About Jimei Tool

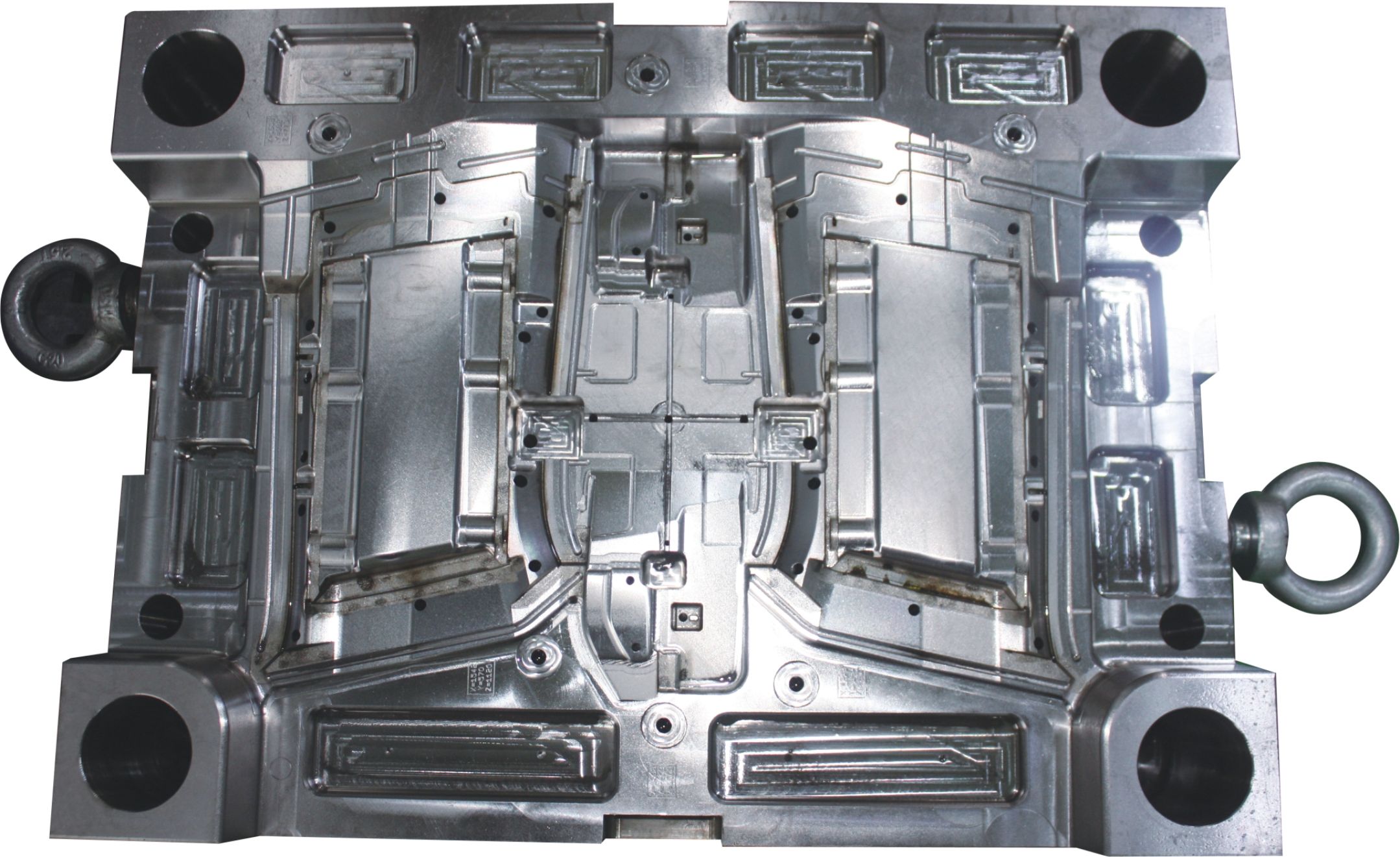

A trusted name in precision mold manufacturing with over 20 years of experience serving global clients in automotive, electronics, and industrial sectors.

Precision. Innovation. Reliability.

Shenzhen Jimei Mold Technology Co., Ltd., established in 2004, is a leading manufacturer of high-precision plastic injection molds. As a member of the Shenzhen Machinery Association, we serve clients across North America, Europe, and Asia.

Our molds meet strict U.S. and European precision standards, with capabilities in CNC machining up to 0.005mm tolerance, WEDM cutting, and advanced surface treatments including SPI, VDI 3400, and MOLD-TECH texturing.

We integrate ERP systems for full project transparency, providing weekly updates so customers can track mold progress remotely from design to delivery.

- 20+ Years of Industry Experience

- ISO-Compliant Manufacturing Standards

- Weekly Production Progress Reports

- Global Customer Support