Fully Drawn Yarn: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Fully Drawn Yarn (FDY)

USA and EU buyers need FDY that delivers uniformity, on-time delivery, and compliance without compromise. Yet sourcing faces volatile logistics, shifting quality norms, and sector-specific certifications—apparel, sportswear, home textiles, and upholstery all impose different reliability and hand requirements. FDY is a stabilized, directly-usable filament with excellent dyeability, available in Semi-Dull and Bright lusters. Its high-speed spin-draw orientation simplifies downstream knitting/weaving and improves cost efficiency.

Why FDY vs. alternatives

| Factor | FDY (Fully Drawn Yarn) | DTY (Draw Texturized Yarn) |

|—|—|—|

| Process | High-speed spin + integrated draw | POY + drawing + texturing |

| Hand | Crisp, non-textured | Bulk/textured |

| Typical end-uses | Apparel, sportswear, home fabrics, upholstery | Knitwear, stretch fabrics |

| Downstream steps | Direct knitting/weaving/twisting | Requires texturing |

| Lusters | Semi-Dull, Bright | Bright/Dull options |

What this guide covers

- Define FDY specifications, lusters, and quality indicators matched to end-uses.

- Compare FDY vs. DTY on cost, processability, and fabric aesthetics.

- Source globally with USA/EU delivery expectations and logistics planning.

- Ensure compliance (REACH, CA Prop 65), recycled claims, and textile-to-textile (T2T) options.

- Reduce risk through testing protocols, defect root-cause analysis, and pilot trials.

Top 10 Fully Drawn Yarn Manufacturers & Suppliers List

1. Top Yarn Manufacturing Companies [List] – Matchory

Domain: matchory.com

Registered: 2017 (8 years)

Introduction: Top Yarn Manufacturing Companies · SAINT-GOBAIN AMERICA SA DE CV · RELIANCE INDUSTRIES LIMITED · ORIENTAL INDUSTRIES (SUZHOU) LTD · LEALEA ENTERPRISE CO., LTD….

2. Thailand’s top Manufacturers | High-Quality Polyester Yarn and Fiber

Domain: thaipolyester.com

Registered: 1999 (26 years)

Introduction: Operating with a German system and specializing in Virgin and Recycled Polyester yarn, fiber, and filament. Guaranteed with OEKO-tex and GRS….

3. Top FDY Polyester Yarn Manufacturers | Verified Global Suppliers

Domain: accio.com

Registered: 1997 (28 years)

Introduction: Analysis: Manufacturers dominate in production scale – Zhejiang Huilong (30,000+m²) and Shishi Yiming (160,000+m²) offer substantial capacity ……

Understanding fully drawn yarn Types and Variations

Understanding Fully Drawn Yarn Types and Variations

FDY (Full Drawn Yarn) is a directly usable, fully oriented and crystallized polyester filament yarn suitable for both weaving and knitting. While the base material and process are standardized (spin, draw, and stabilization at high speeds), practical performance and application fit vary with luster, color strategy, functional finish, and twist level. The table below outlines the most common commercially relevant types and their trade-offs.

| Type | Key Features | Primary Applications | Pros/Cons |

|---|---|---|---|

| FDY Semi-Dull | Standard luster; high uniformity; excellent dye consistency; stable and direct-use | Wovens (taffeta, satin, poplin, oxford) and flat knits; apparel, uniforms, home textiles | + Balanced cost/performance; + easy sourcing; − Higher visibility of shade variance vs solution-dyed; − Moderate pilling resistance; + high dye reproducibility (Filatex, 2020) |

| FDY Bright | Higher luster and specular reflectance; controlled micro-fibrillation for surface sheen | Decorative apparel, ties, linings, fashion fabrics, trims | + Eye-catching visual effect; + good hand at moderate deniers; − Can show shade shifts under different lighting; − May accentuate surface defects in tight constructions |

| FDY Solution-Dyed | Pigment pre-dispersed in melt; no dyeing step; high shade consistency and UV resistance | Outdoor and workwear; awnings; automotive interiors; industrial textiles; products with frequent washes | + Excellent wash and light fastness; + lower effluent and faster lead times; − Limited color flexibility post-production; − Higher yarn cost vs conventional greige/dyed |

| FDY Functional (Engineered) | Additives integrated (wicking, antimicrobial, antistatic, flame retardant) with targeted mechanical properties | Activewear, sportswear liners, healthcare textiles, upholstery; niche industrial uses | + Targeted performance; + durable finish due to melt integration; − Price premium; − Validation and compliance required by end-use; + versatile in both knitting and weaving (Thai Polyester, 2023) |

| FDY Low/Zero Twist | Lower twist factor (often 30–50 TPM), high filament count per yarn for softness and drapability | Soft-hand woven fabrics, dresswear, scarves, lingerie, home textiles | + Superior drape and softness; + lower twisting cost; − Reduced tensile and seam strength; − Risk of fuzzing without proper tension control during processing |

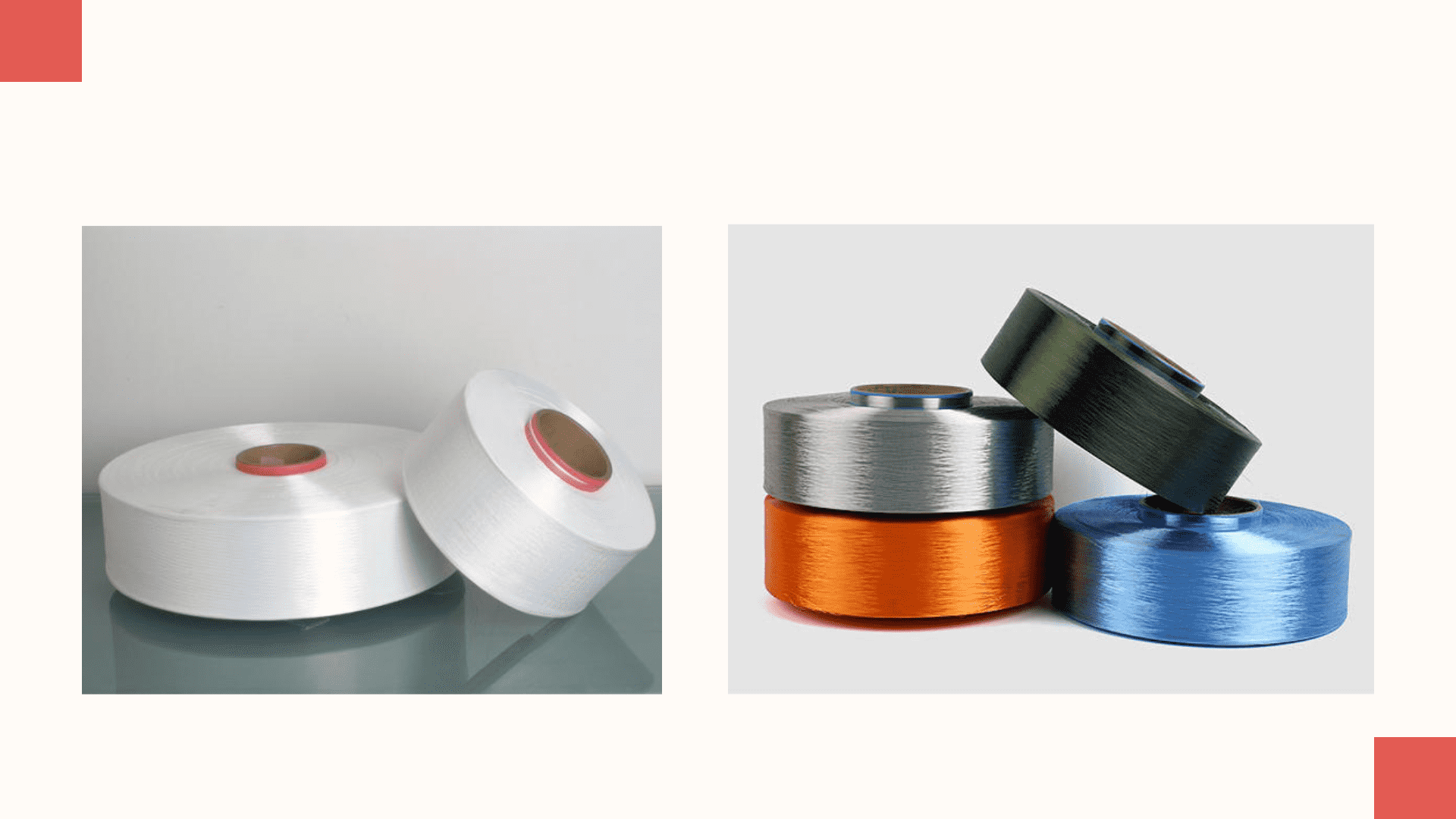

FDY Semi-Dull

Direct-use, uniform filament yarn with moderate luster. Produced at high speeds with integrated drawing for orientation and crystallization, eliminating the need for downstream texturizing. Provides consistent dye uptake and stable performance in woven and flat knit constructions. (Filatex, 2020)

Illustrative Image (Source: Google Search)

FDY Bright

Bright luster variant of standard FDY using similar spin-draw conditions but tuned optics for enhanced reflectance. Commonly specified for visibility-driven fashion and linings; best specified with lighting/shade approvals to avoid metamerism in high-sheen applications. (Thai Polyester, 2023)

FDY Solution-Dyed

Color is introduced at the chip stage for melt-level uniformity, delivering high wash/light fastness and shorter lead times. Often preferred for products with strict color consistency and frequent laundering. Higher upfront cost is offset by sustainability (lower water/energy use) and predictability in large campaigns.

FDY Functional (Engineered)

Specialty additives are integrated to impart moisture management, antimicrobial, antistatic, or flame-retardant properties. Because the additive is part of the polymer, performance remains durable through processing and end-use. Ideal where targeted performance is critical; specify with end-use standards and verify data packs for compliance. (Thai Polyester, 2023)

FDY Low/Zero Twist

A process strategy that trades twist for softness and drape. Typically specified with higher filament counts and carefully managed tension during warping and weaving to minimize fuzzing. Use where aesthetic hand and fluid drape outweigh maximum tensile requirements.

