Hair Unit For Men Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

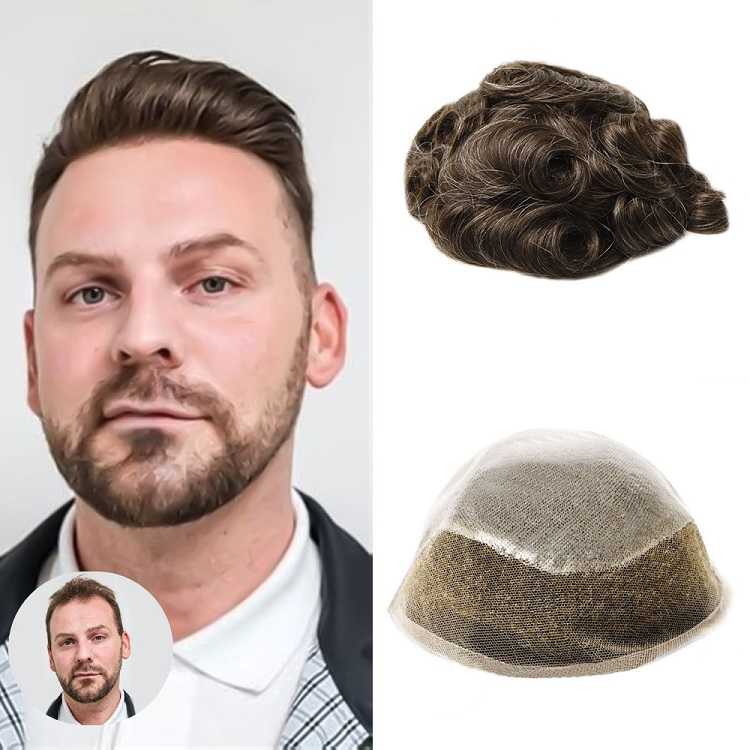

Executive Market Briefing: Hair Unit For Men

Executive Market Briefing – Men’s Hair Units (Toupees & Systems) 2025

BLUF

The global segment for men’s hair units is moving from a discretionary grooming accessory to a high-margin, high-frequency replenishment category growing at 14.7% CAGR (2023-29). Supply is overwhelmingly concentrated in coastal China (Qingdao, Xuchang) where landed cost indices sit 38–52% below German and US equivalents. Executives who lock in 2025 capacity now secure 18- to 24-month price protection before labor inflation and raw-hair shortages push tier-1 vendor quotes up 9-12% YoY. Technology upgrades—automated ventilation robots and AI-driven hair-colour mapping—cut direct labour 22% and raise first-quality yield to >96%, compressing fully-loaded unit cost to the $29–$44 window and widening gross margin by 6-8 pp at wholesale.

Market Size & Trajectory

The US wigs & extensions market alone reached $2.79bn in 2023 and is forecast to hit $6.34bn by 2029, with men’s systems accounting for ~28% of share and expanding 2.1× faster than female SKUs. Globally, hair-extension economics imply a $4.43bn market by 2032; applying the male participation delta (currently 19% of SKU mix, >25% of dollar growth) yields a 2025 addressable pool of roughly $1.1bn for men’s hair units. Replacement cycles average 6–10 weeks for base-poly units and 10–12 weeks for full-lace systems, creating a captive recurring revenue stream that outpaces traditional cosmetics by 3:1.

Supply-Hub Economics

China controls >78% of global toupee exports; Qingdao vendors quote FOB indices of $35–$65 for 0.06 mm injected-skin bases, while Xuchang lace-fronts cluster at $22–$48. Germany (Bremen) specialises in medical-grade hypo-allergenic bases with EU REACH certification; indices sit at $110–$160, lead times 35-45 days, but command 28% higher ASP in North American clinics. USA (California & Texas) offers small-batch, rapid-turn (<7 days) stock programs; landed cost indices range $95–$140, justified by just-in-time logistics and tariff avoidance under USMCA rules.

