Kenworth T660 Accessories: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Kenworth T660 Accessories

For U.S. and European fleets, the Kenworth T660 demands reliable, fit‑specific accessories to minimize downtime and total cost of ownership. Buyers face a predictable set of challenges: correct fitment across T660 variants, sourcing across fragmented distributors, price parity across regions, and ongoing compliance with safety and environmental standards.

This guide streamlines procurement by focusing on three practical pillars. First, it maps fitment essentials—hood shields, fenders, steps, battery boxes, and mud flaps—to T660 models so the right parts arrive the first time. Second, it outlines sourcing options in the U.S. and EU, including reputable suppliers and distributor networks, with a comparison checklist to reduce supplier risk. Third, it sets a maintenance-by-design approach: select durable materials, verify installation fit before purchase, and align parts with safety/compliance norms in your operating region.

What to expect from the guide:

– A concise cross-comparison of access needs between U.S. and EU fleets.

– A fitment and compatibility checklist, with example accessories and what to verify.

– A sourcing and price visibility framework to standardize RFQs and reduce variability.

– Implementation timelines and KPIs to track uptime gains and cost outcomes.

The objective is simple: faster sourcing, fewer returns, and better on-road performance for your T660 fleet.

Top 10 Kenworth T660 Accessories Manufacturers & Suppliers List

1. Shop Kenworth T660 Parts – 4 State Trucks

Domain: 4statetrucks.com

Registered: 1998 (27 years)

Introduction: Whether you’re swapping out worn parts or customizing your ride, this is your one-stop shop for Kenworth T660 parts and accessories. Built for durability….

2. Kenworth T660 Shop Semi Truck Exterior Accessories and more

Domain: iowa80.com

Registered: 1999 (26 years)

Introduction: 2–6 day deliveryShop our selection of semi truck exterior accessories from Iowa 80. We offer fenders for trucks, truck hood ornaments, semi truck bumpers ……

3. Kenworth – T660 – Truck Town, LLC

Domain: shopsemitruck.com

Registered: 2017 (8 years)

Introduction: 6–14 day delivery 30-day returns12″ Kenworth T660 Sunvisor, no Light Holes – Replaces OEM visor. SKU: TSUN-K14 Years 2008+. Designed to Fit Curved glass Models with sleeper. OEM replacement….

Illustrative Image (Source: Google Search)

4. Compatible with Kenworth T660

Domain: floridasfinestcustomworks.com

Registered: 2021 (4 years)

Introduction: Free deliveryKenworth T660 Accessories. … Kenworth 13 inch Visor for T600 T660 W900 By Floridas Finest Customs Works, Mirror Finish Made In USA….

5. Kenworth T660 Truck Parts & Accessories

Domain: raneystruckparts.com

Registered: 2006 (19 years)

Introduction: Raney’s Truck Parts carries a wide selection of Kenworth T660 truck parts and accessories! A shift in design philosophy for Kenworth….

6. Kenworth Truck Parts & Accessories

Domain: dietersaccessories.com

Registered: 1999 (26 years)

Introduction: Our Kenworth truck accessories are available for all models which include T660, T680, T800, W900L, W900, W900B and T880….

7. Parts & Accessories for Kenworth T660 for sale – eBay

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Shop Parts & Accessories for Kenworth T660 with eBay Guaranteed Fit. Great deals. Massive selection from top brands on eBay.com….