Illustrative Image (Source: Google Search)

References

Filatex India Limited. (2020). Full Drawn Yarn (FDY). https://www.filatex.com/product/full-drawn-yarn-fdy

Thai Polyester Co., Ltd. (2023). What is the difference between FDY and DTY yarn. https://www.thaipolyester.com/what-is-the-difference-between-fdy-and-dty-yarn

Key Industrial Applications of fully drawn yarn

Key Industrial Applications of Fully Drawn Yarn (FDY)

FDY’s high orientation and crystallinity deliver stable, dye-consistent, directly usable filaments for woven and knitted structures at competitive cost, enabling consistent quality in both mass‑market and performance‑driven applications.

| Industry/Segment | Typical Products (FDY‑based) | Detailed benefits | Why FDY works best here |

|---|---|---|---|

| Apparel & Fashion | Dresses, blouses, suiting, uniforms, outerwear; micro‑filament fashion knits | Excellent dyeing uniformity, crisp hand/structure, wrinkle resistance, lightweight comfort, broad luster options (Semi‑Dull/Bright) | Integrated spin‑draw process stabilizes orientation/crystallinity, eliminating downstream draw steps and enabling direct knitting/w weaving for fashion clarity and color repeatability. |

| Sportswear & Performance Knits | Baselayers, singlets, T‑shirts, activewear | Dimensional stability, low pilling when blended, consistent dye batch‑to‑batch, soft hand with micro‑filaments, fast production setup | Oriented filaments deliver tenacity and recovery with consistent quality for high‑volume apparel runs; avoids rework steps typical of POY. |

| Home Textiles | Bedsheets, curtains, drapes, upholstery, mattress ticking, decorative fabrics | Durable weave integrity, excellent colorfastness, low shrinkage, broad luster palette, cost‑effective production | Stability and direct usability reduce defects in large‑width goods and ensure consistent shades across batches. |

| Automotive Interiors | Car seat covers, door panels, headliners, seat belts (reinforcement), safety nets | UV/aging stability (with finishes), abrasion resistance, high seam strength, dye consistency across lots, low weight | Oriented filaments provide structural integrity for high‑wear zones; tight dyeing windows help meet OEM shade tolerances. |

| Narrow & Technical Wovens | Webbing, straps, tapes for harnesses, cargo restraint, safety restraints | High tensile strength, low elongation, low shrink, heat resistance, consistent filament count | Directly wound/beamable yarns maintain filament alignment and tape uniformity; critical for safety‑critical webbing. |

| Medical & Hygiene | Surgical gowns, drapes, masks, sanitary napkins, baby diapers, wipes, hospital linens | Purity/cleanliness options, low linting, excellent dye uniformity for brand labeling, lightweight comfort | Stable orientation/crystallinity ensures reliable GSM and seam performance; low contamination risk for hygiene components. |

| Protective & Safety Textiles | Cut‑resistant knits, high‑visibility apparel, cut sleeves, gloves (liners), safety vests | Abrasion resistance, tenacity, dye fastness for reflective/high‑visibility coloration, dimensional stability | High orientation improves cut/abrasion resistance and garment longevity under repeated wash cycles. |

| Rope, Cordage & Nets | Static/dynamic ropes, marine lines, industrial cordage, cargo nets | High breaking strength, controlled elongation, UV stability, knotting performance | Oriented filaments optimize load‑bearing efficiency; low stretch supports safety and operational reliability. |

| Filtration & Fluid Handling | Filter bags, filter media, fluid transfer belts | Fine filament control, consistent permeability, abrasion tolerance | Filament uniformity yields predictable pore structures; FDY’s strength supports pressure differentials. |

| Geotextiles & Construction | Erosion control mats, reinforcement grids, drainage composites, architectural membranes | Tensile strength and modulus, UV/weather resistance, dimensional stability, dye consistency for coded systems | Oriented yarns improve load distribution and longevity; low shrinkage maintains installed geometry. |

| Flooring & Floorcoverings | Carpet backings, tufted carpet bases, resilient backings, step nosings | Tuft bind strength, abrasion resistance, dimensional stability, colorfastness | Strong, stable filaments keep tuft locks and backing integrity through wear cycles. |

| Coatings & Lamination | Adhesive backings, bonded composites, insulation layers | Uniformity for glue/foam lines, excellent dye consistency for finished goods, predictable filament distribution | Process stability reduces rework in line coating; consistent yarn enables thin, uniform laminates. |

| Packaging & Logistics | Flexible intermediate bulk containers (FIBC), sacks, straps, pallet nets | High strength‑to‑weight, puncture resistance, color coding via dyeing | Oriented filaments deliver reliable load capacity; low shrink reduces bag distortion under load. |

Notes:

– FDY is available in Semi‑Dull and Bright lusters for fine shade control in color‑critical applications.

– Typical denier/luster options enable both crisp structure and soft hand via micro‑filament variants.

– Integration of drawing/orientation with high‑speed spinning delivers consistent, direct‑to‑fabric performance at competitive cost.

3 Common User Pain Points for ‘fully drawn yarn’ & Their Solutions

3 Common User Pain Points for Fully Drawn Yarn (FDY) & Their Solutions

Pain Point 1 — Barre/Cross-Dye and Shade Inconsistency

- Scenario: Knitted or woven fabrics made from FDY show visible bars, uneven shade, or color drift across batches.

- Problem: Variation in dye uptake (e.g., fine denier variation or birefringence differences) and uneven stress/strain during knitting or beaming increase optical non-uniformity.

- Root Causes:

- Process: Inconsistent quench and spin-draw parameters, higher tension variance, or variability in oil/wetting agents.

- Batch-to-batch: Deviation in yarn orientation/crystallization leading to differing bulk/shrinkage and dye kinetics.

- Process window: Dyeing temperature/time outside fiber-specific optimum for disperse dyes.

- Solution:

- Specify and contract to a “shrinkage window” (e.g., 5–7% dry heat) and a denier/tenacity/elongation window with tight tolerances, and request batch COAs including birefringence (for orientation proxy) and boiling water shrinkage.

- Standardize dye process with pre-set, maintain 130°C dye temperature for 30–45 minutes using dye-class-matched disperse dyes, and verify K/S versus lab standards before bulk.

- Stabilize knitting/beaming: maintain 60–65% RH, pre-humidify FDY, and ensure oil uniformity; use electronic tension control on knitting and beaming to keep ΔT/T ≤ 2–3%.

- What to require on the COA and process:

- Denier, tenacity (≥ 3.8–4.2 cN/dtex typical for apparel-grade FDY), elongation (≈12–20%), boil-off shrinkage, Uster unevenness, and birefringence if available.

- Pre-set fabric conditions, dye-bath pH, and temperature profile recorded per lot.

Pain Point 2 — High Tension, Broken Filaments, and Low Machine Speeds

- Scenario: Frequent breaks during beaming/warping or knitting; lint accumulation; lower throughput.

- Problem: Insufficient lubrication, static buildup, or low bundle cohesion (especially in bright luster FDY) cause tension spikes and broken filaments.

- Root Causes:

- Yarn friction: Too low or uneven oil level, rough guide surfaces, or static discharge path not controlled.

- Electrostatic build-up: Low RH, high line speed, or lack of conductive elements in finish.

- Solution:

- Specify finish levels (e.g., 0.6–1.2% owf depending on machinery) with antistatic/friction-control additives verified by coulombmeter; require 4-point test across the lot (start/end, top/mid bobbin).

- Use ceramic/polished guides, electronic tension regulators, and anti-static bars; keep ≥ 60% RH in the aisle and pre-dry/condition yarn.

- Adjust yarn path and reduce abrupt angles; for low-cohesion FDY, use slightly higher filament count or twisted construction where feasible to reduce strand spreading.

- What to monitor (on line and in QA):

- Yarn-on-package finish and moisture content, tension variance (ΔT/T) in winding and beaming, lint rate, and breaks per thousand (BKT). Define acceptance criteria (e.g., ΔT/T ≤ 3%, BKT ≤ 0.3 for critical apparel lines).

Pain Point 3 — Quality Variation Across Shipments

- Scenario: Slight shifts in denier, tenacity, or elongation lead to processing variability (tension, stoppages) and inconsistent appearance.

- Problem: Insufficient lot consistency controls and missing tight incoming QA gates.

- Root Causes:

- Supplier variability: Line maintenance, upstream POY quality shifts, or seasonal humidity changes.

- QC gaps: Lack of SPC/SQC on critical parameters; insufficient sampling frequency.

- Solution:

- Implement incoming QA with AQL 1.5 on key COA items; use statistically sound sampling (e.g., ISO 3951) and reject outside defined windows.

- Conduct on-reel dye trials per batch and run lot acceptance tests including shrinkage, U%, tenacity, and elongation; quarantine lots not within agreed ranges.

- Require supplier SPC on spin-draw, consistent quench, and final wind speed; use change-control with 30-day stability before full adoption.

- What to enforce:

- Denier within ±2%, tenacity ±0.2 cN/dtex, elongation ±2 percentage points, U% within supplier spec, and moisture content 0.3–0.6% (subject to finish level).

- Document deviations and corrective actions; maintain lot traceability with 2D code labels for audit trails.

Quick Comparison Table: Pain Point to Solution Mapping

| Pain Point | Key Causes | Immediate Controls | Acceptance/Indicators |

|---|---|---|---|

| Barre/Cross-dye inconsistency | Variable orientation, uneven finish, process drift | Shrinkage window, denier window, 130°C disperse dyeing, pre-set | K/S target ±3%, ΔT/T ≤ 3%, boil-off shrinkage within window |

| Tension/breaks/low speed | Low oil/antistatic, static, guide wear | Oil/antistatic specification, RH control, polished guides | BKT ≤ 0.3, ΔT/T ≤ 3%, lint rate below threshold |

| Lot-to-lot variation | Inadequate SPC, wide spec | Incoming AQL 1.5, SPC, on-reel dye test | Denier ±2%, tenacity ±0.2 cN/dtex, elongation ±2 pts |

Notes aligned to references:

– FDY is fully drawn via high-speed spin-draw and heated drawing; avoids texturizing. This enables consistent orientation/crystallization and high dye uniformity.

– Use semi-dull vs bright luster where bright’s higher specular reflection can exacerbate optical variations under suboptimal control.

Strategic Material Selection Guide for fully drawn yarn

Strategic Material Selection Guide for Fully Drawn Yarn (FDY)

1. What FDY Brings to the Table

- Fully Oriented Yarn – Produced by high‑speed spinning + integrated drawing, eliminating the need for downstream texturising.

