Advanced Plastic & Fiber

Extrusion Machinery

Leading manufacturer of high-efficiency plastic extrusion lines, fiber spinning machines, recycling systems, and pulp molding solutions trusted by industries worldwide.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Leading manufacturer of high-efficiency plastic extrusion lines, fiber spinning machines, recycling systems, and pulp molding solutions trusted by industries worldwide.

Innovating the Future of Plastic Processing Technology

Suzhou Jwell Machinery Co., Ltd. is a key strategic development and manufacturing center under the JWELL GROUP, specializing in advanced plastic processing equipment. With decades of engineering excellence, we deliver cutting-edge extrusion solutions for pipes, sheets, films, profiles, and recycling applications.

Our commitment to innovation has positioned us as a trusted partner for over 100 countries, offering energy-efficient, high-capacity production lines that meet international quality standards.

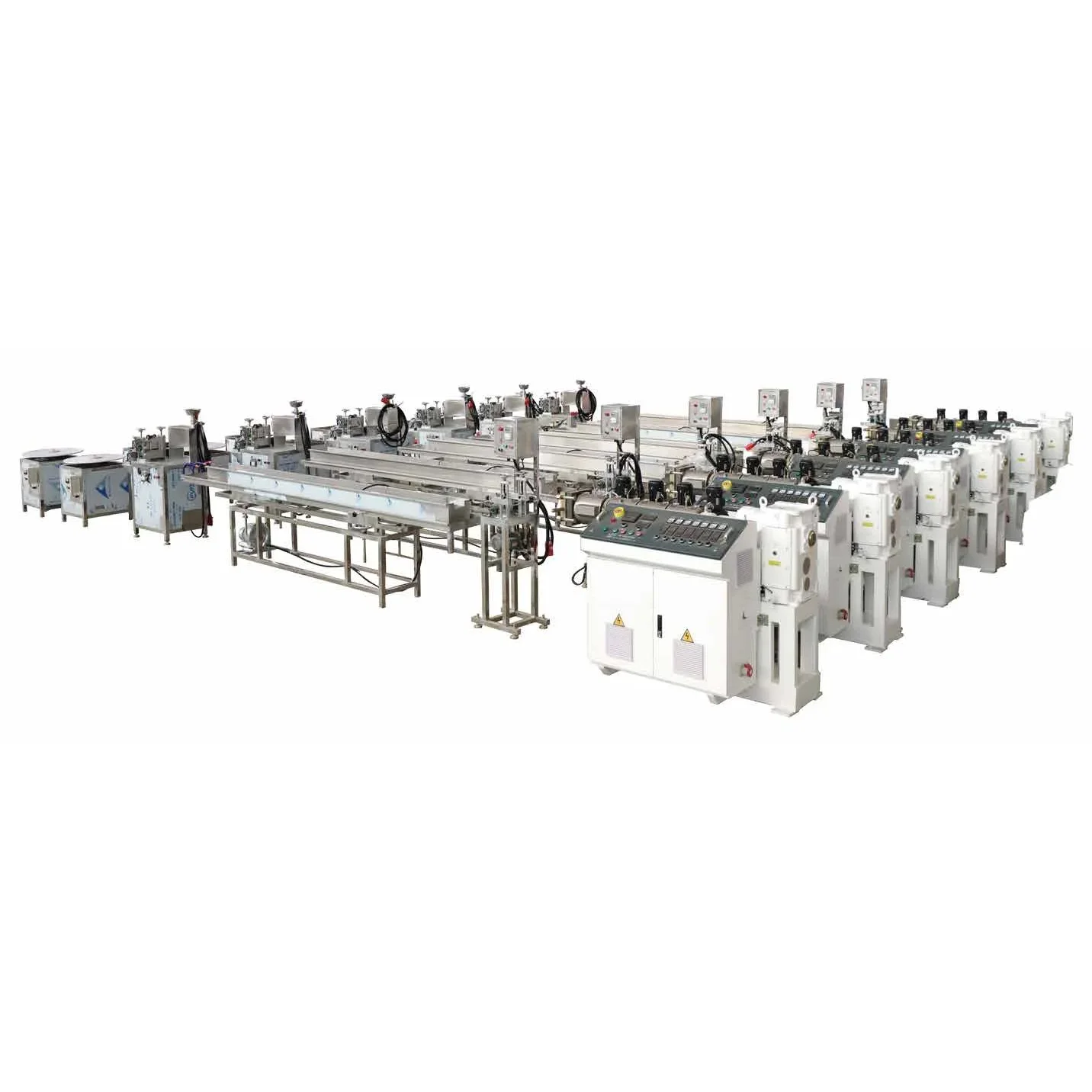

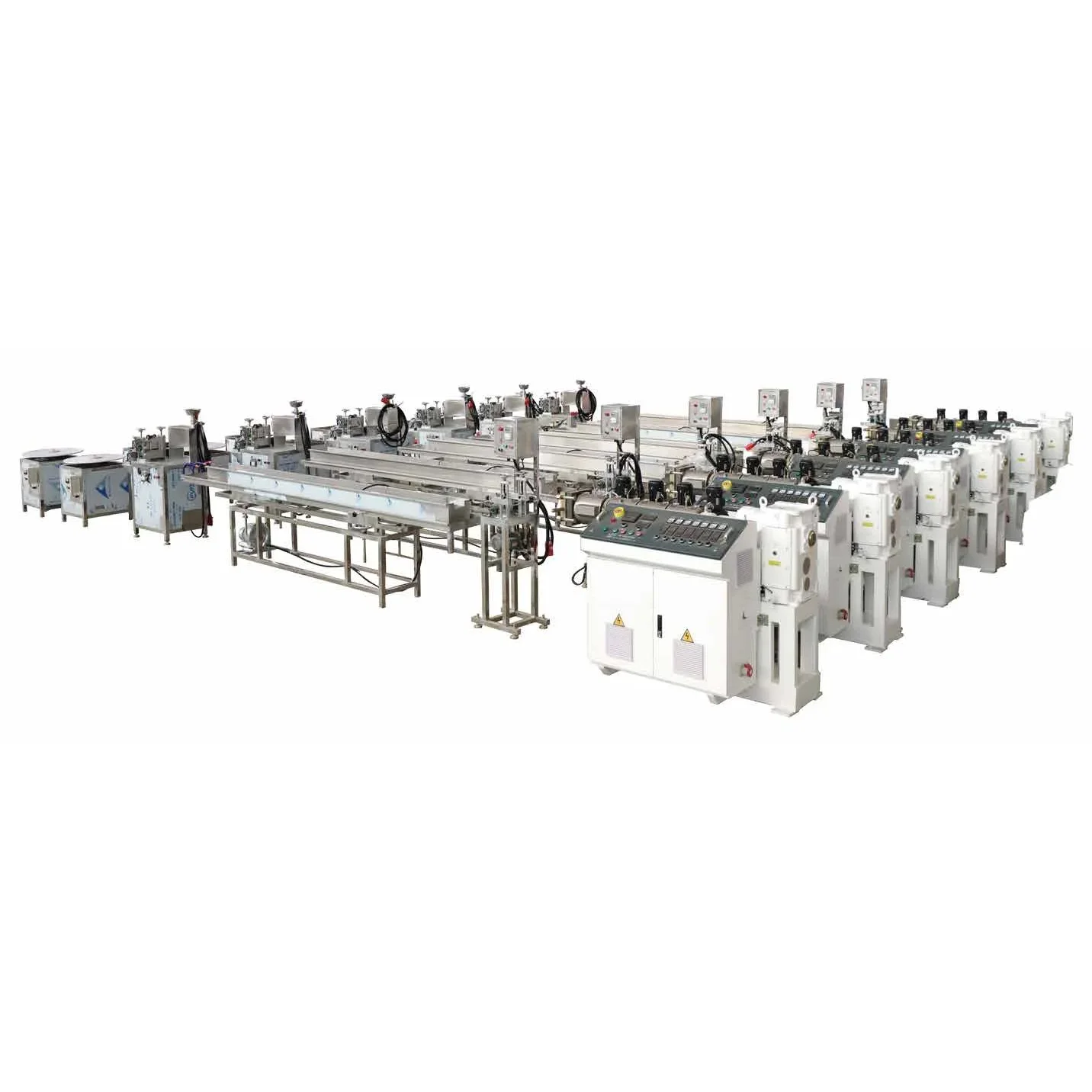

