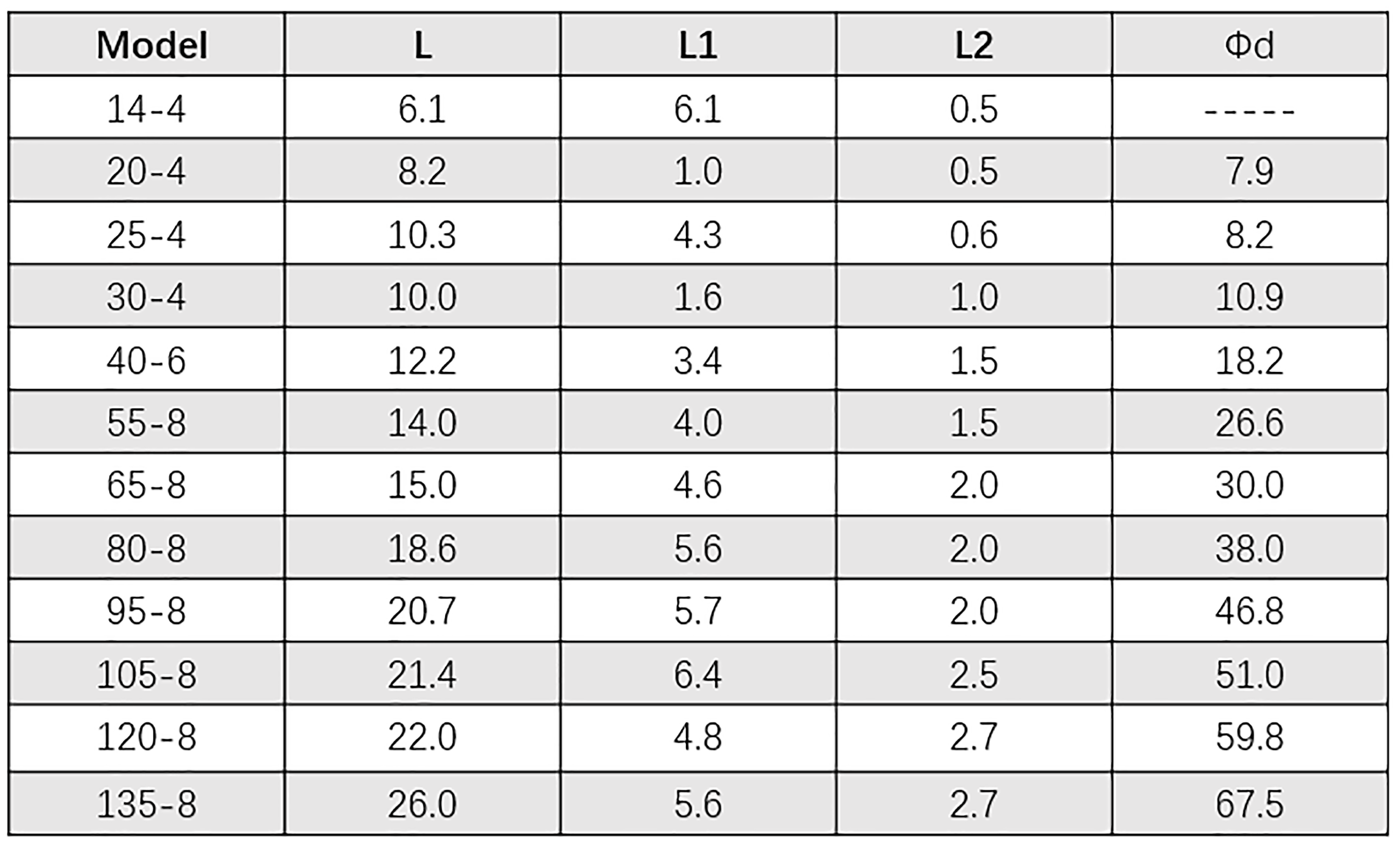

Durable elastomer spider design for vibration damping and misalignment compensation.

Excellent for parallel misalignment with minimal backlash and smooth torque transmission.

Monolithic design with high torsional rigidity and excellent electrical insulation.

High flexibility with excellent misalignment compensation and fatigue resistance.

Combines keyway connection with disc flexibility for high-torque transmission.