- Consistent Property Profile – Orientation and crystallisation are fixed at the spinneret, giving reliable tenacity, elongation, and shrinkage.

- Direct‑to‑Fabric Use – Suitable for weaving, knitting, and twisting without intermediate processing steps, which translates into lower conversion cost and faster time‑to‑market.

2. Core Material Criteria – What to Evaluate

| Criterion | Typical PET‑FDY Range | Why It Matters |

|---|---|---|

| Polymer (Base) | PET (Polyethylene terephthalate) – virgin or recycled (rPET) | Availability, cost, recycling compliance. |

| Intrinsic Viscosity (IV) | 0.62 – 0.66 dL/g (standard) 0.68 – 0.72 dL/g (high‑tenacity) |

Controls melt strength → tenacity & draw‑ratio tolerance. |

| Denier / Filament Count | 30/24 – 150/48 (customizable) | Determines fabric weight, cover, and hand feel. |

| Tenacity | 4.0 – 5.5 cN/dtex (standard) 5.5 – 6.5 cN/dtex (high‑tenacity) |

Strength‑to‑weight ratio for end‑use durability. |

| Elongation at Break | 15 % – 25 % (standard) 12 % – 18 % (high‑tenacity) |

Influences fabric stretch, recovery, and seam performance. |

| Shrinkage (190 °C, 15 min) | 4 % – 6 % (standard) 3 % – 4 % (low‑shrink) |

Critical for dimensional stability in garments & home textiles. |

| Moisture Regain | 0.4 % (standard PET) | Affects comfort (wicking, breathability). |

| Luster | Semi‑dull or Bright | Determines visual appeal, opacity, and dye uptake. |

| Dyeability | Conventional (disperse dyes) Cationic‑dyeable (CO‑PET) |

Enables colour depth, fastness, and special finishes. |

| Sustainability | Virgin PET, rPET (20 %‑100 % recycled) GRS / OEKO‑TEX compliant options |

Required for compliance in US/EU markets. |

3. Selecting the Right Luster

| Luster | Key Characteristics | Recommended End‑Uses |

|---|---|---|

| Bright | High specular reflectance → sheen, vivid colour pop | Sportswear, fashion apparel, active‑wear, swimwear |

| Semi‑dull | Matte finish, softer hand, better opacity | Casual wear, home textiles, upholstery, technical fabrics |

Tip: For printed or digitally dyed fabrics, bright yarns often yield richer colour density, while semi‑dull reduces shine for a “natural‑look” aesthetic.

4. Count & Denier – Matching to Fabric Weight

| Target Fabric Weight (GSM) | Typical Yarn Denier | Filament Count Guidance |

|---|---|---|

| 80 – 120 g/m² (lightweight) | 30 – 50 dtex | 24 – 48 filaments |

| 120 – 200 g/m² (mid‑weight) | 70 – 110 dtex | 48 – 96 filaments |

| 200 + g/m² (heavy‑weight / technical) | 120 – 150 dtex | 96 + filaments |

Why: Lower denier reduces fabric bulk, higher denier improves abrasion resistance and dimensional stability.

5. Process‑Level Parameters You Can Influence

| Parameter | Impact on Yarn Properties | Practical Levers |

|---|---|---|

| Spin‑draw speed | Higher speed ↑ orientation → ↑ tenacity, ↓ elongation | Adjust spin‑draw tension control |

| Draw ratio | Determines crystallinity; higher ratio ↑ tenacity, ↓ shrinkage | Optimise multi‑stage draw |

| Heat‑setting temperature | Affects crystallite size → controls shrinkage & dye diffusion | Fine‑tune after‑drawing heater set‑point |

| Winding tension | Low tension → more uniform filament spacing → better dye uniformity | Use tension feedback loops |

| Additive level (e.g., UV stabiliser, anti‑static) | Adds functional performance | Specify during polymer formulation or melt‑mixing stage |

6. Mapping End‑Uses to Material Specs

| End‑Use | Preferred Luster | Tenacity (cN/dtex) | Elongation (%) | Shrinkage (190 °C) | Typical Denier |

|---|---|---|---|---|---|

| Activewear / Sportswear | Bright | ≥ 5.5 | 12‑18 | ≤ 4 % | 30‑70 dtex |

| Casual Apparel (t‑shirts, dresses) | Semi‑dull (for matte) or Bright (for shine) | 4.5‑5.0 | 15‑22 | 4‑5 % | 50‑90 dtex |

| Home Textiles (curtains, bedding) | Semi‑dull | 4.0‑4.5 | 18‑25 | 5‑6 % | 70‑110 dtex |

| Upholstery / Car Seat Covers | Bright or Semi‑dull (depending on finish) | ≥ 5.5 (high‑tenacity) | ≤ 15 | ≤ 4 % | 110‑150 dtex |

| Technical / Industrial (filters, flooring) | Bright or Semi‑dull (functional finish) | 5.0‑6.0 | 12‑18 | ≤ 4 % | 120‑150 dtex |

| Recycled‑Content Products (EU/US markets) | Semi‑dull (preferred for natural feel) | 4.0‑4.5 | 15‑25 | 4‑6 % | 70‑110 dtex (rPET) |

Note: Cationic‑dyeable PET can be selected for deep‑colour fashion or when colourfastness is a regulatory requirement.

7. Sustainability & Compliance Checks

| Requirement | Acceptable Options | Documentation |

|---|---|---|

| Recycled Content | rPET (20 %‑100 % recycled) | GRS (Global Recycled Standard) or RCS certificates |

| Restricted Substances | OEKO‑TEX Standard 100, REACH compliance | Test reports, compliance letters |

| Carbon Footprint | Use of renewable electricity in polymerisation, low‑temp drawing | Supplier carbon disclosure statements |

| End‑of‑Life | Recyclable PET; possibility of mechanical or chemical recycling | Supplier recycling program statements |

8. Decision Flow – From Requirement to Specification

- Define end‑use performance priorities (strength, hand, shrink, sustainability).

- Select luster based on visual/aesthetic need.

- Choose polymer & IV – standard PET vs high‑tenacity PET vs rPET.

- Pick denier/filament count to achieve target GSM.

- Specify tenacity, elongation, shrinkage thresholds aligned with end‑use.

- Add functional additives (UV, anti‑static, cationic dyeability).

- Validate compliance (GRS, OEKO‑TEX, REACH).

- Confirm process capability (spin‑draw speed, draw ratio, heat‑setting).

9. Comparison Table – FDY vs DTY vs POY

| Property | FDY (Fully Drawn Yarn) | DTY (Drawn Textured Yarn) | POY (Partially Oriented Yarn) |

|---|---|---|---|

| Process | High‑speed spin + inline drawing (no downstream texturising) | FDY + false‑twist texturising | Spun at lower speed, drawn later (usually off‑line) |

| Orientation / Crystallinity | Fully oriented & crystallised at spinneret | Oriented (partial) + texture‑induced orientation | Partially oriented, requires further drawing |

| Typical Tenacity | 4.0 – 6.5 cN/dtex | 3.5 – 5.0 cN/dtex (lower due to texturising) | 3.0 – 4.0 cN/dtex |

| Typical Elongation | 12 % – 25 % (depends on draw) | 15 % – 30 % (higher because of false‑twist) | 30 % – 50 % |

| Typical Shrinkage | 3 % – 6 % (controlled) | 4 % – 7 % (higher due to texture) | 7 % – 12 % (needs further heat‑setting) |

| Luster Options | Semi‑dull, Bright (same as base polymer) | Same luster as base yarn (often bright) | Usually semi‑dull (requires downstream finishing) |

| Typical End‑Uses | Woven fabrics, knit fabrics, industrial (no texturising needed) | Elastic/technical fabrics, sportswear, hosiery (requires stretch) | Base yarn for texturising, low‑cost fabrics |

| Processing Cost | Lower (single step) | Higher (extra texturising step) | Lowest (raw yarn) but requires downstream processing |

10. Key Takeaways

- Match material specification to the garment’s functional demands – prioritize tenacity for durability, elongation for stretch, and shrinkage for dimensional control.

- Choose luster deliberately – bright for fashion impact, semi‑dull for a natural hand or opacity.

- Leverage FDY’s single‑step production to reduce lead‑time and processing cost versus POY or DTY when texture is not required.

- Confirm sustainability credentials (rPET, GRS, OEKO‑TEX) early; they affect both cost and market准入 in the US/EU.

- Use the comparison matrix to evaluate alternative yarn types only when the performance trade‑offs (e.g., stretch, bulk) outweigh FDY’s advantages.

By systematically aligning polymer chemistry, filament architecture, and process parameters with the targeted end‑use, you can maximise product performance while optimising total cost of ownership for your FDY supply chain.

Illustrative Image (Source: Google Search)

