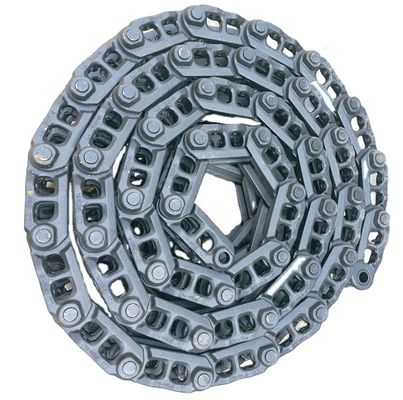

About Excavator TrackLink

As a leading manufacturer and exporter of excavator undercarriage components, we specialize in producing durable, heat-treated track links, rollers, idlers, sprockets, bucket teeth, and fasteners for major brands including Komatsu, Caterpillar, Hyundai, Doosan, Volvo, and JCB.

Our factory, Quanzhou Jintai Machinery Co., Ltd., operates under strict quality control standards with advanced forging, heat treatment, and CNC machining capabilities. Every product undergoes rigorous testing to ensure longevity and performance in extreme working conditions.