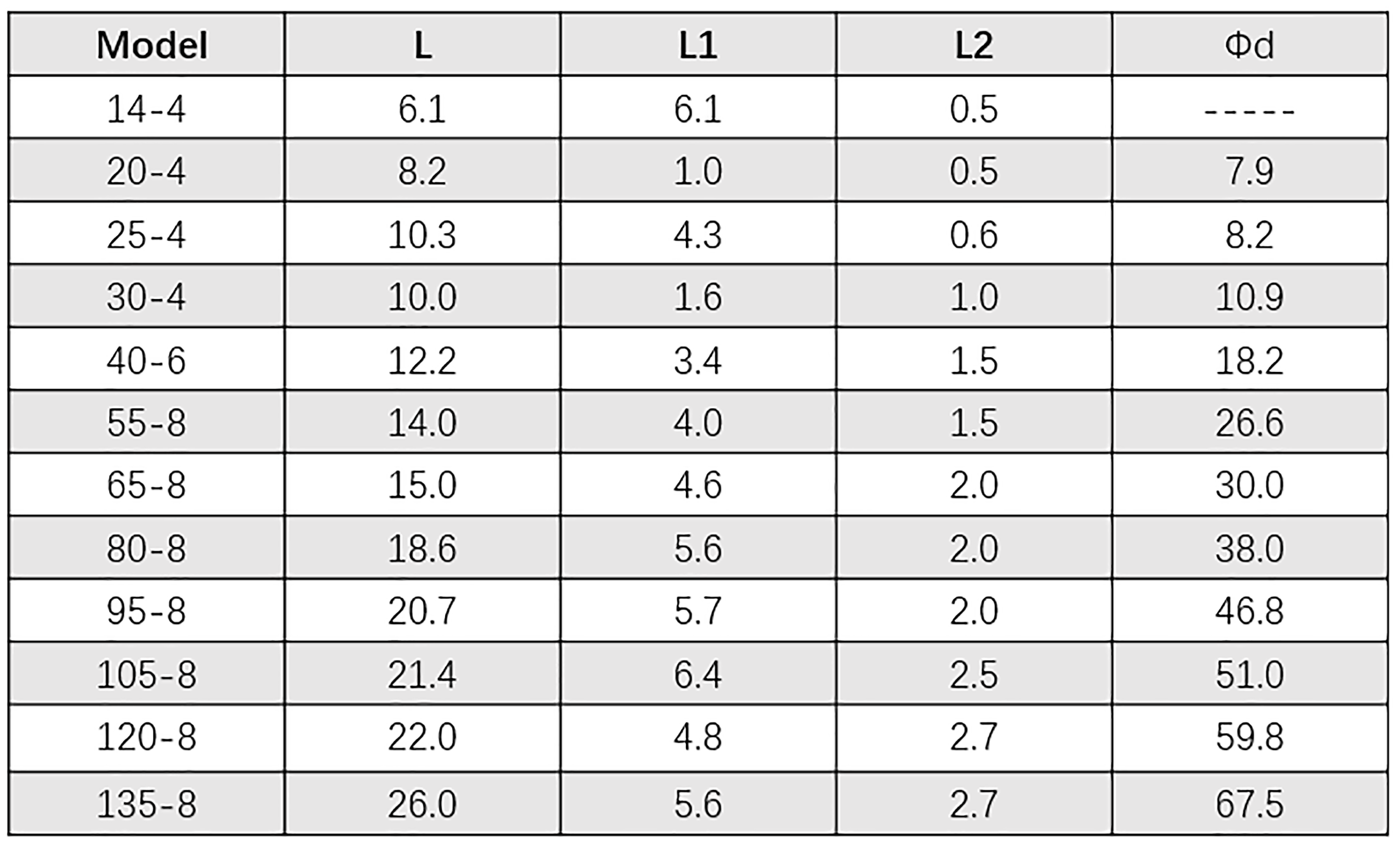

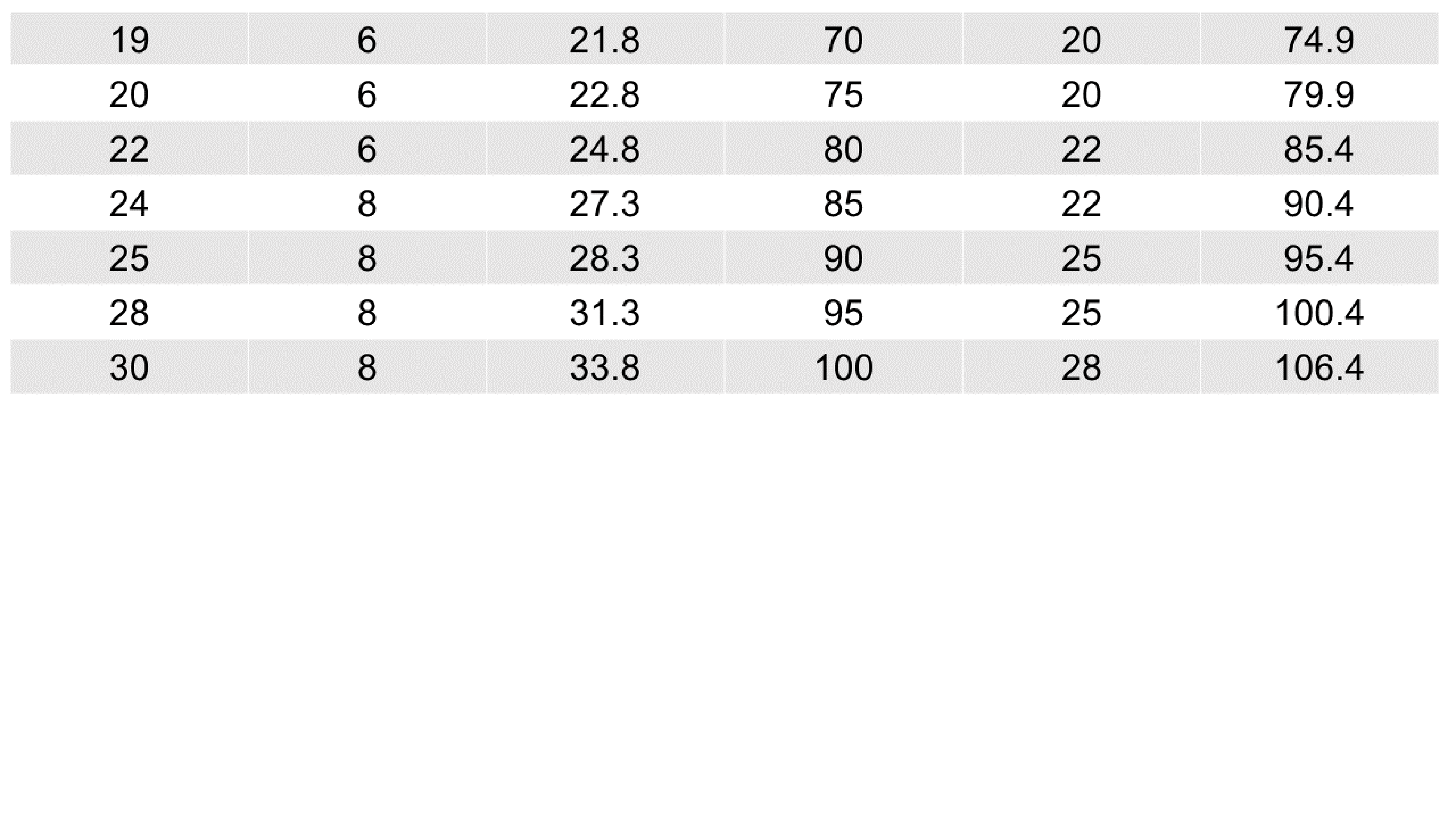

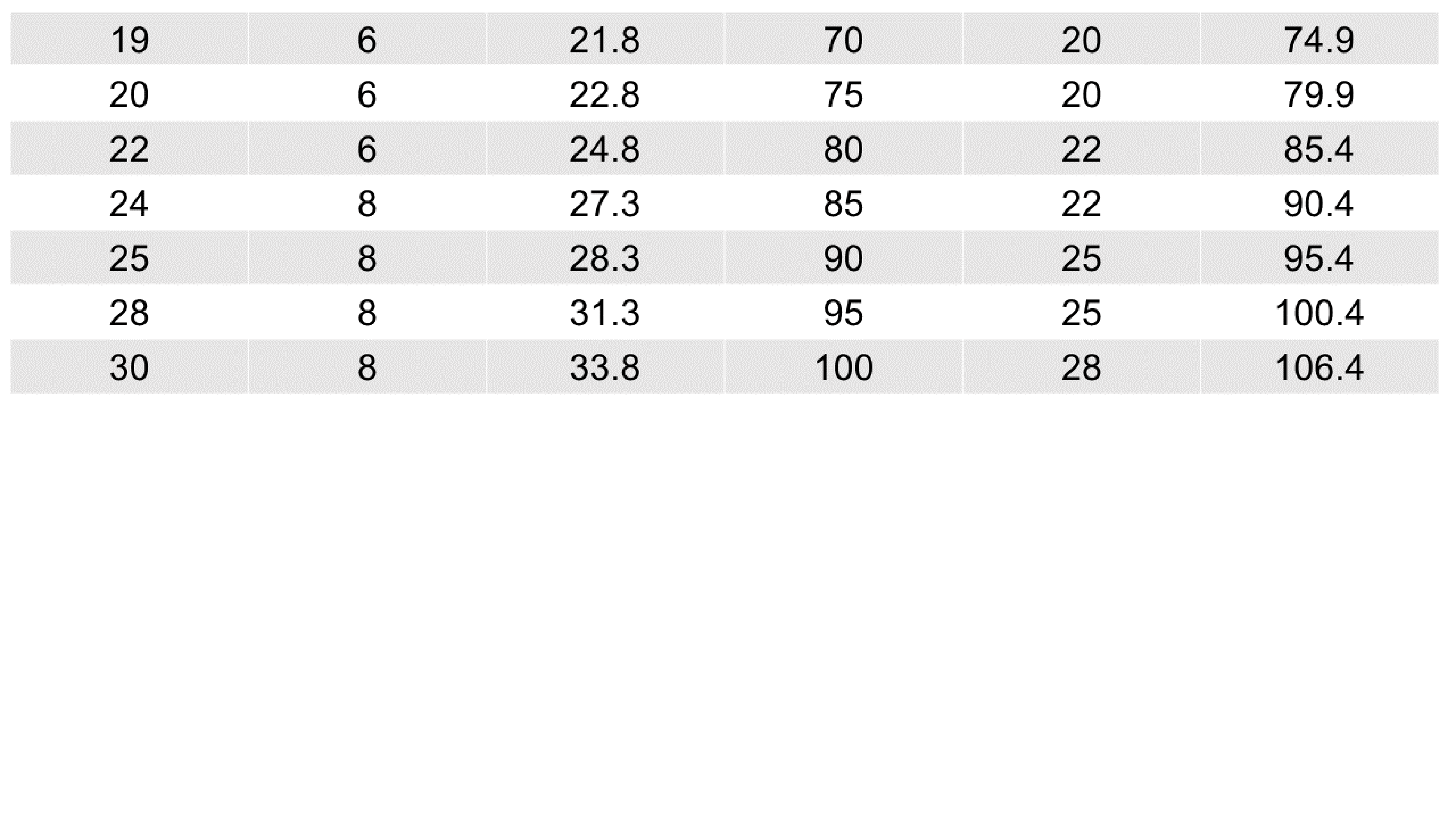

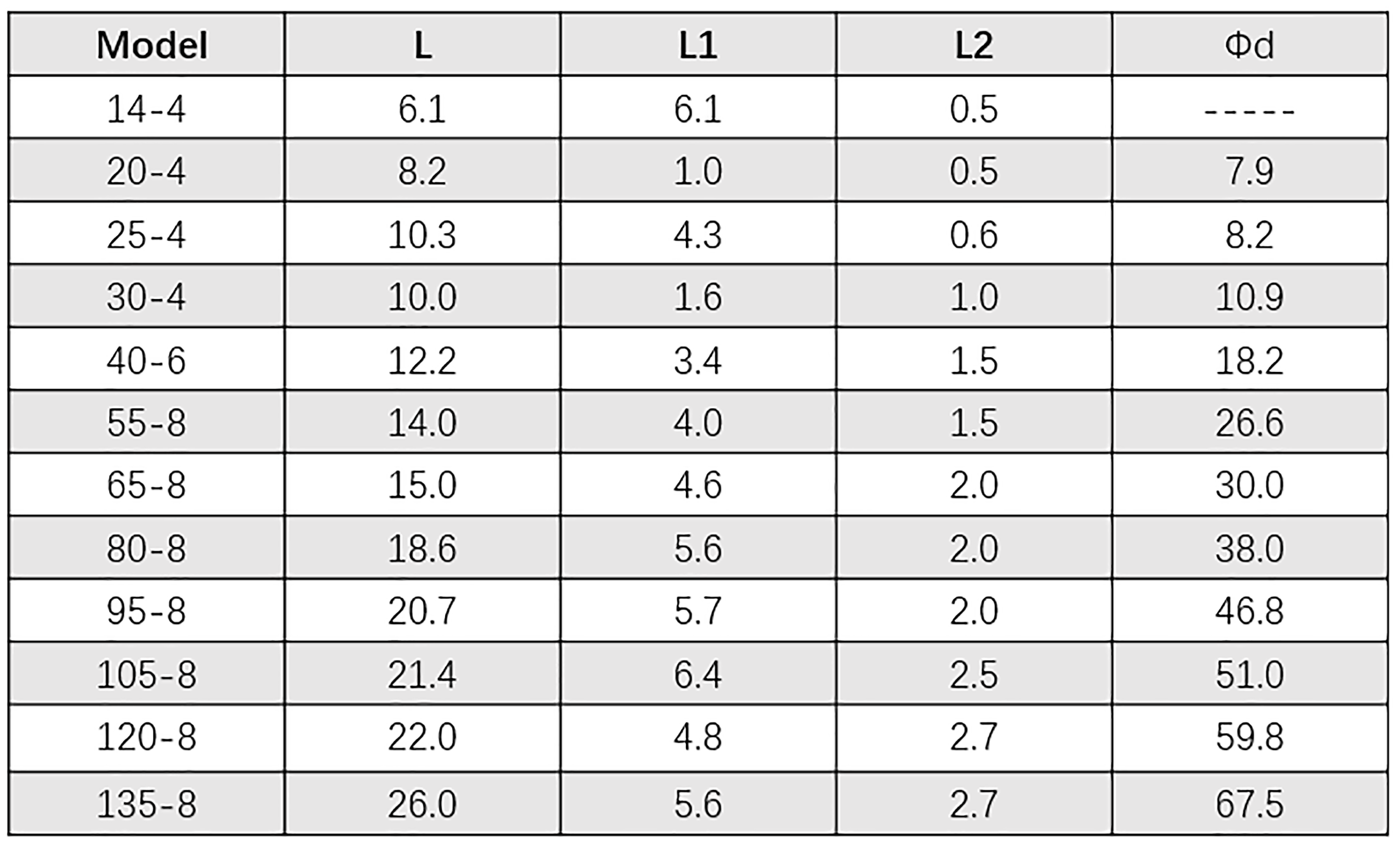

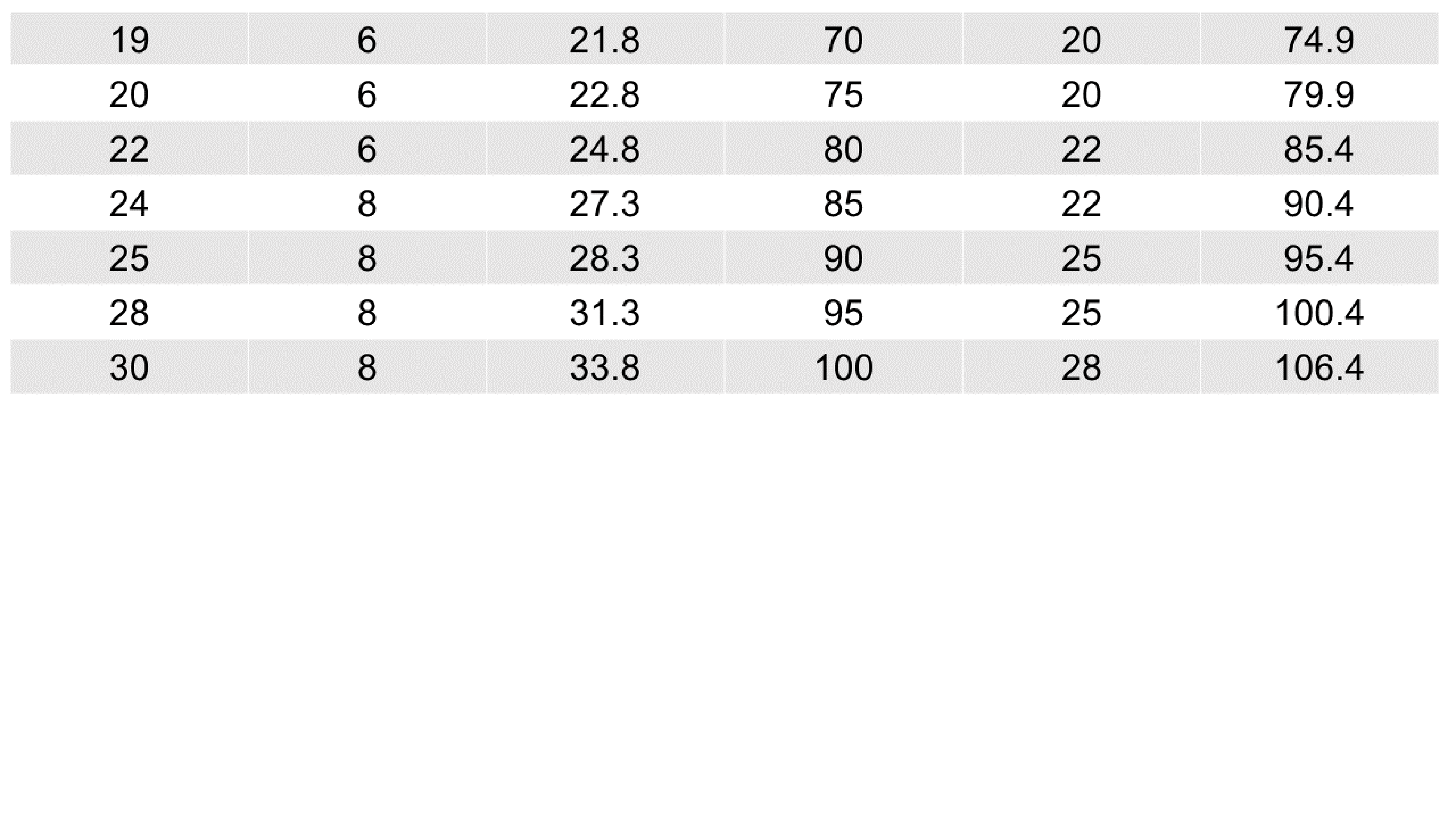

High-load capacity units with precision bearings for ball screw end support.

Integrated linear motion systems with guide rails, ball screws, and motor brackets.

Precision-machined brackets for secure motor mounting and alignment.

Designed for high-speed spindle applications with minimal vibration and high torque.