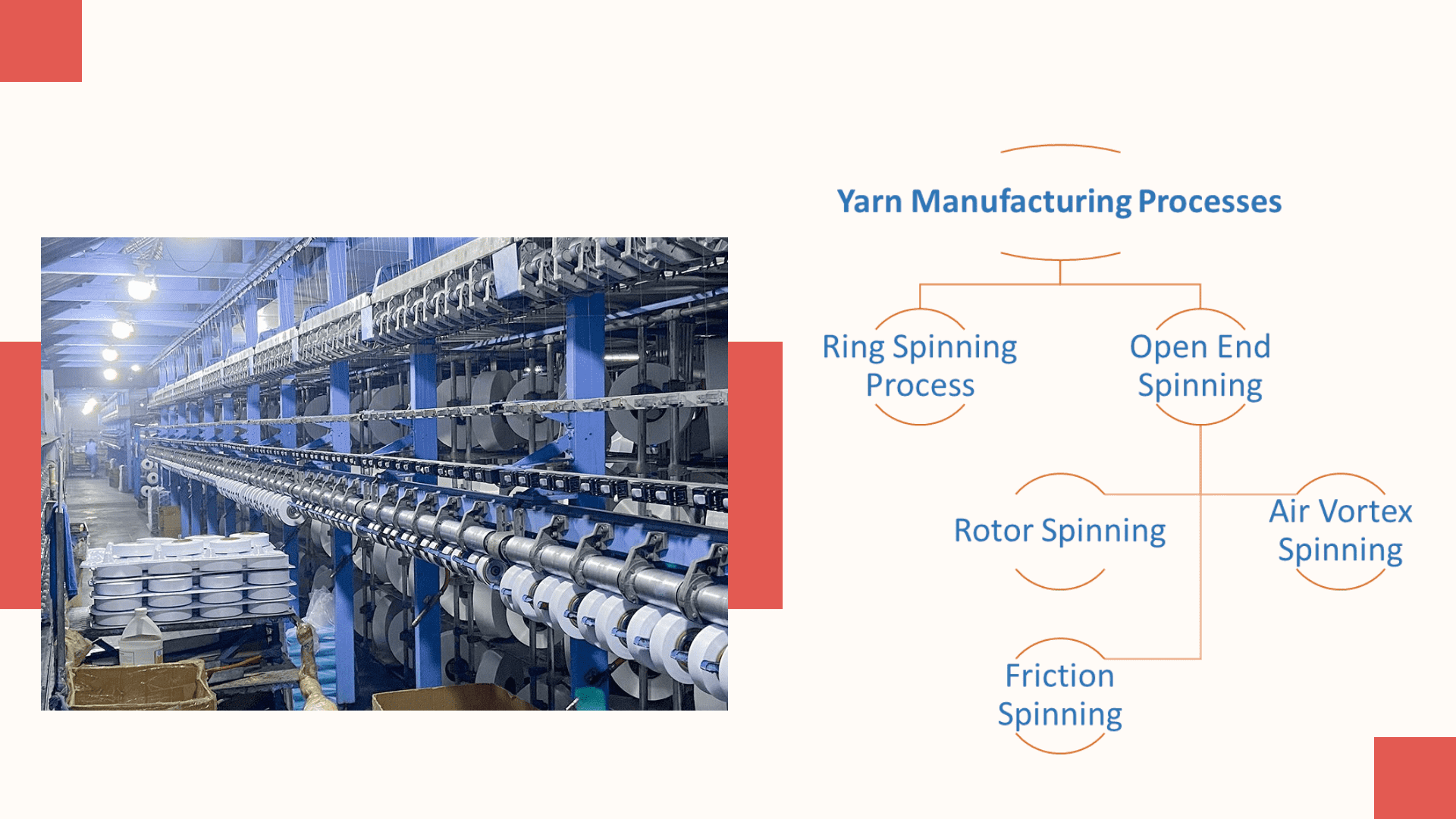

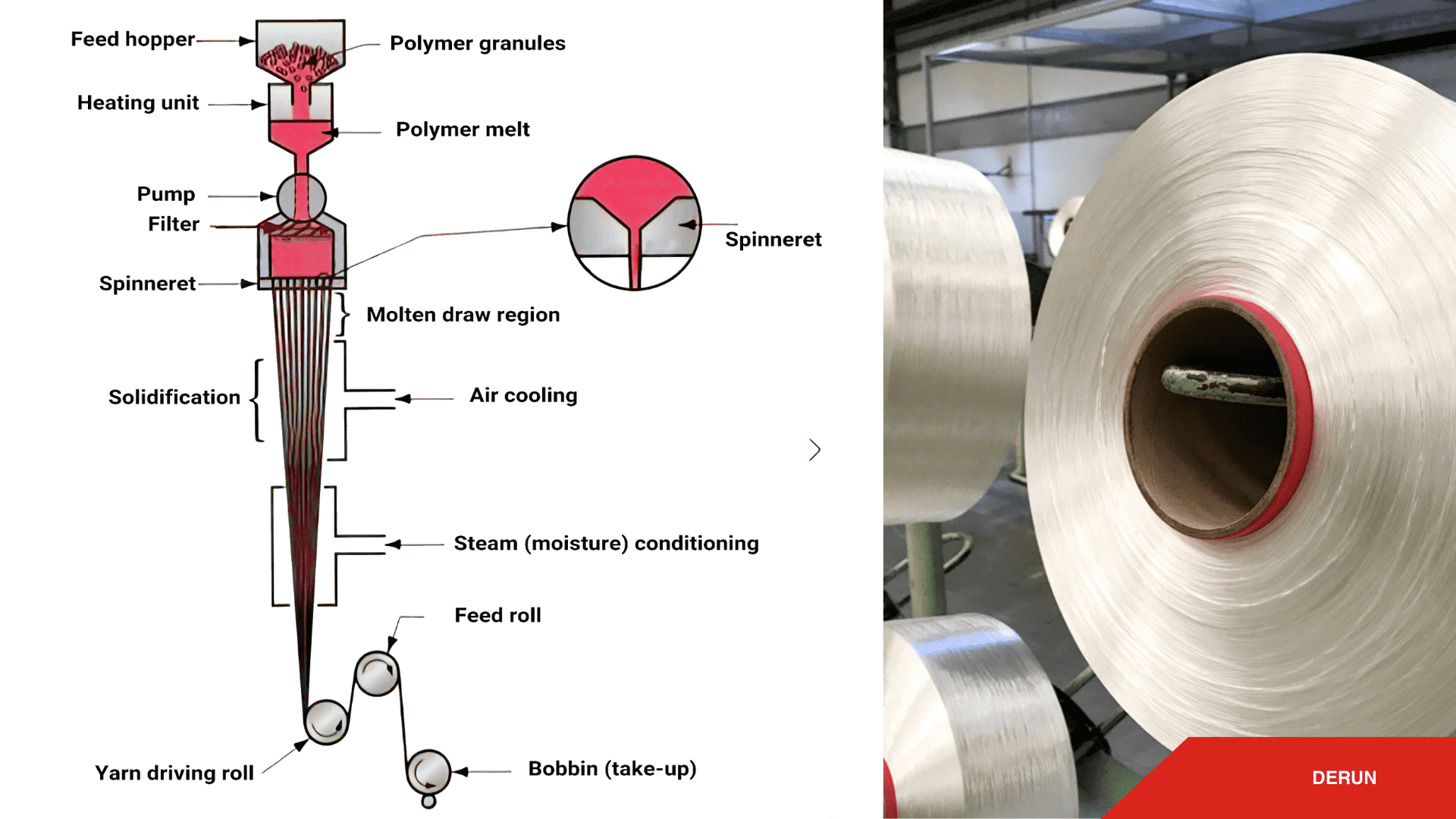

In-depth Look: Manufacturing Processes and Quality Assurance for fully drawn yarn

In-depth Look: Manufacturing Processes and Quality Assurance for Fully Drawn Yarn (FDY)

FDY is produced via a high‑speed spin‑draw‑wind process in which spinning, drawing, and stabilization are combined. The process yields molecular orientation and crystallization directly in-line, so the yarn can be used for knitting, weaving, twisting, or beaming without further drawing. Typical configurations include godet pairs for heated drawing, quenching with controlled air, finish application, interlacing/airs, and automatic winder tension control.

Manufacturing Steps

Prep

- Polymer selection and drying: Grade, intrinsic viscosity (IV), and moisture content are controlled to stabilize melt viscosity and prevent hydrolysis during extrusion.

- Masterbatch/pigments: Concentrates are mixed to achieve target luster (Semi‑Dull/Bright) and color consistency; dispersion quality is verified.

- Melt filtration and metering: Filters remove particulates; gear pumps metering ensure stable throughput.

- Spin finish: Lubricant and antistat levels are adjusted for friction control, cohesion, and processability.

Forming

- Quenching and solidification: Controlled cross‑flow air induces filament solidification with uniform thermal profile to minimize denier variation.

- Spin‑draw: High‑speed godets apply heat and tension to orient and crystallize filaments in one pass; the drawing ratio is set to achieve target tenacity and elongation.

- Stabilization: Heat setting in-line stabilizes shrinkage and dimensional consistency.

- Interlacing/Airs: Filaments are interlaced to improve cohesion for weaving/knitting; interlacing level is tailored to end‑use.

Assembly (Winding & Finishing)

- Winding: Automatic winders maintain constant tension and traverse to produce packages suitable for downstream processes.

- Twist (optional): When required, direct twisting yields cords or technical yarns.

- Beaming (optional): Yarn is wound onto beams for weaving; tension uniformity and end count accuracy are critical.

QC (In‑Process and Final)

- Inline monitoring: Mass per meter (MPY), U%, CV%, tension, godet temperatures, and wind stability are continuously tracked.

- AQC: Samples are drawn per sampling plans and tested for tensile, shrinkage, and dye uniformity.

- Visual inspection: Package defects and finish uniformity are inspected.

- Lot release: Certification of compliance against customer specifications.

Typical process parameters (illustrative ranges; set per grade and speed profile):

– Line speed: typically 3,000–6,000 m/min

– Draw ratio: tuned to achieve required tenacity/elongation

– Draw block temperature: sufficient for orientation and crystallization while limiting shrinking variability

– Interlacing level: set per end‑use cohesion and tension requirements

Typical FDY characteristics (specifiable targets vary by denier and grade):

– Yarn structure: continuous multi‑filament

– Luster: Semi‑Dull or Bright

– Tenacity: optimized for direct weaving/knitting without additional drawing

– Elongation: controlled to balance strength and processability

– Shrinkage: stabilized to ensure fabric dimensional stability

– Dyeing uniformity: typically strong and uniform due to consistent solidification and orientation

Quality Standards and Methods (ISO and related)

Quality assurance relies on internationally recognized test methods. The primary ISO test families used in the US/EU include:

Illustrative Image (Source: Google Search)

- Yarn linear density: ISO 2060 (Textiles—Yarns from packages—Determination of linear density by methods such as skein and single‑end)

- Tensile properties: ISO 2062 (Textiles—Yarns from packages—Determination of single‑end breaking force and elongation at break)

- Moisture conditioning and testing atmosphere: ISO 139 (Textiles—Standard atmospheres for conditioning and testing)

- Irregularity (U% and CV%): ISO 2647 (Textiles—Wool—Determination of irregularity of slivers, rovings, and yarns—Photoelectric method)

- Shrinkage: ISO 3005/3006 (Textiles—Polyester filament yarns—Determination of boiling‑water shrinkage—Part 1/Part 2)

- Friction and finish performance: ISO 2110 (Textiles—Warp and weft—Determination of yarn length, linear density, and number of twists—Determination of yarn length)

- Luster assessment (visual/parametric): ISO 16504 (Textiles—Lustredness—Determination of lustre)

Additional widely used methods in US/EU:

– ASTM D1425 (Irregularity of yarn by the capacitance method)

– ASTM D1578 (Single‑end method for breaking force and elongation)

– ASTM D2258 (Sampling yarn for test)

QC plan elements:

– Incoming polymer verification: moisture, IV, pigments, and contaminants.

