Engineered for Industrial Excellence

SUZHOU MANFENGXIANG TECHNOLOGY CO., LTD. is a specialist manufacturer of steel bending and forming equipment, including steel roll forming machines, hydraulic press brakes, shearing machines, and more. Our machinery is widely used in construction, especially for factory buildings, warehouses, and commercial facilities.

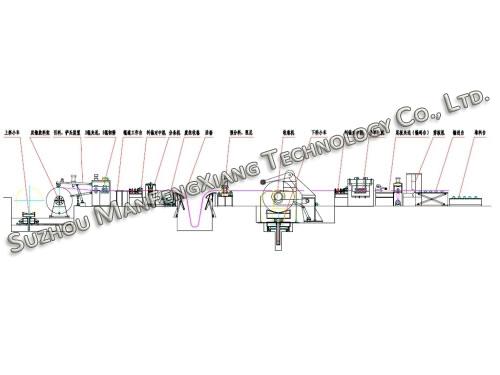

We have developed over 30 series of metal processing machines. Our roll forming systems meet the structural demands of modern steel construction, producing roof sheets, color steel tiles, C/Z/W purlins, and floor decking. We also supply production lines for guardrails, shutter doors, garage doors, and other steel structure components.