Cylinder Head Resurfacing Machine: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Cylinder Head Resurfacing Machines

The modern cylinder head resurfacing market has matured into an industrial-grade decision. For B2B buyers in the USA and Europe, the risk isn’t choosing a machine—it’s choosing the wrong philosophy of precision, throughput, and cost of ownership.

Why this decision matters

Cylinder heads and blocks demand flat, true contact surfaces with repeatable micron-level accuracy. Today, resurfacing spans cast iron and aluminum, supports car and truck capacities, and must deliver high-volume consistency with quality assurance. The gap widens for shops that still rely on manual or low-speed methods: rework, inconsistent surface finishes, unpredictable cycle times, and rising energy and tooling costs.

What this guide covers

- Standards and methods: Compare milling vs. grinding; understand how CBN and milling heads drive speed and finish.

- Evaluation criteria: Flatness, repeatability, throughput, capacity, power, consumables, serviceability, and safety.

- Market landscape: Ranges from manual belt or low-end resurfacers to mid-range milling machines and CNC-controlled systems with laser sensing and self-sufficient operation.

- Integration: Fixture systems, fixturing, surface measurement, and workflow automation.

- Total Cost of Ownership: Tooling, spares, service networks, uptime strategies, and energy usage.

- Vendor scenarios: Profiles of leading brands and available models to benchmark capabilities.

To orient your selection, the following snapshot contrasts three archetypes:

| Category | Typical Machines | Key Features | Control & Automation |

|—|—|—|—|

| Entry-Level / Budget | SPN800; Storm Vulcan 85B | Belt or grinder; compact | Manual |

| Mid-Range | RP850; VM2000; RP1000 | Milling; head/block capability; inverter control of feed | Manual with electronic feed control |

| Advanced / Heavy-Duty | RP1000 CNC; RP1400.CNC; HBS-2100 | CNC; laser scanning; automation; high precision | CNC and automated operation |

Use this guide to define your performance benchmarks, avoid procurement traps, and build an ROI case aligned to your shop’s volumes and service strategy.

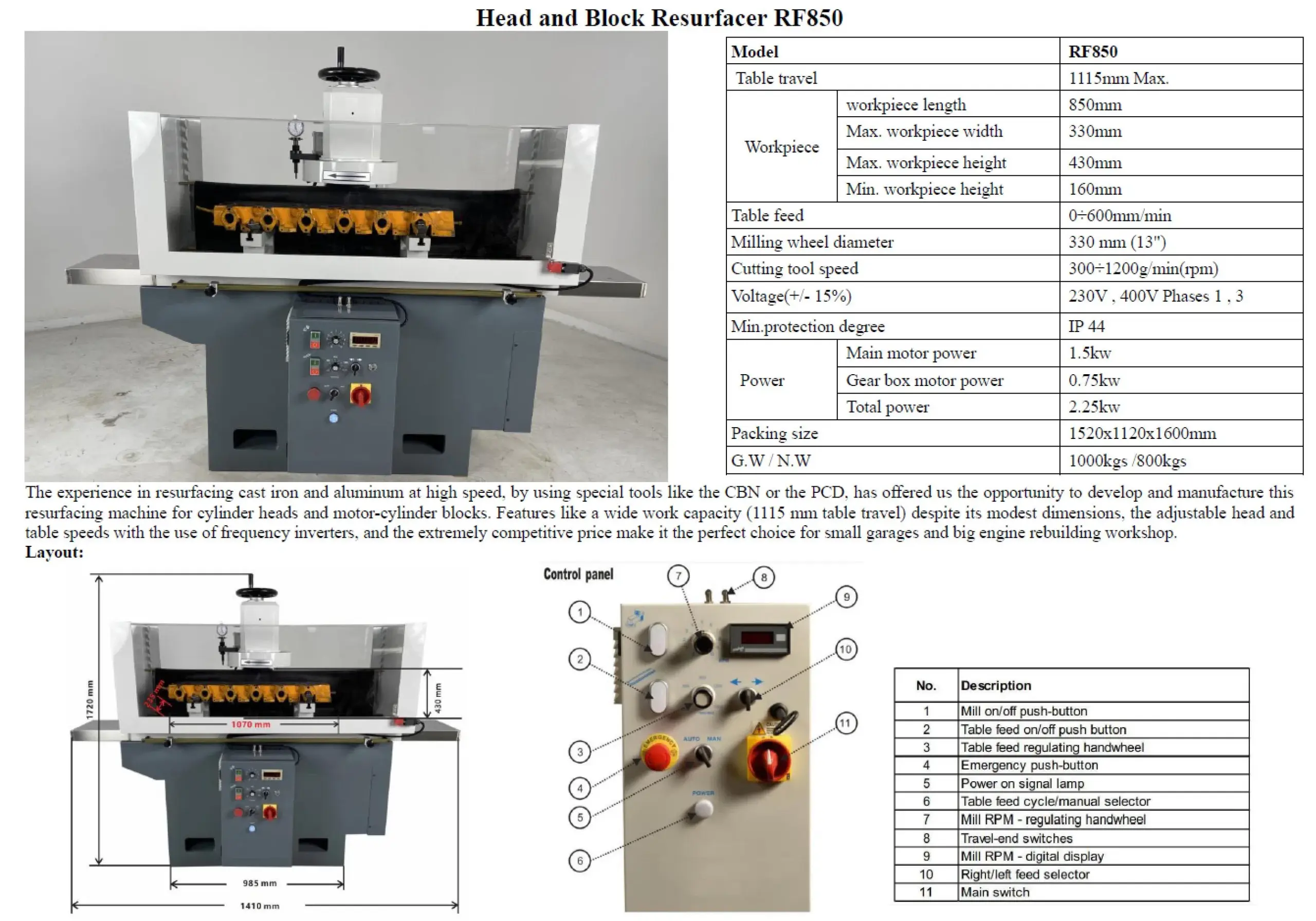

Illustrative Image (Source: Google Search)

Top 10 Cylinder Head Resurfacing Machine Manufacturers & Suppliers List

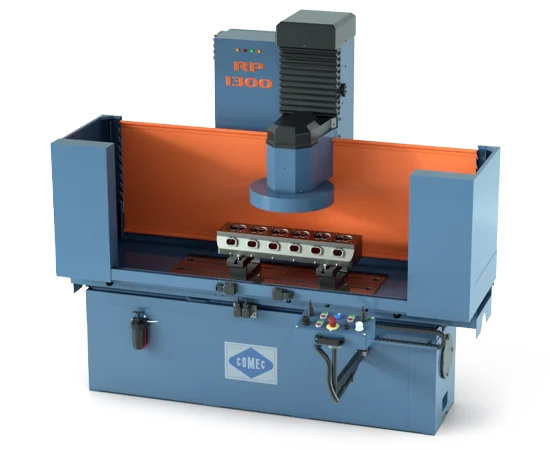

1. Engine Resurfacing Machines | COMEC

Domain: comecpn.com

Registered: 2000 (25 years)

Introduction: Wide selection of CNC cylinder head resurfacing machine of both cars and trucks. Discover them now….

2. Resurfacing Machines | Jamison Equipment

Domain: jamisonequipment.com

Registered: 1999 (26 years)

Introduction: WVN VM2000 cylinder head and block milling machine. Ready to go to work, includes block tooling also. Comec 300/900 CBN Head & Block Resurfacer. $13,500.00….

3. Cylinder Head Repair Machines

Domain: machtrade.us

Registered: 2022 (3 years)

Introduction: MachTrade has been a long-term proud representative of globally renowned cylinder head resurface machine manufacturer, POLEKS. Its range of cylinder head ……

4. Automotive Cylinder Head and Block Resurfacing Machines

Domain: robinsmachines.com

Registered: 2021 (4 years)

Introduction: Robins Cylinder surfacing offers several benefits, including: Improved Engine Performance: Resurfacing ensures proper sealing and prevents leaks ……

5. Cylinder Head Resurfacing Machines and Equipment for Sale

Domain: theultimatetooling.com

Registered: 2016 (9 years)

Introduction: Thanks to partnerships with top brands like Comec and Industrias Kras, we ensure high-quality machinery for cylinder head resurfacing and block milling….

6. Cylinder Head Resurfacing Machinery – Rottler Manufacturing

Domain: rottlermfg.com

Registered: 1998 (27 years)

Introduction: Cylinder head resurfacing is a key function of Rottler equipment. We offer dedicated automatic, manual and CNC surfacers, as well as multi-purpose machining ……

7. Cylinder Head Work – Shop For Valve Adjustment Tools & More!

Domain: regismanufacturing.com

Registered: 2010 (15 years)

Introduction: 5–9 day deliveryShopping for cylinder head work tools & supplies? Shop Regis Manufacturing for the latest selection of valve adjustment tools, honing oils & more!…

Understanding cylinder head resurfacing machine Types and Variations

Understanding Cylinder Head Resurfacing Machine Types and Variations

Resurfacing machines fall into several distinct classes based on machining method, automation, and capacity. Selecting the right type hinges on your mix of materials (cast iron, aluminum), throughput and repeatability needs, and required tolerances.