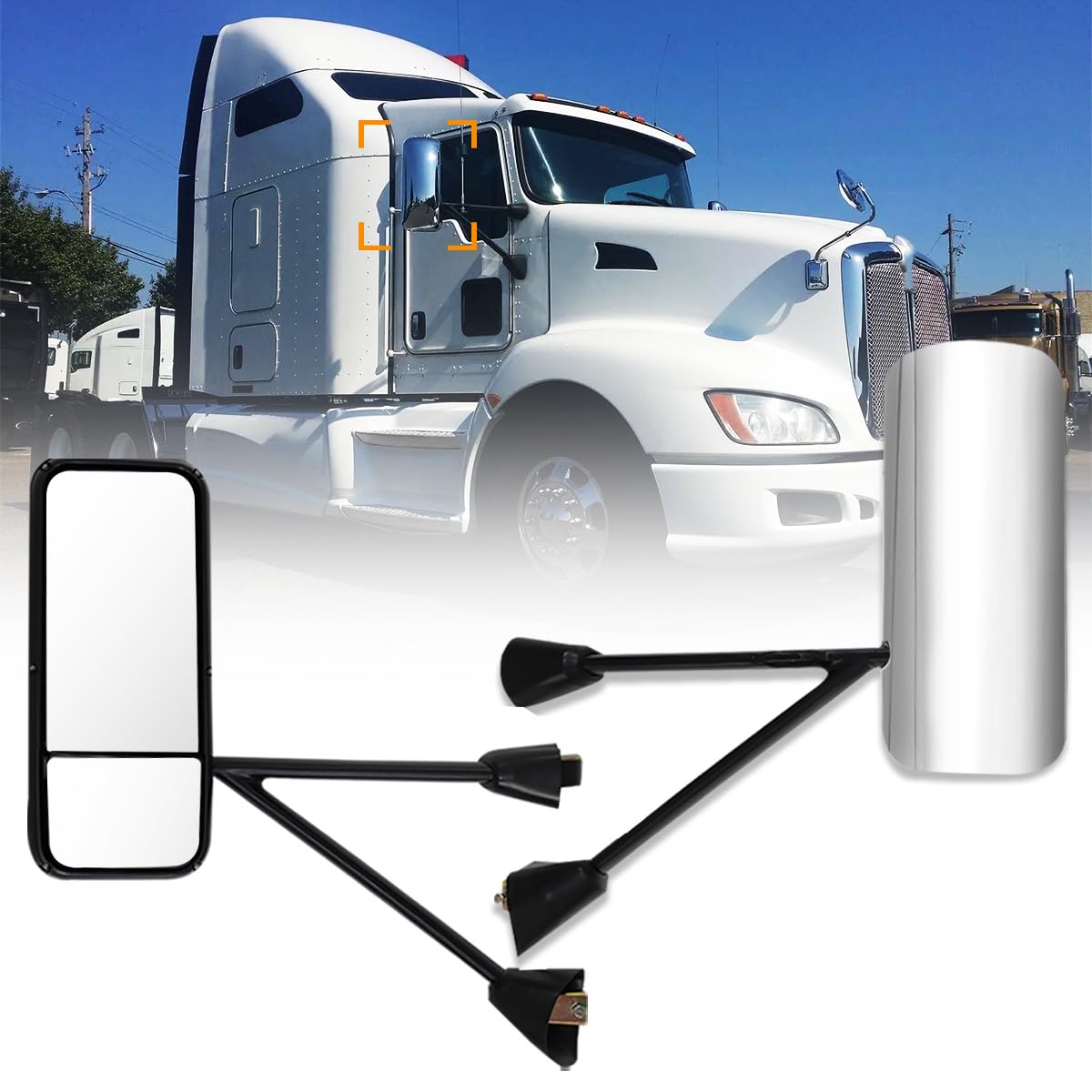

Illustrative Image (Source: Google Search)

8. Aftermarket Kenworth T660 Parts for Sale – Big Truck Hoods

Domain: bigtruckhoods.com

Registered: 2009 (16 years)

Introduction: $999 delivery · 30-day returnsLooking for high-quality aftermarket Kenworth T660 body parts for sale? Order hoods, bumpers, grille guards, headlights, fenders, and more at Big Truck ……

9. Kenworth T660 – Fitzgerald Glider Kits

Domain: fitzgeraldgliderkits.com

Registered: 2007 (18 years)

Introduction: The Kenworth T660 set a milestone in aerodynamics when it was first introduced. As Fitzgerald’s best selling Kenworth, this truck performs as good as it looks….

Understanding kenworth t660 accessories Types and Variations

Understanding Kenworth T660 Accessories: Types and Variations

Accessory selection for the T660 should align with your fleet’s operating profile, route mix, and maintenance plan. In practice, most procurement and operations teams group T660 accessories by function and installation zone. Below is a concise mapping of the dominant categories, key features, primary applications, and trade-offs to inform sourcing decisions and prevent fitment/returns.

| Type | Features | Applications | Pros/Cons |

|---|---|---|---|

| Aerodynamic & Front-End Protection | Deflectors, deflector brackets, hood shields, visor extenders; materials vary by SKU | Long-haul aero optimization, road debris mitigation | Pros: Improve slipstream, reduce hail/rock damage; Cons: Fitment varies by T660 configuration; inspect brackets and visor angle before purchase |

| Cab & Sleeper Steps & Access | Front, sleeper, and fold-away steps; options include cast aluminum, slip-resistant treads, grab handles; polished or powder-coated finishes | Driver safety, frequent cab access | Pros: Reduce slip risk, increase uptime; Cons: Warranty varies by finish and mounting surface; verify weight rating and attachment method |

| Back-End, Undercarriage & Payload Protection | Mud flaps and holders, fender accents, license/permit holders | Regional hauls, winter/salt exposure, urban delivery | Pros: Protects finish, meets roadside checks; Cons: Salt/chemicals can degrade non-stainless holders; holders must match license plate standards |

| Tool, Battery & Storage Boxes; Electrical/Horns | Locking tool/battery boxes, battery box rails, air horns, horn wiring; materials range from aluminum/stainless to composite | Maintenance access, safety/compliance (audible warning), secure storage | Pros: Organized gear, secure contents, compliance; Cons: Drilling/mounting risks; air systems require correct plumbing and fuse protection |

Aerodynamic & Front-End Protection

T660 fleets often prioritize airflow management and hood/nose protection to reduce stone chips and maintain paint integrity. Hood shields and deflectors shape the wake across the front surface, while visor extenders can trim turbulence over the windshield. Fitment can differ by hood style and factory optioning (e.g., extended hood vs. standard nose), so confirm bracket compatibility and hinge/trim clearances before ordering. In mixed fleets, standardizing on universal designs that tolerate small alignment differences can reduce stocking depth and installer variability.