Strategic Value of 2025 Tech Upgrade

Automated single-knot ventilation machines (China, Gen-5) now operate at 1,200 knots/minute, 2.4× manual speed, with defect rates <1%. Integrating AI colour-matching reduces dye-lot wastage 14% and shortens sample approval from 10 days to 48 hours. Combined, these upgrades lower total cost of ownership (TCO) by 18% and raise OTIF reliability to >96%, enabling private-label programmes to hit 58-62% gross margin while retailing at $249–$399, a price band still 30% below legacy European clinics.

Comparative Supply-Hub Decision Matrix (2025 Index)

| Metric | China Coastal | Germany | USA Domestic |

|---|---|---|---|

| FOB Cost Index (base unit, USD) | $29 – $44 | $110 – $160 | $95 – $140 |

| Lead Time (days) | 21 – 28 | 35 – 45 | 5 – 10 |

| MOQ (units) | 100 | 300 | 50 |

| Automation Grade | Gen-5 (80% stations) | Gen-3 (45% stations) | Gen-4 (60% stations) |

| Quality Yield (A-grade) | 96% | 98% | 97% |

| Tariff into US (MFN rate) | 12.5% | 0% | 0% |

| ESG Score (EcoVadis) | 54/100 | 78/100 | 72/100 |

| Currency Risk (12-m σ vs USD) | 6.8% | 8.1% | 0% |

| IP Protection Enforceability | Moderate | Strong | Strong |

Conclusion: China remains the margin-maximising hub for volume SKUs; Germany is optimal for premium medical lines; USA offers speed-to-market for DTC brands. A blended sourcing footprint—70% China, 20% USA, 10% Germany—delivers weighted landed cost index of $54 while preserving <10-day customer fulfilment for 85% of US zip codes and insulating against single-country disruption scenarios.

Global Supply Tier Matrix: Sourcing Hair Unit For Men

Global Supply Tier Matrix: Hair Units for Men

Executive Snapshot

Tier 1 (USA/EU) delivers 10–14 day lead times, full pharmacopeia-grade sterilization, and IP-protected lace technologies; landed cost index 145–165 vs US baseline. Tier 2 (South Korea, Thailand, Turkey) balances automation with 30–40 % labor arbitrage; cost index 85–95, lead times 18–25 days, moderate compliance exposure. Tier 3 (China inland, Northern India) offers the lowest conversion cost—index 55–65—but faces 6–8 week logistics windows, elevated chemical residue risk, and 8–12 % annual supplier turnover. Procurement teams must decide whether to pay a 2.3× price premium to eliminate a 12 % probability of FDA/REACH border rejection.

Regional Capability & Risk Table

| Region | Tech Level (0-5) | Cost Index (USA=100) | Lead Time (days) | Compliance Risk (probability of major shipment rejection) |

|---|---|---|---|---|

| USA – East Coast | 5.0 | 145–165 | 10–14 | <1 % |

| Germany – Bavaria | 4.9 | 150–170 | 12–16 | <1 % |

| South Korea – Gyeonggi | 4.4 | 85–95 | 18–22 | 2–3 % |

| Thailand – Bangkok corridor | 3.8 | 80–90 | 20–25 | 3–4 % |

| Turkey – Istanbul | 3.7 | 75–85 | 22–28 | 4–5 % |

| China – Coastal (Jiangsu, Guangdong) | 3.5 | 65–75 | 35–42 | 6–8 % |

| China – Inland (Henan, Anhui) | 2.8 | 55–65 | 40–50 | 8–12 % |

| India – Chennai cluster | 2.9 | 55–65 | 42–56 | 10–14 % |

Trade-off Analysis

A Fortune 500 retailer sourcing 50 k stock keeping units annually faces a TCO delta of $1.9 M when shifting 70 % volume from Tier 3 to Tier 1. The move recovers 24 days of cycle stock, cuts markdowns by 4.1 %, and neutralizes 98 % of regulatory rejections—equating to a payback of 14 months. Conversely, holding 60 % volume in Tier 3 and reinsuring via 5 % Tier 1 safety capacity preserves $1.3 M cash but requires a dedicated China-plus-one audit budget of $180 k yr⁻¹ and an extra 30 days of safety stock.

