Our Products

High-performance disc springs, Belleville washers, wave springs, and specialized elastic components for demanding industrial environments.

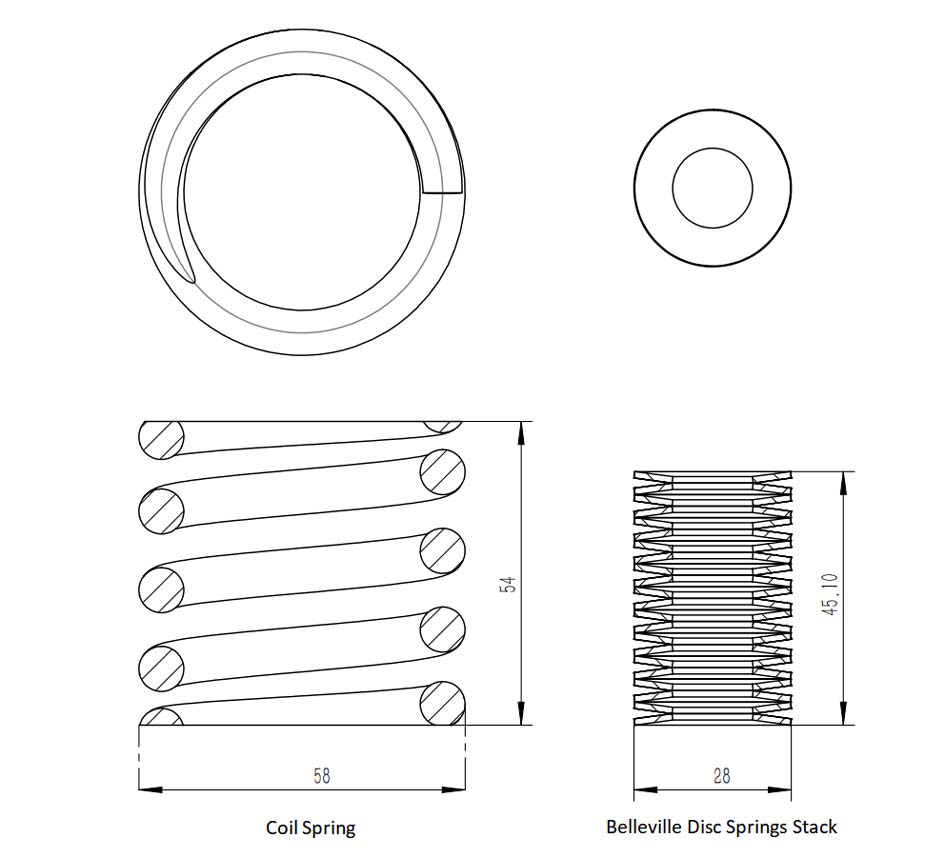

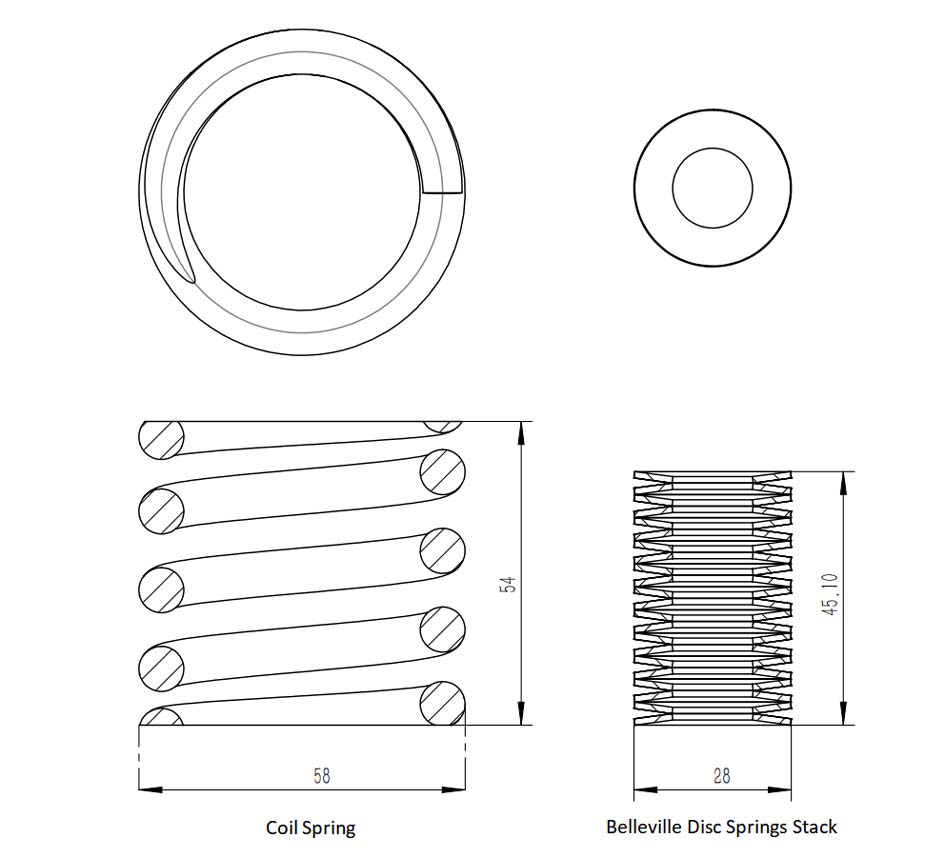

Belleville Disc Springs

Precision conical disc springs designed for high-load applications. Available in various sizes and materials per DIN 2093 standards.