Type, Features, Applications, Pros/Cons

| Type | Typical Features | Primary Applications | Pros | Cons |

|---|---|---|---|---|

| Manual Belt-Type Resurfacer | High-speed abrasive belt; adjustable workhead; manual feed; often wet capability; economical fixtures | Light- to medium-duty cast iron and aluminum heads/blocks; small shops; resurfacing of gasket surfaces and light warpage | Low cost; simple operation; quick setup; wet capability reduces heat and dust | Lower flatness repeatability under high stock removal; limited automation and integration |

| Conventional (Manual) Milling Machines (CBN/carbide) | Milling with CBN/carbide inserts; manual/pedal feed; variable spindle speed; robust workholding; coolant management | Medium/high-volume resurfacing of cast iron and aluminum heads/blocks; flatness/straightness targets with fixturing | Reliable precision; predictable flatness; lower cost than CNC; mature tooling (CBN) | Operator-dependent consistency; no automatic leveling; longer cycle time for series |

| CNC Milling Machines | CNC control for traverse and depth; optional laser scanning and auto-leveling; automated feeds; digital presets | High-throughput production and large-volume job shops; tight tolerances; mixed head geometries | High repeatability; reduced operator time; auto-scan for uneven parts; better for high-value blocks | Higher capex; more setup for fixturing; trained operator; software/firmware support requirements |

| Wet Grinding/Milling Machines | Wet abrasive wheel or wet CBN; coolant management; dedicated hubs (e.g., R8/Bridgeport compatible) | Head and block resurfacing where wet machining minimizes thermal distortion; heavy stock removal scenarios | Effective heat management; robust stock removal; established tooling ecosystem | Generally slower than milling; more consumables; potential maintenance on hubs and pumps |

| Heavy-Duty/Large-Capacity Systems | Extended work envelope (e.g., 35″ length on Comec 300/900); high-amp spindles; industrial-grade fixturing; 3-phase power | Large diesel truck heads/blocks; marine and heavy equipment; long or tall parts | Capacity to handle large components; stable performance at scale | Larger footprint; higher power and coolant requirements; more expensive per setup |

Manual Belt-Type Resurfacer (e.g., COMEC SPN800)

- Core method: high-speed abrasive belt resurfacing with adjustable console and variable forward speed via inverter.

- Materials: designed for cast iron and aluminum.

- Applications: light to medium-duty resurfacing of heads/blocks; gasket surface restoration; warpage correction where flatness requirements are moderate.

- Operational notes: wet operation typically reduces thermal distortion and dust; manual feed requires operator control to maintain consistent finish.

- Pros: low cost; simple; quick setup.

- Cons: lower flatness repeatability under heavy stock removal; operator-dependent results; limited automation.

Conventional (Manual) Milling Machines (CBN/carbide) (e.g., Winona Van Norman VM2000; COMEC RP330/RP850/RP1000/RP1300/RP1400)

- Core method: milling using CBN or carbide inserts for precision flatness and finish; variable spindle speed and feed control.

- Materials: cast iron and aluminum; high-speed milling for series production.

- Applications: medium/high-volume resurfacing with robust fixturing; flatness and straightness targets; head and block resurfacing.

- Operational notes: use dedicated fixtures for repeatability; coolant is recommended; manual traverse is operator-driven; optional equipment and accessories depend on model.

- Pros: reliable precision at lower capex; predictable flatness; strong tooling ecosystem (CBN hubs/inserts).

- Cons: no automatic leveling; operator skill required; longer cycles for high-mix jobs.

CNC Milling Machines (e.g., COMEC RP1000.CNC, RP1400.CNC)

- Core method: CNC-controlled traverse and depth; optional laser sensor for automatic surface scanning and leveling.

- Materials: cast iron and aluminum; automation suited for series production.

- Applications: high-throughput production shops; jobs requiring tight tolerances and repeatable outcomes; complex head geometries.

- Operational notes: digital presets and automated operation reduce operator involvement; the laser sensor scans surfaces and automates flattening; ensure standard equipment and optional accessories match throughput needs.

- Pros: high repeatability; reduced operator time; automatic leveling; better integration in standardized workflows.

- Cons: higher investment; requires trained operators and service support; integration effort for fixturing and software.

Wet Grinding/Milling Machines (e.g., Kwik Way 860; Sunnen HBS-2100; Comec 300/900 CBN Head & Block Resurfacer)

- Core method: wet abrasive wheel or wet CBN milling with dedicated hubs (e.g., R8/Bridgeport-style), coolant management, and robust fixturing.

- Materials: cast iron and aluminum; wet operation aids thermal control and finish quality.

- Applications: head and block resurfacing, particularly where heavy stock removal or thermal stability is critical; medium shops to industrial operations.

- Operational notes: ensure coolant flow and filtration; use original grinding/milling hubs designed for resurfacing; confirm 3-phase power and tooling availability.

- Pros: effective heat management; proven for heavy material removal; established tooling supply.

- Cons: slower throughput than dry milling in some cases; consumables and coolant maintenance; machine-specific hubs required.

Heavy-Duty/Large-Capacity Systems (e.g., Comec 300/900 CBN Head & Block Resurfacer; large COMEC RP1300/RP1400 variants)

- Core method: extended envelopes (e.g., 35″ length capacity), high-amp spindles, industrial fixtures, and 3-phase power.

- Materials: large cast iron and aluminum heads/blocks; marine, off-highway, and diesel components.

- Applications: big bore diesel heads; long blocks; tall manifolds; heavy equipment service.

- Operational notes: ensure fixturing can secure large components; coolant capacity and chip handling are key; expect 220–480V 3-phase supply depending on model.

- Pros: capacity to handle large components; robust performance at scale.

- Cons: large footprint; higher power and coolant demands; increased investment.

Key Industrial Applications of cylinder head resurfacing machine

Key Industrial Applications of cylinder head resurfacing machine

Target industries, use-cases, and value outcomes

| Industry | Primary application | Detailed benefit |

|---|---|---|

| Automotive service shops | Resurfacing car cylinder heads and blocks | Restores flatness for leak‑free gasket sealing; handles both cast iron and aluminum to standard; consistent results support warranty confidence and lower comebacks |

| Heavy‑duty and fleet maintenance | High‑volume resurfacing of truck and equipment heads | Stable, repeatable milling reduces lead times on critical fleet assets; variable feed control delivers uniform finish and extends component life |

| Diesel service centers | Rebuilding diesel cylinder heads (common‑rail, injector seats, pre‑combustion chambers) | High‑precision milling maintains deck flatness within tight tolerances; compatible with aluminum and cast‑iron for modern diesel architectures |

| Performance and racing | Port matching and precise deck finish before head‑gasket swaps | Programmable control (CNC) standardizes process across batch jobs; laser‑assisted scan automates flattening for high consistency in race‑spec assemblies |

| Remanufacturing and engine rebuilders | Batch processing of core heads and blocks | CNC automation and high‑speed milling streamline throughput; adjustable console and inverter feed provide operator flexibility across diverse part sizes |

| Marine and off‑highway | Resurfacing engine heads and blocks for long‑duty cycles | Reliable flatness on cast‑iron and aluminum improves sealing in harsh environments; fixturing and variable speed controls support repeatable, shop‑floor quality |

| Industrial engine service | Overhaul of stationery engine heads for power generation and compressors | Series production‑grade precision improves assembly quality; standardized operation reduces variability across multi‑machine shops |

Operational notes relevant across applications:

– Machines are suitable for cylinder heads and blocks of both cars and trucks.

– High‑precision milling produces perfectly flat contact surfaces on cast iron and aluminum.

– CNC models enable automated flattening via laser sensor; variable feed control is used to optimize results.

– Adjustable consoles and standard/optional equipment support a range of part sizes and shop preferences.

3 Common User Pain Points for ‘cylinder head resurfacing machine’ & Their Solutions

3 Common User Pain Points for Cylinder Head Resurfacing Machines & Their Solutions

Pain Point 1: Inconsistent Flatness and Surface Quality

- Scenario

- Mixed material cylinder heads (cast iron and aluminum) with varying warpage across makes and models; rework and leakage complaints from downstream assembly.

- Problem

- Manual leveling, feed-rate variability, and soft fixturing yield uneven stock removal, micro-scratches, and finish issues.

- Solution

- Standardize on machines with CNC-controlled milling and laser-assisted leveling. Use variable-speed inverters for consistent feed and rigid fixturing. Choose CBN milling heads for high-speed precision on cast iron and aluminum.

- How it works

- CNC platforms (e.g., COMEC RP1000 CNC, RP1400 CNC) scan and flatten automatically with high precision. Variable feed control via inverter maintains optimal surface finish and flatness; adjustable consoles suit different operators and workpieces.

- Result

- Repeatable flatness and finish reduce rework and sealing failures. Automation also supports series production with stable quality standards.

Features comparison (select models)

| Feature | SPN800 | RP330 | RP850/RP1000 | RP1000 CNC | RP1300 | RP1400 CNC |

|---|---|---|---|---|---|---|

| CNC-controlled | — | — | — | Yes | — | Yes |

| Laser sensor (auto leveling) | — | — | — | Yes | — | Yes |

| Inverter feed control | Yes | Yes | Yes | Yes | Yes | Yes |

| Adjustable console | Yes | Yes | Yes | Yes | Yes | Yes |

| Typical capacity (length) | — | — | — | — | — | — |

| Wheel type (CBN recommended) | Recommended (belt) | CBN compatible | CBN compatible | CBN compatible | CBN compatible | CBN compatible |

Pain Point 2: Throughput and Labor Efficiency

- Scenario

- High-mix shop serving both car and truck cylinder heads and blocks; operator fatigue and uneven cycle times restrict throughput.

- Problem

- Manual leveling, manual traverse control, and frequent setup changes produce bottlenecks and limit series production.

- Solution

- Migrate to CNC machines with laser-guided flattening and automated traverse. Maintain inverters for optimal feed, and standardize fixtures to reduce setup times.

- How it works

- COMEC CNC models (RP1000 CNC, RP1400 CNC) scan the workpiece surface and automate flattening, reducing operator intervention and improving repeatability for series work.

- Result

- Increased productivity with stable quality; shorter cycle times and less operator-dependent variation.

Pain Point 3: Wear, Downtime, and Operating Cost

- Scenario

- Frequent wheel replacements and unexpected downtime due to grinding/surfacing head wear; rising consumable and service costs.

- Problem

- Using grinding hubs with slower material removal and higher heat; manual feed variation accelerates wear and uneven stock removal.

- Solution

- Replace with high-speed CBN milling heads to reduce heat, improve material removal, and extend tool life. Use inverters to match feed to material and maintain consistent removal. Implement preventive maintenance on spindles, bearings, and fixturing.

- Result

- Fewer changeovers, lower consumable cost, reduced rework, and improved machine uptime. For fast upgrades, variable speed kits (e.g., Storm Vulcan 85B Variable Speed Kit) offer a cost-effective retrofit to stabilize feed and finish.

Technology references

- COMEC: Engine Resurfacing Machines (SPN800, RP330, RP850, RP1000, RP1000 CNC, RP1300, RP1400 CNC). CNC production cycle, laser sensor-based automation, adjustable console, inverter-controlled forward speed, standard/optional accessories. Suited for cast iron and aluminum at high speed.

- Jamison Equipment (resale listings and parts): Offers Sunnen HBS-2100, Comec 300/900 CBN, Winona Van Norman VM2000, Storm Vulcan/Stormill surfacers, and upgrades like Storm Vulcan 85B Variable Speed Kit. Useful for benchmarking capabilities and retrofit opportunities.

Strategic Material Selection Guide for cylinder head resurfacing machine

Strategic Material Selection Guide for Cylinder Head Resurfacing Machines

Resurfacing performance hinges on three material choices that must be aligned with the workpiece and the machine’s capabilities: cutting/grinding media, machine/holder materials, and tooling strategy. The right combination reduces cycle time, maintains flatness and surface integrity, and preserves coolant life.

- Cutting/grinding media

- Cast iron heads: use cubic boron nitride (CBN) grinding or aluminum oxide (Al2O3) belts; keep speeds moderate to avoid heat, and dress or switch media to maintain sharpness.

- Aluminum heads: use CBN or silicon carbide (SiC) belts; prefer dry or low-foam, non-staining coolants; avoid aluminum contamination in coolant systems dedicated to iron.

- Overlays and hardened alloy seats: prefer CBN hubs or grinding heads to maintain profile and reduce glazing.

-

Diamond is not recommended for iron overlays due to low compatibility; reserve diamond for non-ferrous, non-ferrous MMC, or ceramics.

-

Machine and holder materials

- Steel and aluminum construction for precision rigidity and corrosion resistance.

- Use hardened steel fixturing plates; if both iron and aluminum are processed, segregate or dedicate fixtures to avoid cross-contamination that affects wetting and finish on aluminum.

-

Align fixture geometry with the machine’s bed and head geometry to achieve the “perfectly flat contact surfaces” CNC milling lines (e.g., COMEC RP series) are engineered to deliver.

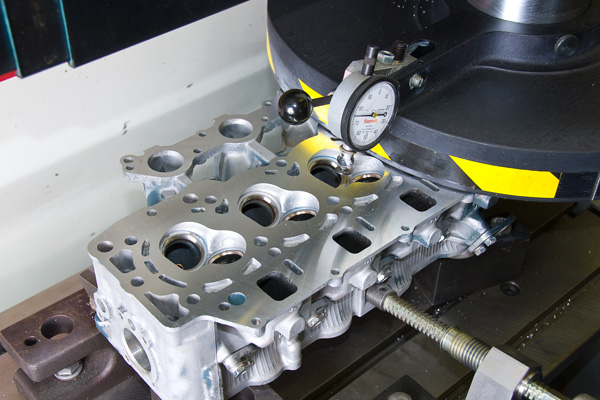

Illustrative Image (Source: Google Search)

-

Tooling strategy by machining mode

- Belt sanding: efficient for light material removal on cast iron and aluminum; manage belt change intervals to prevent smearing and heat.

- Milling (CNC): high-precison approach for series production; COMEC’s CNC systems (e.g., RP1000 CNC, RP1400.CNC) use precise motion control for consistent results.

-

Rotary grinding with CBN hubs: suitable for both iron and aluminum; control speed, feed, and coolant to maintain flatness and surface finish.

-

Coolant and cleanliness

- Use water-soluble coolants for aluminum to aid chip evacuation and heat control; keep systems aluminum-free.

- Cast iron can run dry or with minimum fluid; if wet, use non-staining fluids and manage filtration.

-

Maintain clean fixture surfaces and dry sealing faces before clamping; contamination often forces extra passes.

Illustrative Image (Source: Google Search)

-

Operational controls

- Use the machine’s adjustable console and variable-speed feed (via inverter) to match material removal rates and surface finish targets.

- For CNC machines with laser sensors (e.g., COMEC RP1000 CNC), verify sensor calibration and material-specific parameters before running mixed materials.

Analysis of materials used in reference equipment

- COMEC machines: advanced milling line with CNC control delivers high-precision flatness. Models span manual (e.g., RP850, RP1000) to fully automatic CNC (e.g., RP1000 CNC, RP1400.CNC). The CNC models use advanced control to automate the flattening process.

- Jamison Equipment listings: highlights common abrasives and toolings such as “CBN Milling head,” “CBN Head & Block Resurfacers,” and “Grinding Hubs,” indicating widespread adoption of CBN for head/block resurfacing and the availability of CBN hubs for retrofitting.

Abrasive comparison for resurfacing

| Abrasive | Ideal workpiece | Typical tools/machines | Advantages | Considerations |

|---|---|---|---|---|

| Cubic boron nitride (CBN) | Cast iron, cast steel, aluminum | CBN grinding heads/hubs; CNC/Comec CBN-equipped resurfacing; Jamison “CBN Milling head” | High removal rates, long life, minimal glazing; good on iron and aluminum; heat resistant | Requires adequate machine power; cost higher than conventional abrasives; keep wheels balanced |

| Diamond | Non-ferrous metals (e.g., pure aluminum, MMC), hard non-metallics | Specialized grinding discs or hubs | Excellent on soft non-ferrous; strong edge retention | Not recommended for iron overlays (graphite interaction); risk of smearing on aluminum without proper control |

| Aluminum oxide (Al2O3) | Cast iron | Belts/discs (e.g., COMEC SPN800 belt resurfacer) | Cost-effective; widely available | Can glaze with heat; slower on aluminum; requires frequent dressing/change |

| Silicon carbide (SiC) | Aluminum, gray cast iron | Belts/discs; CBN alternatives on aluminum | Sharp edges; good for aluminum | Faster wear on iron; control heat to avoid smear; use dry/low-foam coolant if needed |

Machining parameters (guideline)

| Workpiece | Cutting media | Recommended machining mode | Coolant | Fixture and notes |

|---|---|---|---|---|

| Cast iron (gray) | Al2O3 belt or CBN hub | Belt for light removal; grinding for rapid stock; CNC milling for high precision | Dry or minimal coolant; avoid contamination | Keep fixture surfaces clean; manage feed/speed via inverter; maintain wheel balance |

| Aluminum alloys | SiC belt or CBN hub | Belt for light removal; CBN grinding for moderate-heavy | Water-soluble or dry; keep aluminum-free system | Clamp gently to avoid distortion; prioritize chip evacuation; monitor surface smear |

| Overlays/hardened alloys | CBN hub | Rotary grinding or CNC milling | Moderate coolant to control heat | Inspect overlay hardness before selecting speeds/feeds; verify CBN bond selection |

| Mixed production (iron and aluminum) | CBN hub or belt | Both | Separate coolant circuits or run dry for one | Dedicate fixturing per material; validate runout and flatness before batch start |

Notes:

– COMEC’s CNC line emphasizes high-precision milling and series production; for high-throughput iron/aluminum processing, consider models with CNC and automated flatness checks.

– If upgrading legacy resurfacers, ensure CBN hubs and associated spindle specs are compatible; keep fixture height and clamping geometry within the machine’s working envelope.

In-depth Look: Manufacturing Processes and Quality Assurance for cylinder head resurfacing machine

In-depth Look: Manufacturing Processes and Quality Assurance for Cylinder Head Resurfacing Machines

Scope

– End-to-end manufacturing and quality assurance for cylinder head resurfacing machines—machined housings, precision slides and lead screws, CNC controllers, grinding/milling heads (CBN/SiC hubs), fixtures, spindles, power transmission (inverters), and control panels.

– Designed to machine cast iron and aluminum heads and blocks, producing flat, contact-ready sealing surfaces through high-speed milling/grinding cycles.

Reference context

– COMEC machines (SPN800, RP330, RP850, RP1000, RP1300, RP1400.CNC, RP1000.CNC) use CNC-controlled milling with adjustable consoles and inverter-controlled feed speeds for consistent quality; RP1000.CNC adds a laser sensor for automatic surface scanning and flattening.

– Machining ranges cited: ~35 in length capacity (e.g., RP330/900), typical 220 V 3-phase supply (subject to region), CBN milling heads.

Manufacturing process overview

| Step | Key activities | Process focus |

|---|---|---|

| Prep & materials | Structural steel and cast iron housings; CNC-machined frames; ball screws/linear guides; bearings; spindle modules; grinding/milling hubs; electrical/control components | Sourcing, receiving inspection, storage & traceability |

| Machining & forming | CNC machining of bases, columns, gibbs, worktables; precision boring/turning of spindles; grinding of journals and ways; hard coating/surface treatments | Flatness, parallelism, squareness; vibration control |

| Assemblies | Slideway assembly (linear rails/ballscrew); spindle and drive assembly; CNC controller and I/O; grinding/milling heads; fixturing; cooling/lubrication | Alignment and preload; thermal stability; safety interlocks |

| Control & electronics | PLC/CNC controller configuration; inverter parameters; HMI console; laser scanning module (CNC systems) | Integration, fail-safe logic, repeatability |

| Final assembly | Component mating; cable harnessing; guard installation; fluid lines; ergonomics | Accessibility, serviceability |

| Calibration & testing | Geometric verification (flatness/parallelism), runout, thermal drift checks; acceptance protocol; demo cuts on iron/aluminum | Conformance to specified tolerances and repeatability |

| Documentation & marking | CE/UL marking; wiring diagrams; manuals; certificates; software version control | Compliance and traceability |

Forming and machining controls (representative)

| Feature | Typical method | Why it matters |

|---|---|---|

| Worktable/workpiece flattening | Milling with CBN hub; laser-guided flattening (CNC models) | Ensures head/block sealing surface flatness |

| Slideway straightness/parallelism | Ground ways; linear guides with zero-clearance preloads | Stable feed, low chatter |

| Spindle runout and balance | Precision boring; dynamic balancing | Surface finish and tool life |

| Rigid fixture design | Mechanical clamps, adjustable stops, locating pins | Minimizes vibration; safe, repeatable fixturing |

| Surface roughness | Feed control via inverter; CBN/SiC grinding; coolant/lubrication | Sealing performance and finish consistency |

Assembly and integration checkpoints

| Subsystem | QA checks | Acceptance criteria (illustrative) |

|---|---|---|

| Linear motion (X/Y) | Straightness, backlash, repeatability | Within machine spec; smooth motion with no stick-slip |

| Spindle assembly | Runout, vibration, thermal behavior | Within spec; no excessive heat or noise |

| Feed drive (inverter) | Acceleration, speed range, torque response | Stable speed, no oscillation under load |

| Laser/autoscan (CNC) | Detection threshold, alignment, repeatability | Correctly identifies contours; repeatable flattening results |

| Fixtures | Clamp rigidity, locating accuracy | Heads/blocks securely held without deflection |

| HMI/console | Key functions, emergency stop, interlocks | Meets region-specific safety requirements (e.g., ISO 12100 principles) |

Quality assurance and standards alignment

| QA domain | Typical standard/practice | Evidence/records |

|---|---|---|

| Quality management | ISO 9001:2015 | QMS procedures, audits, CAPA |

| Environmental management | ISO 14001 | Environmental aspects/controls |

| Functional safety (control systems) | ISO 13849-1 (EU) / UL 508A (US) | Safety circuits, risk assessment, wiring diagrams |

| Risk & safety design | ISO 12100 (machinery safety principles) | Risk matrix, guards, labels, interlocks |

| EMC and electrical safety | EU: EMC Directive; US: UL/NFPA 70 | EMC test reports; UL-listed components; CE marking |

| Geometrical product specification | ISO 1101, ISO 14236 (machine tool coordinate systems) | GD&T on drawings; inspection results |

| Tolerancing system | ISO 286 (limits and fits) | Part and assembly tolerances |

| Roughness measurement | ISO 4287 (profile method) | Surface roughness charts |

| Electrical schematic and PLC safety | EN 60204-1 (machinery electrical equipment) | Wiring diagrams; PLC logic documentation |

| Spindle performance | ISO 230 series (machine tool acceptance tests) | Acceptance test logs and traces |

Notes on standards

– Standards cited reflect commonly applied frameworks for machine builders in USA/EU; certification scope and pathways vary by model and destination market.

Illustrative Image (Source: Google Search)

Factory tests and acceptance

| Test type | Metric | Purpose |

|---|---|---|

| Geometric | Worktable flatness; spindle runout; slide straightness | Baseline accuracy and stability |

| Dynamic | Chatter threshold; feed smoothness under load; thermal drift | Reliability and consistency of finish |

| Functional | HMI controls; inverter tuning; emergency stops; interlocks | Operator safety and ease of use |

| Demo machining | Flattening on representative cast iron and aluminum heads | Proof of performance and repeatability |

Configurations and features (reference-based)

| Model example | Key capability | Why it matters |

|---|---|---|

| RP1000.CNC (COMEC) | Laser sensor for automatic surface scanning and flattening | Automation reduces operator variability; speeds throughput |

| RP330/900 family | ~35 in length capacity; 220 V 3-phase; CBN milling head | Handles large car/truck heads/blocks; efficient material removal |

| Belt surfacer (SPN800) | Belt-based resurfacing option | Complementary process for certain applications |

| RP850/RP1000/RP1300/RP1400.CNC | Bench and CNC variants across capacity ranges | Fit for workshops with different throughput and automation needs |

| Typical grinder line | Wet grinding setups; various fixturing options | Flexibility for workshop preferences and part mix |

Practical QA tips during operations

- Verify fixturing repeatability using a reference test plate and height gauge; log clamping force/position to detect drift.

- Use inverter-driven feeds to match material hardness; slow the feed for aluminum to avoid smear; use CBN hubs for high MRR on cast iron.

- On CNC models, calibrate laser thresholds per material type; validate automatic passes against a dial indicator trace.

- Check surface finish with a stylus profile per ISO 4287 for trending; address outliers via spindle balancing or feed tuning.

- Maintain coolant/ lubrication systems to stabilize temperature and reduce thermal drift; log spindle bearing temps.

Compliance and documentation readiness

- US: Maintain UL 508A control panel documentation; ensure NFPA 70 (NEC) conformance; supply OSHA-compliant guarding and labels.

- EU: Ensure EMC and machinery directives conformity; prepare technical file, DoC, CE marking, and EN 60204-1 wiring diagrams.

- Provide manuals with spare parts lists, consumables (CBN hubs), and calibration procedures to support ISO 9001 traceability.

This approach aligns process control and safety with the automation and precision demonstrated by leading equipment like COMEC’s CNC line, and the accessory ecosystem commonly encountered in the resurfacing market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cylinder head resurfacing machine’

Practical Sourcing Guide: Step-by-Step Checklist

Use this checklist to systematically source a cylinder head resurfacing machine that fits your operation in the USA and Europe. Focus on application fit, site readiness, configuration options, vendor capability, and total cost of ownership (TCO). Adapt the items to your mix (cars, trucks; cast iron, aluminum; series or job-shop).

Step 1 — Define job scope and performance targets

- Head materials: cast iron and/or aluminum

- Capacity envelope: max deck length and width (e.g., up to 35 in)

- Flatness spec and surface finish requirements (RMS or Ra if your process specifies)

- Throughput: parts per shift/week and uptime target

- Skill level: operator training time and complexity acceptable

- Automation: prefer manual or CNC with laser scanning (e.g., COMEC RP1000 CNC)

Step 2 — Confirm site readiness

- Power: 220 V, single- or three-phase for USA; 230/400 V, 50 Hz for Europe; confirm per model

- Space and ergonomics: ensure bench/fixture access; adjustable console helpful

- Coolant and filtration: wet or dry milling capability as required

- Spindle and consumables: CBN milling/abrasive hub availability and lead time

- Safety and CE/UL: machine labeling, guards, and compliance validation in region

Step 3 — Choose features and configuration

- Automation: manual control vs CNC with laser sensor for automated flattening (COMEC RP1000 CNC)

- Control of forward speed: inverter or variable speed

- Fixturing: head/block adapters for your engine families

- Optional accessories: collets, clamps, alignment tools, coolant systems

- Aftermarket and spare parts: hubs, belts, tooling; availability and support

Step 4 — Evaluate vendors

- Technical support: training, commissioning, and phone/remote support

- Lead time: standard build time and expedite options

- Warranty and service response: coverage duration, SLA

- Installed base and references: regional case studies

- Software/controls: usability and updates

- Global footprint: COMEC has sales networks; Jamison ships worldwide (used), some items must be picked up in Louisiana

Step 5 — Build a TCO model

Include:

– Purchase price (new or used)

– Import duties, freight, insurance, customs clearance

– Site preparation (power/coolant/space)

– Training and commissioning

– Consumables (CBN hubs, abrasives)

– Spare parts stock and scheduled maintenance

– Downtime costs (MTBF, MTTR, service availability)

Step 6 — Compare options (example models)

Use manufacturer/vendor data to validate suitability. The table below highlights candidate equipment and typical price cues from Jamison (used market) to benchmark budget.

Illustrative Image (Source: Google Search)

| Model | Key capability | Materials | Capacity (indicative) | Automation | Power (indicative) | Optional features | Price cue (used market) | Region notes |

|---|---|---|---|---|---|---|---|---|

| COMEC SPN800 | Belt resurfacer | Cast iron, aluminum | Not specified | Manual | To be confirmed | Adjustable console; inverter for speed | N/A | COMEC global network; CE/UL to verify |

| COMEC RP330 | Head resurfacer | Cast iron, aluminum | Not specified | Manual | To be confirmed | Adjustable console; inverter; standard/optional equipment | N/A | European/US availability via COMEC sales network |

| COMEC RP850/RP1000/RP1300 | Head and block resurfacer | Cast iron, aluminum | Up to 35 in (RP850 series reference) | Manual/CNC variants | To be confirmed | Adjustable console; inverter; CNC version available | N/A | CE/UL and power per region to confirm |

| COMEC RP1000 CNC / RP1400.CNC | CNC head and block resurfacer with laser scanning | Cast iron, aluminum | Not specified | CNC with laser sensor | To be confirmed | Self-sufficient operation | N/A | Confirm software/support availability in region |

| Kwik Way 860 Surfacer | Belt resurfacer | Not specified | Not specified | Manual | 220 V, 3-phase | Wet grinder; fixturing included | $4,250.00 | Jamison item; ship worldwide |

| Storm Vulcan 85B | Resurfacer | Not specified | Not specified | Manual | 110 V (with optional kit) | Variable speed kit available | $4,250.00 | Jamison item; must pick up in Louisiana |

| Winona Van Norman VM2000 | Cylinder head and block milling machine | Not specified | Not specified | Manual | Not specified | Includes block tooling | $9,685.00 | Jamison item; ship worldwide |

| Sunnen HBS-2100 | Head & block resurfacer | Not specified | Not specified | Manual | Not specified | 8-inch parallels; head/block fixturing | $23,750.00 | Jamison item; ship worldwide |

| COMEC 300/900 CBN | Head & block resurfacer | Not specified | 35 in length capacity | Manual | 220 V, 3-phase | CBN milling head | $13,500.00 | Jamison item; ship worldwide |

Notes:

– COMEC models are CNC-capable, with adjustable consoles and inverter-controlled speed; RP1000 CNC includes laser scanning for automation.

– Jamison’s used equipment includes a wide price range; verify power, capacity, and tooling fit before purchase.

– Capacities, voltages, and finish capabilities vary; confirm with vendor for your exact application.

Step 7 — Select and buy

- Request quotations from at least two vendors per tier (manual and CNC).

- Ensure quotes include fixturing, spare parts, training, and warranty details.

- Include delivery terms (incoterms), lead time, and site readiness checklist in the PO.

- Specify acceptance criteria: flatness, finish, and cycle time using a pilot job.

Step 8 — Pilot install and validation

- Run a set of representative heads (cast iron and aluminum if applicable).

- Validate flatness and surface finish against your specs.

- Record cycle time, downtime, and consumable usage.

- Capture operator feedback on ergonomics and ease of use.

Step 9 — After-sales and risk management

- Secure spare parts and consumables contracts; stock CBN hubs and key wear parts.

- Define service SLA and escalation path; confirm regional support footprint.

- Insure the equipment; verify warranty terms per region.

- Maintain SOPs and calibration logs; schedule preventive maintenance.

Step 10 — RFQ template (ready-to-use)

Include these fields in your request for quotation:

– Application: head materials, max size, throughput targets

– Power and frequency: 220 V single-/3-phase (USA); 230/400 V 50 Hz (Europe)

– Capability: flatness target, finish spec, cutting method (CBN milling)

– Automation: manual vs CNC with laser scanning

– Fixturing: head/block adapters for your engine families

– Optional accessories: coolant system, alignment tools, collets

– Warranty and service: duration, response time, training included

– Lead time and delivery terms

– Compliance: CE/UL marking for target region

– Spare parts: availability and pricing for 12–24 months

Quick pre-sourcing risk check

- Unknown voltage/phase vs site power? Clarify before PO.

- Consumable supply (CBN hubs) uncertain? Tie to vendor with stockholding.

- Long lead time? Plan buffer capacity or interim use of rental/used unit.

- No pilot run spec? Add acceptance criteria and pilot plan now.

- Unclear service coverage? Prefer vendors with regional support networks.

Use the checklist above to move from “needs definition” to a confident purchase decision with fit-for-purpose machines and clear commercial terms.

Comprehensive Cost and Pricing Analysis for cylinder head resurfacing machine Sourcing

Comprehensive Cost and Pricing Analysis for Cylinder Head Resurfacing Machine Sourcing

1) How Total Cost Breaks Down (Materials, Labor, Logistics)

Sourcing the right resurfacer is only half the story; unit price is a subset of total cost of ownership (TCO). The table below maps the major buckets and typical inclusions for USA and Europe.

Illustrative Image (Source: Google Search)

| Cost bucket | What’s included | Typical range (qualitative) | Notes/region differences |

|---|---|---|---|

| Equipment (core) | Base machine; standard fixtures; basic wheel/insert set; documentation | Small manual: low; mid spec: medium; large mill/cnc: high | Higher capacity and automation cost more |

| Options & upgrades | Extra fixtures; CNC/autolaser; coolant systems; tooling kits; higher-voltage transformers | From modest to significant | Lasers/automation reduce labor variability but raise capex |

| Controls/automation | Variable-speed inverter; CNC; laser scanning | None to high | Automation reduces operator skill requirements and cycle time |

| Installation & commissioning | Site prep; anchoring; utilities; setup; acceptance test | Low to medium | Larger/precision machines need more time and tooling |

| Consumables | Wheels/inserts/cbn cutters; belts; grinding stones; coolants; filters | Periodic | Tooling strategy (CBN vs abrasive) impacts $/part and life |

| Spares & wear | Cables; spindles; belts; seals; bearings; sensors | Periodic/annual | Keep a recommended spares kit (e.g., 2–5% of capex per year) |

| Training | Operator/maintenance; safety; best practices | Low to medium | Critical for quality consistency and uptime |

| Operator labor | Time per head: load/unload; dressing; inspection | Usage-driven | Cycle time and first-pass yield drive cost per part |

| Utilities | Electricity; water/coolant | Usage-driven | CNC/laser add modest electrical load |

| Calibration/maintenance | Annual calibration; PM; lubrication; spindle checks | Low to medium | Preventive PM protects quality and uptime |

| Logistics (domestic) | Pallet/crating; freight; insurance; delivery | Low to medium | Multi-site deliveries add cost |

| Logistics (international) | Packaging for export; freight to port; duties/VAT; customs clearance; DDP vs EXW | Medium to high | EU: EU VAT on import; USA: duty varies by HS code |

| Financing | Loan/lease interest; depreciation | Usage-driven | Leasing preserves cash but adds carrying cost |

| Floor plan | Space; climate control; dust/coolant management | Usage-driven | Heavy mills benefit from stable, clean environment |

| Compliance & documentation | CE/UL marking; safety interlocks; documentation | Low to medium | Non-compliance adds rework and risk |

| Warranty & support | On-site or RMA; response SLAs | Warranty included; after-market support priced | Remote support reduces travel cost for vendors |

Key components that materially shift TCO:

– Machine size and capacity: affects throughput and space

– Automation level: operator time, repeatability, scrap rate

– Tooling strategy: CBN vs abrasive wheels determines tooling life and $/part

– Fixturing completeness: coverage for head geometries and fast changeovers

– Supplier support model: local distributor vs factory direct

2) Market Price Bands (Used vs New) — Benchmarks

Use the market reference data below as directional ranges; actual prices vary by condition, tooling included, and logistics.

| Brand/model | Type | Reference price (USD) | Notes |

|---|---|---|---|

| Kwik Way 860 Surfacer | Portable grinder | 4,250 | Wet grinder; basic; local pick-up typical |

| Storm Vulcan 85B Resurfacer | Manual resurfacer | 4,250 | Variable speed upgrade kit 1,050 (optional) |

| Winona Van Norman VM2000 | Head/block mill | 9,685 | Includes block tooling; larger footprint |

| Comec 300/900 CBN Resurfacer | Head/block mill | 13,500 | 3-phase; 35″ capacity; CBN milling head |

| Sunnen HBS-2100 | Head/block mill | 23,750 | Includes 8″ parallels; CBN milling head |

Implications:

– Older manual grinders can be attractive on price but carry higher operator time, quality variability, and retooling risk.

– Mid-price CBN mills (e.g., Comec, Sunnen) typically offer better balance of throughput, quality, and tooling life.

– High-end CNC/laser systems (e.g., Comec RP1000/1400 CNC) command higher capex but reduce labor per part and improve repeatability on mixed production.

3) Labor and Throughput: Cost-per-Part Model

- Cycle time = Load/unload + Dressing + Surface pass + Inspection + Teardown

- Operator cost per cycle = Operator hourly rate × Cycle time (hours)

- Tooling amortization per part = Annual tooling spend / Annual parts

- Utilities per part = kWh (machine + coolant) × Electricity rate

- Cost per part = Operator cost + Tooling amortization + Utilities + Scrap (if applicable)

Sensitivity:

– Automated systems often cut cycle time and dressing time, increasing first-pass yield and lowering operator hours.

– CNC/laser systems reduce process variability, which reduces scrap and rework (major drivers of cost variability).

Illustrative Image (Source: Google Search)

4) Logistics: Domestic vs International Sourcing

| Step | Domestic (USA) | International (EU→USA or USA→EU) |

|---|---|---|

| Packaging | Standard crating/pallet | Export crating; moisture control |

| Freight | Door-to-door carrier | Port handling; ocean/air; drayage |

| Customs & duties | US border clearance; duties by HS code | EU customs; EORI; import VAT; EU port fees |

| Incoterms | Typically FOB/DDP preferred | EXW vs FOB/CIF vs DDP—DDP reduces your risk but increases price |

| Lead time | Short (days to few weeks) | Longer (weeks to months); plan buffer tooling |

| Insurance | Carrier or all-risk policy | Cargo insurance; delay risk mitigation |

| Responsibilities | Simpler coordination | Broker fees; documentation; compliance checks |

Practical note: Incoterms affect who carries risk and cost. DDP can price out the hidden risks (port fees, handling, penalties), but generally costs more.