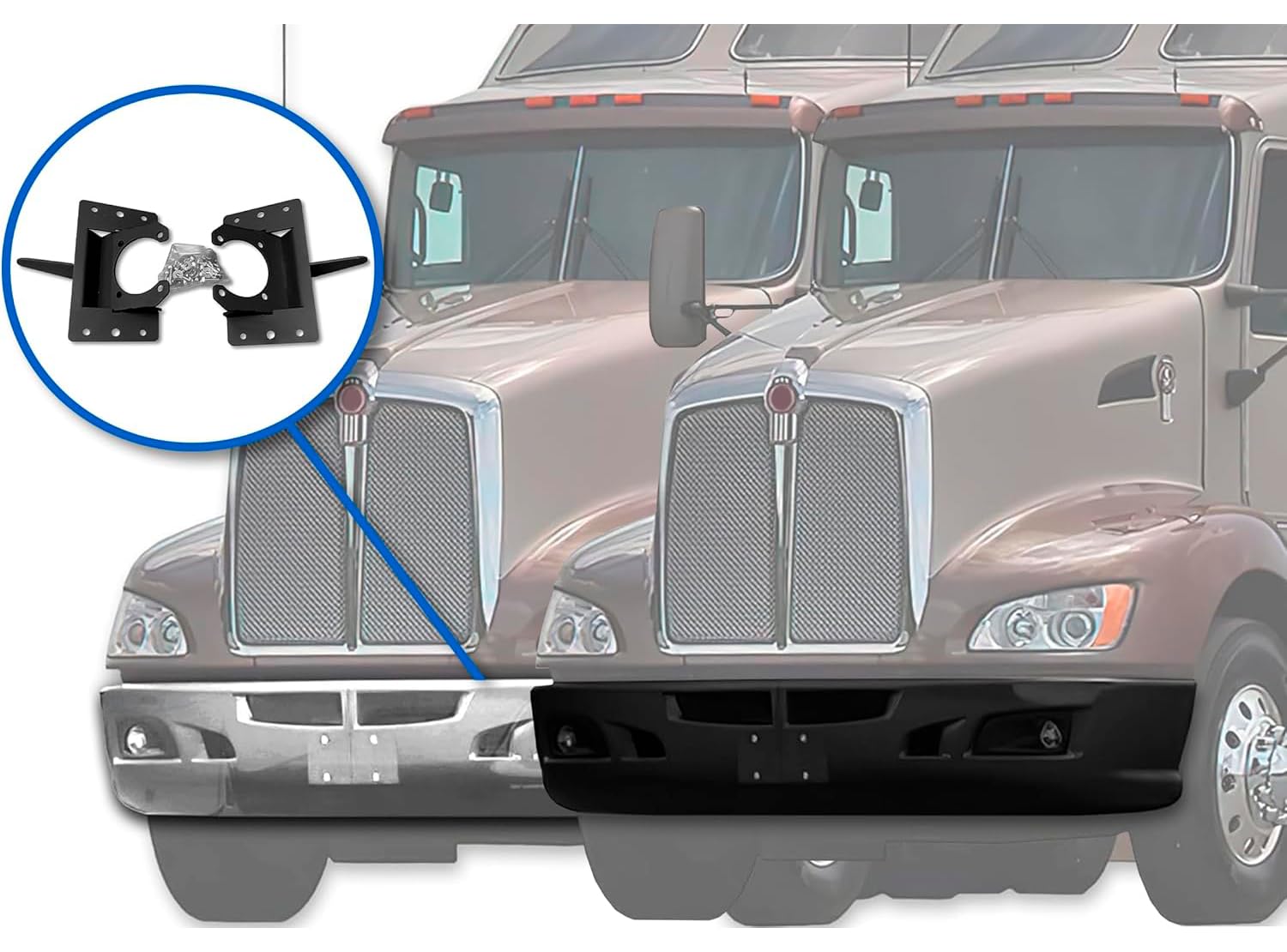

Illustrative Image (Source: Google Search)

Cab & Sleeper Steps & Access

Daily cab access is a safety-critical point. Steps with deep-tread casting, anti-slip inserts, and robust grab handles minimize slips, especially in wet or cold conditions. Finish matters: polished aluminum reduces corrosion but requires maintenance; powder-coated finishes protect better but can show wear under heavy use. Verify bolt pattern and load rating, and consider fold-away or swing-clear designs where space constraints exist. Matching step height to yard/pad surface profiles reduces driver fatigue and helps meet OSHA-aligned safety practices.

Back-End, Undercarriage & Payload Protection

Mud flap systems and holders protect the rear axle area, wheels, and undercarriage from road spray and debris. For fleets operating in winter corridors, stainless or aluminum holders resist salt; heavy-duty flaps minimize flutter at highway speeds. License and permit holders should use UV-stable materials and quick-access designs to support inspections without scraping or damaging plates. Where municipal rules govern reflectorization or flap height, confirm regional compliance during SKU selection.

Tool, Battery & Storage Boxes; Electrical/Horns

Secure, organized storage reduces service calls and driver downtime. Tool and battery boxes with locking latches and weather gaskets keep critical items protected; aluminum/stainless builds aid longevity. Battery box rails can strengthen the box-to-frame interface and protect the box bottom. Air horn systems must be plumbed correctly with sufficient air volume and protected with inline fuses and relays; confirm voltage and compressor output capacity to avoid in-cab noise complaints or insufficient audibility.

Procurement guidance:

– Standardize accessory families by installation zone to simplify stocking and reduce mis-picks.

– Require SKU-level fitment confirmation by T660 build (hood style, sleeper length, bumper/visors).

– Prioritize materials that match duty cycle (e.g., stainless for winter routes; composite for lighter urban use).

– Document installation torque and routing to prevent warranty claims and electrical failures.

Illustrative Image (Source: Google Search)

Key Industrial Applications of kenworth t660 accessories

Key Industrial Applications of Kenworth T660 Accessories

| Industry | Accessory | Detailed Benefits | Item No. | Price Range |

|---|---|---|---|---|

| Long-haul and intermodal | Hood Shield (Aeroshield II) | Deflects stones and road debris; reduces hood and front-end paint chipping; lowers repair and prepaint spend; helps maintain aerodynamic profile and front-end finish. | 42115 | $223.99–$236.99 |

| Long-haul and intermodal | Cab & Sleeper Steps | Improves safe ingress/egress in tight bunks and busy yards; reduces slips and slip-related injuries; supports driver retention and safety KPIs. | — | — |

| LTL and regional distribution | Bumpers | Adds front-end protection against dock and yard contact; restores OEM aesthetics; supports uptime by minimizing low-speed damage. | — | — |

| LTL and regional distribution | License & Permit Holders | Secures registrations and permits; reduces lost paperwork and DOT checks delays; improves CSA compliance documentation retrieval. | — | — |

| LTL and regional distribution | Mud Flaps | Reduces splash and stone damage to lower body panels and trailers; improves safety and appearance in urban operations. | — | — |