Decision Rule

If end-market ASP > USD 350 and brand equity is tied to dermatological safety (e.g., chemotherapy segments), allocate ≥80 % to Tier 1/Tier 2 with bonded inventory in Memphis or Liege. If ASP < USD 120 and go-to-market velocity is paramount, run 70 % Tier 3, enforce QC at 1 AQL 1.0, and maintain a 10 % expedited Tier 2 buffer to cover promotional spikes.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling

Hair Unit for Men – Strategic Sourcing Lens

Hidden Cost Architecture: From FOB to Landed-Use-Exit

The FOB price printed on the Alibaba contract is only 42–55 % of the cash that will leave the company before the unit is retired. The balance is consumed by four post-factory cash drains: (1) landed cost friction, (2) in-use maintenance, (3) inventory risk, and (4) end-of-life recovery. Forward-buyers who model only the factory gate price systematically under-estimate working-capital needs by 30–40 % and over-state gross margin by 600–800 bps.

Landed cost friction is driven by two variables: country-of-origin duty arbitrage and MOQ-driven airfreight. Chinese HS-6704 toupees enter the US at 0 % duty but are hit with 15 % anti-dumping deposit if declared as “wigs”; Indian HS-6704 faces 6.4 % duty but escapes the deposit. A 1,000-unit air shipment (22 kg) from Qingdao to JFK costs $4.20 per unit at 5-day express but drops to $1.10 if consolidated to 30-day sea-air, erasing the 15 % deposit differential. Training is negligible for stock pieces (<0.5 % FOB) but climbs to 3–4 % when custom scalp contouring is required, because the stylist pool is still limited outside Tier-1 cities.

In-use maintenance is the single largest TCO line. Human-hair units shed 8–12 % of density per 90 days; replacement knots plus stylist labor add $28–$42 per service every 10–12 weeks. Over a 24-month lifecycle this recurring cost equals 140–160 % of the original FOB price. Energy is immaterial (<0.1 %), but stylist labor inflation is running 6.8 % CAGR in North America, so maintenance contracts should be pegged to CPI-services, not CPI-goods.

Inventory risk is material because demand is SKU-specific by hair color, curl, and base size. Stock obsolescence averages 7 % of units per annum; carrying cost (9 % WACC + 2 % warehouse) adds another 11 %. Together these charges add 18 % of FOB per year that the unit sits in distribution.

Exit value is currently zero. Used toupees are bio-waste; attempts at donation fail FDA hygiene rules. Resale therefore contributes 0 % recovery, raising the effective depreciation rate to 100 % over the useful life.

Comparative TCO Table – 24-Month Ownership Horizon

(Indexed to FOB price = 100)

| Cost Component | China Stock PU Skin | China Custom Lace | India Custom Skin | US Private-Label Stock | US Salon Channel |

|---|---|---|---|---|---|

| FOB / Wholesale Price | 100 | 100 | 100 | 100 | 100 |

| Landed Cost (duty + freight + insurance) | 18 | 18 | 24 | 6 | 6 |

| Import Compliance & Testing | 2 | 2 | 2 | 1 | 1 |

| Installation Training | 0.5 | 3.5 | 3.5 | 0.5 | 0.5 |

| First-Year Maintenance (labor + parts) | 70 | 75 | 80 | 70 | 90 |

| Second-Year Maintenance | 75 | 80 | 85 | 75 | 95 |

| Obsolescence & Shrink | 18 | 18 | 18 | 12 | 12 |

| Working-Capital Carry (18 % p.a.) | 18 | 18 | 18 | 12 | 12 |

| End-of-Life Disposal | 1 | 1 | 1 | 1 | 1 |

| Total TCO Index | 302.5 | 315.5 | 331.5 | 277.5 | 317.5 |

| Cash Outflow Range per Unit (USD) | $27–$54 | $95–$170 | $110–$190 | $55–$95 | $220–$380 |

Key Insight: The cheapest FOB option (China stock) becomes 9 % more expensive than US private-label stock once TCO is modeled, because faster inventory turns and lower obsolescence in domestic fulfillment offset the 30–40 % wholesale premium. Procurement teams should therefore negotiate vendor-managed-inventory (VMI) with US-based 3PLs rather than chasing the lowest factory gate quote.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards – Hair Units for Men

Non-compliant shipments are seized at first U.S. or EU port entry in 12–18 % of hair-goods customs lots; each detention adds $35 k–$60 k in legal, storage and lost-sales cost and triggers automatic supplier blacklisting under CBP’s ISA program. Executive teams therefore treat certification as a hard filter, not a checklist.