– In‑line inspection: yarn speed, tension, godet temperatures, quench airflow, and finish pickup.

– AQC sampling: batch-based sampling per lot size; replicate testing for critical properties.

– Defect tracking: systematic logging of yarn breaks, loops, and finish variations.

– Customer specifications alignment: tolerances for tenacity, elongation, shrinkage, and dye reproducibility are set per end‑use.

– Traceability: batch records linking polymer lots, machine settings, and test results to each shipment.

Key takeaways:

– The integrated spin‑draw‑wind process is optimized for high productivity and consistent yarn properties.

– Tight control of quench airflow, godet temperature, and winding tension is central to consistent dyeing and fabric performance.

– ISO‑aligned methods ensure reliability and facilitate acceptance across US/EU supply chains.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fully drawn yarn’

Practical Sourcing Guide: A Step-by-Step Checklist for Fully Drawn Yarn (FDY)

Purpose and quick context

FDY is a fully drawn polyester filament suitable for direct knitting/weaving and non-textured fabrics. It is spun at high speed with integrated drawing, then oriented and stabilized, and is commonly available in Semi-Dull and Bright lusters.

Illustrative Image (Source: Google Search)

Step-by-step sourcing checklist

1) Define application and fabric architecture

- What to decide: End-use (apparel, fashion, sportswear, home furnishing, upholstery, car seat covers), knitting vs weaving, and whether FDY will be used alone or blended with other filament yarns.

- Why it matters: FDY is best for direct knitting/weaving and non-textured fabrics. If textured aesthetics or bulk are required, DTY is typically used.

2) Select FDY specifications

- What to specify: Denier/Decitex and filament count (e.g., 75D/36f, 150D/48f), twist level and direction (if applicable), and finish.

- Why it matters: Controls fabric hand, drape, and mechanical performance; compatibility with downstream machinery.

3) Choose luster and color

- What to specify: Semi-Dull or Bright; raw white or solution-dyed.

- Why it matters: Affects visual appearance and downstream dyeing (solution-dyed reduces dyeing steps).

4) Confirm quality properties

- What to check: Tenacity, elongation, boiling shrinkage, evenness; dyeing consistency; light weight characteristics; defect tolerance (broken filaments, filaments per yarn).

- Why it matters: Ensures processability and uniformity in finished fabrics; FDY has excellent dyeing consistency.

5) Document trade and commercial terms

- What to agree: Incoterms (FOB/CIF recommended for initial orders), payment terms, currency (USD/EUR), minimum order quantity, pricing basis, order validity, and price validity window.

- Why it matters: Aligns expectations and reduces cost/lead-time variance.

6) Set compliance and sustainability requirements

- What to check: Recycled content claims and documentation, packaging materials compliance, and any applicable region-specific restrictions.

- Why it matters: Confirms authenticity of recycled inputs and avoids regulatory issues in USA/EU.

7) Align on logistics and packaging

- What to define: Packaging type and labeling (net weight per package, lot/batch ID, lot mixing rules), shipping marks, required palletization, expected delivery lead time, and delivery location (port, warehouse).

- Why it matters: Ensures efficient unloading and lot traceability.

8) Validate laboratory sampling and pre-production approval

- What to do: Request sample yardage with agreed specs; run small knitting/weaving trials; approve shade/performance; document acceptance.

- Why it mitigates risk: Avoids large defects; confirms dyeing consistency and process performance at scale.

9) Confirm scale-up plan and monitoring

- What to agree: Production schedule, periodic lot checks, inspection points, and communication cadence.

- Why it keeps timelines: Aligns capacity and minimizes delay exposure.

10) Establish QC, inspections, and claims

- What to set: AQL inspection levels, rework/claims process, spare allowance policy, and corrective-action responsibilities.

- Why it ensures recourse: Clarifies remedies if targets are not met.

Typical FDY quick specs (for specification drafting)

- Material: Polyester FDY (PFY/SDY)

- Luster: Semi-Dull; Bright

- End-uses: Direct knitting/weaving; non-textured fabrics such as apparel, fashion fabrics, sportswear, home furnishings, upholstery, car seat covers

Where FDY fits vs DTY (for buyer education)

- FDY: Fully drawn, suitable for direct knitting/weaving, non-textured fabrics; offers excellent dyeing consistency and consistent quality at a low price.

- DTY: Drawn and textured for bulkier, textured aesthetics; suited when elasticity/texture is desired; not interchangeable when direct weaving/knitting and non-textured fabrics are required.

Optional vendor info panel (for sourcing outreach)

- Company: Filatex India Limited

- Head Office: 43, Community Centre, New Friends Colony, New Delhi, 110025, India

- Phone: +91-11-26312503; +91-11-26801105; +91-11-26801106

Use this checklist as your procurement gate before placing purchase orders and as a live control during production and delivery.

Comprehensive Cost and Pricing Analysis for fully drawn yarn Sourcing

Comprehensive Cost and Pricing Analysis for Fully Drawn Yarn (FDY) Sourcing

FDY (Fully Drawn Yarn) is a high-speed, integrated spin-draw filament yarn that skips texturizing. That single design choice—drawing and crystallization in-line at high speeds—matters for both cost and performance. For buyers in the USA and Europe, the practical question is this: how do you quantify FDY’s cost structure, model pricing, and capture savings without compromising quality? Below is a structured view of the economics, levers, and common pitfalls, designed for B2B sourcing.

1) Key Differences That Drive Cost (FDY vs DTY)

What changes the bill of cost is the process path. FDY omits texturizing; DTY adds it. FDY’s integrated orientation and crystallization yield lower conversion cost and greater consistency, especially for basic-luster end uses.

| Aspect | FDY (Fully Drawn Yarn) | DTY (Drawn Textured Yarn) | Cost Implications |

|---|---|---|---|

| Process | Spin → High-speed draw + orientation + crystallization (integrated) | POY → Drawing + Texturizing (two-step) | FDY: fewer steps, lower conversion cost; DTY: extra unit ops add cost |

| Texturizing | Not needed | Required | FDY: direct use for woven/knit flat fabrics; DTY: premium stretch handle |

| Luster | Semi-Dull / Bright | Often Semi-Dull / Bright; textured bulk | FDY: simple luster options reduce complexity |

| End-use fit | Non-textured fabrics: apparel, fashion, sportswear, home, upholstery, car seats | Textured fabrics: performance stretch, athleisure | FDY fits direct weaves/knits; DTY if elasticity and bulk are essential |

| Performance | Excellent dye consistency, light-weight, consistent quality | Texturized bulk and elasticity; dye consistency depends on upstream yarn | For non-textured use, FDY’s path can yield higher contribution (margin) due to fewer operations |

2) Cost Model Overview

Costs break into three blocks. Each varies by region and contract structure. This view keeps your modeling practical.

| Category | Line Items | USA vs Europe Notes |

|---|---|---|

| Materials | PET chips (virgin or recycled), additives, dyes for masterbatch, luster modifiers (TiO₂), finishes, lubricants | EU buyers often request REACH-compliant and GRS recycled content. Virgin vs recycled chip premiums can vary by market conditions and available GRS volumes. |

| Labor | Spinning operators, maintenance, QC, supervision, downtime coverage | US/EU typically higher base labor rates; automation and line utilization drive real cost per kg. |

| Utilities | Electricity (spinning/draw), steam/hot oil (draw godets, heaters), compressed air, water | Europe often faces higher gas prices historically; US electricity varies by grid and demand. |

| Conversion | Capex depreciation (spin-draw lines), spare parts, tooling, line cleaning, process monitoring | Higher-speed lines improve unit cost; stable operation and tight OEE are critical. |

| Logistics (Inbound) | Ocean freight/feeder for chips, domestic trucking/rail, bulk storage | Asia-to-EU/USA: long-haul freight volatility; inventory strategies matter. |

| Logistics (Outbound) | Packaging (cartons/pallets), warehousing, domestic transport to mills, customs brokerage | EU and US have strict labeling/handling. Unitized loads reduce handling costs. |

| Overheads & Compliance | QA testing, certifications (GRS, REACH), ESG reporting, IT, finance | Buyers with strict compliance benefit from fewer change orders and lower rejects. |

| Selling Terms | Incoterms (EXW/FOB/CIF/DAP), payment terms, volume discounts | Align terms to volatility in raw materials and freight. Use formula-based pricing for transparency. |

3) Formula-Based Pricing for Stability

If markets swing, tie your price to a formula you can defend.

| Component | Description | Example Considerations |

|---|---|---|

| Base Material Cost | PET chip cost per kg + additives/dyes | Update monthly; normalize moisture content and yield loss factors |

| Conversion Cost | Spinning/drawing, utilities, labor, maintenance | Include depreciation of spin-draw lines; OEE affects effective unit cost |

| Logistics | Inbound chips + outbound FDY (packaging, freight, customs) | Consider Incoterms; use lane-specific freight indexes when available |

| Operating Margin | Target contribution (EBITDA basis) | Set a clear band (e.g., x–y%) tied to quality and service KPIs |

| FX Adjustment | Foreign exchange impact on chips and freight | Monthly adjustment using an agreed index |

| Total Price | Sum | Formula: Material + Conversion + Logistics + Margin (adjusted for FX) |

- Use a “price calendar” with monthly index references for PET chips and energy. This stabilizes cash flow for both buyer and seller.

- For long-term contracts, introduce an option to revisit conversion and logistics bands if key indices move beyond agreed thresholds.

4) Cost Levers and Region-Specific Notes

Materials

– Pet chip grades: Higher orientation in FDY means consistent molecular alignment. Quality consistency reduces rework.

– Virgin vs recycled: Recycled content (GRS) can attract premiums; confirm stable supply and consistent lot quality. Dyes may differ in recycled streams—impact on consistency must be tested.

– Luster decisions: Bright vs Semi-Dull shifts TiO₂ loadouts; check dye uptake and optical stability before locking specs.

Conversion

– High-speed lines: With integrated draw and crystallization, throughput and stability are the big levers. Line downtime directly spikes $/kg.