- • High load capacity

- • Compact design

- • Stackable configurations

- • Custom dimensions available

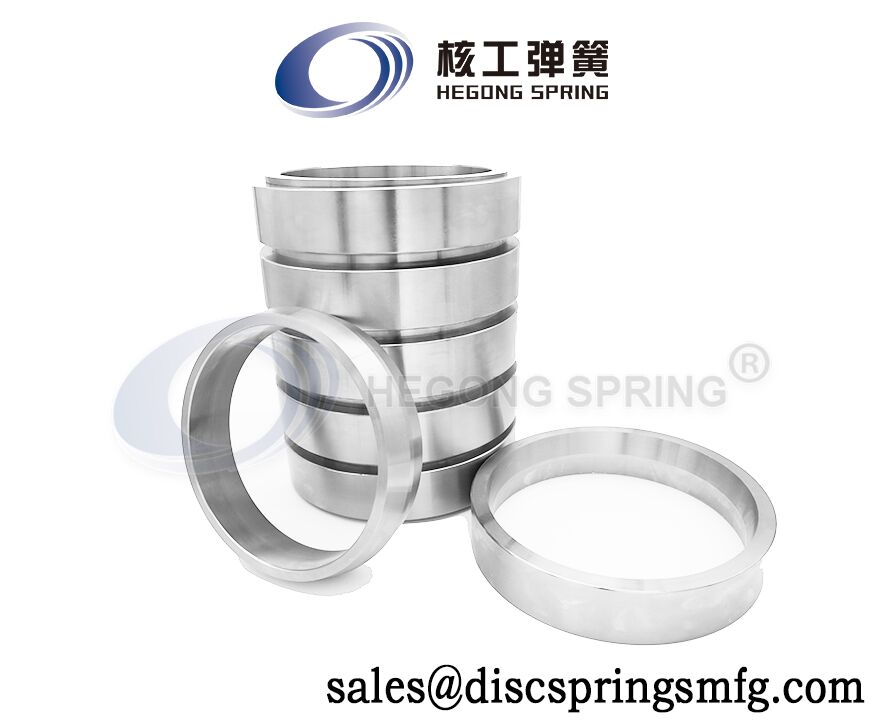

Corrosion Resistant Disc Springs

Stainless steel disc springs made from SUS301, SUS302, SUS316, 17-4PH, 17-7PH, and 15-7Mo for superior corrosion resistance.

