Precision Extrusion for Modern Industry

Manufacturer of advanced drip irrigation, PET/PP strapping, film, and plastic sheet extrusion lines. Engineered for efficiency, durability, and global scalability.

Explore ProductsThis page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Manufacturer of advanced drip irrigation, PET/PP strapping, film, and plastic sheet extrusion lines. Engineered for efficiency, durability, and global scalability.

Explore ProductsDashing Extruder is a leading manufacturer specializing in extrusion machinery for drip irrigation systems, PET/PP strapping, plastic sheets, and solar film production. With years of engineering excellence, our equipment is trusted by clients across continents for its reliability, energy efficiency, and innovative design.

Our production lines are built with advanced servo-driven motors, low-temperature plasticization technology, and high automation to reduce energy consumption by up to 30%. We serve agriculture, packaging, construction, and renewable energy sectors with precision-engineered solutions.

Energy Savings

Global Clients

High-performance extrusion systems engineered for precision, speed, and long-term reliability across multiple industrial applications.

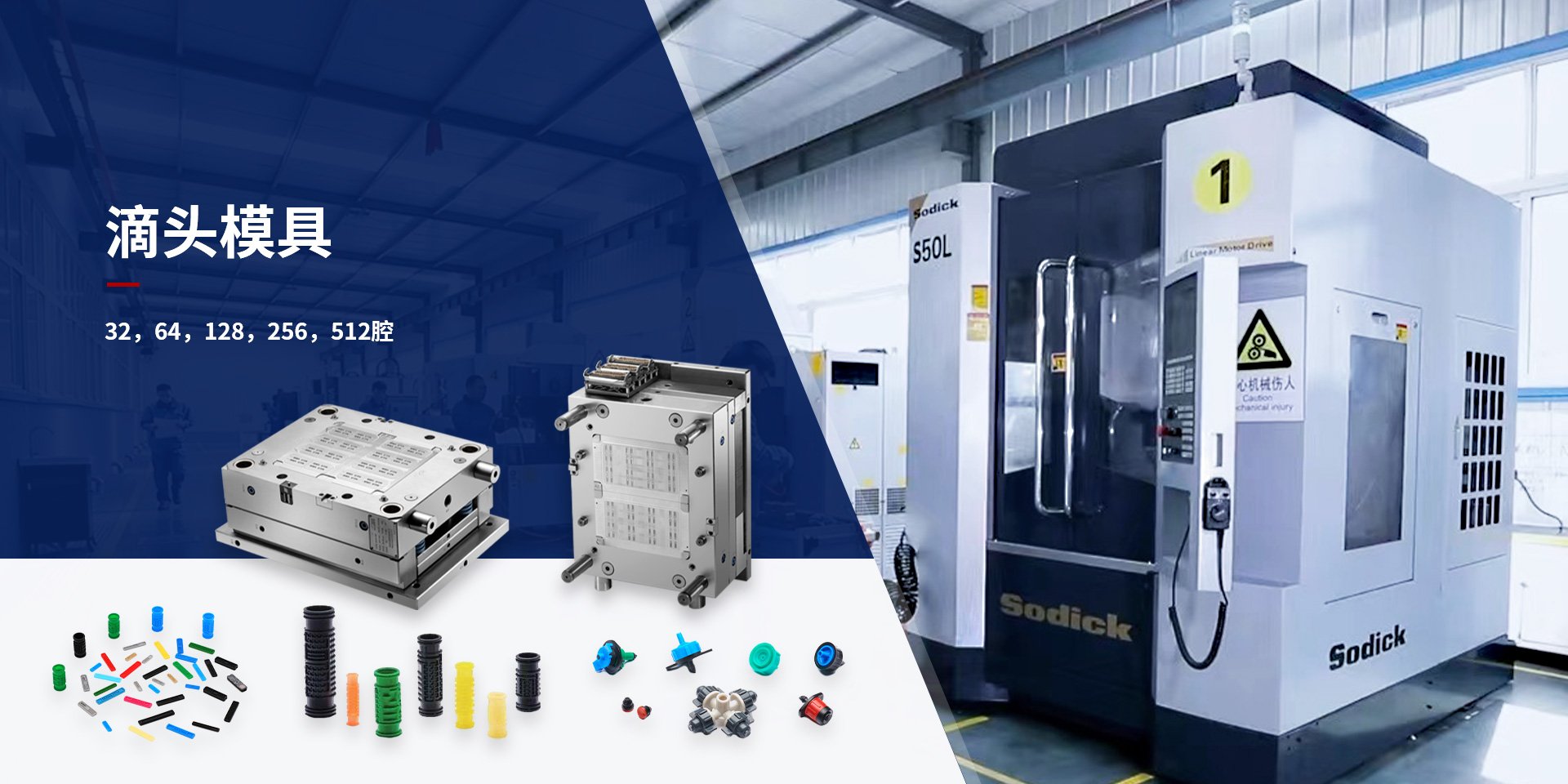

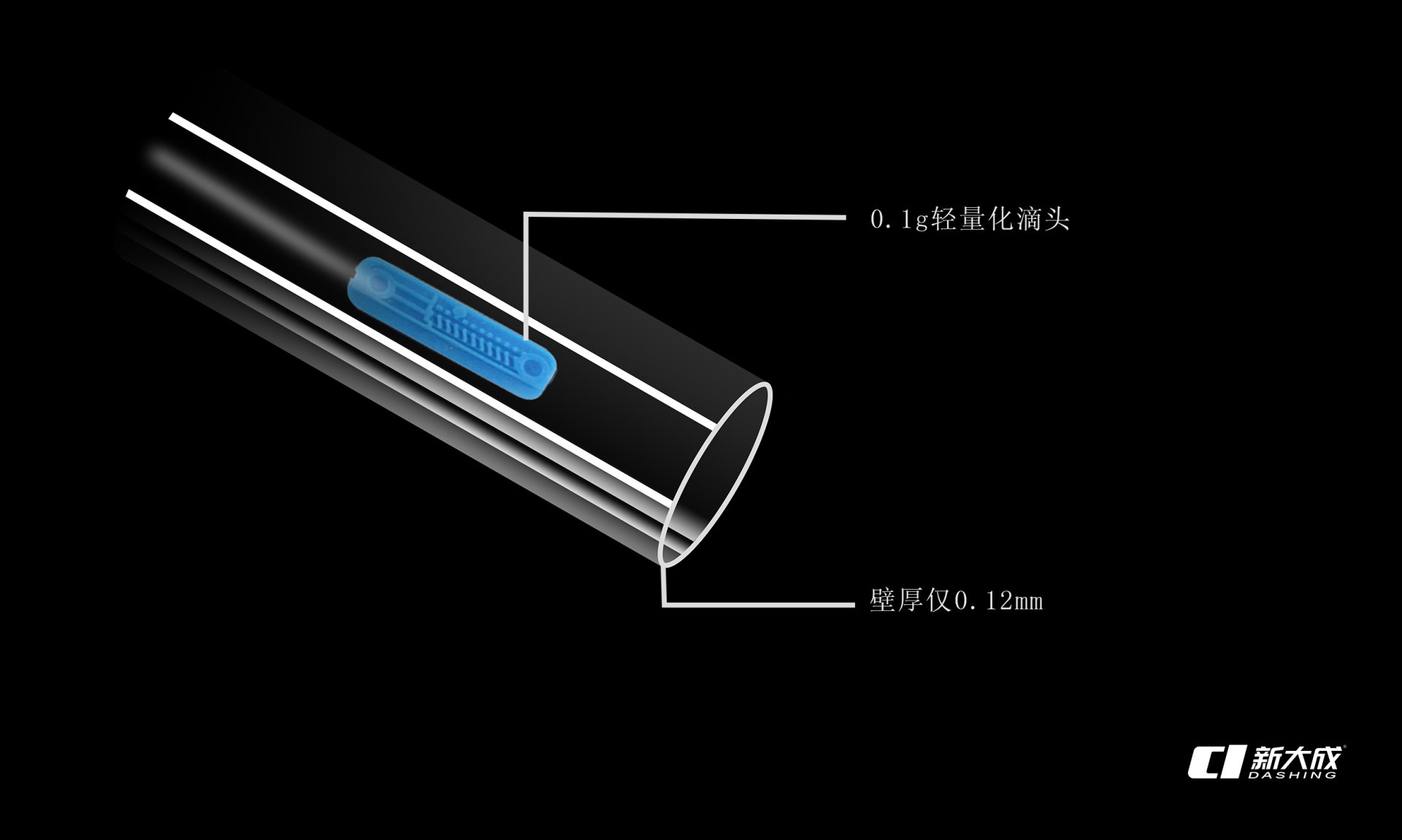

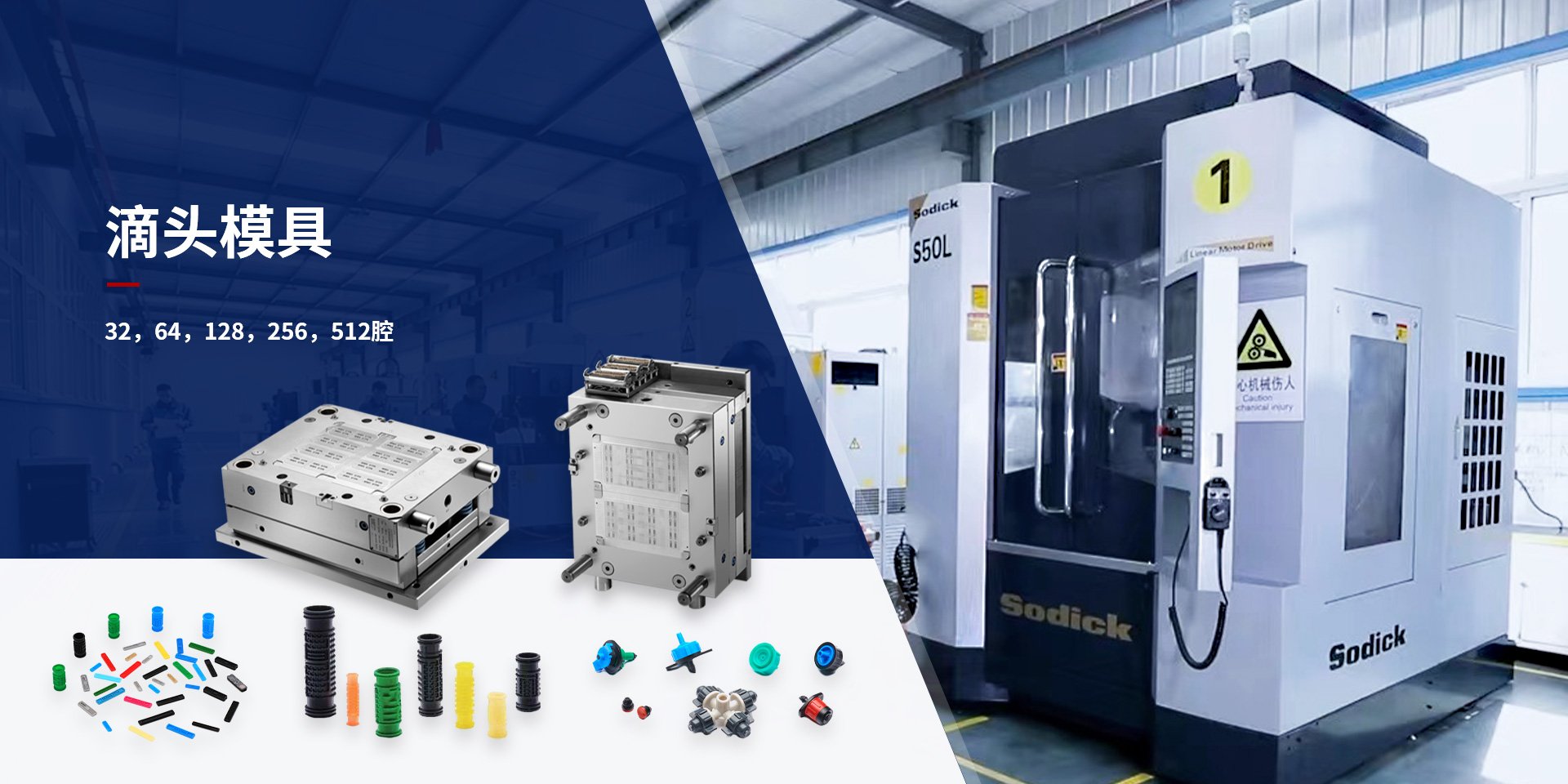

High-speed extrusion line for agricultural drip irrigation systems with precision hole punching and uniform wall thickness.

Flexible pipe production line with integrated outlet welding for efficient water distribution networks.

Internal flat dripper irrigation pipe machine with optimized flow design and anti-clogging features.

Worldwide used packaging material line, replacing steel belts with eco-friendly, high-tensile PET plastic straps.

Polypropylene-based strapping line offering lightweight, flexible, and high-strength packaging solutions.

Produces flat or cylindrical monofilament from pellets or recycled PET flakes for industrial use.

Twin-screw extrusion line for biodegradable and recyclable sheets with high output and low energy use.

Extrusion line for corrugated PVC roofing tiles using conical twin-screw technology for durability.

Our engineering philosophy combines innovation, efficiency, and sustainability to deliver industrial extrusion solutions that stand the test of time.

Servo motors and low-temperature plasticization reduce power consumption by up to 30%, lowering operational costs.

Robust construction and precision engineering ensure long service life and minimal downtime in demanding environments.

Backed by a responsive team and trusted by customers worldwide, we provide installation, training, and technical support.

Years Experience

Machines Installed

Energy Saved

Countries Served

Our lines handle PET, PP, PVC, PC, PMMA, PLA, EVA, and POE materials, including recycled PET flakes for sustainable production.

Yes, we provide tailored solutions based on output capacity, material type, automation level, and factory layout requirements.

We offer comprehensive on-site installation, operator training, and technical support to ensure smooth startup and operation.

Delivery ranges from 60 to 90 days depending on the complexity and customization of the production line.

For inquiries, quotes, or technical support, visit our official website to connect with our team.

Visit Official WebsiteNotice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info