About Us

Ningbo Heng Zhenglong Precision Casting Co., Ltd. is located in Fenghua, Ningbo, China — approximately 200 kilometers from Shanghai. Founded in 1997, we are a leading manufacturer of high-wear resistance components for heavy machinery.

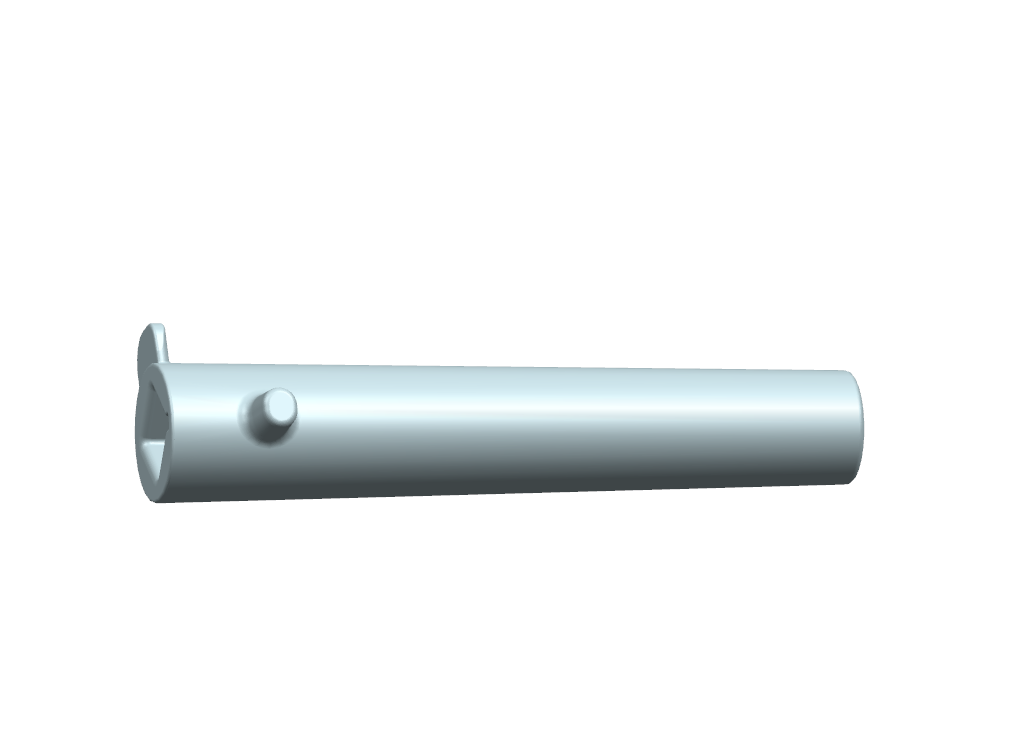

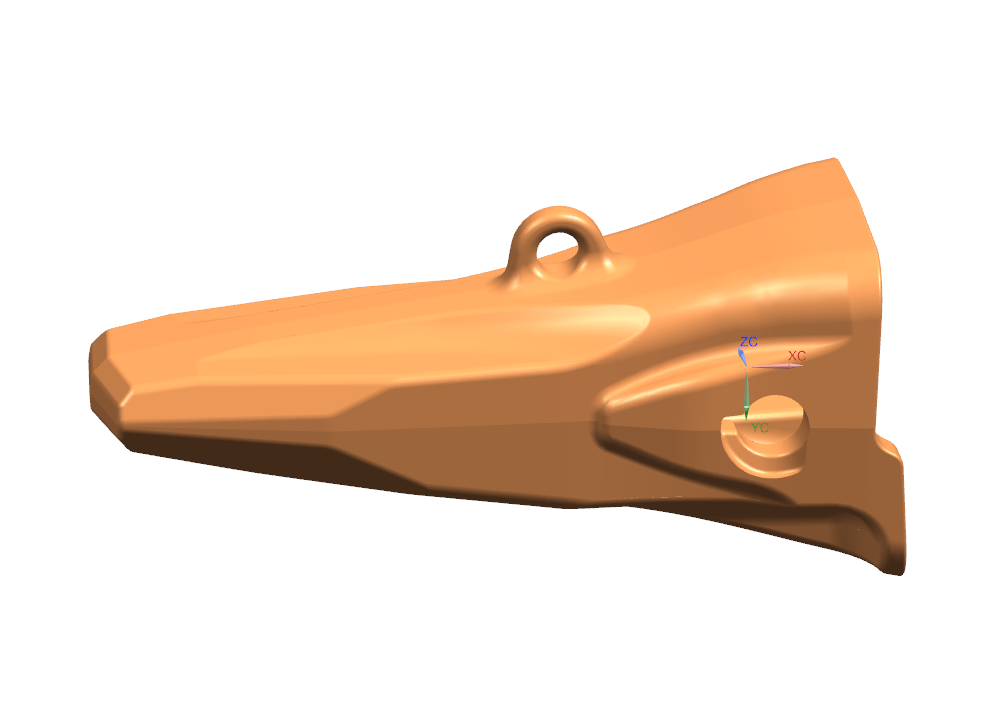

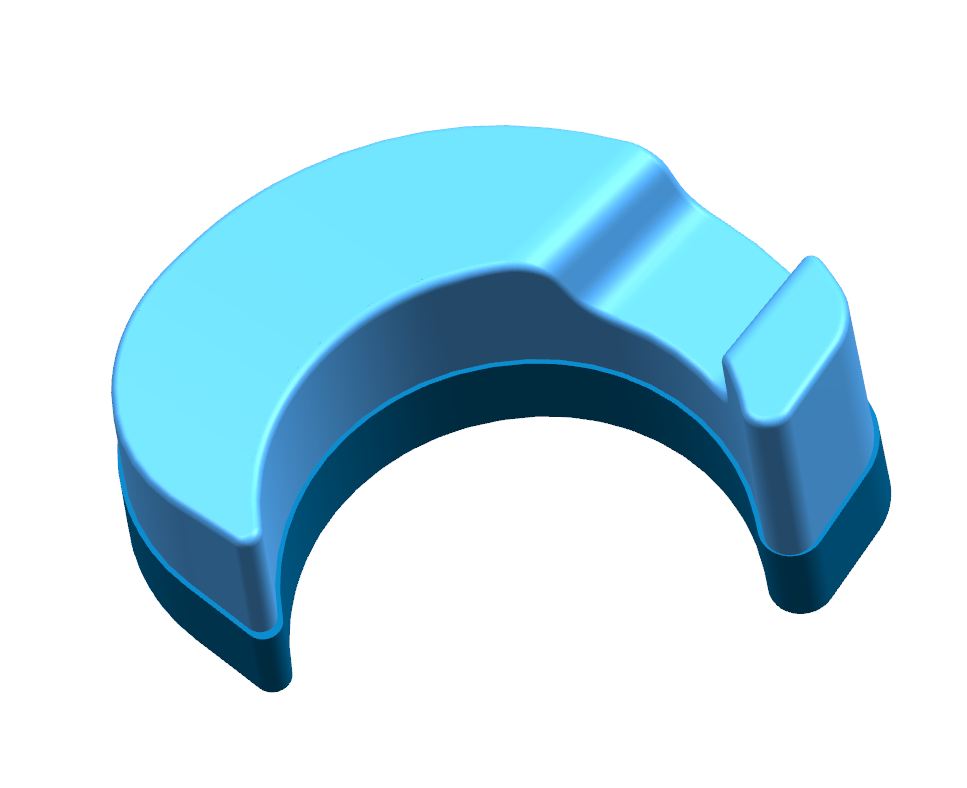

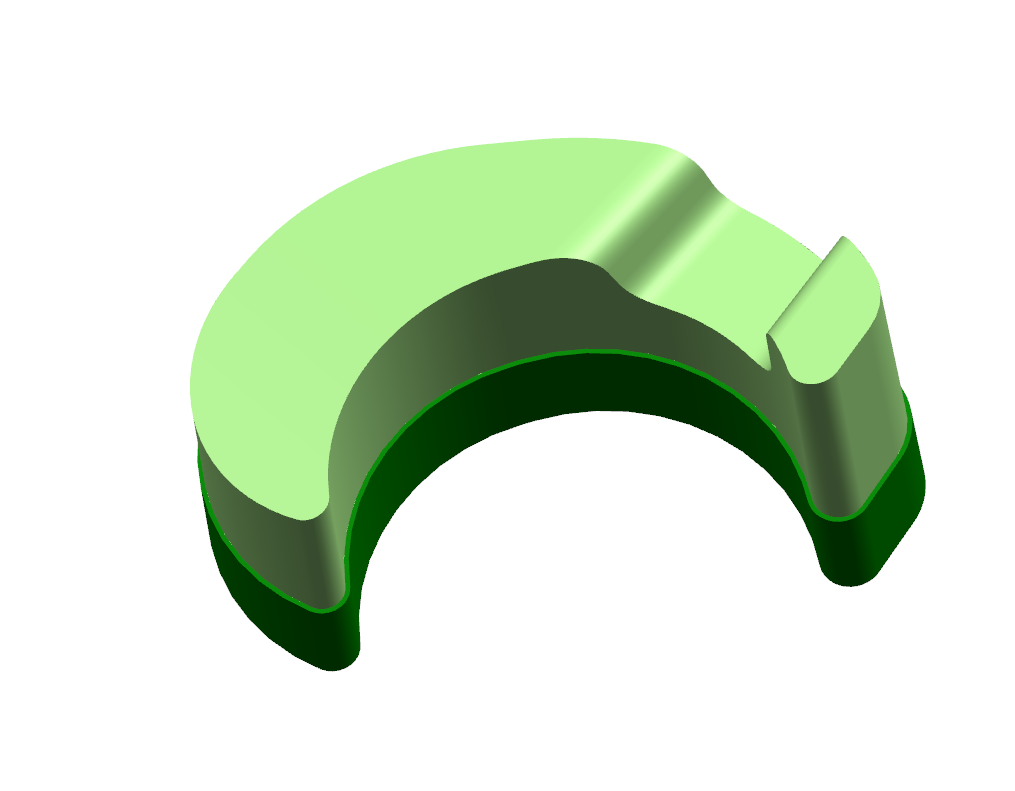

We specialize in producing excavator bucket teeth, loader united teeth, bulldozer ripper teeth, dredging vessel teeth, and rotary drilling teeth. Our products are engineered for durability and performance in the harshest environments.

With a team of 15 senior engineers dedicated to material research and quality control, and a 20,000 square meter manufacturing facility, we ensure every product meets the highest international standards. Our bucket teeth are recognized as No.1 in quality across China.

1997

Founded

15+

Senior Engineers

20,000m²

Factory Area

100+

Countries Served