- • Long service life

- • Ideal for chemical & marine environments

- • Low wholesale pricing

- • High fatigue resistance

Disc Springs for Valves

Critical components for ball valves, regulating valves, globe valves, pigging valves, and sea valves.

- • Ensures consistent sealing force

- • Compensates for thermal expansion

- • Used in oil & gas industry

- • High reliability under pressure

Belleville Washer DIN6796

Heavy-duty conical washers compliant with DIN6796 standard, used in defense, metallurgy, power, and heavy machinery.

- • High load distribution

- • Prevents loosening under vibration

- • Multiple size options

- • Durable under extreme conditions

Wave Washer / Wave Springs

Elastic wave-shaped springs used for axial load compensation in tight spaces. Supplied in various wave counts and thicknesses.

- • Space-saving design

- • Uniform load distribution

- • Ideal for precision assemblies

- • Market-leading pricing

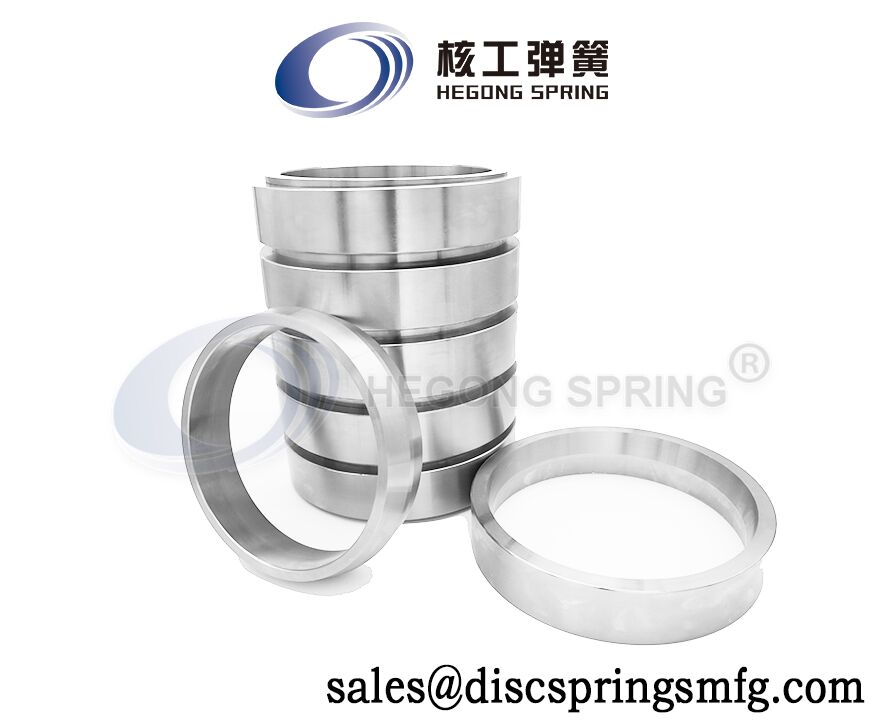

Flange Washers

Also known as flange bolting washers or spring washers, used in flange-bolt connections across petrochemical, power, and metallurgy sectors.

- • Prevents bolt loosening

- • Distributes clamping force

- • Resists vibration fatigue

- • Compatible with high-pressure systems

U-Shaped Spring for Elevator Safety Gear

Also known as safety gear leaf spring, used in progressive elevator safety mechanisms for reliable activation.

- • High fatigue resistance

- • Precision-tuned elasticity

- • Critical safety component

- • Manufactured to strict tolerances

High Temperature Disc Springs

Engineered for operation in elevated temperature environments without loss of spring characteristics.

- • Stable performance up to 650°C

- • Special heat-resistant alloys

- • Used in turbines & reactors

- • Long-term reliability

Cryogenic Disc Springs

Designed for ultra-low temperature applications where standard springs may become brittle.

- • Operates down to -196°C

- • Maintains elasticity at low temps

- • Used in LNG & aerospace

- • Special material selection