Lightweight, high-strength long-span couplings for reduced inertia and high-speed use.

Tailored coupling designs based on specific torque, speed, and misalignment requirements.

We provide comprehensive engineering support to ensure optimal coupling selection, installation, and performance.

Understand radial, angular, and axial misalignment tolerances for different coupling types.

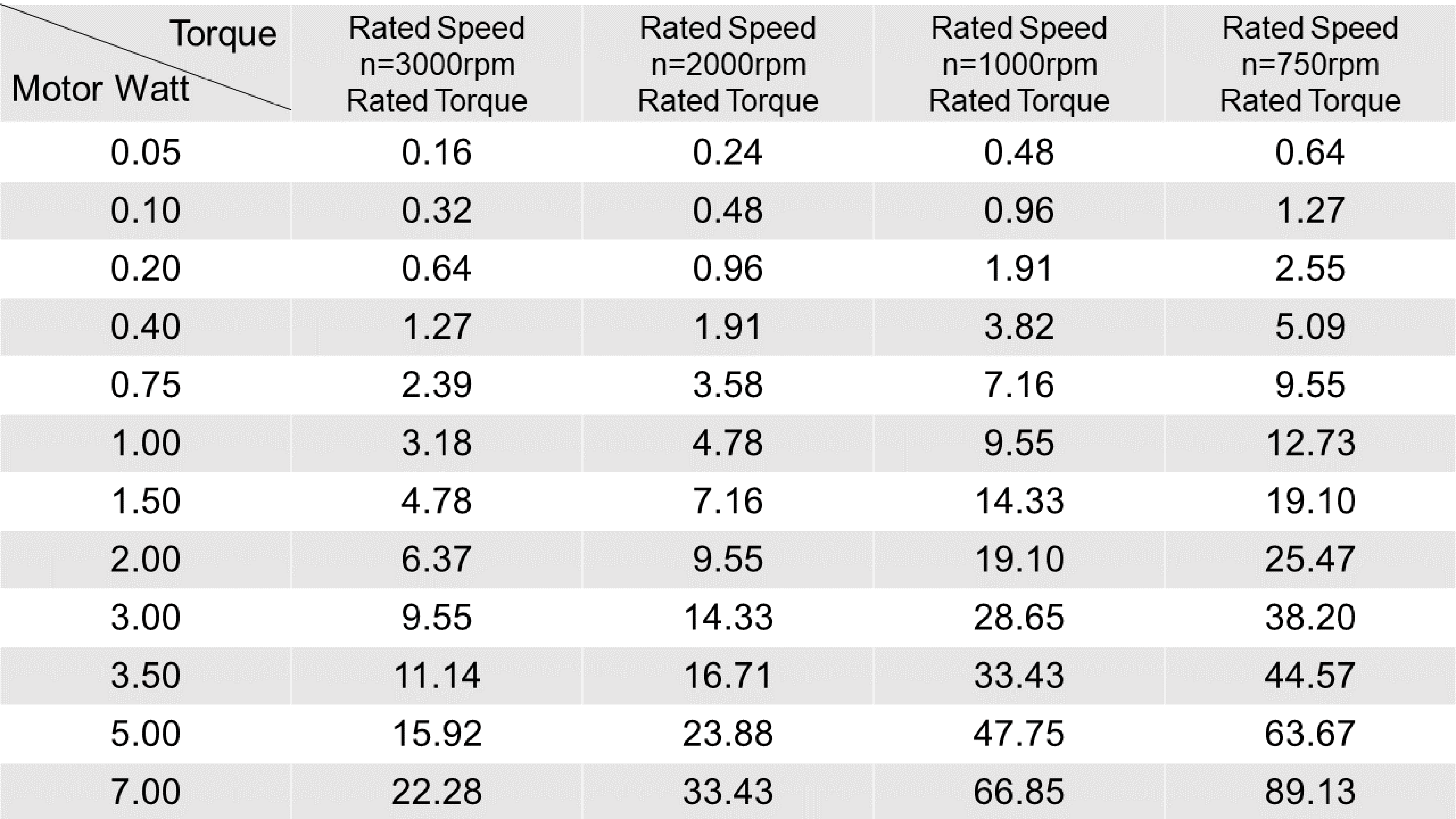

Selection guide for jaw coupling spiders based on torque, temperature, and chemical resistance.