| Tanker and hazmat | Horns | High-output air horns for audible warning; aids in low-visibility situations; supports incident prevention and audit-readiness. | — | — |

| Tanker and hazmat | Tool & Battery Boxes | Secure storage; protects valuable tools and equipment; reduces theft and downtime; organized tools speed inspections. | — | — |

| Heavy-haul and oversize | Cab & Sleeper Steps | Stable, safe access in foul weather and remote yards; consistent step height reduces strain. | — | — |

| Heavy-haul and oversize | Air Cleaners & Air Inlet | Protects engine from dust ingress; maintains intake flow; critical for high-demand operations and dusty routes. | — | — |

| Heavy-haul and oversize | License & Permit Holders | Keeps oversize/escort permits visible and intact; reduces roadside check friction; accelerates corridor clearance. | — | — |

| Reefer (temperature-controlled) | Fuel Tanks | Reliable range for freezer units and auxiliary power; supports fuel planning and temp compliance routes. | — | — |

| Reefer (temperature-controlled) | Battery Boxes | Secure power source storage for reefers and telematics; reduces theft; supports consistent data logging. | — | — |

| Construction and logging | Bumpers | Reinforces front-end against brush, lumber, and gate contact in job sites; minimizes damage to lights and sensors. | — | — |

| Construction and logging | Fenders | Contain tire spray and debris; improve road safety around worksites; protect components from thrown material. | — | — |

| Construction and logging | Mud Flaps | Limit ballast and grit spray; reduce undercarriage erosion; keep DOT-compliant with wheel splash control. | — | — |

| Construction and logging | Horns | Audible warning in noisy sites; enhances yard and on-site safety signaling. | — | — |

| Owner-operators | Hood Shield | Protects front-end finish; maintains resale value; reduces paint repair cycles. | 42115 | $223.99–$236.99 |

| Owner-operators | Emblems | Refreshes OEM styling; supports brand identity and lease return standards. | — | — |

| Owner-operators | Steps | Safer daily cab access; reduces minor injuries and fatigue; better ergonomics around tight parking. | — | — |

| Owner-operators | Horns | Personal branding with quality tone; improved road presence for urban driving. | — | — |

| Fleet services (compliance and uptime) | Air Cleaners & Air Inlet | Extends engine service intervals; reduces wear in dusty climates; fewer intake-related failures. | — | — |

| Fleet services (compliance and uptime) | Tool & Battery Boxes | Centralized tool storage for drivers and maintenance; faster service calls; loss prevention for assets. | — | — |

| Fleet services (compliance and uptime) | License & Permit Holders | Reliable permit visibility; reduces fines; streamlines DOT inspections. | — | — |

| Utility and municipal | Horns | High-output signaling for urban/traffic operations; supports safety SOPs. | — | — |

| Utility and municipal | Fuel Tanks | Extended route capability for auxiliary equipment and idling in remote yards. | — | — |

| Bulk and aggregate | Mud Flaps | Reduces airborne aggregate from trailers; lowers underbody corrosion; improves road safety. | — | — |

| Bulk and aggregate | Bumpers | Front-end protection against yard equipment and quarry contact; minimal downtime. | — | — |

| Bulk and aggregate | Air Cleaners & Air Inlet | Prevents dust ingestion during haul and dump cycles; maintains power and mpg. | — | — |

3 Common User Pain Points for ‘kenworth t660 accessories’ & Their Solutions

3 Common User Pain Points for “Kenworth T660 Accessories” & Their Solutions

Pain Point 1 — Fitment and compatibility risk

Scenario: A T660 arrives for service. A technician orders a hood shield or air cleaner that looks “close,” but mounting points or dimensional tolerances don’t match the T660’s configuration (year range, extended vs short hood, aero features). Downtime increases due to returns or rework.

Problem: Fitment mismatches between model years or variants, unclear part descriptions, and missing mounting details.

Solution:

– Map by model year and specific variant (extended hood/short hood/aerocab) before ordering; confirm if any bracket kits or trim panels are required.

– Require clear part illustrations, fitment notes, and OEM-style mounting specifications; prefer vendors with T660-specific fitment references.

– Standardize a pre-order fitment check: VIN-to-part lookup (where available), truck photos, and a short “fitment checklist” validated by a shop foreman.

– Keep common T660 exterior brackets, gaskets, and mounting hardware in stock for first-fit and return parts.

Quick-fitment checklist (use this before ordering)

| Component | Key fitment info to confirm |

|—|—|

| Hood shield/deflector | T660 model year, hood type (extended/short), required brackets, existing hardware |

| Air cleaner/air inlet | Year range compatibility, inlet/outlet diameter, mounting orientation, clearance to fairing |

| Cab/sleeper hardware | Exact model fitment, bed ladder mounting, door latch/strike compatibility |

| Back-end components | Year-specific back-of-cab hardware, bumper mounting, crossmember spacing |

| Fenders/mud flaps | Axle spacing, wheelwell geometry, splash/drip provisions, wheel/tire clearance |

| Steps/tool boxes | Mounting foot pattern, reach to door handle, latch type, lock compatibility |

Pain Point 2 — Supply continuity and lead times

Scenario: A fleet pre-bills hours for a T660 accessory job (e.g., cab interior package, battery box, and lights). The vendor backorders, delaying the truck and increasing detention costs.

Problem: Lead-time variability and fragmented supplier timelines across the US/EU.

Solution:

– Keep high-velocity accessories (mud flaps, steps, horns, license holders, tool boxes) stocked locally to avoid schedule slippage.

– Identify pre-approved equivalents by category (e.g., 6″ vs 8″ steps, steel vs aluminum boxes, LED vs halogen work lights) and maintain a small set of alternates.

– Use a staging calendar: pre-order core components 4–6 weeks ahead for EU destinations; hold critical items in a reserve pool.

– Consolidate shipments to cut customs handling and expedite receiving; align dock windows with vendor lead times.

– Leverage periodic promotions for planned buys to protect cash and reduce unit costs.

Pain Point 3 — Compliance and cross-border documentation

Scenario: A T660 accessory crosses US/EU borders without the right paperwork. Import duties, VAT, or restricted item flags slow clearance, and the part sits in customs while the truck sits in the bay.

Problem: Incomplete or inconsistent documentation; unclear certifications; duty/VAT exposure.

Solution:

– Standardize HS codes by category and keep a cross-reference matrix for common parts (see table).

– Provide HS code and clear product descriptions on invoices, packing lists, and BOLs; ensure manufacturer names and model details match the T660.

– Pre-advance entries or use trusted carrier programs; for EU, include EORI/VAT and IOSS/De Minimis handling where applicable.

– For electrical accessories, confirm safety/EMC compliance (SAE/ECE), include test reports or declarations; retain documentation in your TMS or ERP.

– Align with supplier’s return procedures and maintain proof of compliance to streamline warranty or RMA.

Illustrative Image (Source: Google Search)

Common accessories and documentation needs

| Accessory category (T660-relevant) | Typical documentation for US/EU |

|—|—|

| Hood shields, bumpers, fenders | HS code, invoice with part description and model fitment, packing list, BOL |

| Air cleaners/inlets | HS code, diameter/outlet specs, origin of manufacturing, invoice |

| Mud flaps, steps | HS code, quantity and dimensions, invoice and packing list |

| Tool/battery boxes | HS code, lock/latch type, material spec, invoice |

| Horns, lighting (LED work lights) | HS code, safety/EMC compliance (SAE/ECE), invoice, test reports (where applicable) |

| Cab/sleeper accessories | HS code, fitment notes, invoice; include bed ladder/handle compatibility |

Strategic Material Selection Guide for kenworth t660 accessories

Strategic Material Selection Guide for Kenworth T660 Accessories

Audience: USA, Europe

Executive summary and scope

This section helps fleet managers and installers choose the right materials for Kenworth T660 accessories across exterior applications—hood shields, bumper systems, cab/sleeper exterior components, air inlets, fenders, fuel tanks, license/permit holders, mud flaps, steps, boxes, and horns. It balances durability, weight, corrosion performance, and compliance in North American and EU conditions. It uses real product categories available for the T660 to anchor recommendations.

Known from reference:

– Hood shields for the T660 are offered as part of a broad Aeroshield II portfolio, indicating strong demand for deflectors and hood-mounted exterior parts in T600-series trucks.

– Store range spans 150+ exterior items across categories like bumpers, fenders, fuel tanks, steps, tool/battery boxes, mud flaps, and horns.

– Accessories commonly differentiate by OEM fitment (e.g., hood variations, sleeper configurations) and finish.

Illustrative Image (Source: Google Search)

Decision criteria for T660 applications

- Duty and exposure: Road salt, de-icers, UV, stone impact, frequent washdowns.

- Compliance and safety: Roadworthiness, corrosion integrity, secure mounting, and fitment without interfering with sensors/lights.

- Lifecycle costs: Initial cost, weight contribution, repairability, and expected service life in mixed USA/EU climates.

- Interoperability: Compatibility with T600-series hood geometry, Vortec-style roof fairings or extenders, and existing hardware.

- Sustainability and resale: Powder coat and e-coat options (repairable), stainless and aluminum recyclability.

Material recommendations by category (T660-specific)

Hood

– Hood shields/deflectors: PMMA (acrylic) or polycarbonate (PC). PMMA offers high UV resistance, gloss, and clarity at low weight; PC offers superior impact and crack resistance. Choose PMMA for superior UV and optical quality; choose PC where chip/impact risk is high or deflector is exposed to road debris. Fasten with OEM-matched hardware; verify T660 hood geometry (2008–2016) fitment before ordering.

– Hood ornament/logo bases and bezels: 304/316 stainless steel for durability and corrosion resistance; aluminum with clear anodize for weight saving; ASA/PC for painted plastic bezels.

– Air cleaners/inlets: 304 SS for housings and housings’ trim rings; powder-coated steel for painted housings; PC/ABS for fairings that require integrated ducting or complex geometry.

Cab & sleeper (exterior surfaces and mounts)

– Grab handles and step supports: 304 SS or aluminum 6061-T6. SS for higher durability in icy conditions; aluminum for weight savings. Powder coat over e-coated steel is acceptable in low-corrosion regions or when budget is tight.

– Roof fairings (where applicable to T600-series): ABS/PC for cost-effective, painted fairings; aluminum 5052/6061 for heavy-duty, long-life applications; 304 SS for trims and accent panels.

– Mirrors and mounting arms: Aluminum 6061 or 304 SS; choose aluminum for lighter weight if strength criteria are met; SS for high-corrosion and high-impact duty. All exposed fasteners should be stainless or coated to minimize corrosion.

Back end (rear fairings, bumper faces, step pans)

– Rear closure/impact pans: 304 SS or aluminum 5052. SS for maximum dent and impact resistance; aluminum for reduced mass and corrosion immunity.

– Step lips and splash guards: 304 SS or aluminum 5052; both resist corrosion and provide cleanability. For heavy salt exposure, SS is preferred.

– Tool/battery box bodies and doors: 304 SS for longevity and security; aluminum for weight savings; painted steel with e-coat and powder topcoat for budget. Doors: SS preferred for hinge longevity and dent resistance.

Bumpers

– Bumper faces, brackets, and reinforcements: 304 SS or 5052/6061 aluminum. SS maximizes dent/pothole resistance; aluminum reduces mass. Use e-coat under paint on steel and powder coat or clear anodize on aluminum. Include drain provisions and corrosion-friendly fasteners.

– Air dam and lower deflectors: ABS/PC for integration with aerodynamic geometry; aluminum for high-abrasion zones.

Illustrative Image (Source: Google Search)

Emblems

– Badge substrates: Stainless steel (laser-etched, PVD, or painted); aluminum (anodized/painted); ASA/PC for plastic badges. PC or PMMA lenses provide scratch resistance with appropriate hardcoat.

Fenders

– Outer panels: 304 SS or 5052/6061 aluminum. SS resists denting from debris; aluminum resists corrosion and simplifies customization. Maintain proper radius and mounting clearance to avoid vibration fatigue.

Fuel tanks

– Tanks: Aluminum 5052/6061 or stainless steel (where permitted). Aluminum provides excellent corrosion resistance and weldability; stainless adds extra durability in harsh environments. Include baffling and proper mounting isolators to reduce stress and NVH.

License & permit holders

– Frames: 304 SS or aluminum. Use UV-stable plastics (ASA or PC) for windows. Ensure clear visibility and secure mounting without obstructing lighting or registration plates.

Illustrative Image (Source: Google Search)

Mud flaps

– Materials: Reinforced rubber compound (natural/SBR) or thermoplastic elastomer (TPE/TPU). Rubber for durability and weight; TPU/TPE for improved crack resistance in cold climates. Include reflective options and proper mounting geometry for tire splash/spray control.

Steps

– Treads and supports: 304 SS or aluminum 5052/6061. SS provides best grip and durability; aluminum reduces weight and corrosion risk. Non-slip coating recommended over bare metal in high-wet zones.

Tool & battery boxes

– Bodies and doors: 304 SS preferred for security, impact, and washdown durability; aluminum for lighter assemblies; painted steel with e-coat/powder for cost-sensitive builds. Use stainless hinges and gas struts.

Horns

– Housings: 304 SS for corrosion resistance and acoustic stability; aluminum as a lighter alternative. Ensure adequate drainage and seal design.

Illustrative Image (Source: Google Search)

Finishes and coating decisions

- Steel: E-coat (cathodic) for corrosion undercoat + polyester or urethane powder topcoat; stainless where feasible for ultimate corrosion performance.

- Aluminum: Clear anodize (Type II/III) for corrosion and cosmetics; powder coat for color matching; PVD for premium trims.

- Plastics: ASA or PMMA/PC where UV stability is critical; PMMA for clarity; PC where impact safety matters; UV-stable paints over ABS/PC for body-color parts.

Regulatory and compliance (USA/EU)

- Roadworthiness: Ensure all exterior parts are securely fastened; avoid edges that could present snagging or injury hazards; verify placement does not obscure lights, registration, or visibility.

- Materials: Ensure finishes are lead-free and RoHS compliant where applicable for EU distribution.

- Reflection/marking: Mud flaps and reflective elements should meet visibility standards in relevant regions; confirm local requirements during specification.

- Procurement: Choose distributors and products with clear fitment references for T660 (2008–2016) hood/sleeper configurations to minimize rework.

Sourcing and cost notes

- Accessories listed for T660 include hood shields, bumper systems, steps, fenders, and boxes, with a broad SKU range and fitment variants. Price varies significantly by material grade and finish (e.g., stainless vs painted steel).

- Budget scenarios:

- Cost-optimized: E-coated steel with powder coat; ASA/ABS for non-critical painted plastic; rubber mud flaps; PMMA hood shield.

- Balanced: Aluminum 5052/6061 in high-exposure zones; 304 SS for functional hardware; PC deflector; clear anodize on aluminum; PC/ABS for fairings.

- Premium: 304 SS or thick-gauge aluminum with premium finishes; PC deflector with hardcoat; stainless structural supports; TPU mud flaps.

Maintenance planning

- Quarterly inspection of fasteners and hardware on high-vibration parts (steps, boxes, bumpers).

- Annual finish audit on steel components in northern US/Canada and northern EU; touch up powder or anodize as needed.

- Periodic check for underbody corrosion on painted steel components; replace with aluminum or stainless where corrosion is recurrent.

Sustainability and resale

- Specify recyclable alloys (aluminum) and corrosion-resistant steel where life-cycle benefits outweigh initial cost.

- Design for repairability: powder coatable steel and replaceable SS trims increase resale value and reduce scrap.

Quick material decision cheat sheet (field guidance)

- Highest impact: 304 SS > 5052/6061 aluminum > PC > PMMA > ABS/ASA.

- Best corrosion (bare metal): 304 SS ~ aluminum 5052/6061 > painted steel.

- Best UV: PMMA > PC > clear anodize > powder coat.

- Lowest weight: Aluminum 5052/6061 > ABS/PC > 304 SS > PMMA ~ PC.

- Highest durability: 304 SS > 5052/6061 aluminum > painted steel > plastics.

