Precision Die Casting

Engineered in China

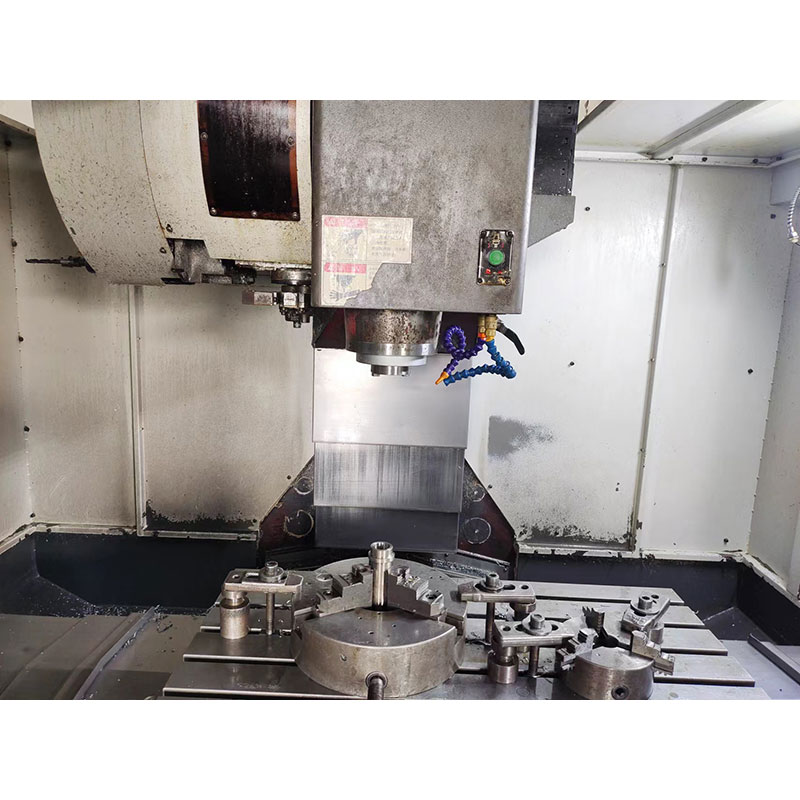

Over 17 years of expertise in aluminum and zinc die casting, gravity casting, low pressure casting, and CNC machining. Trusted by global partners for high-quality, durable metal components.