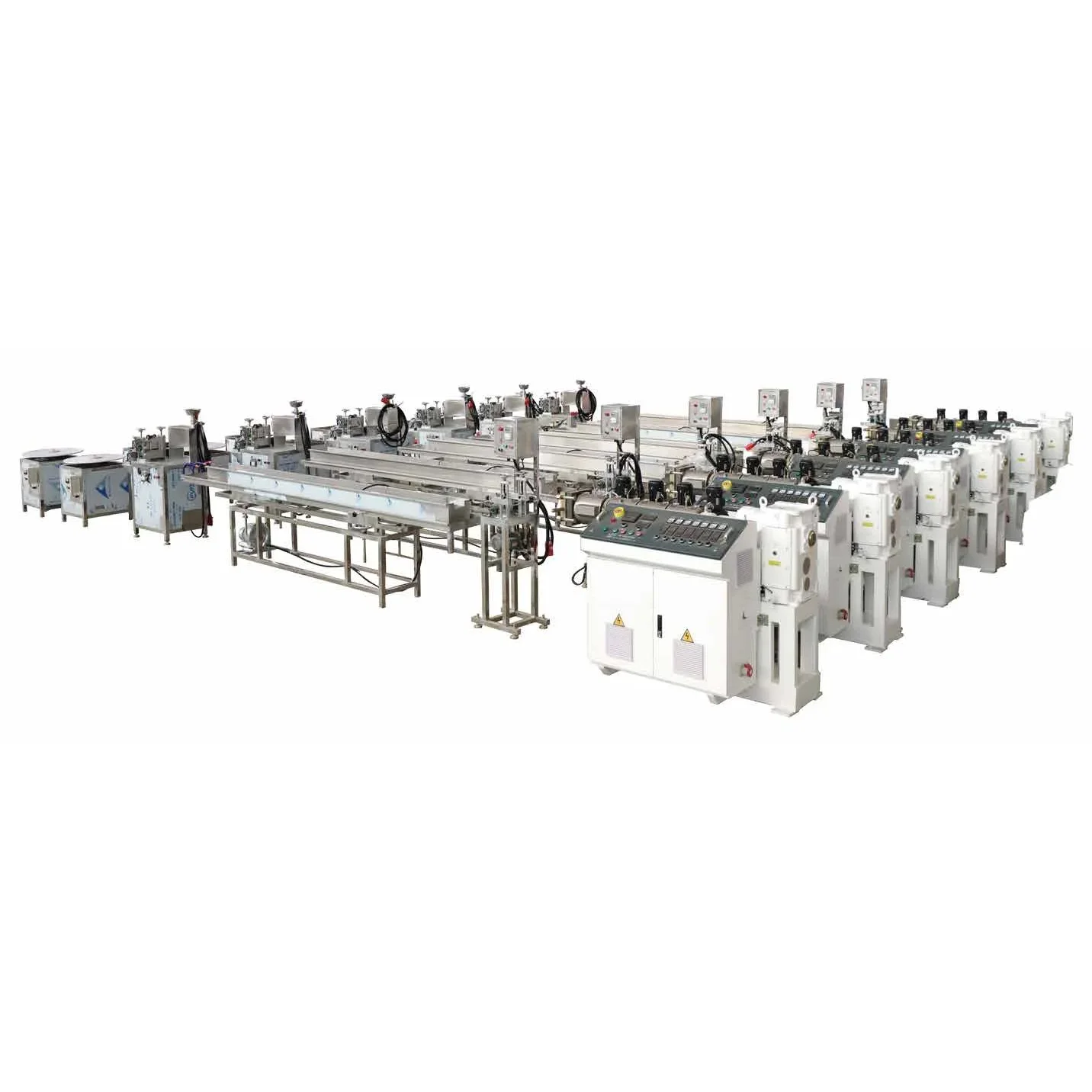

Engineered for Performance, Efficiency, and Reliability

Advanced multi-layer co-extrusion line for PLA, APET, PETG, CPET. Over 30% higher efficiency than standard lines.

Energy-saving line with co-rotating twin-screw extruder. Vacuum degas drying-free system reduces viscosity drop.

Standard high-capacity line with excellent plasticization and stable operation for PP and PS materials.

5-layer symmetrical and 7-layer asymmetrical lines for superior barrier performance in packaging.

Produces lightweight, high-strength hollow boards for construction, signage, and protective shielding.

Precision spinning systems for synthetic fibers with consistent denier and tensile strength.

Fully integrated system for producing eco-friendly meal bags, trays, and packaging from recycled pulp.

High-efficiency recycling line for converting waste plastic into reusable pellets with minimal degradation.

Engineering Excellence Backed by Global Trust

Our lines deliver over 30% higher efficiency compared to industry standards.

Patented screw configurations and cooling systems for optimal performance.

Dedicated service teams across continents ensure fast response and uptime.

Advanced thermal management reduces power consumption by up to 25%.

Our machines handle a wide range of thermoplastics including PP, PE, PS, PET, PLA, PVC, PC, PMMA, EVA, EVOH, and biodegradable materials. Specific lines are optimized for each polymer family.

Yes, we provide tailored solutions based on your required output—from small-scale to high-volume industrial lines. Our engineering team works with you to optimize the configuration.

We offer comprehensive support including installation supervision, operator training, maintenance guidance, and 24/7 technical consultation via email and WhatsApp.

Yes, we maintain a global inventory of critical spare parts including screws, dies, rollers, and T-dies. Most components can be shipped within 48 hours.

Connect with our team for product inquiries, technical support, or custom solutions.

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info