About HysterTech

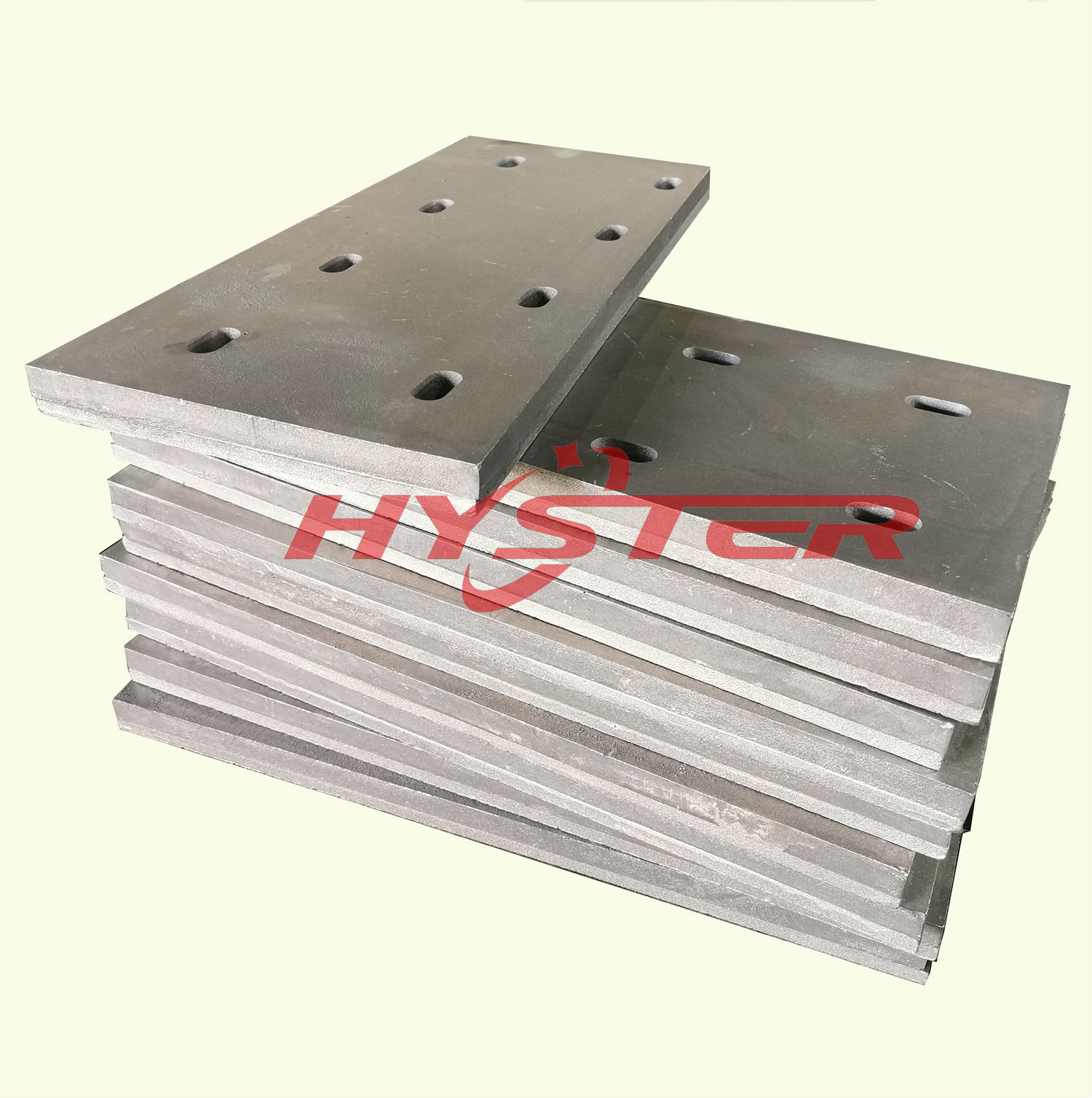

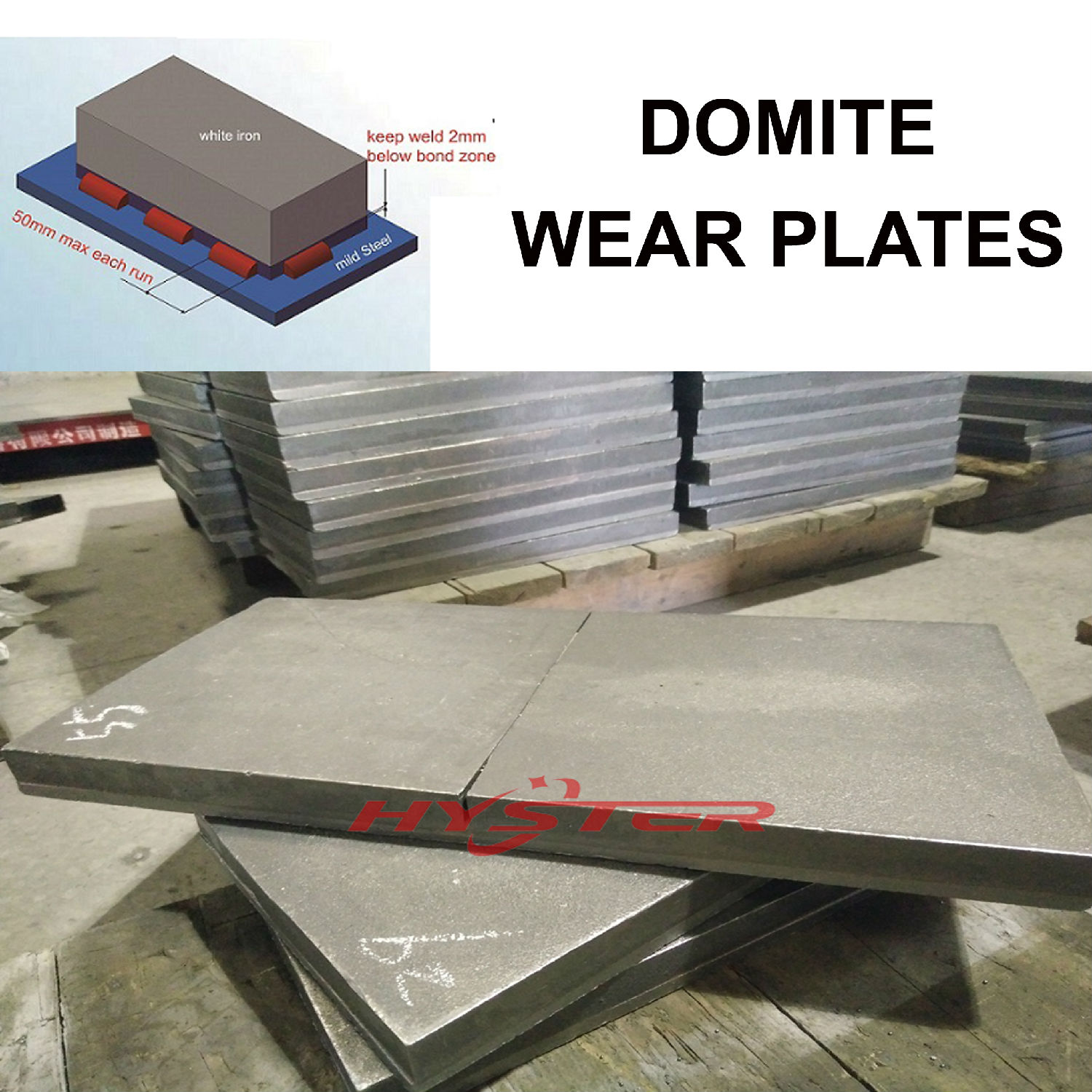

Hunan Hyster Material Technology Co., Ltd., founded in 1995, is a professional manufacturer and exporter of bimetallic wear blocks/plates, chocky bars, wear buttons (white iron vacuum brazed onto mild steel, 63HRC/700BHN), chromium carbide overlay wear plates, Ni-hard castings/plates, and tungsten carbide castings for mining, quarrying, and other heavy industries.

Located in the New and High-Tech Development Zones of Changsha City, Hunan Province, China, we combine advanced metallurgical engineering with strict quality control to deliver wear parts that outperform in the harshest conditions.

- ISO-Certified Manufacturing

- Vacuum Brazing Technology

- 400+ Standard & Custom Designs

- Global Export Network