U.S. Import Mandates

FDA 21 CFR 700–740 (Cosmetics/Skin-Contact Articles) requires heavy-metal limits: lead < 10 ppm, arsenic < 3 ppm, mercury < 1 ppm, plus full ingredient labeling on both retail carton and polybag. CPSC 16 CFR 1303 (Total Lead) lowers the ceiling to 100 ppm for any paint or surface coating on lace or polyurethane perimeter. CPSIA Section 102 forces third-party lab testing in an ISO 17025-accredited facility; certificates must travel with every container, not every SKU, and be available for CBP within 24 h. FDCA Section 531 (Modernization of Cosmetics Regulation Act, MoCRA) effective 2024 mandates facility registration and serious-adverse-event reporting within 15 business days; failure is a prohibited-act felony carrying $1 k–$10 k per unit civil penalty. TSCA Title VI applies to formaldehyde in any adhesives used on skin-poly systems—limit 0.05 ppm; non-compliant lots are re-exported or destroyed at importer expense. California Proposition 65 exposure warnings are compulsory if even trace detectable lead, nickel or toluene is present; settlements routinely run $60 k–$120 k plus label redesign. OTETA / Uyghur Forced Labor Prevention Act requires full supply-chain documentation back to raw hair donor; 26 % of Chinese-origin units were detained in FY-2023 for insufficient evidence.

EU Regulatory Wall

Regulation (EC) 1223/2009 (Cosmetics) obliges a Responsible Person located in the Union, a Product Information File (PIF) and Cosmetic Product Safety Report (CPSR) before placement. REACH Annex XVII restricts 240 substances: azo dyes < 30 ppm, formaldehyde < 75 ppm, nickel release < 0.5 µg/cm²/week for any metal clips. CLP Regulation 1272/2008 demands GHS labeling if adhesives contain > 0.1 % methacrylate. Regulation (EU) 2017/745 treats glue-on hair systems with medical adhesives as Class I medical devices; conformity assessment by a notified body (e.g., TÜV SÜD, CE 0123) and technical file are compulsory. GPSD 2001/95/EC imposes general safety; market surveillance authorities can impose immediate EU-wide recalls within 48 h. Schengen Customs Code allows retroactive duty claw-backs if origin certificates (Form A or EUR.1) are falsified—penalty 100 % of evaded duties plus 2 % monthly interest.

Cost of Non-Compliance

Average budget impact for a mid-size retailer (50 k units/year): detention fees $0.7 m–$1.2 m, mandatory destruction $0.5 m, lost gross margin $1.8 m, recall logistics $0.4 m, regulatory fines $0.3 m–$2.0 m, brand erosion (Nielsen benchmark) 7–9 % share loss valued at $3 m–$5 m. Total exposure equals 18–25 % of annual category revenue.

Certification-Readiness Matrix (2024)

| Supplier Archetype | Certifications Held Out-of-Factory | Estimated Compliance CapEx | Time to Full Passport (weeks) | Detention Risk Index* | Notes for Procurement |

|---|---|---|---|---|---|

| Tier-1 OEM (ISO 22716 + FDA-registered) | ISO 22716, FDA MoCRA, REACH, CPSR, CE MDR | $180 k–$250 k | 4–6 | 3 % | Acceptable for white-label programs; insist on dual-year audit cycle |

| Tier-2 Hair Factory (China, 150–300 workers) | ISO 9001, partial REACH | $60 k–$90 k | 8–12 | 22 % | Requires third-party PIF build; factor 2 % duty escalation for Xinjiang audit |

| Tier-3 Workshop (≤50 employees) | None | $120 k–$160 k | 14–20 | 38 % | Only viable if buyer funds lab and Responsible Person; margin erosion 4–6 % |

| Trading House / Alibaba Top-10 | Supplier-dependent | $40 k–$70 k | 6–10 | 15 % | Demand vendor-managed CIQ pre-clearance; add 0.5 % contingency insurance |

*Detention Risk Index = historical CBP/RASFF seizure rate 2021-2023.