– Utilities: European gas constraints historically raised heating costs; US grids vary but can be cost-effective. Monitor energy indices.

– Maintenance: Dedicated godet heating, high-speed winders, and filtration systems drive stable operation; predictive maintenance lowers hidden costs.

Logistics

– Inbound chips: Asia-to-EU/USA ocean freight is volatile. Consolidate shipments and use bulk packaging to cut unit freight.

– Outbound FDY: Unitized pallets and consistent cartonization help minimize handling. Use Incoterms to align risk. Customs delays add cost; pre-clear documentation.

– Lead times: FDY can be stocked and staged; shorter inland distances from port to mill reduce last-mile costs in both USA and EU.

Illustrative Image (Source: Google Search)

5) Savings Without Sacrificing Quality

Think in layers: eliminate waste, stabilize inputs, and tune operations.

- Eliminate process waste

- Optimize yarn path to reduce tension spikes and breakage; lower snarl = less reprocessing.

-

Tighten temperature/heat set windows for draw godets; this cuts defect rate and dye variations.

-

Align luster and denier to demand

- Semi-Dull vs Bright: if apparel targets neutral tones, Semi-Dull can improve dye uniformity; reduce retries.

-

Denier and filament counts: standardize commonly used counts; avoid frequent changeovers that drive setup losses.

Illustrative Image (Source: Google Search)

-

Lock material specs early

-

Masterbatch and finishes: ensure dye lot consistency and binder levels are pre-validated. Changes mid-contract create hidden costs.

-

Improve line utilization

-

Target higher OEE through scheduled maintenance, spare parts readiness, and clear SOPs. More minutes at speed = fewer fixed-cost allocations per kg.

Illustrative Image (Source: Google Search)

-

Lean logistics

- Consolidate ocean shipments; leverage off-peak cycles; negotiate volume freight windows.

-

Use direct mill delivery lanes; minimize transshipment and storage churn.

-

Contract structures

- Formula pricing with monthly indexation avoids fire drills. Tie volume commitments to predictable cash outlays.

-

Incoterms clarity: FOB or CIF for predictability; DAP if you want tighter control over last-mile.

Illustrative Image (Source: Google Search)

-

Compliance as a cost saver

-

Pre-approve REACH-compliant chemistries and GRS certificates. Fewer change orders = stable conversion costs.

-

Waste-to-value

- Reprocessable offcuts and end-of-lot materials: evaluate re-entry if quality permits; this reduces absolute waste cost.

6) Risk Control and Practical Checks

- Test dye consistency across lots. FDY is praised for dye consistency; keep a routine shade bench check to catch drift early.

- Maintain a short “qualification lane” for recycled content. Confirm denier stability and filament integrity before scaling.

- Keep a dynamic freight buffer in contracts. Use corridor-specific adjustments to avoid overspending during spikes.

- Monitor energy and FX indices. If indices move beyond a band, trigger the pricing revisit clause.

7) Cost vs Value: When FDY Beats DTY (Economically)

- For non-textured fabrics with basic lusters—fashion fabrics, sportswear, home furnishings, upholstery, car seats—FDY often delivers a higher contribution because texturizing is skipped and consistency is strong. Buyers can redeploy value into better greige, higher-end finishing, or tighter delivery schedules.

- If elasticity or bulk is a must, DTY’s extra processing is justified. Match the process to the end-use, not the other way around.

8) Quick Action Checklist

- Build a cost model with Material, Conversion, Logistics, and Margin; separate out FX for Asia-origin supply.

- Lock in monthly indices for PET chips, electricity/gas, and freight; set bands for resets.

- Pre-qualify luster/denier/filament sets; standardize what the mill consumes most.

- Confirm REACH and GRS credentials; include them as must-have contract clauses.

- Set OEE targets for your suppliers; review downtime causes quarterly.

- Negotiate Incoterms aligned to your mill locations; minimize transshipment steps.

Done right, FDY offers a compelling cost-performance combination for non-textured end uses in the USA and Europe. The trick isn’t just cheaper inputs; it’s fewer steps, fewer surprises, and tighter execution across the value chain.

Illustrative Image (Source: Google Search)

Alternatives Analysis: Comparing fully drawn yarn With Other Solutions

Alternatives Analysis: Comparing FDY with Other Solutions

Fully Drawn Yarn (FDY) is spun at high speeds with integrated drawing and orientation/crystallization. It does not require texturizing and is typically used directly in knitting or weaving to produce flat-filament fabrics with consistent dye uptake and competitive pricing.

To clarify where FDY fits relative to other common polyester filament solutions, the table below contrasts FDY with DTY (drawn textured yarn) and POY (partially oriented yarn).

Comparative overview: FDY vs. DTY vs. POY

| Attribute | FDY (Fully Drawn Yarn) | DTY (Drawn Textured Yarn) | POY (Partially Oriented Yarn) |

|---|---|---|---|

| Production route | Spun at higher speeds with integrated drawing; orientation + crystallization; no separate texturizing | POY → drawing + texturizing (e.g., false-twist); additional processing step | Spun; lower draw; intermediate orientation; requires further drawing/texturizing |

| Orientation/tenacity | High orientation and stability; direct-use tenacity | Balanced orientation for elasticity | Lower orientation; higher elongation; intermediate tenacity |

| Elasticity/bulk | Flat filament; low elasticity; minimal bulk | Elasticity (controlled stretch) and bulk; soft hand | Elasticity only after texturizing; flat |

| Hand-feel & drape | Uniform hand; crisp drape | Softer, more bulk, better drape for knits | Firmer, less soft unless further processed |

| Dyeing consistency | Excellent dye consistency; flat filament effect | Good; texture can affect shade uniformity slightly | Variable; typically requires texturizing and finishing for target shade |

| Luster | Semi-dull and bright available | Semi-dull and bright available | Semi-dull and bright available |

| Typical applications | Woven/knit apparel, fashion fabrics, sportswear, home furnishing, upholstery, car seat covers, technical fabrics (non-textured uses) | Knits demanding stretch and comfort (activewear, sportswear, athleisure), bulk and softness | Intermediate feedstock for DTY/ATY or industrial yarns; some direct use after additional processing |

| Typical downstream processes | Direct weaving/knitting, twisting, beaming; no texturizing required | Texturizing required; dyeing and finishing to manage stretch/hand | DTY/ATY conversion, drawing, texturizing, heat-setting |

| Suitability for non-textured fabrics | Excellent | Good for textured knits; not preferred for crisp non-textured | Requires additional steps to be suitable |

| Cost/price expectations | Typically lower than DTY due to avoiding texturizing | Higher than FDY due to additional process | Lower than FDY but requires conversion; total landed cost depends on destination steps |

| Supply chain risk | Lower (single-step FDY production; simpler logistics) | Higher (two-step conversion; more potential bottlenecks) | Higher (needs downstream processing; risk on conversion capacity) |

Key selection implications

– For flat-filament, crisp-hand fabrics with strong dye uniformity, FDY is the simplest, most direct path—especially for wovens, technical non-textiles, and bright/semi-dull aesthetics without bulk.

– When elasticity, softness, and bulk are required (e.g., activewear knits), DTY is the standard choice; its added processing improves hand and stretch but increases cost and operational complexity.

– POY is a lower-cost intermediate that must be further processed (drawing/texturizing) to achieve usable hand, elasticity, and shade performance; ideal only if you control or have access to robust conversion capacity downstream.

– Compliance and sustainability: FDY’s direct-use process lowers energy and processing steps versus DTY (which adds thermal/mechanical treatment), offering a straightforward basis for claims around reduced energy intensity per yard/knit, all else equal.

Essential Technical Properties and Trade Terminology for fully drawn yarn

Essential Technical Properties and Trade Terminology for Fully Drawn Yarn (FDY)

What FDY Is

Fully Drawn Yarn (FDY) is a multi-filament polyester yarn spun at high speeds with in-line heated drawing. The process locks in molecular orientation and crystallization, producing a ready-to-use, non-textured filament that can be directly knitted or woven. FDY is available in Semi-Dull and Bright lusters.

Illustrative Image (Source: Google Search)

Core Technical Properties

| Category | Property | Typical Range / Notes | Why It Matters |

|---|---|---|---|

| Mechanical | Linear density (denier/filaments) | Commonly 30–300 den; counts vary by application (e.g., 50/24, 75/36, 150/48) | Drives loom setting, weft/knit density, and product weight |

| Mechanical | Tenacity | ~4.0–5.5 cN/dtex | Yarn strength for breakage-free processing and durability |

| Mechanical | Elongation at break | ~15–25% | Elasticity for warp tension control and knitability |

| Mechanical | Evenness | Low inter/intra-lot variation | Consistent shade and performance across lots |

| Thermal | Heat-setting response | Highly responsive; low shrinkage vs POY | Enables dimensional stability in fabrics |

| Thermal | Shrinkage (Boiling Water) | Low to moderate; application-specific | Predictable finishing and hand feel |

| Thermal | Temperature handling | Stable during dyeing/finishing within standard polyester ranges | Avoids yellowing or excessive shrinkage |

| Dyeing | Shade consistency | High dye uptake and shade reproducibility | Minimizes shade patching across batches |

| Dyeing | Disperse-dye class | Class 4+ (typical for polyester) | Reliable wash fastness after dyeing |

| Physical | Moisture regain | ~0.4% (polyester typical) | Lower moisture uptake vs cotton; stable in storage |

| Physical | Abrasion resistance | Adequate for knitting/warping and typical apparel/household uses | Reduces breakage and fuzzing on machinery |

| Handling | No texturizing needed | Direct twist/beam/knit/weave | Faster, simpler, and cost-effective conversion |

| Luster | Appearance | Bright or Semi-Dull options | Controls visual impact and fabric aesthetics |

Notes:

– Property values are indicative; confirm exact specs with the supplier before committing to critical constructions.

– FDY’s stabilized orientation and crystallization improve runnability and yield versus POY, which typically benefits from additional texturizing.