Material comparison table

| Material | Density (g/cm³) | Tensile strength (MPa) | Corrosion resistance (uncoated) | UV stability | Impact resistance | Temperature range (typical) | Typical T660 applications | Finishing options | Notes |

|---|---|---|---|---|---|---|---|---|---|

| 304 stainless steel (SS304) | ~7.9–8.0 | 520–620 | Excellent; resists road salt and washdowns | Very good; surface can haze without passivation | Excellent | -50 to ~300°C | Bumper faces/panels, step supports, box bodies/doors, mirror arms, housings | Passivation, powder coat (optional), PVD for trims | Premium corrosion; heavier than aluminum |

| 5052/6061 aluminum alloy | ~2.70 | 5052: ~230; 6061: ~310 | Excellent natural oxide layer | Good to very good depending on alloy and finish | Good; dents less than steel | -50 to ~150–200°C | Fuel tanks, fenders, step lips, air dam panels, box bodies | Clear anodize, powder coat, natural finish | Light weight; thermal expansion higher than steel |

| Mild steel (with e-coat + powder) | ~7.85 | 250–400 (structural applications) | Good if fully e-coated + powder | Good with quality powder topcoat | Good when coated | -50 to ~150–200°C | Budget boxes, brackets, bumper reinforcements | E-coat + polyester or urethane powder | Cost-effective; monitor chip and edge corrosion |

| PMMA (acrylic) | ~1.18–1.20 | 60–80 | Good | Excellent UV stability; optical clarity | Low to moderate (brittle) | -40 to ~80–100°C | Hood shields, emblems’ transparent lenses | Polished surface; hardcoat optional | Best for optical, UV stability |

| Polycarbonate (PC) | ~1.20 | 60–70 | Good | Very good; can yellow if unprotected | High (tough) | -40 to ~115–130°C | Hood shields, housings, lenses, impact panels | Hardcoat, UV-stable paint, optical polish | Higher impact than PMMA |

| ABS/PC (plastic alloy) | ~1.05–1.10 | 40–60 | Good | Good; paintable | Moderate | -30 to ~100–110°C | Exterior bezels, fairings, non-structural parts | Painted or texturized | Balances cost and toughness |

| ASA | ~1.08 | 40–50 | Good | Very good; inherently UV-stable | Moderate | -30 to ~90–100°C | Emblems, external trim, painted parts | Painted or uncoated | More UV-stable than ABS; good for badges |

| Rubber (mud flap) | ~1.2–1.4 (varies) | 10–25 (compounds vary) | Good when compounded | Good; color stability depends on additives | High in compression; cut/tear risk | -40 to ~80°C | Mud flaps | Plain or reflective tape | Durable; heavy; consider TPU/TPE for cold climates |

| TPU/TPE (mud flap alternative) | ~1.1–1.3 | 15–35 | Good | Very good; maintains flexibility | High flexibility, cut/tear depends on grade | -40 to ~90–100°C | Mud flaps | Pigmented; reflective options | Cold-climate crack resistance |

Fitment notes for Kenworth T660

- Confirm year range (2008–2016) and hood/sleeper configuration before ordering hood shields, fairings, and bezels.

- Align accessories with T600-series mounting points to reduce drilling and vibration-related failures.

- When specifying external parts, validate interference with sensors, antennas, lights, and fairing extensions unique to T660 configurations.

Appendix: Specification pack to request from suppliers

- Hood shield: Material (PMMA or PC), thickness, UV hardcoat status, mounting kit (fastener grade/coating), year fitment, edge finishing.

- Bumper/panels: Material grade (SS304 or 5052/6061), thickness, finish, corrosion warranty terms, mounting provisions and hardware.

- Steps and supports: Material and finish, load rating, slip resistance treatment, hardware grade.

- Boxes: Material and thickness, door sealing method, hinge type, gas struts, lock mechanism.

- Mud flaps: Material compound (rubber or TPU/TPE), reinforcement, reflective class, mounting hardware.

- Emblems: Substrate (SS, aluminum, ASA/PC), finish (PVD, anodize, paint), adhesion method.

This guide aligns material choices with real accessory categories offered for the Kenworth T660, optimizing performance and lifecycle costs in USA and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for kenworth t660 accessories

In-depth Look: Manufacturing Processes and Quality Assurance for Kenworth T660 Accessories

Overview

Kenworth T660 accessory manufacturing focuses on repeatability, fit-and-finish for the T660 platform, and transport-ready packaging. The product families covered include hood shields, steps and platforms, fender systems, bumper components, air cleaner inlets, mud flaps, and various cab/sleeper attachments. Across these SKUs, the production methodology is standardized into Prep, Forming, Assembly, and QC to ensure the mechanical interface and finish meet heavy-duty service demands.

Manufacturing Steps

1) Prep

- Engineering: Release of part drawings, material specifications, fastener schedules, torque values, and finish requirements. For T660-specific parts, fitment is locked to Kenworth T660 mounting templates and body panel contours.

- Materials: Primary materials include 304/316 stainless steel (corrosion resistance and durability), 5052-H32 aluminum (lightweight panels and tanks), galvanized steel (structural brackets), and engineered polymers for UV-stable shields and splash protection. Material compliance to REACH/RoHS is documented.

- Cutting and Blanking: CNC laser or plasma cutting, waterjet for polymer shields. Deburr and edge prep to remove oxide, scale, and contamination.

- Subcomponent Prep: Cleaning and coating prep (degreasing, iron phosphate or chromate-free conversion where applicable), fastener collation to spec, and weld prep including fixturing alignment.

2) Forming

- Bending/Forming: CNC press-brake forming for stainless and aluminum panels; radius and flange control maintained per drawing tolerances. Formed parts are verified against T660 body geometry to ensure clearance and interface compatibility.

- Joining: GMAW/MIG/TIG welding for stainless/steel assemblies; quality is monitored via process parameters. Structural adhesives may be specified for non-welded interfaces on polymeric components. Spot welding used where appropriate on steel brackets.

- Finish Preparation: Masking and prep for powder coating or e-coat (where applicable). HSMs receive cutouts and stiffening where required. Post-weld cleanup and passivation for stainless.

3) Assembly

- Fixture-Based Assembly: Subcomponents assembled to fixtures that replicate the T660 interface. Fasteners are torqued to specification and documented (e.g., M6–M10 classes). Locking hardware (prevailing torque nuts, lock washers) is used per bill of materials.