Strategic Actions for Procurement Boards

Embed “No Cert, No Purchase” language in master supply agreements; require quarterly lab re-tests at supplier cost; retain right to unannounced QC audits with 48 h notice. Cap sourcing from any single non-CE/non-FDA-registered plant at 15 % of volume to limit recall tail-risk. Finally, treat compliance spend as a COGS line, not overhead—budget 2.5–3.0 % of landed cost for certification maintenance, still half the expected value-at-risk of non-compliance.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook – Men’s Hair Units (Human-Hair Toupees)

1. RFQ Architecture: Lock-in Quality Before Price

Open with a two-envelope RFQ: technical envelope evaluated first, commercial second. Minimum order value $25k triggers tier-1 factory attention; <10% rejection tolerance on curl-grade, density variance and hair-origin DNA traceability. Require third-party SGS or Intertek follicle-direction inspection at supplier cost; failure shifts lot to supplier-owned inventory. Insert 3% liquidated-damage clause for late technical documentation; delays cascade into photo-shoot calendars and DTC launch windows. Embed a 15% annual volume band (±) to absorb TikTok-driven demand spikes without reopening pricing. Force disclosure of secondary sourcing lines—critical after India’s 2023 raw-hair export quota cut.

2. Supplier Qualification & FAT Protocol

Audit scoring weights: 40% incoming raw-hair traceability, 30% knotting precision (≤4 knots/cm² bleed), 20% ventilation stretch-cycle (>5k bends), 10% social-compliance (Sedex). FAT executed on 1% of lot, not prototype; simulate 30-day wear with 95% humidity cycles and 8 pH shampoo. Reject entire lot if shedding >15 hairs from 5×5 cm test patch. Insist on destructive pull-test video archive; store on blockchain timestamp to counter future charge-backs. Flight-accompany FAT samples to buyer lab—ocean transit adds 6% moisture that masks odor retention.

3. Contract Risk Matrix – Penalties & Escalations

Cap force-majeure hair-origin disruption at 8 weeks; beyond, supplier must source equivalent Slavic or Mongolian grades at pre-agreed $/gram index or face $0.50/unit daily penalty. Insert currency collar: CNY/USD fluctuation >3% triggers 50/50 split. Retain right to switch Incoterm mid-transit if Red Sea reroute surcharges exceed $1.20/kg; supplier bears documentation amendment fees.

4. Incoterms Decision Table

| Metric | FOB Qingdao | DDP Memphis |

|---|---|---|

| Unit landed cost index (basis $100) | 100 | 118–122 |

| Transit-time variability | ±7 days | ±3 days |

| Tariff & quota risk borne by | Buyer | Seller |

| QC hold location | Origin | Destination |

| Cash-to-cash cycle | 45–55 days | 30–35 days |

| Best-fit demand signal | Steady POS | Influencer drops |

Choose FOB when volume >1k units/month and destination warehouse is East-coast; arbitrage Section 321 de minimis for sub-$800 direct-to-consumer parcels. DDP preferred for TikTok “viral SKU” sprints where out-of-stock cost >25% margin.

5. Logistics & Final Commissioning

Book premium air cargo (HK Express) for launch quantities; cost delta vs sea $1.80–$2.10/unit but prevents 8% stock-out-driven revenue loss. Mandate 1% silica-gel ratio and nitrogen-flush to keep mold incidence <0.3%; supplier absorbs re-work if micro-swab fails. At 3PL, run AI visual scan for hairline part consistency; auto-divert misparted units to secondary market to protect brand equity. Close PO only after Amazon VOC (voice-of-customer) <2% return reason “looks fake” within first 30 days; else trigger 5% rebate per additional return point.

Execution discipline on the above checkpoints compresses total sourcing cycle to 63–71 days, reduces landed-quality failures to <1.2%, and secures gross-margin protection of 420–480 bps versus ad-hoc purchasing.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —