This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

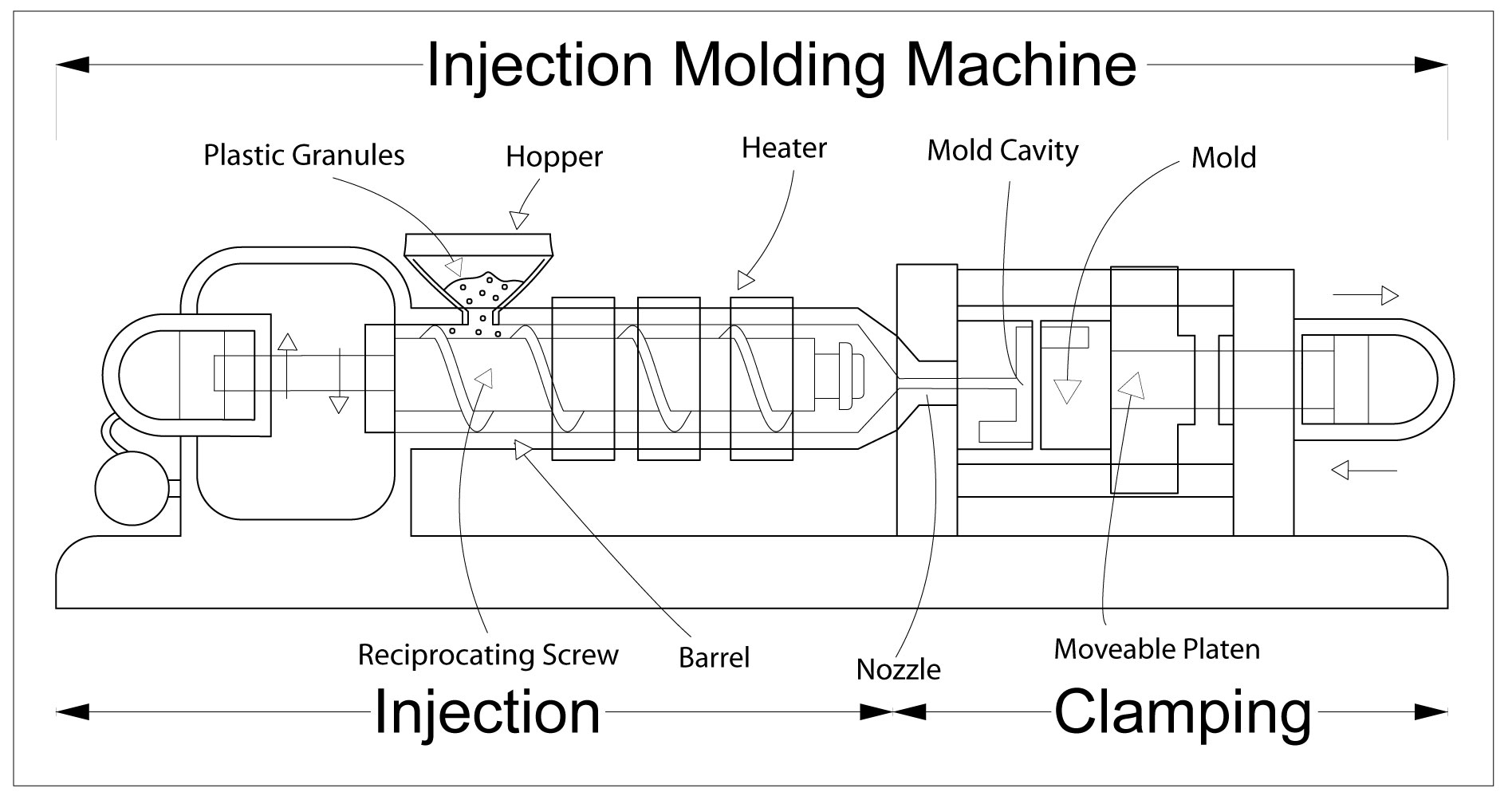

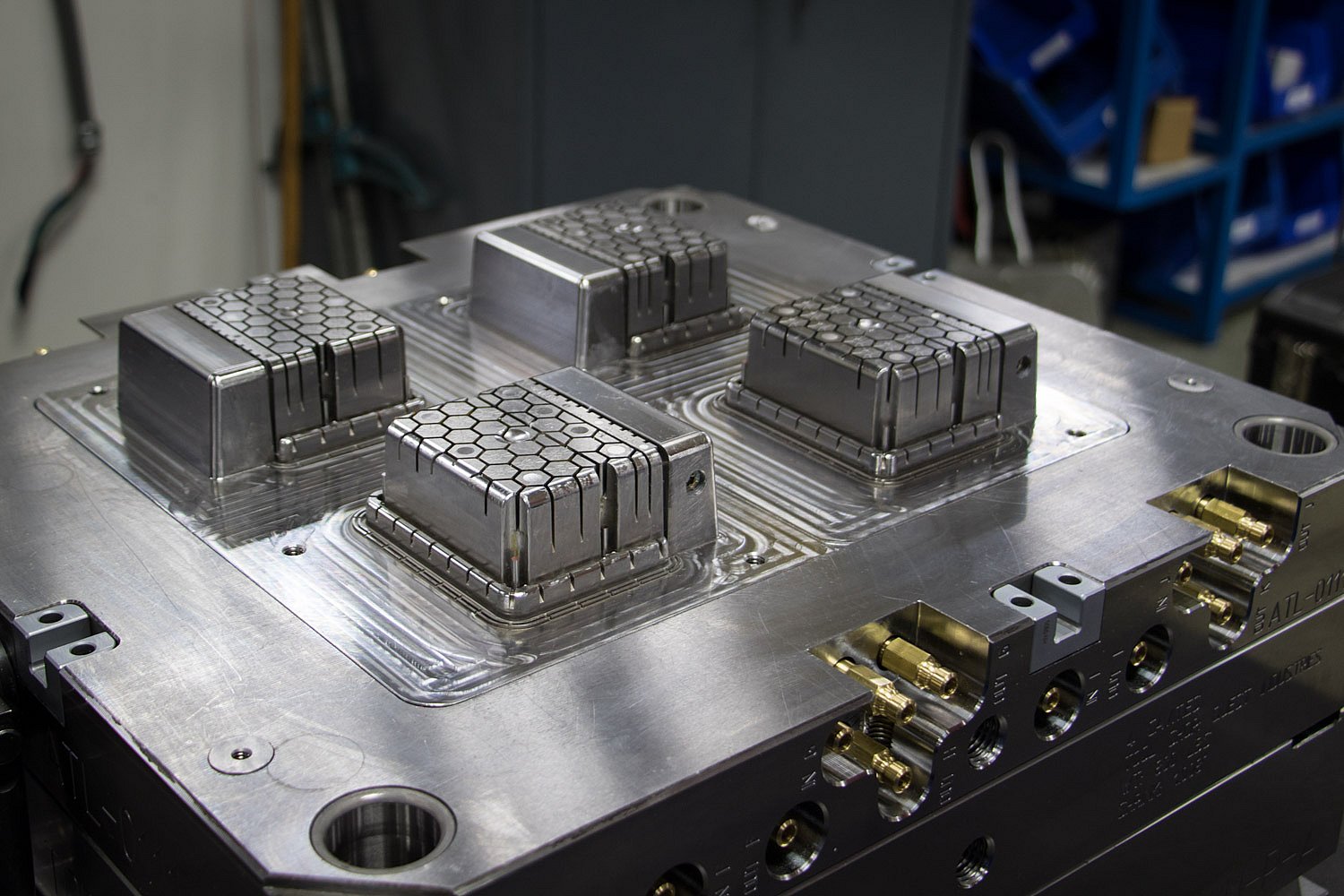

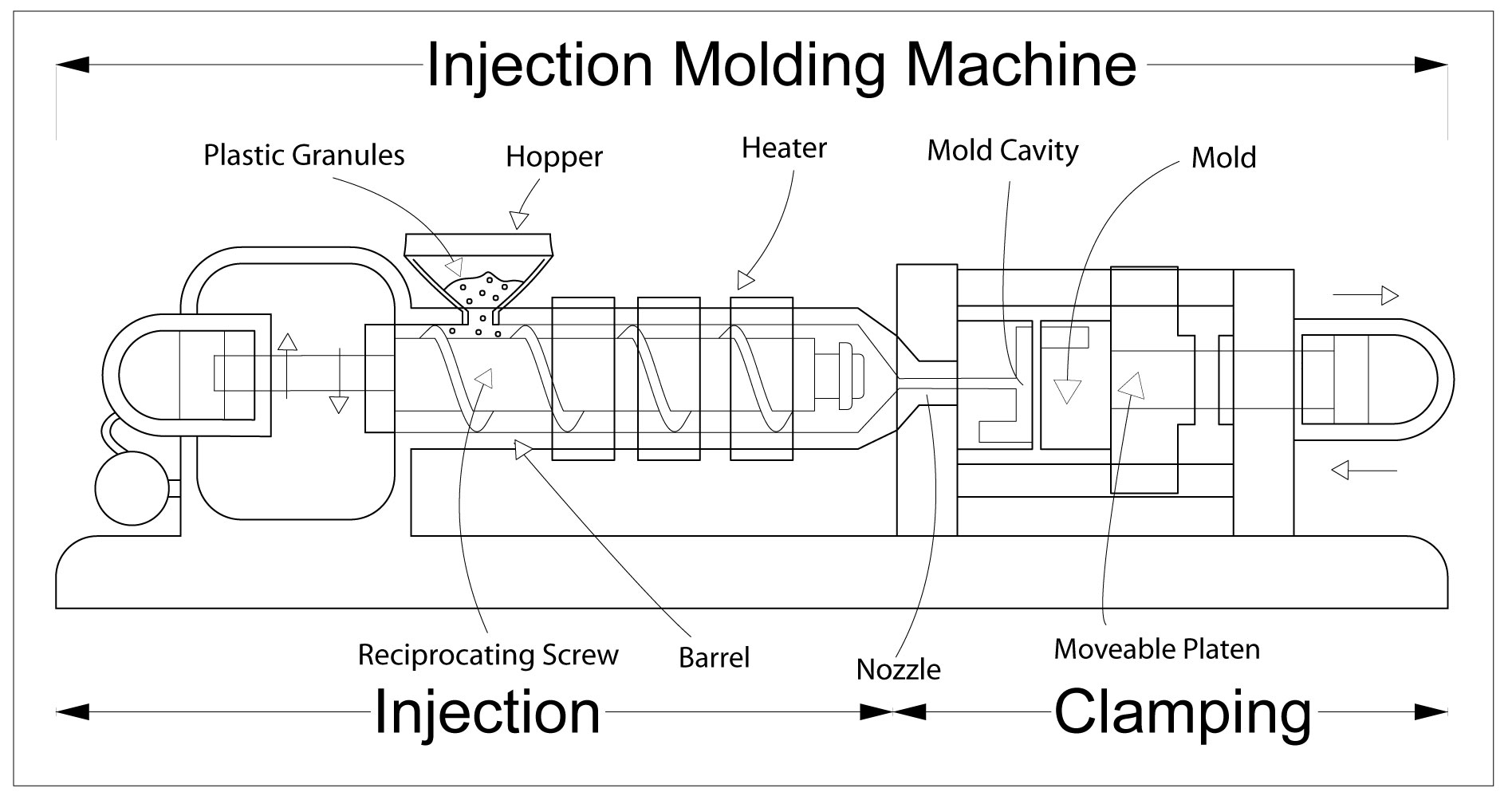

With 20,000 sqm manufacturing space and over 20 years of industrial experience, Holly delivers high-precision plastic injection molding, rapid prototyping, and full-service production for global brands.

20+

Years Experience

60,000+

Projects Delivered

42+

Countries Served

99.7%

On-Time Delivery

As a leading China-based injection molding manufacturer since 2000, Holly has delivered over 60,000 plastic part projects with precision, speed, and reliability.

We are proud to serve industry leaders including EPSON, BMW, HONDA, HP, and Honeywell. Our expertise spans automotive, medical, electronics, aerospace, and industrial applications.

With a manufacturing footprint of 20,000 sqm and a defect rate under 0.03% over the past 5 years, we ensure every component meets the highest standards of quality and consistency.

From concept to production, we offer end-to-end manufacturing solutions with rapid turnaround and uncompromising quality.

High-volume production with tight tolerances, clean finishes, and materials ranging from ABS to PEEK.

Rapid prototyping using SLA, SLS, and FDM technologies for functional testing and design validation.

Precision machining for metals and plastics with tolerances down to ±0.005mm.

Low-volume production using silicone molds for urethane and epoxy resins.

We specialize in complex molding techniques to meet the most demanding engineering requirements.

Metal or plastic inserts are placed into the mold before injection, creating strong, integrated components ideal for automotive and electronics.

Two different materials injected in sequence for soft-touch finishes, seals, or multi-color parts.

Nitrogen gas used to hollow out thick sections, reducing weight and sink marks.

ISO Class 7 cleanroom environment for medical, pharmaceutical, and optical components.

Labels or graphics are placed in the mold, resulting in durable, scratch-resistant finishes.

High-speed molding of parts with wall thicknesses under 1mm, ideal for packaging and consumer goods.

Tolerances down to ±0.01mm with advanced metrology and process control.

Low-cost, fast-turnaround molds for pre-production testing and validation.

Tailored manufacturing solutions for critical applications across industries.

Interior trims, connectors, housings, and under-hood components with high durability and thermal resistance.

ISO 13485 compliant production of surgical tools, diagnostic devices, and drug delivery systems.

Enclosures, connectors, and heat-resistant components for consumer and industrial electronics.

20+ years of experience serving global brands with consistent quality and reliability.

Tolerance ±0.01mm, certified mold steel, and defect rate under 0.03%.

Owned facility with no rental cost allows cost-effective low-volume runs.

Free mold design analysis and part optimization from experienced engineers.

From tooling to assembly, we manage the entire production lifecycle.

Mold and parts delivered in 20–30 days with 99.7% on-time rate.

Ready to start your project? Contact us today for a free quote and expert consultation.

info@hollyplasticparts.com

+86 183-2438-9805

Jiaxing City, Zhejiang Province, China

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info