5) Regional Considerations (USA vs Europe)

| Factor | USA | Europe |

|---|---|---|

| Voltage/phasing | 208–240 V, 3-phase common | 400 V, 3-phase common; check local voltage and earthing |

| Electrical protections | NRTL requirements; local permits | CE compliance; CE/UL documentation; local norms |

| Warranty/SLA | Dealer/brand-specific | Dealer/brand-specific; parts coverage may differ |

| Tax & import | Duty by HS code; taxes vary by state | VAT on import; EORI for customs |

| Financing | OEM leasing; vendor financing common | OEM/distributor financing common; VAT implications |

| After-sales | Local distributor service | Local distributors; language/cultural alignment helps |

| Documentation | English; UL | English/German/Italian; CE Declaration of Conformity |

6) ROI and Payback Scenarios (Directional)

For planning, compare two or three options:

– Manual grinder (lower capex, higher operator time, more variable quality)

– Mid-spec CBN mill (balanced capex and operator time)

– CNC/laser mill (higher capex, lower operator time and scrap)

Simple template for your numbers:

– Labor savings vs manual = Hours saved per part × Operator hourly rate × Annual volume

– Scrap reduction savings = Scrap % improvement × Average rework cost × Annual volume

– Payback years = Incremental capex / (Labor + Scrap + Warranty savings – Incremental maintenance/insurance/finance)

Automation tends to pay back faster in shops with high mix/variety and higher operator rates, where consistency and fast changeover matter most.

Illustrative Image (Source: Google Search)

7) Procurement Strategy and Negotiation Levers

- Bundle quotes: Base machine + tooling + spare kit + training + DDP freight for a single invoice.

- Payment terms: Progress payments linked to milestones (order, factory acceptance test, delivery, commissioning) reduce cash flow strain.

- Spare kit inclusion: Secure a first-year spares kit at quoted price; otherwise expect distributor markups later.

- Tooling strategy: Lock tooling life and pricing for 12–24 months; specify wear rates and replacement lead times.

- Warranty: Clarify on-site vs RMA, response SLAs, and what’s included; tie penalty clauses to uptime.

- Calibration: Request calibration procedure and initial certificate; clarify annual fees if outsourced.

- Options: If you buy manual now but need expansion later, ensure fixturing and tooling compatibility; otherwise, pay more to migrate later.

8) Tips to Save Cost Without Compromising Quality

- Buy used with tooling included: Prioritize machines that come with comprehensive fixtures and tooling (e.g., block/head kits).

- Upgrade path: Start with a high-quality mid-spec mill; plan to add automation later to avoid stranded assets.

- Right-size capacity: Match length/width capacity and throughput to your actual part mix.

- Tooling life control: Use CBN where possible for lower $/part and longer life; stock dressers and key consumables.

- Preventive maintenance: Annual calibration and PM reduce downtime and quality escapes.

- Consolidated shipping: Group accessories and spares to reduce freight and handling costs.

- Finance wisely: Compare leasing vs cash vs loan; leverage tax advantages where applicable.

- Local distributor: Lower your shipping/clearance costs and faster service; weigh that against factory-direct support.

9) Hidden Costs Checklist

- Tooling omissions: Without full fixtures, operators spend time on setup, raising $/part.

- Consumables shortfall: Understocking CBN inserts or coolants causes unplanned downtime.

- Calibration gaps: Without periodic checks, scrap and rework rise.

- Unclear warranty: Travel, parts, and response time costs can be significant.

- Incoterms missteps: Choosing EXW without a broker increases admin costs and risk.

- Site prep oversights: Power supply upgrades, anchoring, and dust control add unplanned spend.

10) Actionable Next Steps

- Build your 12–24 month TCO model using the cost buckets and formulas above; tailor cycle time, operator rate, and volume to your shop.

- Source multiple options: include at least one manual, one mid-spec CBN mill, and one CNC/laser; compare $/part at your actual mix.

- Request DDP quotes with bundled tooling and first-year spares; include calibration and training.

- Pilot a job mix and measure cycle time, first-pass yield, and tooling wear; use those metrics to finalize ROI.

- Specify warranty SLAs, documentation, and commissioning criteria in the PO to protect uptime.

In short, make your decision on more than sticker price. The right balance of equipment, tooling, automation, logistics, and after-sales will reduce your real cost per part while protecting quality and uptime.

Alternatives Analysis: Comparing cylinder head resurfacing machine With Other Solutions

Alternatives Analysis: Comparing Cylinder Head Resurfacing Machines with Other Solutions

Summary

A resurfacing platform that delivers predictable flatness, throughput, and long-term consumable cost controls ROI. Three archetypes illustrate the trade-off curve: belt/resurfacers (cost-first), entry millers (balanced), and premium CBN/fully automated mills (precision/throughput-first).

Quick comparison

| Supplier/Model | Type | Automation level | Flatness control | Typical tooling | Capacity (length) | Power | Indicative price (USD) | Position |

|---|---|---|---|---|---|---|---|---|

| Comec SPN800 | Belt resurfacer | Manual | Belt flatness; manual handling | Standard fixtures/accessories | Not specified | Not specified | Not specified (entry model) | Cost-first |

| Winona Van Norman VM2000 | Milling machine | Manual | Milling produces a flat, planar surface via spindle accuracy | Includes block tooling; add-on head tooling | Not specified | Not specified | 9,685 | Balanced |

| Sunnen HBS-2100 | Head & block resurfacer (CBN) | Manual; CNC available on other platforms | Milling; CBN tooling supports high precision and consistency | 8 in parallells; head & block fixturing included | Not specified | Not specified | 23,750 | Premium/precision |

Notes: COMEC lists multiple lines (SPN800, RP330, RP850, RP1000, RP1000 CNC, RP1300, RP1400), with advanced CNC models such as RP1000 CNC that automate flattening via a laser sensor, while the SPN800 is a belt-type with basic features. Pricing from Jamison Equipment for WVN and Sunnen; COMEC pricing not listed.

Analysis

- Throughput and rework risk

- Belt resurfacing (SPN800) offers the fastest ramp-up for low-volume shops but depends on operator consistency. It requires careful fixturing and monitoring to avoid taper and dish-out on critical surfaces.

-

Milling (VM2000, HBS-2100) removes material in a controlled, planar fashion with consistent chip load and pass strategy. CBN tooling (as on the HBS-2100) maintains edge sharpness and heat management, supporting higher feed rates with less rework than traditional grinding.

-

Flatness and quality

-

Milling is inherently a planar operation and tends to yield predictable flatness when tools and speeds are managed. On COMEC’s CNC models, laser scanning automatically normalizes warpage to a target plane; this reduces reliance on operator judgment and enables better repeatability at scale.

-

Consumables and life-cycle cost

- Belts wear quickly with aluminum or cast iron, requiring frequent changeovers and variable surface finish.

-

Mill/CBN platforms use replaceable CBN heads that retain geometry longer and produce consistent finishes, lowering scrap and regrind rates over time.

Illustrative Image (Source: Google Search)

-

Flexibility and workload fit

- Belt: excellent for budget-constrained shops, quick turnaround jobs, and limited tooling investment.

- Entry milling: best for mixed car/truck throughput and block work with existing fixturing, delivering a strong cost-to-capacity ratio.

-

Premium CBN: suited for high-volume production, complex multi-angle fixtures, and plants with tight flatness/finish specifications, where automation or laser-based leveling is an advantage.

-

Total cost of ownership

- Initial outlay, fixturing completeness, and consumable strategy drive TCO. Premium CBN units command a higher entry price but often reduce per-part cost, rework, and downtime. Belt units minimize capex but increase labor vigilance and replacement-part spend.

Recommendation

- Cost-first or starter bay: consider a belt resurfacers such as COMEC SPN800 to get reliable throughput on routine heads at the lowest capex; monitor flatness with gages and keep consumables in stock.

- Balanced mixed fleet: select a proven entry miller like the WVN VM2000; complement with proper head fixtures to minimize setup time and protect flatness.

- Quality-first, high-throughput bay: deploy a premium CBN platform such as the Sunnen HBS-2100; where available, explore automation features (e.g., COMEC RP1000 CNC with laser leveling) to standardize flatness across varying warpage patterns.

If you operate across multiple bays, a “belt + mill” mix often delivers the most resilient workflow: belt for quick-service jobs and mill for predictable, repeatble flattening across mixed materials and complex head geometries.

Illustrative Image (Source: Google Search)

Essential Technical Properties and Trade Terminology for cylinder head resurfacing machine

Essential Technical Properties and Trade Terminology for Cylinder Head Resurfacing Machines

Below is a practical specification and vocabulary checklist for evaluating and sourcing cylinder head resurfacing machines for USA and Europe. It draws on documented feature sets from COMEC and inventory/equipment types listed by Jamison Equipment to anchor examples without inflating technical claims.

