About CY Molds

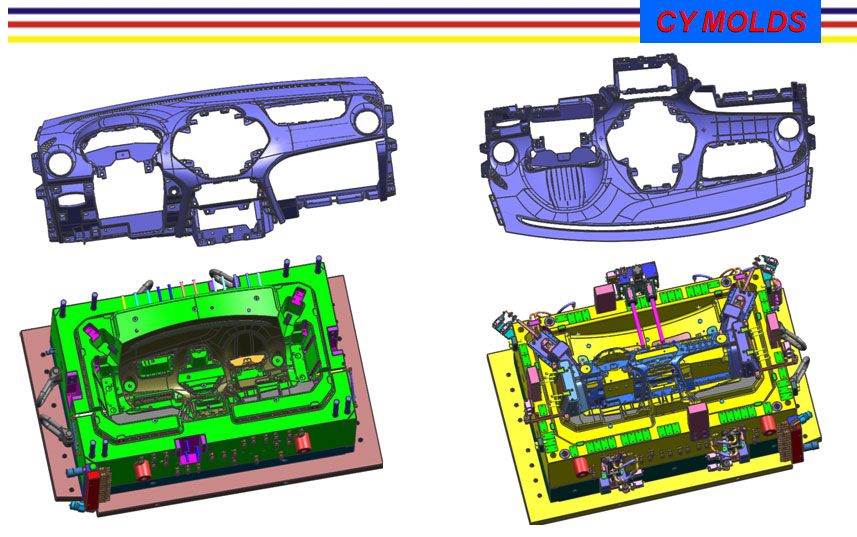

CY Molds, YOUR RELIABLE OFFSHORE PARTNER, is a global high-quality manufacturer in China, established in 1997. We specialize in plastic injection mold/molding, die-casting mold/parts, and precision machining for industries worldwide.

With a 10,000 ㎡ factory in Dongguan and a team of 230 skilled professionals, we manufacture up to 800 sets of molds annually using lean manufacturing systems and advanced engineering solutions.

In May 2018, CY acquired Junting Company to expand our die-casting and machining services, offering customers more value-added solutions. Our strong project management and engineering systems ensure seamless execution from design to delivery.

Learn More About Us