Quick-Reference Property Snapshot

| Parameter | Guidance |

|---|---|

| Process | Integrated spin-draw at high speed; no texturizing required |

| Fineness range | Commonly 30–300 den; multiple filament counts available |

| Mechanical performance | Tenacity 4.0–5.5 cN/dtex; elongation 15–25% |

| Thermal behavior | Low shrinkage vs POY; suitable for heat-setting |

| Dyeing | High shade consistency; disperse dyes |

| Lusters | Bright and Semi-Dull |

| Moisture regain | ~0.4% |

| Typical end uses | Apparel, fashion fabrics, sportswear, home textiles, upholstery, automotive seat covers |

| Fabric form | Knitted or woven, with or without other filaments |

Trade Terminology

| Term | Meaning | Application / Notes |

|---|---|---|

| FDY | Fully Drawn Yarn | Non-textured, ready-to-use polyester filament |

| PFY | Polyester Filament Yarn | Alternate naming for FDY |

| SDY | Spin Draw Yarn | Equivalent to FDY |

| POY | Partially Oriented Yarn | Precursor to FDY; not ready-to-use |

| DTY | Drawn Textured Yarn | Different process; typically crimped/bulk |

| Denier / dtex | Linear density | Denier = mass in grams per 9,000 meters |

| Filaments (f) | Count of filaments per yarn | Affects hand, drape, and coverage |

| Luster | Bright vs Semi-Dull | Aesthetic control |

| MOQ | Minimum Order Quantity | Typically set by denier/filament/lot mix |

| Lead time | Production + logistics window | Confirm for seasonal urgency |

| Packaging | Winding, cones, spools, warp beams | Standard options vary by mill |

| QA/QC | Quality assurance/control | Evenness, shade and shrinkage checks |

| Shrinkage | Dimensional change under heat | Verify finishing compatibility |

| Shade/Color lot | Batch-matched dyeing | Minimize shading issues in production |

| Color fastness | Wash/care performance | Confirm disperse-dye class (e.g., ≥4) |

| Evenness | Thickness and uniformity | Critical for knitting/warping stability |

| OEM | Original Equipment Manufacturer | Supplier-made per your specifications |

| ODM | Original Design Manufacturer | Supplier-developed products |

| Custom count | Non-standard denier/filaments | Requires process qualification |

| Certification | GRS, OEKO-TEX, REACH | Availability varies by producer and order |

Implications for Buyers and Sourcing

- FDY is a cost-effective, ready-to-process input that reduces steps versus POY and avoids the texturizing stage, supporting higher contribution and throughput.

- Consistent quality and shade reproducibility minimize rework and color matching issues across multiple lots.

- Two luster options enable straightforward aesthetic tuning in flat-woven or knitted structures.

- Typical end-use breadth spans apparel, home, and specialty automotive upholstery—confirm performance in any regulated or high-abrasion applications.

For definitive specifications, sampling, and compliance certifications, request the product data sheet from your FDY supplier.

Navigating Market Dynamics and Sourcing Trends in the fully drawn yarn Sector

Navigating Market Dynamics and Sourcing Trends in the Fully Drawn Yarn (FDY) Sector

FDY fundamentals and process

Full Drawn Yarn (FDY), also called Polyester Filament Yarn (PFY) or Spin Draw Yarn (SDY), is a multi-filament yarn that is stretched, oriented, and crystallized during manufacturing and is ready for direct use without further drawing. Reason: Clarifying what FDY is and its unique readiness reduces downstream processing for converters.

FDY is produced at higher line speeds than partially oriented yarn (POY), with drawing integrated into spinning to stabilize molecular orientation and crystallinity. Reason: Higher-speed spin-draw lines enable consistency and cost efficiency by combining operations.

Illustrative Image (Source: Google Search)

FDY is available in Semi-Dull and Bright lusters and typically exhibits high dye uniformity, lightweight feel, and stable product quality at relatively competitive pricing. Reason: These properties align FDY with applications that prioritize consistent aesthetics and mechanical performance.

FDY can be knitted or woven on its own or blended with other filament yarns to produce diverse fabric structures. Reason: Compatibility with multiple fabric-making methods extends FDY’s applicability across end-use segments.

FDY vs DTY vs POY (key contrasts)

Process

– FDY: Higher-speed spin-draw-wind; drawing and orientation integrated. Reason: In-line drawing yields a fully stabilized filament with stable tenacity and shrinkage.

– DTY: Drawing and texturing applied post-spinning; crimp/bulk introduced. Reason: Texturing imparts elasticity, comfort, and bulk commonly used in knits.

– POY: Intermediate pre-oriented filaments that require drawing before use. Reason: POY is a precursor with higher potential shrinkage, not yet stabilized for end use.

Performance

– FDY: Tenacity typically in the 3.8–5.5 g/d range; elongation around 10–18%; lower shrinkage. Reason: Balanced mechanical properties suitable for weaving and direct warping.

– DTY: Elasticity via crimp; elongation typically 25–45%; lower tenacity than FDY. Reason: Comfort and stretch drive selection in apparel knits.

– POY: Higher shrinkage and lower tenacity than FDY; must be drawn further. Reason: POY’s utility hinges on subsequent drawing and stabilization.

Illustrative Image (Source: Google Search)

Typical applications

– FDY: Woven and knitted fabrics for apparel, fashion, sportswear, home furnishing, upholstery, car seat covers; direct warping, twisting, beaming, and knitting. Reason: Stability and dye uniformity suit both apparel and technical fabrics.

– DTY: Knitted fabrics where elasticity and softness are essential (e.g., athleisure, innerwear). Reason: Texturing adds body and comfort typical of knitted apparel.

– POY: Feedstock for drawing/texturing or intermediate yarn stages. Reason: POY functions as a step toward stable yarns rather than direct end use.

Business implication

– FDY: Lower downstream processing and faster lead time for woven/technical applications. Reason: Avoiding texturing reduces operations and variability.

– DTY: Higher processing cost but premium attributes in stretch comfort knits. Reason: Texturing steps and quality controls add cost and value.

– POY: Flexibility at the expense of additional steps and risk of inconsistent downstream performance. Reason: Incomplete stabilization shifts risk to downstream processing.

End-use segmentation and quality mapping

| End-use segment | Typical luster | Denier/filaments (indicative) | Key properties | Reason |

|---|---|---|---|---|

| Apparel (shirts, pants, dresses) | Semi-Dull or Bright | 75–150 denier; 24–72 filaments | Tenacity 3.8–5.5 g/d; elongation 10–18%; low-to-moderate shrinkage; high dye uniformity | Balanced aesthetics and mechanicals for weaves with crisp hand. |

| Fashion fabrics (specialty wovens) | Semi-Dull or Bright | 50–150 denier; variable filaments | Consistent dye, controlled lustre; optional dope-dyed | Colorfastness and uniform shade needed for branded apparel. |

| Sportswear (knits/wovens) | Semi-Dull | 75–150 denier; 24–72 filaments | Low shrinkage; fast-dye; moisture transport via finish | Stability and dye fastness help performance fabrics maintain performance. |

| Home furnishing (drapery, upholstery) | Semi-Dull or Bright | 100–300 denier; 24–144 filaments | Tenacity at upper end; elongation 10–16% | Structural integrity for textiles with heavier loads. |

| Upholstery and car seat covers | Semi-Dull | 150–300 denier; higher filament counts | Elevated tenacity; consistent elongation; abrasion resistance | Durability and uniform shade across large pieces are critical. |

| Technical nonwovens/industrial | Semi-Dull | 50–300 denier; varied | Controlled shrinkage; consistent tenacity | Functional performance rather than fashion drives selection. |

Sustainability and compliance

- Recycled feedstock (rPET) claims should align to Global Recycled Standard (GRS) certification and include content verification at bale and chip stages. Reason: Traceability and content verification are key to credible claims.

- OEKO-TEX Standard 100 is recommended for restricted substance checks on finished yarns; ZDHC MRSL may be relevant for chemical inputs. Reason: Compliance reduces product risk and aligns with brand procurement policies.

- GOTS applicability is typically downstream at fabric/garment level rather than at yarn stage. Reason: Yarn-level GOTS certification is uncommon; focus on GRS and OEKO-TEX for yarn due diligence.

- Dope-dyed solutions (solution-dyed) reduce water and energy use versus post-dyeing, especially for bright lusters. Reason: Integrated coloration lowers process intensity and improves shade consistency.

- Transparency on denier/filament counts, tenacity, and shrinkage in spec sheets and COAs aids downstream testing and compliance audits. Reason: Documented parameters support consistency and risk mitigation.

Sourcing strategy for USA and Europe

- Diversify suppliers across Asia and the EU/EEA; consider nearshoring in Mexico for USA demand. Reason: Multi-origin sourcing reduces regional disruptions and logistics risk.

- Use FDY for non-textured fabrics and when direct warping or twisting is planned. Reason: Choosing the right process (FDY vs DTY/POY) simplifies operations and lowers total cost.

- Standardize on Semi-Dull for most woven apparel and home textiles; reserve Bright for specific aesthetic or technical requirements. Reason: Semi-Dull offers broader shade and handle options with stable dye uptake.

- For knitted apparel with stretch, test DTY alternatives in parallel and use FDY for woven components. Reason: Matching process to product avoids unnecessary texturing costs while preserving comfort.

- Implement lot-to-lot quality control covering tenacity, elongation, shrinkage, and yarn count; request COAs for each lot. Reason: FDY’s high-speed production benefits from rigorous downstream quality checks.

- Plan for 2–4 weeks lead time ex-Asia and 1–2 weeks ex-EU/EEA for standard lusters; 4–8 weeks for specialty or recycled content. Reason: Lead-time expectations align procurement with production schedules.

- Confirm HS codes and duties up front for HS 5402.20 (Polyester filament yarns, including FDY) and understand rules-of-origin preferences (e.g., USMCA). Reason: Duty and trade rules materially impact landed cost.

- Consider consignment or flexible call-off contracts for high-volume items; use spot buys for specialty shades. Reason: Contract structures can reduce inventory while ensuring supply for standard grades.

- Build buffer stock for critical colors and widths; keep safety stocks aligned to demand variability. Reason: Color matching and continuity minimize rework and avoid line stoppages.

- Align suppliers with brand sustainability targets (recycled content, chemical restrictions, traceability) and maintain audit trails. Reason: Stronger compliance protects brand reputation and ensures regulatory conformance.

Historical context and recent trends

- FDY matured as a stable, high-throughput process, displacing multi-stage yarn preparation in many woven and technical applications. Reason: In-line drawing and winding streamlined production, cutting time and cost.

- Post-2000 apparel supply chains concentrated in Asia, but recent constraints highlighted by disruptions accelerated nearshoring interest in the USA and EU. Reason: Regional resilience became a procurement priority.

- Sustainability shifted toward recycled content and process efficiencies, with dope-dyed options gaining traction. Reason: Lowering water/energy footprints and improving shade uniformity aligns with ESG goals.

Risk management

- Monitor key inputs—energy (natural gas/electricity), PX/MEG, PET chips, and FX—plus transportation and port schedules. Reason: Cost drivers directly affect FDY pricing and project timelines.

- Define technical KPIs per application (tenacity/elongation/shrinkage/crimp where applicable) and embed them in supplier contracts. Reason: Clear specifications reduce disputes and rework.

- Use pre-shipment inspection and lab verification for shade and strength; retain samples as reference. Reason: Early detection avoids costly corrections during fabrication.

Quick sourcing checklist

- Match yarn type to fabric process: FDY for direct warping and non-textured woven/knits; DTY for stretch knits. Reason: Proper selection reduces processing and cost.

- Confirm denier/filaments, tenacity, elongation, shrinkage, luster, and dye method (solution-dyed vs post-dye) in the spec. Reason: Exact parameters are essential for downstream performance.

- Validate certifications: GRS for recycled content; OEKO-TEX 100 for restricted substances. Reason: Certification consistency underpins claims and compliance.

- Define lead times, lot sizes, and color inventory; set safety stock levels. Reason: Operational clarity prevents stockouts and missed milestones.

- Close the loop with COAs, test reports, and traceability documents per lot. Reason: Documentation enables audits and consistent quality assurance.

Frequently Asked Questions (FAQs) for B2B Buyers of fully drawn yarn

Frequently Asked Questions (FAQs) for B2B Buyers of Fully Drawn Yarn (FDY)

1) What is FDY and how is it different from POY and DTY?

FDY (Fully Drawn Yarn) is a multi-filament polyester yarn that is spun and drawn in a single integrated high‑speed process, delivering stabilized molecular orientation and crystallization without further drawing or texturizing. It is ready‑to‑use in weaving/knitting and is available in Semi‑Dull and Bright lusters. Typical end uses include apparel, sportswear, home furnishings, upholstery, and car seat covers.

- FDY vs DTY vs POY

- FDY: Smooth, low bulk, low stretch, high tenacity. Ideal for wovens and flatknits where stability and dye uniformity are critical.

- DTY: Textured yarn with bulk and stretch for comfort stretch knits. Less uniform dyeing if insufficient finish removal; typical end uses include apparel knit fabrics.

- POY: Un-drawn precursor with high elongation and shrinkage; requires further drawing/texturing. Used as feed for DTY or draw‑twisting; not suitable for direct fabric production in most cases.

2) What are the typical technical attributes and quality expectations for FDY?

- Appearance/structural characteristics: Smooth filament bundle, excellent dyeing consistency, consistent product quality, low price.

- Luster options: Semi‑Dull (SD), Bright (BR). (Note: Full‑Dull lusters may be available on request by some producers.)

- Mechanical properties (typical tendencies; confirm exact ranges with your supplier)

- Tenacity: High vs POY; acceptable for many wovens and narrow fabrics.

- Elongation: Lower than POY, typically moderate; suitable for dimensional stability.

- Shrinkage: Moderate; verify low‑shrinkage options if you need extra stability in dyeing/finishing.

- Colorways: Available in raw (undyed) or dope‑dyed (solution dyed) options depending on supplier.

- Use without texturizing, and blend freely with other filament yarns to create fabric variations.

- Expect narrow property windows and consistent denier uniformity to reduce barré risk in weaving/knitting.

3) Which end‑use segments commonly use FDY and why?

- Apparel and fashion fabrics: Reliable dye uniformity, good handle, dimensional stability.

- Sportswear and athleisure: Consistent mechanicals support durable constructions and printing.

- Home furnishing and upholstery: Durability and color consistency for curtains, upholstery, car seat covers.

- Narrow woven fabrics (NWF) and technical end uses: Good filament cohesion and processability at weaving/knitting.

Note: Avoid comparing FDY with stretch‑oriented DTY when comfort stretch is required; match yarn type to end‑use mechanics.

4) What dyeing and finishing conditions are recommended?

- Pre‑treatment: Proper scouring to remove spin finishes; ensure complete removal for optimal, uniform dye uptake.

- Dye selection: Use disperse dyes suitable for polyester. For light shades and critical uniformity, consider carrier‑free high‑temperature dyeing where equipment permits.

- Temperature and time: Typical polyester dyeing at high temperature (e.g., ~130°C) with controlled ramp and hold times; confirm with your dyehouse to match the supplied finish chemistry.

- Post‑set/stabilization: Finish‑set or under‑frame tenter settings can be used to stabilize dimensions and reduce residual shrinkage.

- Dope‑dyed advantages: Reduced water/energy usage and improved color fastness; recommend for repeated wash/durability requirements.

- Risk control: Maintain tight color、工艺 windows to avoid barré, streaks, or shading issues; audit finish residuals before dyeing.

5) What quality assurance and certifications should buyers expect?

- QC scope: Each lot typically verified for denier uniformity, tenacity, elongation, shrinkage, yarn defects, and package build integrity.

- Sampling and acceptance: Use AQL‑based inspections for package defects and physical tests; align on COA (Certificate of Analysis) content and tolerances during sourcing.

- Compliance (select relevant certifications and confirm vendor status):

- OEKO‑TEX Standard 100 (product safety).

- ISO 9001 (quality management).

- REACH compliance (EU chemical regulation).

- GRS (Global Recycled Standard) if recycled content is claimed.

- ROHS and Prop 65 where applicable (US).

- ZDHC MRSL alignment (recommended for safer chemistry).

- Documentation: Request SDS for spin finishes, test reports, and compliance certificates with shipment.

6) How is FDY packaged and what are typical logistics considerations?

- Package forms:

- Cheese (tube/parallel wound).

- Beam (warper beams for weaving).

- Typical net weights: Confirm with your supplier (values vary by producer and process). Always verify packaging spec sheets.

- Moisture protection and labeling: Ensure sealed packaging to prevent finish contamination, clearly marked with lot number, denier/filament count, twist, luster, and compliance marks.

- Logistics:

- FTL vs LTL: Choose based on volume to control freight cost and lead time.

- Palletization: Standard pallets, corner boards, wrap/strap for stability.

- Loading targets: 40′ containers are commonly used; work with your supplier to optimize cube density by package format and count.

- Lead time: Plan lead times for weaving/knitting beams; expedite options depend on inventory and dye schedules.

7) What customization options are available for FDY?

- Luster: Semi‑Dull, Bright; some producers offer Full‑Dull on request.

- Denier and filament counts: Broad ranges (e.g., common fashion apparel counts typically in 30–150 denier; high‑performance technical grades can be heavier); confirm exact options with your supplier.

- Yarn twist: Zero‑twist or low‑twist for weaving; specified S/Z twist for warp or weft as needed.

- Finish: Spin finishes for knitting/weaving optimization; discuss low‑phenol or “low‑noise” options if knit performance or downstream processes are critical.

- Color: Raw white for subsequent dyeing or dope‑dyed for rapid lead time and improved fastness.

- Recycled content: rPET available from select producers; verify GRS certification, traceable input, and content claims.

- Logistics: Package format tailored to your warping/knitting requirements; beam sizing aligned to loom capacity.

8) What sustainability and compliance options does FDY support?

- Recycled content: rPET chips and yarns with verified GRS claims; available in select lusters and counts.

- Dope‑dyed (solution dyed): Lower dyeing water/energy use and improved wash fastness; ideal for repeat color programs and high‑durability applications.

- Certifications:

- OEKO‑TEX Standard 100 (product safety).

- GRS (recycled content).

- ISO 9001 (quality management).

- REACH compliance (EU).

- Environmental programs: ZDHC MRSL alignment for chemical management; sustainability reporting can be aligned with ISO 14001 at the producer level.

- Circularity: FDY can be integrated into textile‑to‑textile (T2T) recycling streams; confirm with your partner’s collection and reprocessing capabilities.

Notes

– Typical values and availability of specific lusters, finishes, and compliance packages vary by producer. Always confirm denier/filament ranges, mechanical targets, package specs, and compliance status with the supplier before purchase.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for fully drawn yarn

Strategic Sourcing Conclusion and Outlook for Fully Drawn Yarn (FDY)

FDY’s end‑to‑end spin‑draw process yields high molecular orientation and consistent dyeing with no downstream texturizing, enabling direct knitting/weaving, reduced processing steps, and stronger cost contributions than POY. Its balanced tenacity/elongation and light weight suit apparel, home textiles, and upholstery, with bright and semi‑dull luster options aligning to common B2B specifications in the USA and Europe.

Sourcing strategy for US/EU buyers should prioritize: tight quality agreements on titer CV%, elongation at break, and ISO/IEC 17025 dye consistency; compliant certifications (e.g., REACH, OEKO‑TEX Standard 100, ISO 9001/14001/45001); transparent polymer origin (virgin and/or recycled) with lot traceability; logistics plans for fast‑moving 50–150 denier packs; and risk buffers for PTA/MEG‑driven volatility. Near‑term demand remains steady in athleisure, workwear, and soft furnishings, with gradual uptake of recycled FDY where price spreads narrow.

| Attribute | FDY | POY | DTY |

|---|---|---|---|

| Orientation/Crystallization | High, achieved in-line | Low/Intermediate | High via drawing + texturizing |

| Downstream Steps | Direct knitting/weaving | Requires drawing/texturizing | Ready to knit/weave |

| Typical Denier/Filaments | 30–300D, 12–72f | 40–300D, 12–72f | 40–300D, 12–144f |

| End Uses | Apparel, home, upholstery | Intermediates for DTY | Knit/woven fabrics, performance |

| Dye Consistency | High | Moderate | High |

| Price Dynamics | Typically cheaper than DTY; cheaper than POY | Feedstock for DTY | Premium to POY/FDY |

| Sustainability | Recycled option viable | Recycled option viable | Recycled option viable |

FDY’s performance‑cost balance, operational simplicity, and mature supply base make it a dependable pillar for US/EU textile sourcing strategies.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.

Illustrative Image (Source: Google Search)

![Top Yarn Manufacturing Companies [List] - Matchory](https://www.fobcompany.info/wp-content/uploads/2025/12/matchorycom-6277.jpg)