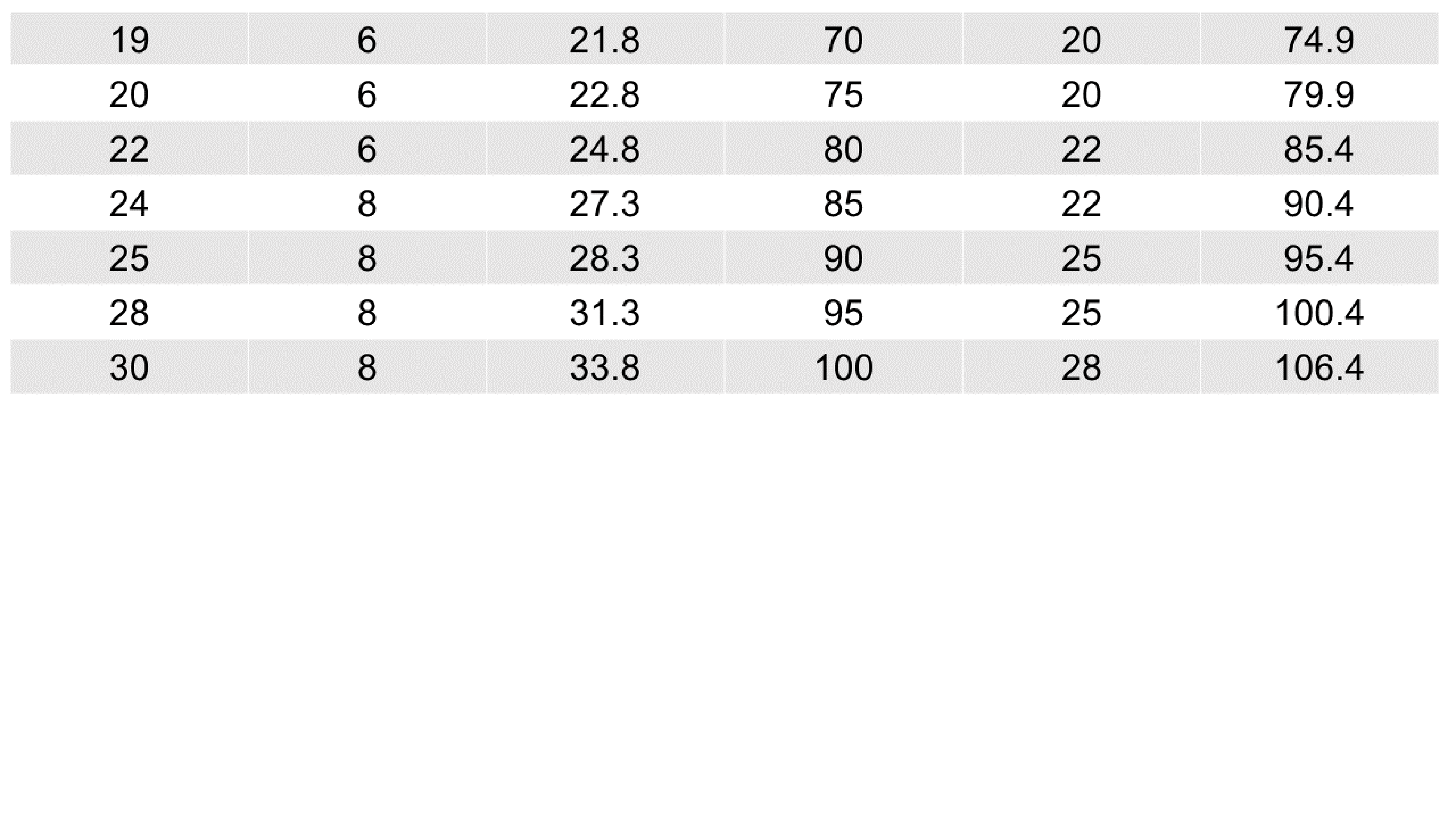

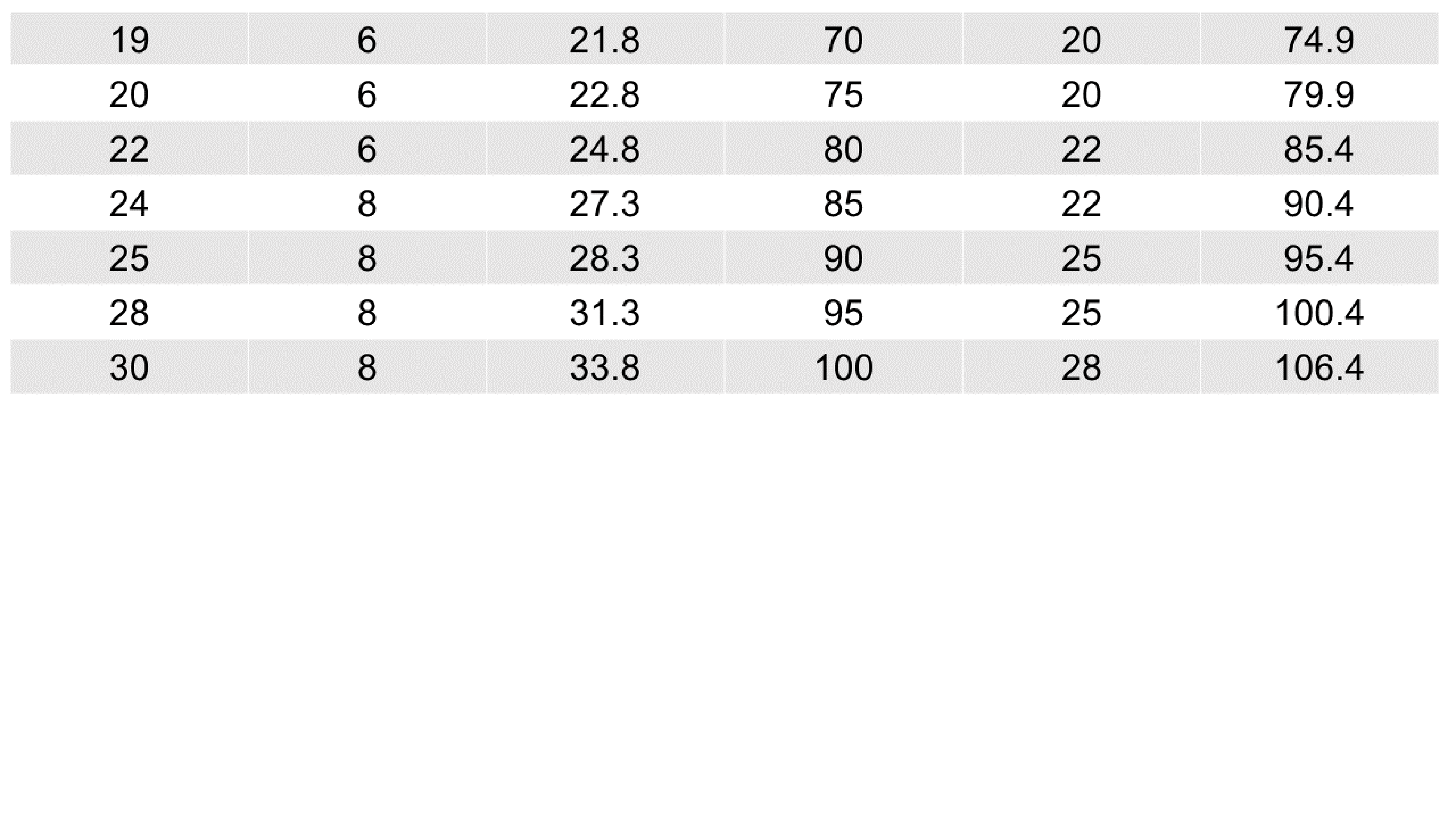

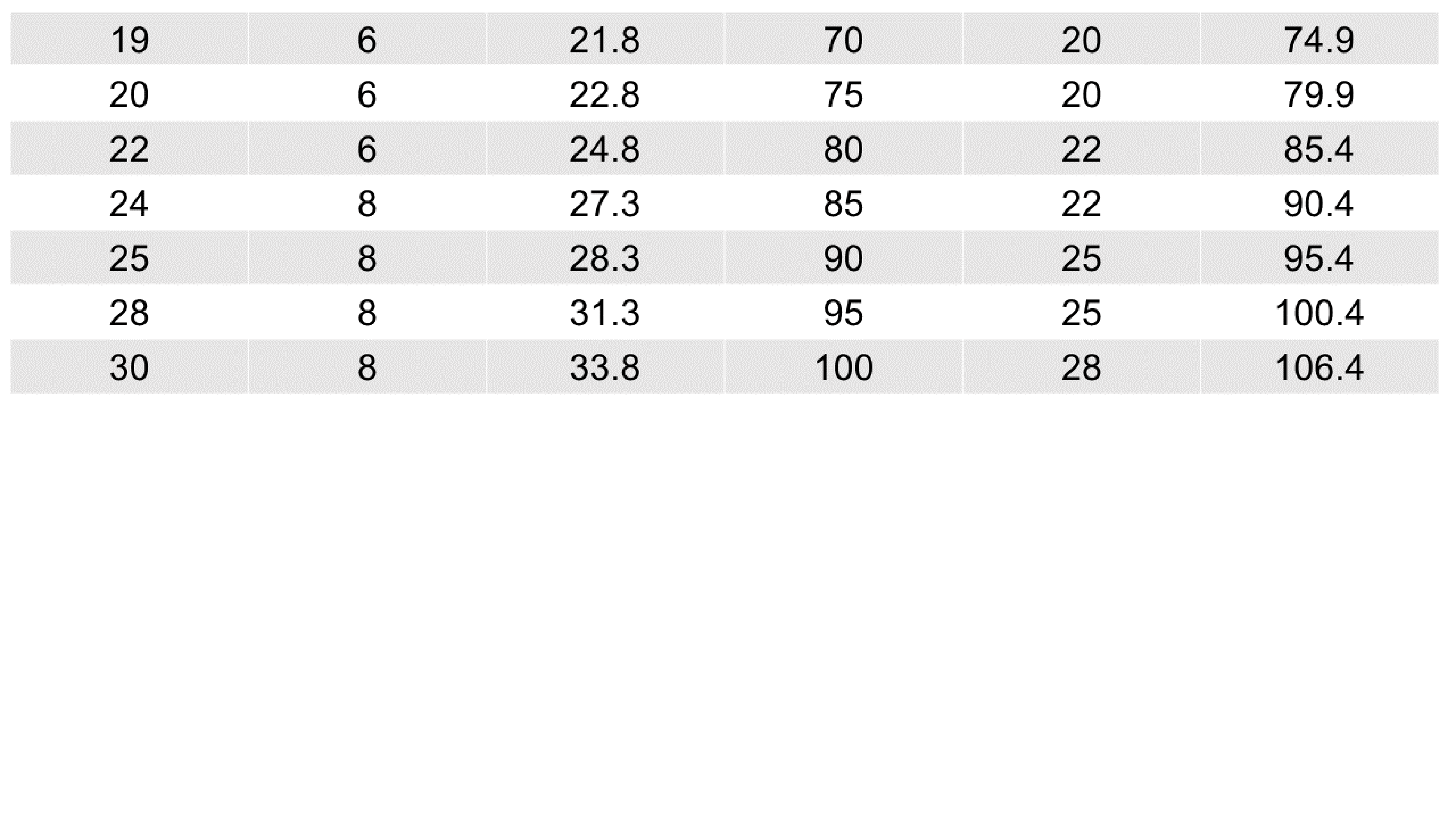

Reference charts for standard keyway dimensions and tolerances.

Precision fit guidelines for shaft and hub to prevent slippage and wear.

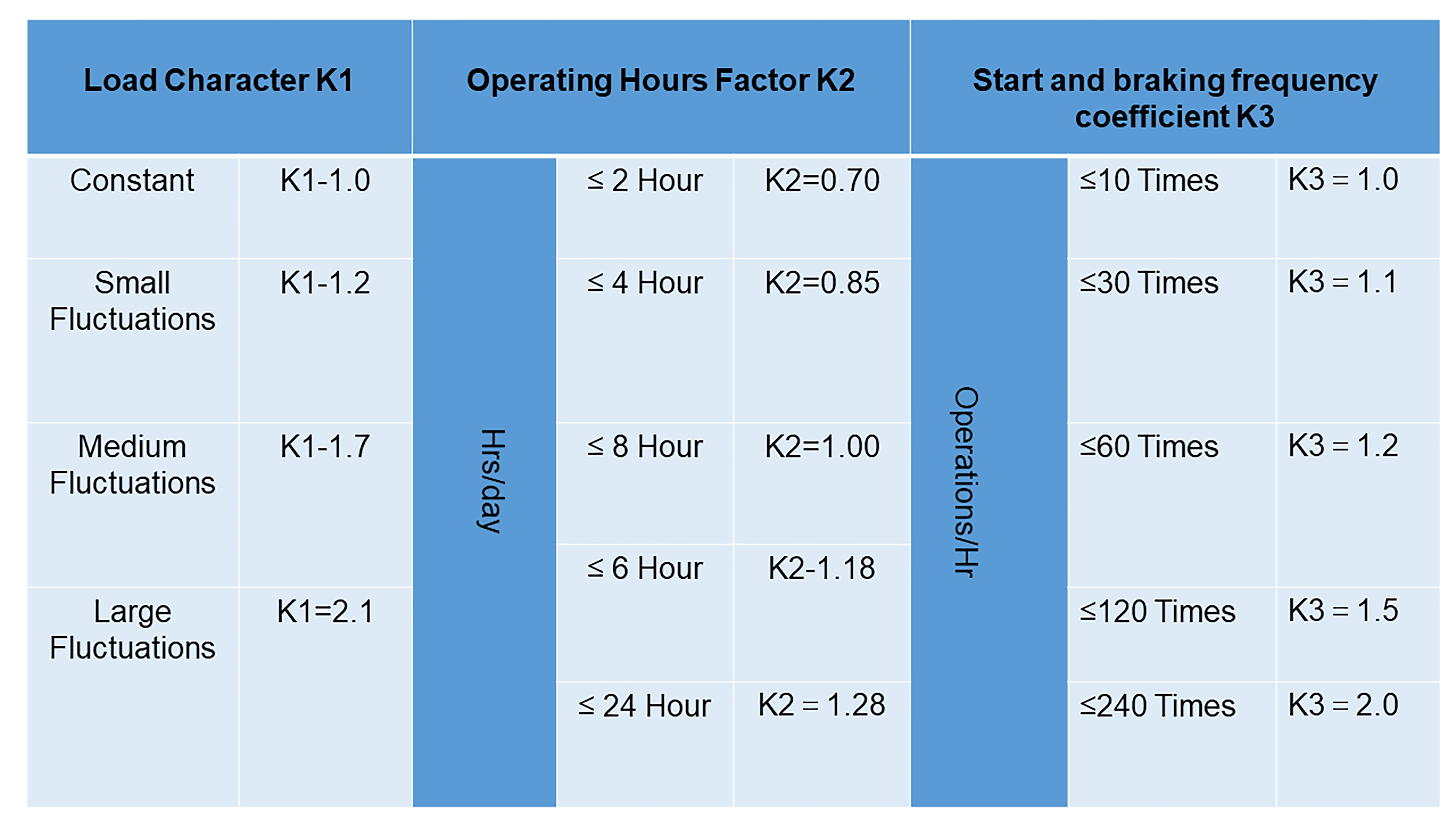

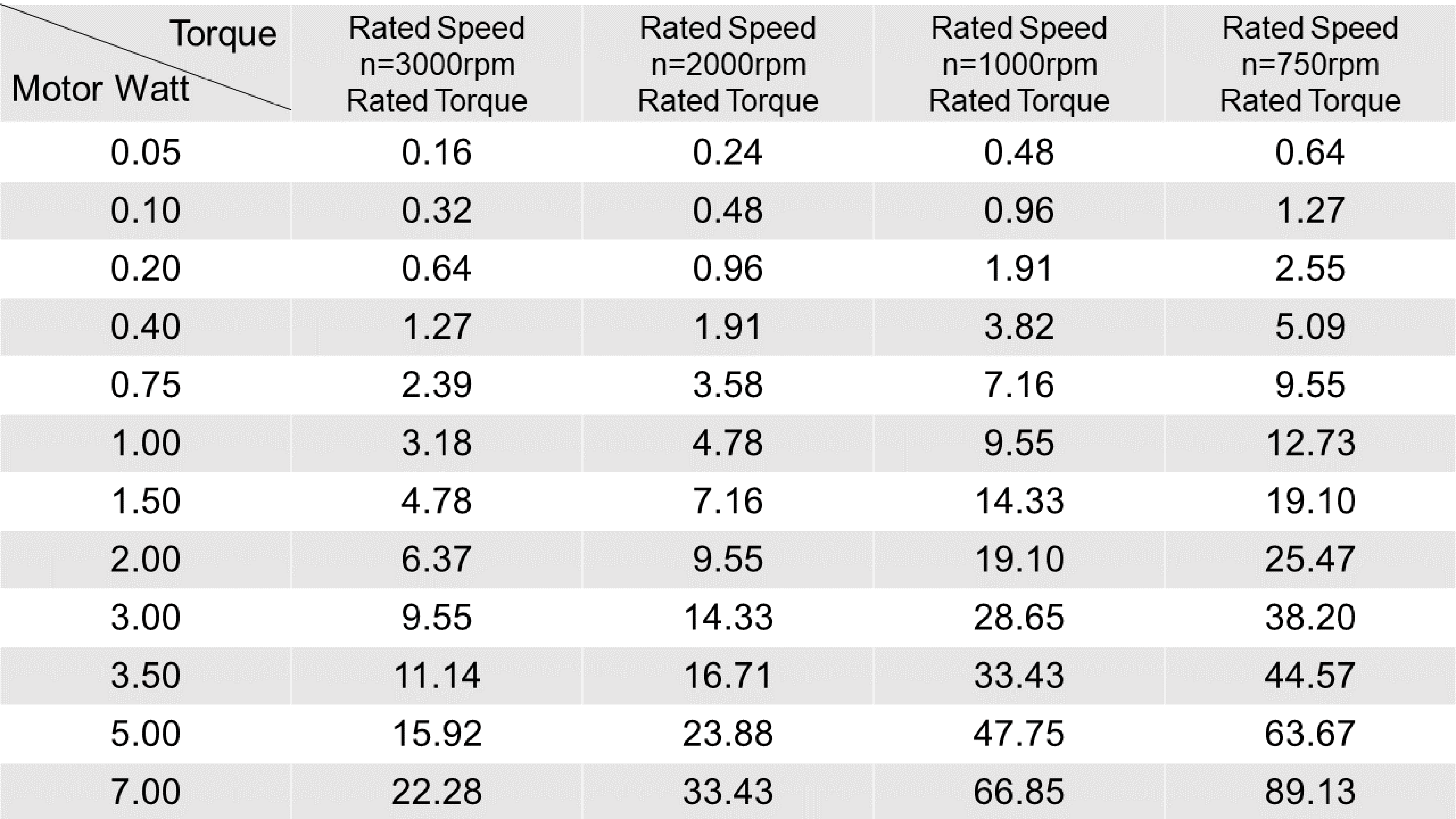

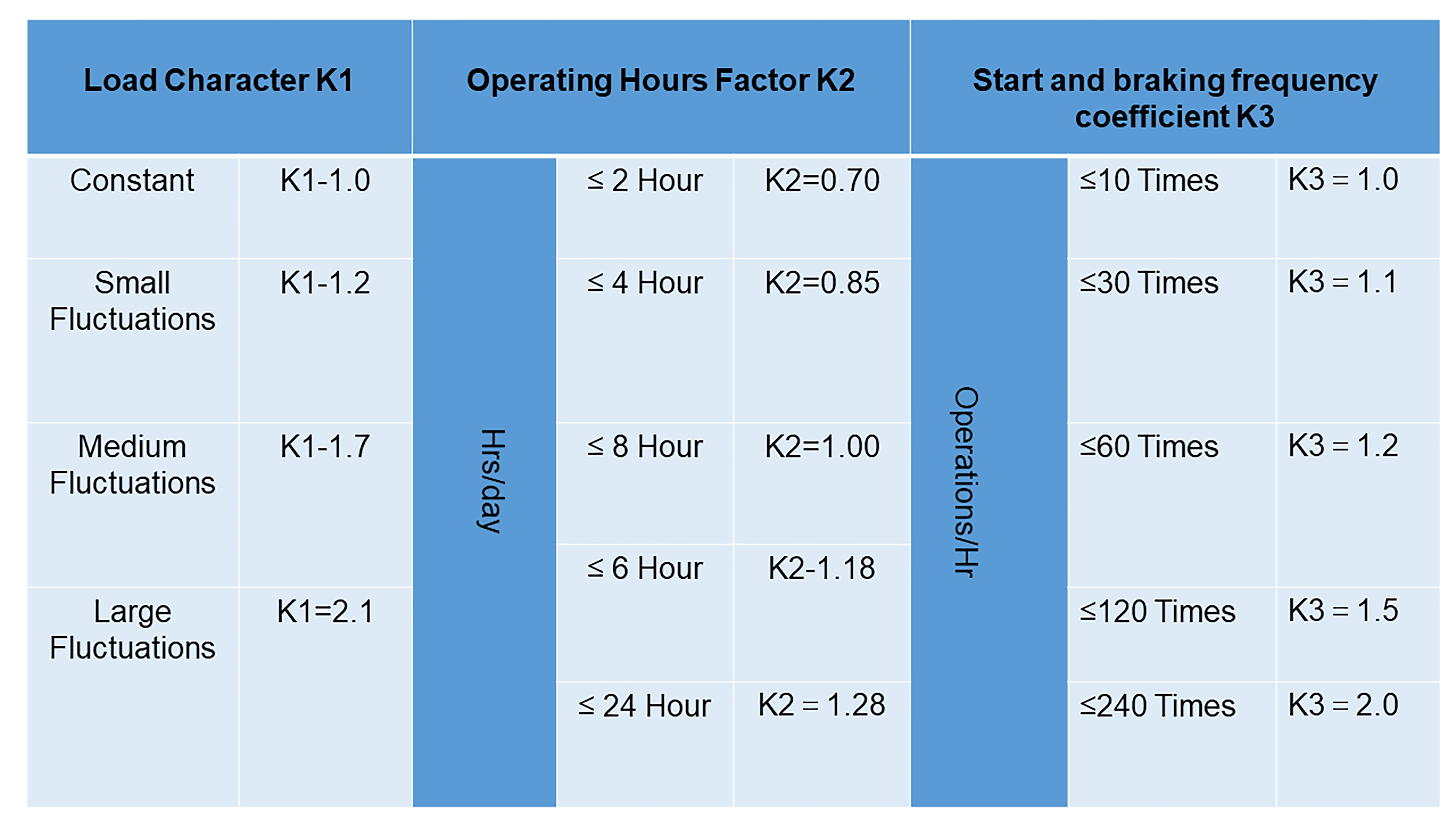

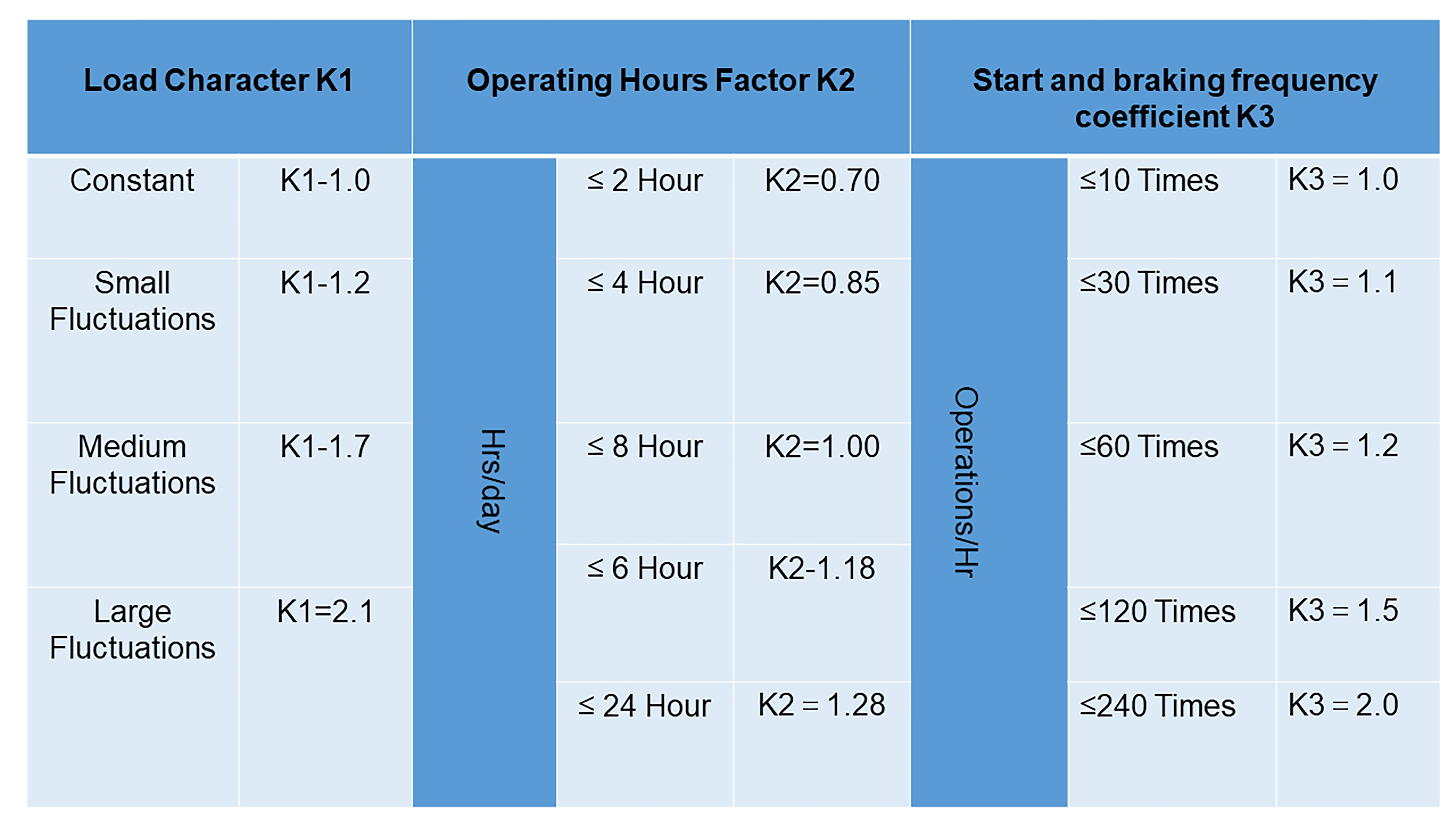

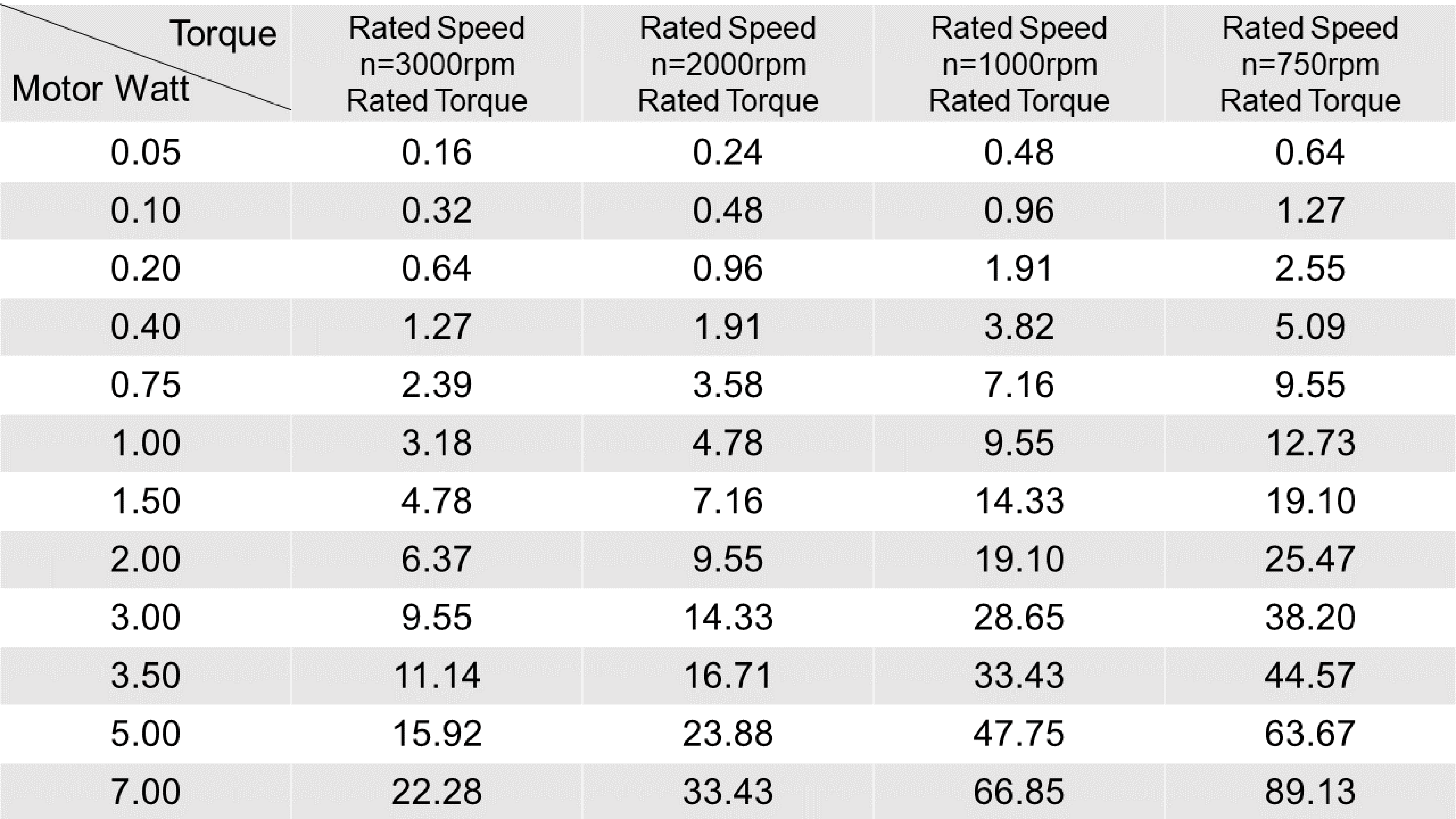

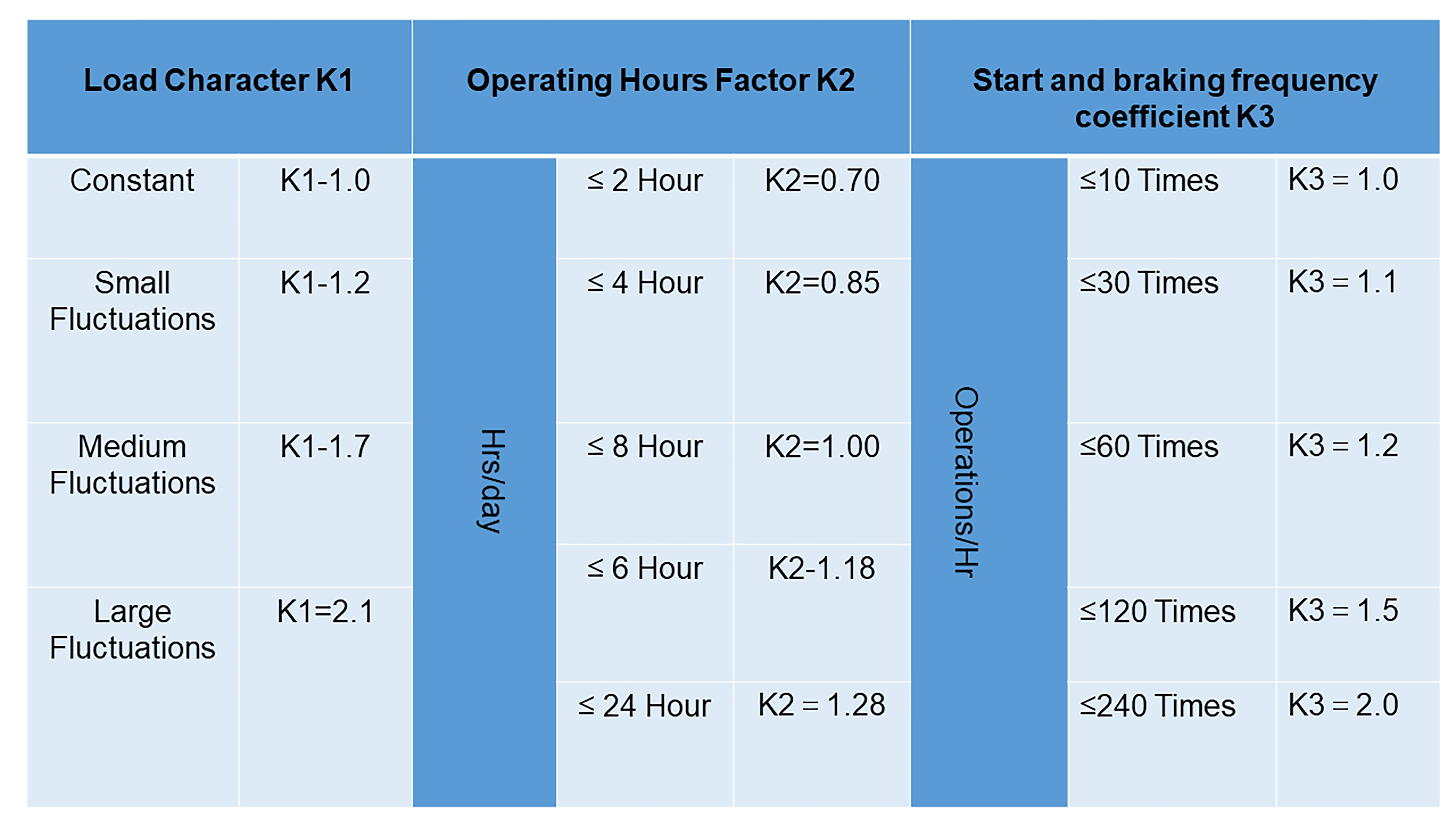

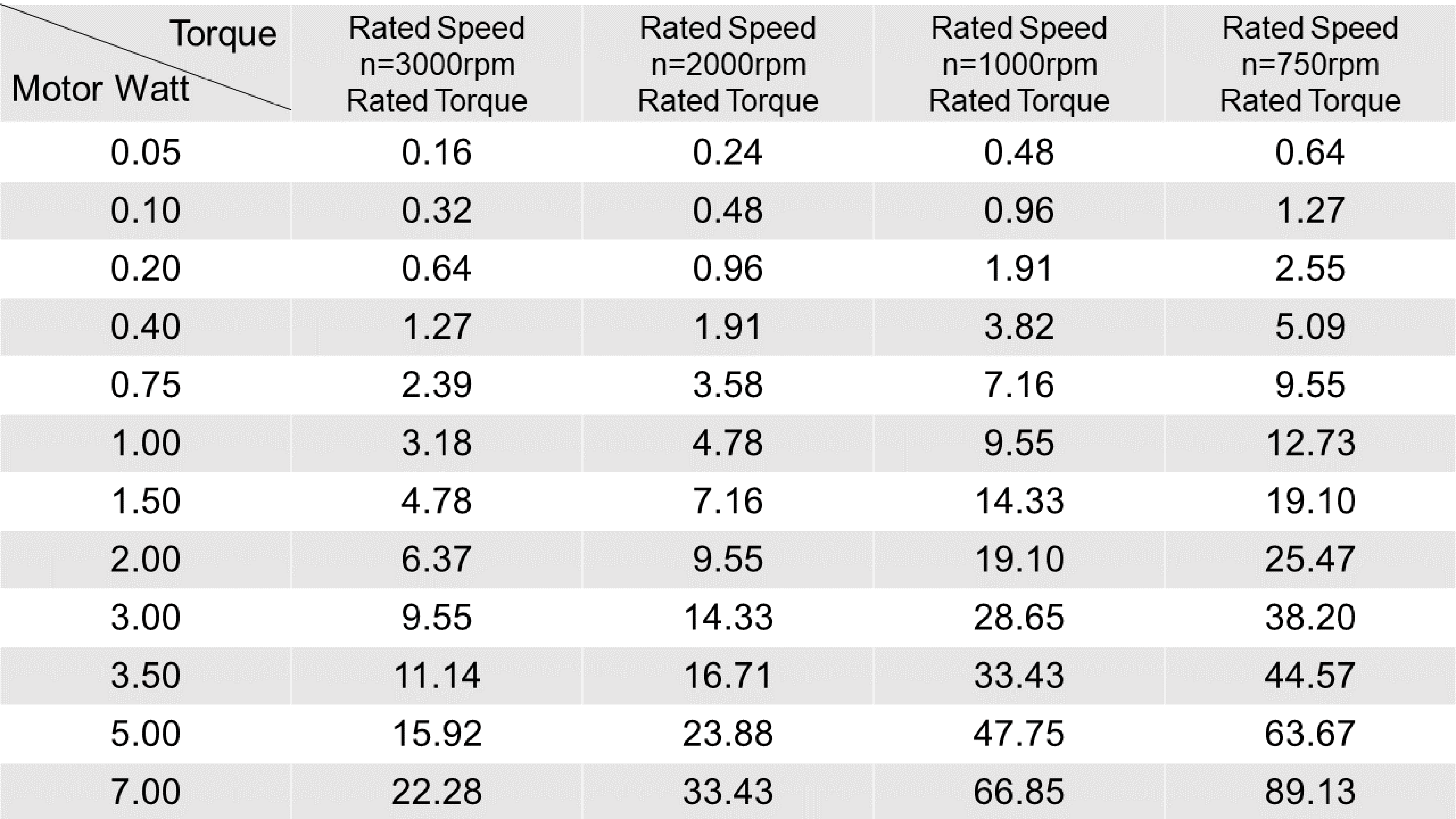

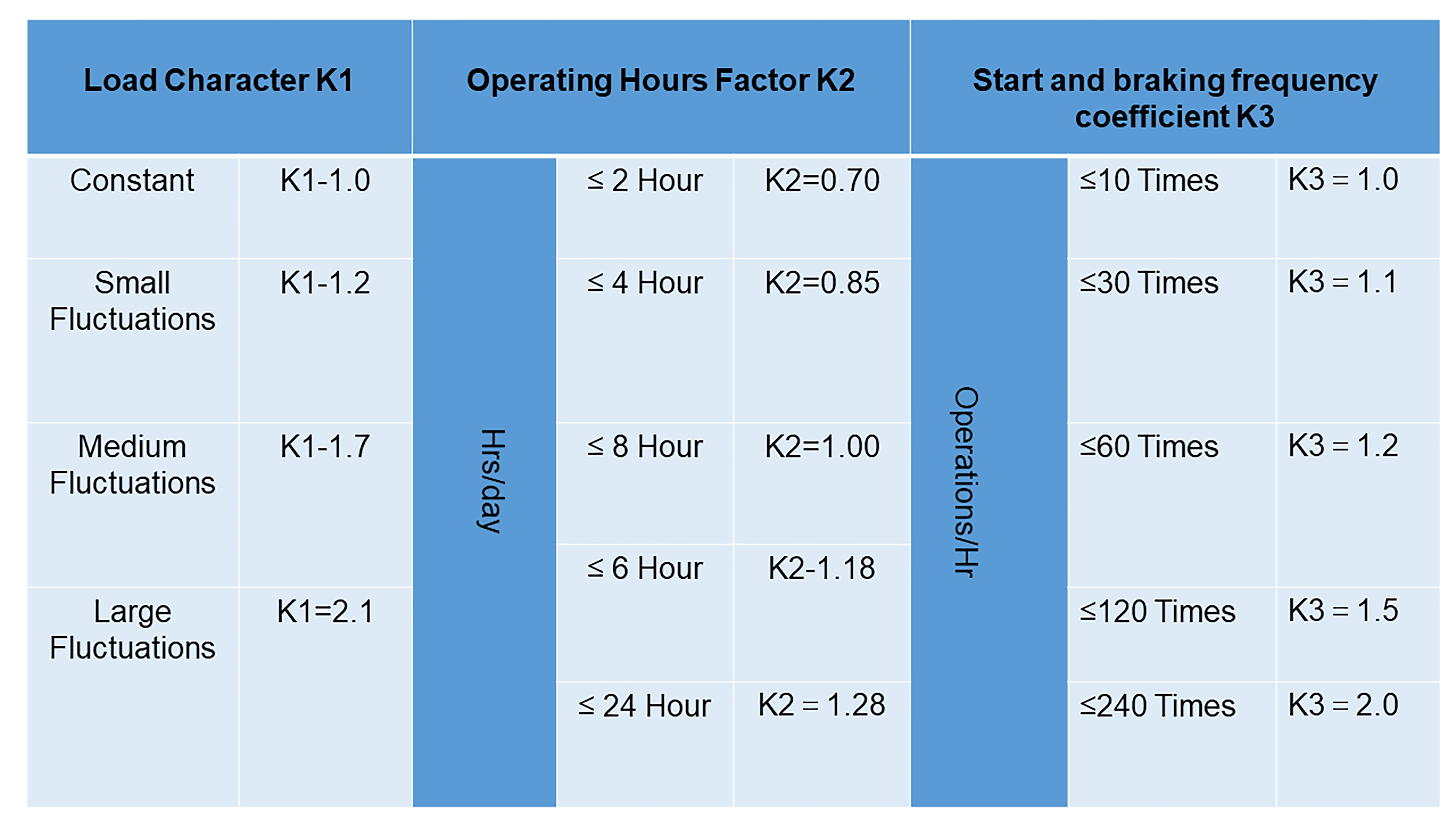

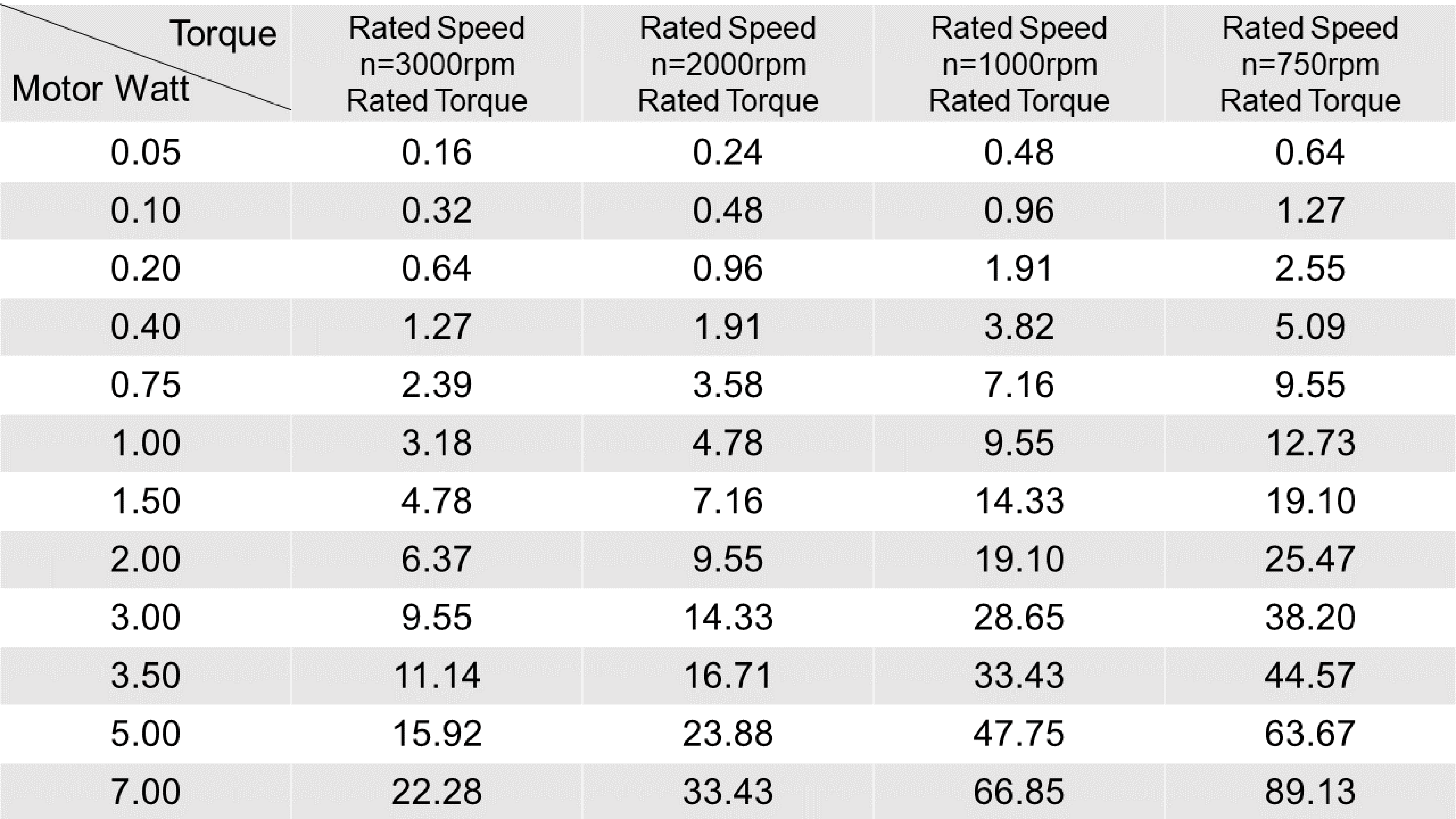

Step-by-step method to calculate required torque with service factors.

Clamp, set screw, and flange mounting options with pros and cons.

Identify imbalance, misalignment, looseness, wear, and resonance through vibration analysis.

Professional techniques including laser alignment and dial indicator methods.

Avoid common failures by selecting the right coupling for your application.

Disc couplings use thin metallic discs for flexibility, offering zero backlash and high torsional stiffness. Jaw couplings use elastomer spiders to absorb shock and dampen vibration, making them better for misalignment and less rigid applications.

Consider torque, speed, misalignment type, environmental conditions, and required service life. Our technical guides and engineers can assist with proper selection to avoid premature failure.

Yes, many of our couplings, especially disc and bellows types, are precision balanced for high-speed operation up to 20,000 RPM or more, depending on size and model.

Yes, we provide OEM and ODM services. Our engineering team can design and prototype couplings based on your specific requirements for size, torque, material, and performance.

Our manufacturing processes comply with international quality standards. We follow strict material and dimensional tolerances to ensure reliability and interchangeability.

For product inquiries, technical support, or custom solutions, visit our official website to contact the COUP-LINK team.

Visit Official Website

COUP-LINK – Guangzhou LINK Automation Equipment Co., Ltd.

Address available on official site.

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info