Key Technical Properties

| Property | What it means in resurfacing | Why it matters | Spec examples (as documented or inferable) |

|---|---|---|---|

| Method | Milling with CNC or conventional; belt or wet grinder; CBN abrasives | Determines flatness control, cycle time, and tooling | COMEC milling line (incl. CNC); belt resurfacers (SPN800); wet grinders (e.g., Kwik Way 860) |

| Automation | CNC control and/or laser sensing for auto leveling | Reduces operator variability and scrap | COMEC RP1000.CNC: laser sensor scans and automates flattening |

| Feed control | Variable forward speed via inverter | Consistency across materials (cast iron, aluminum) | COMEC: inverter-controlled forward speed |

| Capacity (envelope) | Max length and work height | Determines which heads/blocks you can run | Jamison listing: COMEC 300/900—35″ length capacity |

| Power | Voltage and phase (3-phase availability in EU) | Compatibility with shop power | Jamison: 220V 3-phase equipment is common |

| Spindle drive | Motor rating; variable speed | Predictable surface finish and material removal | Conventional vs CNC drive options on milling lines |

| Surface control | Flatness, parallelism, finish (e.g., Ra) | Critical sealing performance | Milling typically delivers fine finish; grinding for bulk material removal and specific finishes |

| Fixturing & tooling | Block and head fixtures, clamping, parallels | Reduces set-up time and handling risk | Jamison: head & block fixturing included with units like Sunnen HBS-2100 |

| Abrasives | Belt grading; CBN milling hubs; grinding hubs | Stock removal and surface texture | COMEC CBN line; Jamison offers original grinding hubs |

| Control ergonomics | Adjustable console/operator interface | Safe reach and operator comfort | COMEC: adjustable console on all models |

Material Capability

| Material | Removal method | Notes |

|---|---|---|

| Cast iron | Milling or grinding (wet/dry) | High-speed milling under CNC improves consistency |

| Aluminum | Milling preferred | Lower heat and consistent flatness; belt or CBN for finishing |

Workholding and Capacity

- Fixture compatibility: Head and block fixturing; height and angle stops; block clamps and head supports. Some listings specify “parallel bars” and “block tooling” with the machine.

- Capacity and envelope: Length and maximum working height define what heads/blocks are admissible. A 35″ length machine supports a wide range of commercial heads and most truck applications.

- Through-spindle height and table size: Ensure clearance for valve pockets, boss reliefs, and cam saddle features.

Automation and Sensors

- CNC: Delivers repeatable passes and profile leveling; enables series production (as documented on COMEC CNC machines).

- Laser scanning: Auto-leveling, surface mapping, and feed modulation for flatness targets.

- Programmable offsets: Store multiple part configurations for changeover efficiency.

Drive and Control

- Variable feed (inverter): Adjusts forward speed to optimize finish vs. cycle time.

- Spindle speed control: Maintain optimal cutting or grinding conditions for each material.

- Adjustable console: Ergonomic positioning to suit different users and tasks.

Abrasives and Tooling

- Milling: Usually with indexable cutters or CBN abrasives for controlled finish and low thermal impact.

- Grinding: Wet or dry; belts for general restoration; CBN grinding wheels for heavy-duty removal.

- Tooling availability: Original grinding hubs and milling heads supported by suppliers like Jamison. Keep part numbers (e.g., “CBN milling hub for R8 Bridgeport-style”) documented.

Power and Environment

- Voltage/phase:

- USA: 110–220V single-phase and 220V 3-phase are typical (per Jamison listings).

- Europe: 220–240V single-phase and 380–400V 3-phase are standard. Confirm local phase and neutral/earth arrangement.

- Grounding and EMC: EU machines typically meet CE/EMC compliance (manufacturer-specific).

Quality Metrics

- Flatness and parallelism: Resurfacing produces flat, parallel mating surfaces with high repeatability; this is the core milling objective on COMEC lines.

- Surface finish: Controlled by method (milling vs. grinding), feed, and abrasive type. Document the target Ra for your application before specification.

- Stock removal: Set minimum stock removal to restore geometry and sealing. Maintain sufficient reserve for subsequent machining operations.

- Step/warpage correction: Capability to remove high spots and restore straightness; record total indicator runout (TIR) before and after for traceability.

Safety, Ergonomics, and Service

- Guarding, E-stop, and coolant/fume control for wet grinding.

- Adjustable console, controls within reach, clear sightlines to the work area.

- Maintenance and service access: Spare parts, lubrication points, and diagnostics.

Purchase and Support Terminology

- MOQ: Minimum order quantity; often 1 unit for standard machines.

- Lead time: Production lead time varies by model and configuration; confirm with supplier.

- Warranty: Standard machine warranty; extended or on-site options may be available.

- OEM: Manufacturer of the machine and key components (e.g., COMEC).

- Spare parts: Keep a list of critical items (belts, wheels, CBN hubs, fixtures, filters) with part numbers.

- Calibration: Annual or per-compliance recalibration; include flatness verification procedures.

- Documentation: Operator manual, electrical drawings, CE/Declaration of Conformity (EU), safety data sheets for abrasives/coolants.

Model and Vendor Examples

- COMEC milling line: SPN800 (belt resurfacer), RP330, RP850, RP1000, RP1000 CNC, RP1300, RP1400.CNC. Feature progression from basic to CNC with laser automation.

- Jamison Equipment: Listings include Kwik Way 860 wet grinder; Storm Vulcan 85B; Winona Van Norman VM2000 (milling machine); Comec 300/900 (35″ capacity); Sunnen HBS-2100 head & block resurfacers with CBN milling head and standard fixturing.

Quick Buyer Checklist

- Confirm capacity (length, height) for your head and block range.

- Decide on automation level: conventional vs. CNC + laser.

- Match power to site: 110–220V (USA), 220–240V or 380–400V 3-phase (Europe).

- Verify fixturing coverage: heads, blocks, cam carriers, manifolds.

- Secure abrasive supply: belts, CBN wheels/hubs; wet vs. dry process.

- Ensure spares, service network, and calibration support.

- Specify finish targets and tolerances; document verification method (straightedge, comparator, surface finish meter).

This section provides a concise technical and commercial vocabulary for specifying cylinder head resurfacing machines, aligning capabilities to practical needs in both USA and Europe.

Navigating Market Dynamics and Sourcing Trends in the cylinder head resurfacing machine Sector

Key points overview

– Demand and resilience: Cylinder head resurfacing stays resilient across North America and Europe, supported by mixed fleets, remanufacturing, and the persistent need to repair cast-iron and aluminum heads.

– Technology shift: CNC and laser-assisted flattening are moving from “nice-to-have” to mainstream, delivering repeatability, throughput, and traceability in busy job shops.

– Capacity and throughput: Larger platforms (e.g., 1000–1400 mm length) with variable-speed milling, CBN tooling, and robust fixturing are preferred for truck heads and heavy-duty blocks.

– Sourcing realities: New equipment from European brands (e.g., Comec) targets precision and automation; US market buyers often mix new and used options with strong support networks (e.g., Jamison Equipment, Sunnen, Winona Van Norman).

– Sustainability: Resurfacing reduces scrap, energy, and cost versus replacement; compliance (coolants, PPE, tool disposal) and waste minimization are now differentiators.

– Regional preferences: US buyers weigh total cost of ownership and availability of service; European buyers emphasize CE compliance, duty cycles, and energy efficiency.

– Procurement considerations: Evaluate TCO (tooling, service, calibration), compliance, and integration with upstream/downstream processes (cleaning, crack detection, valve seat/refinish).

Navigating Market Dynamics and Sourcing Trends in the Cylinder Head Resurfacing Machine Sector

Market dynamics shaping demand (USA and Europe)

- Repair and remanufacture mix: Despite growth in newer vehicles, the installed base of ICE platforms keeps resurfacing steady. Heavy-duty (trucks, construction, agriculture) and legacy fleets are strong contributors.

- Precision and turnaround: Customers increasingly expect flatness (e.g., 0.01–0.02 mm typical), repeatability, and documented outputs. Shops using CNC/automation capture more work by guaranteeing flatness and cycle time.

- Materials and tooling: Aluminum heads and high-speed cast-iron milling require robust CBN inserts, proper fixturing, and vibration control. Shops report faster tooling payback with lower consumable cost and consistent finish.

- Shop consolidation: Larger repair networks standardize on CNC-capable lines to scale throughput and reduce scrap.

- Compliance and safety: Coolant management, dust/mist control, and electrical compliance (CE, OSHA, NFPA 70) are now standard procurement criteria.

Sourcing trends and buyer behavior

- New CNC platforms: Vendors like Comec package precision milling with CNC logic and laser-based surface scanning (e.g., RP1000 CNC), aiming for unattended or semi-automated flattening.

- Used/refurbished mix: US buyers frequently acquire used lines to control capex (e.g., Winona Van Norman VM2000), often supplementing with modern CBN hubs and variable-speed kits.

- Value-add features: Inverter-controlled feed, adjustable consoles, and standardized fixturing are now baseline expectations across mid-to-high spec machines.

- Support networks: Availability of tooling, fixturing, spare parts, and service technicians is a leading factor in brand selection.

- Price ranges (used-market view, USA): Examples from Jamison Equipment show viable options at $9k–$24k plus tooling; buyers then upgrade CBN tools and controls to extend capability and improve consistency.

Machines and capabilities in context

Sourcing trend matrix

| Trend | Why it matters | Practical adoption (USA/Europe) |

|---|---|---|

| CNC automation | Improves flatness, repeatability, throughput, and documentation | Europe: adoption accelerating for standardized programs; USA: selective adoption where labor is constrained and quality is contractually required |

| Laser-based flattening | Removes guesswork on warpage and accelerates cycle times | Growing on premium lines; useful for truck/agri engines with heavy deformation |

| CBN tooling | Faster cuts, less heat, longer tooling life vs. abrasive discs | Strong uptake in both regions; reduces consumable spend and scrappage |

| Inverter-controlled feed | Fine-tuned finish, fewer burn marks on aluminum | Standard on new machines; retrofit kits available in the US |

| Larger capacity (1000–1400 mm) | Accommodates truck heads and heavy blocks; reduces rehandling | Europe: favored for mixed fleets; USA: essential for reman shops with HD volumes |

| Standardized fixturing | Reduces setup time, improves operator ergonomics | Baseline feature; adjustable consoles considered a hygiene factor |

| Used/refurb mix + service | Optimizes capex while maintaining uptime | USA: common strategy; Europe: less frequent but present in budget-constrained contexts |

Sustainability and compliance

| Area | Benefit/standard | What to look for |

|---|---|---|

| Scrap reduction | Resurfacing avoids replacement; preserves castings and keeps materials in use | Require documented flatness and no removal beyond spec; ensure calibration controls |

| Tooling efficiency | CBN inserts reduce consumables and dust compared to discs | Specify CBN heads and insert grade for cast iron and aluminum |

| Energy use | Inverter-controlled feed and optimized spindle power reduce kWh per part | Ask for kW draw and speed ranges; prefer machines with duty-cycle ratings |

| Coolant/mist management | Safer workplace, lower disposal cost | Confirm enclosure/mist control, filtration, and compliant electricals (CE, NFPA/UL equivalents) |

| End-of-life tools | Structured disposal of CBN/hub assemblies | Partner with suppliers for take-back or designated recycling streams |

| Operator safety | Reduced exposure to vibration and particulate | Ergonomic consoles, clear guarding, easy-to-clean designs |

Historical snapshot and what changed

- 1970s–1990s: Manual/motion-controlled grinders and planers dominated; throughput and flatness varied more with operator skill.

- 2000s–2010s: Faster spindles, CBN hubs, and standardized fixturing improved cycle times and finish quality.

- 2010s–Present: CNC platforms and laser-based flattening (e.g., Comec RP1000 CNC) enable series production with higher consistency and lower rework. Larger capacity machines (e.g., Comec RP1300/RP1400) consolidate mixed workloads, from passenger to truck applications.

Spec comparison (sources provided)

| Brand/Model | Type | CNC / Laser | Capacity | Tooling | Notable controls/features | Indicative price (used, USA) |

|---|---|---|---|---|---|---|

| Comec SPN800 | Belt resurfacer | No | — | Belt | Basic | — |

| Comec RP330 | Cylinder head resurfacer | No | — | Milling/CBN | Standard controls | — |

| Comec RP850 | Head & block resurfacer | No | — | Milling/CBN | Variable feed via inverter | — |

| Comec RP1000 | Head & block resurfacer | No | — | Milling/CBN | Variable feed via inverter | — |

| Comec RP1300 | Head & block resurfacer | No | — | Milling/CBN | Variable feed, larger capacity | — |

| Comec RP1400.CNC | Head & block resurfacer | Yes (CNC) | — | Milling/CBN | CNC control; CE region standard | — |

| Comec RP1000.CNC | Head & block resurfacer | Yes (CNC + laser) | — | Milling/CBN | Laser scanning, automation-friendly | — |

| Winona Van Norman VM2000 | Head & block milling | No | — | Milling tooling | Includes block tooling | $9,685 (Jamison) |

| Sunnen HBS-2100 | Head & block resurfacer | No | — | CBN milling | Includes 8″ parallels; fixturing | $23,750 (Jamison) |

| Storm Vulcan 85B | Resurfacer | No | — | Variable speed option | Retrofit kit available ($1,050) | $4,250 (Jamison) |

| Storm Vulcan/ Scledum 850 | Resurfacer | No | — | Milling | “Stormill” setup | $2,995 (Jamison, pickup LA) |

| Comec 300/900 CBN Head & Block | Resurfacer | No | 35″ length | CBN milling | Newer CBN hub configuration | $13,500 (Jamison) |

Regional notes: USA vs Europe

- USA: TCO is decisive; shops blend new investments with targeted upgrades (CBN hubs, variable-speed kits) and strong service/parts availability.

- Europe: Compliance (CE, safety, energy), duty cycles, and automation are emphasized; buyers often spec CNC lines to match high-throughput schedules and quality requirements.

What to evaluate before buying

- Flatness tolerance and repeatability specs; calibration method and frequency.

- Capacity envelope (length and height), fixturing coverage, and changeover time.

- Tooling strategy (CBN inserts/hubs, grinding hubs, belts) and cost per part.

- Controls: inverter-controlled feed; CNC programming and laser assistance; documentation outputs.

- Service network: trained technicians, spare parts lead times, remote diagnostics.

- Compliance: electrical standards, coolant/mist systems, guarding, and documented safety features.

Summary

Cylinder head resurfacing in the USA and Europe remains a disciplined, process-driven space. Buyers increasingly seek CNC capabilities, laser-assisted flattening, and larger capacities to handle mixed fleets and heavy-duty work. Used/refurbished machines paired with CBN upgrades can be cost-effective, particularly in the US market, while European buyers often prioritize standardized compliance and automation. The machines sourced in the USA—from Winona Van Norman to Sunnen and Comec—span a wide value range and capability set, with clear upgrade paths to improve throughput and sustainability outcomes.

Frequently Asked Questions (FAQs) for B2B Buyers of cylinder head resurfacing machine

Frequently Asked Questions (FAQs) for B2B Buyers of Cylinder Head Resurfacing Machines

1) Which machines handle both car and truck cylinder heads and blocks?

Answer:

– COMEC RP850, RP1000, RP1300, and RP1400 CNC handle both heads and blocks for cars and trucks.

– COMEC RP330 is a cylinder head resurfacer.

– COMEC SPN800 is a belt resurfacer.

Recommended use:

– RP series for high-volume or multi-material shops.

– RP330 for dedicated head-only workflows.

– SPN800 for basic resurfacing where belt grinding is sufficient.

2) What materials can these machines process?

Answer:

– All listed COMEC milling machines are designed for high-speed resurfacing of cast iron and aluminum.

– No further media preparation is required beyond standard fixturing, fixturing is model-dependent.

Implications:

– Cast iron and aluminum are standard. If you process exotic alloys, consult the manufacturer for tooling recommendations.

3) What level of automation and scanning is available?

Answer:

– COMEC RP1000 CNC features a laser sensor that scans surfaces and automates flattening.

– Other COMEC milling models use CNC control; manual or semi-automated setup varies by model.

– Typical controls include adjustable console and variable feed speed via inverter for consistent finish.

Best-fit guidance:

– RP1000 CNC for unmanned or low-operator attention cycles.

– RP series for manual or operator-led cycles where throughput is driven by fixture efficiency.

4) What capacity and power options are available across the current-market range?

Answer (summary table):

| Brand/Model | Capability | Power | Max Length Capacity | Pricing (USD) |

|---|---|---|---|---|

| COMEC RP850 | Head & block | Not specified | Not specified | — |

| COMEC RP1000 | Head & block | Not specified | Not specified | — |

| COMEC RP1300 | Head & block | Not specified | Not specified | — |

| COMEC RP1400 CNC | Head & block (CNC) | Not specified | Not specified | — |

| COMEC RP1000 CNC | Head & block (CNC) | Not specified | Not specified | — |

| COMEC RP330 | Cylinder head only | Not specified | Not specified | — |

| COMEC SPN800 | Belt resurfacer | Not specified | Not specified | — |

| Winona Van Norman VM2000 | Head & block | Not specified | Not specified | 9,685 |

| Sunnen HBS-2100 | Head & block | Not specified | Not specified | 23,750 |

| COMEC 300/900 CBN | Head & block | 220 V, 3-phase | 35″ | 13,500 |

| Kwik Way 860 | Surfacer | 220 V, 3-phase | Not specified | 4,250 |

Notes:

– Pricing and limited specs above reflect publicly available US market listings and manufacturer sources.

– Max length capacity and detailed specs vary by fixturing and model; confirm for your application.

Illustrative Image (Source: Google Search)

5) What surfaces can be reconditioned and what finish can we expect?

Answer:

– COMEC milling machines deliver high-precision milling for perfectly flat contact surfaces on heads and blocks.

– Variable forward speed (via inverter) enables consistent results and operator control across different materials and profiles.

– Belt and grinder-based equipment (e.g., SPN800, Kwik Way 860) provide resurfacing for contact surfaces; milling typically yields higher flatness repeatability for mating surfaces.

If you need quantified flatness/roughness metrics, request a test coupon and report from the manufacturer.

6) What tooling, fixturing, and consumables are included or available?

Answer:

– Models include standard and optional equipment with accessories and spare parts (per machine).

– US market listings show:

– Sunnen HBS-2100 includes 8-inch parallels and head & block fixturing.

– Winona Van Norman VM2000 includes block tooling.

– COMEC 300/900 CBN includes head & block fixturing.

– Kwik Way 860 includes lots of fixturing for heads and blocks; includes wet grinder.

– CBN milling heads/hubs, original grinding hubs for resurfacers, and variable speed kits are available.

Recommendations:

– Verify exact fixturing sets for your part mix (passenger car heads, diesel truck heads, light blocks).

– Specify tooling adapters for unusual bore patterns or non-standard deck heights.

Illustrative Image (Source: Google Search)

7) What electrical and service considerations should we plan for?

Answer:

– Voltage: Many North American listings run 220 V, three-phase; confirm local line voltage and phase.

– Service coverage: COMEC offers a global sales network. Local service is typically handled through distributors; confirm coverage in your region.

– Consumables and spares: COMEC lists spare parts and accessories. Distributors can provide lead times and local stocking.

If integrating with your plant, ensure line voltage, grounding, and cooling/ventilation meet the manufacturer’s site requirements before installation.

8) How do COMEC RP models differ in capability and when should we prefer CNC automation?

Answer (capabilities overview table):

| Model | Capability | Automation Level | Typical Use Case |

|---|---|---|---|

| SPN800 | Belt resurfacer | Manual belt feed | Low-cost resurfacing for standard materials |

| RP330 | Head resurfacer | Manual or semi-auto | Dedicated head workflows |

| RP850 | Head & block | Manual/semi-auto with inverter | Mixed workloads, flexible operation |