About Jundro

A trusted high-precision machining service provider specializing in hard and brittle materials for advanced industrial applications.

Our Mission

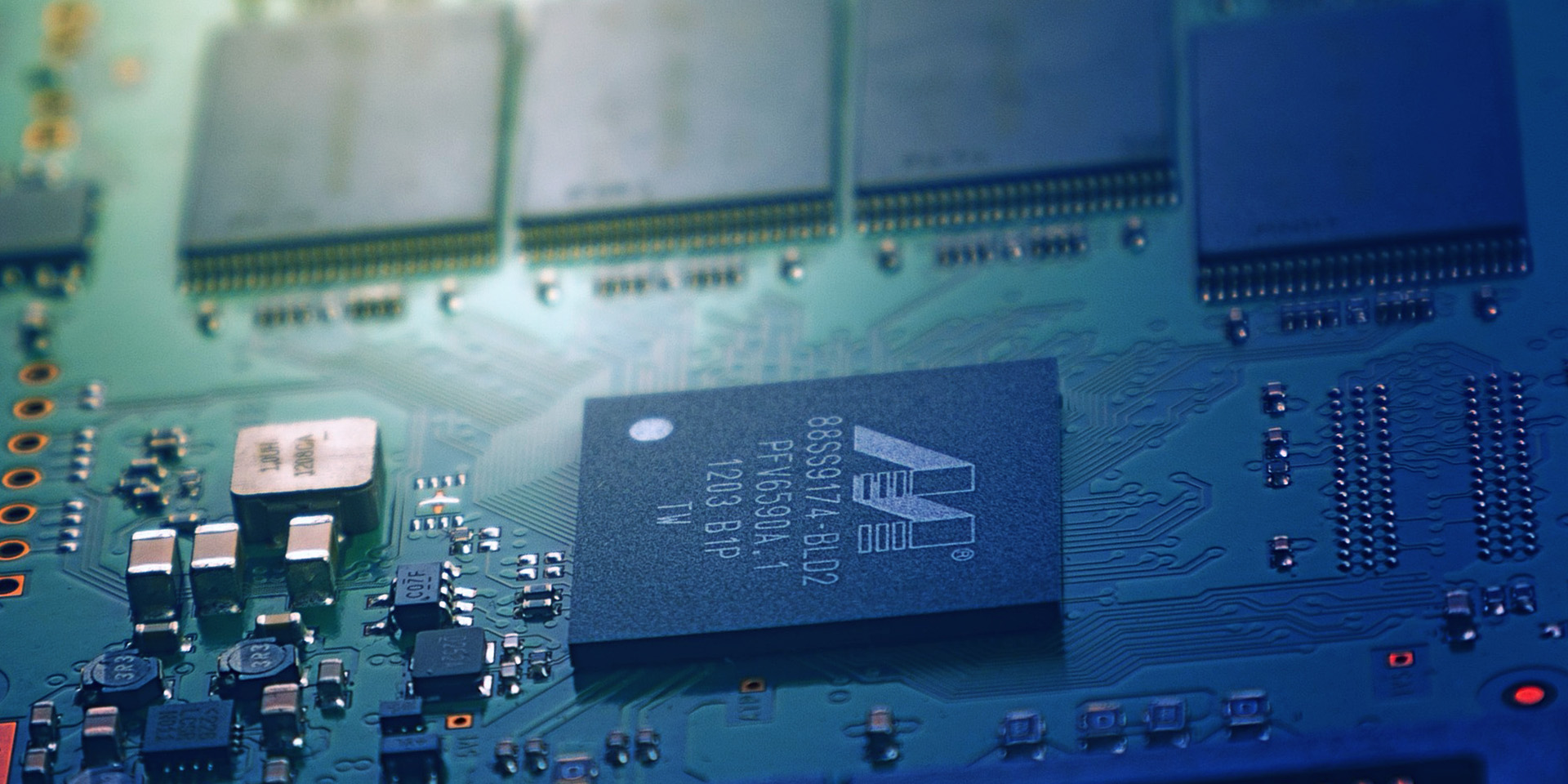

We provide development, design, and production of high-precision components such as ceramics, quartz, sapphire, and hard alloys to meet the special manufacturing needs of users in niche fields including semiconductor, biomedical, aerospace, and new energy.

Jundro deeply cultivates the technical ceramics market, offering strict quality control from material sourcing to final inspection. Our advanced testing equipment ensures every component meets the highest standards of precision and reliability.

Advanced R&D and Production Facility