- Hardware and Sealing: Seals, grommets, and fasteners are inspected for proper fit. For hood and air intake components, gasket compression and clearance checks ensure no rub or interference at operating temps.

- Optional Operations: Powder coat application (where applicable) is cured per coating datasheet. Polymer shields may be trimmed to fit using CNC routing and undergo edge finishing.

4) Quality Control (QC)

- First Article Inspection (FAI) with CMMs/calipers/gages to confirm dimensions, fit to T660 fixtures, and torque values.

- Process Validation: Incoming material certificates, process audits on welding (visual, dimensional, occasional NDT where required by specification), and SPC on critical dimensions.

- Testing and Verification:

- Corrosion resistance: ASTM B117 salt spray or ASTM D1654/ISO 9227 as applicable to coating specifications.

- Finish adhesion: ASTM D4541 or ASTM D3359 pull-off tests.

- UV/weathering: ASTM G154 for polymeric shields and flexible components.

- Load/Cycle tests for steps and brackets (e.g., deflection limits and load rating verification), as per component-specific design criteria.

- Documentation: ISO 9001-compliant DHRs (Device/Part History Records), CoCs and CoAs, and calibration records.

Quality Standards and Certifications

- ISO 9001: Quality management system certification with controlled processes across engineering, production, and inspection.

- ISO 14001 (recommended): Environmental management for waste minimization, coating process controls, and material compliance.

T660-Specific Considerations

- Fitment: Components are tested on T660 geometry for alignment, with fixtures representing the T660 nose, hood openings, bumper interfaces, and sleeper/cab interfaces. Where applicable, SKUs use the Kenworth T660 designation to confirm compatibility.

- Corrosion: Salt spray and field exposure checks to ensure finish durability on steel and stainless components in road salt environments.

- Thermal and Vibration: Parts are checked for stability under highway vibration and thermal cycling (hood/shield proximity and intake systems).

- Logistics: Packaging designed for LTL and parcel shipments, including corner protection, foam inserts, and strapping to prevent abrasion and deformation. Labels include part number and T660 model designation to streamline receiving.

Common Accessory Categories and Fit Notes

- Hood shields: Fit to T660 hood profiles; clearances verified for wiper and hood hardware.

- Steps and platforms: Load rating verified; mounting bracket clearance to frame/suspension components verified.

- Fenders and mud flap systems: Fender geometry and wheel well clearances validated; hardware corrosion resistance confirmed.

- Air inlets: Duct-to-hood interface sealing verified to prevent ingress.

- Bumper and emblems: Attachment methods and torque values documented; finish durability tested for stone chip resistance.

Traceability and Deliverables

- Traceability: Unique lot numbers on parts and packaging, material batch tracking, and calibration logs.

- Deliverables: Part numbers clearly marked (e.g., Kenworth T660-specific variants), CoC, installation guide, torque chart, and maintenance recommendations.

This manufacturing and QA framework ensures consistent fit, finish, and performance for Kenworth T660 accessories across USA and Europe, aligning with ISO practices and heavy-duty truck service expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kenworth t660 accessories’

Practical Sourcing Guide: A Step-by-Step Checklist for Kenworth T660 Accessories

Objective

– Secure compliant, brand-certified exterior and cab/sleeper accessories for Kenworth T660 that align with fleet use-cases and regulatory requirements, in USA and Europe.

– Source reliably, validate fitment with manufacturer guidance, and execute a repeatable procurement workflow.

Illustrative Image (Source: Google Search)

Core Steps

1) Define Accessory Category and Use-Case

– Map needs to exterior accessory categories: Hood, Cab & Sleeper, Back End, Air Cleaners & Air Inlet, Bumpers, Emblems, Fenders, Fuel Tanks, License & Permit Holders, Mud Flaps, Steps, Tool & Battery Boxes, Horns. [Reference: Iowa 80 store category structure]

– Tie each accessory to the fleet objective (protection, utility, brand, compliance).

2) Determine Fitment and Brand Compatibility

– Confirm T660 model year and configuration before selecting SKUs.

– Use manufacturer fitment data as the source of truth. Where fitment data is presented as model lists, treat those lists as definitive. The example “Aeroshield II Hood Shield” explicitly lists fitment for KW T660, T680, T800W, T880, and multiple W900 variants (1984+). [Reference: Iowa 80 product list]

– Validate any “PB” (Peterbilt), “INTL” (International), “Volvo,” and “WS” (Western Star) entries as non-KW when cross-shopping multi-brand catalogs. [Reference: Iowa 80 product list]

3) Check Availability and Lead Time

– Review the vendor’s catalog for stock status. Iowa 80 displays items 1–12 of 156 with pagination options. If the item is not on page 1, engage vendor for lead time confirmation.

– Place backorders only with defined lead-time SLAs and escalation paths.

4) Collect and Record Identifiers

– Capture: Item number, SKU, product description, fitment notes, price, supplier.

Illustrative Image (Source: Google Search)

5) Quantify and Price

– Confirm price visibility. Example: Aeroshield II Hood Shield price range $223.99–$236.99 for specified fitments. [Reference: Iowa 80 product list]

– Confirm if pricing is per-unit or bundled; ask for tier pricing if quantity is known.

6) Validate Warranty and Installation

– Verify warranty duration and coverage; request installation guidelines or service bulletins where available.

7) Proceed to Checkout and Logistics

– Process the order through the vendor’s platform. Ensure purchase order references and invoice details are correct.

– Arrange shipment tracking and delivery confirmation.

Illustrative Fitment Snapshot (Hood Shields)

– The following selection shows manufacturer fitment patterns for hood shields. Use this as a model for confirming T660 compatibility in accessory families.

Illustrative Image (Source: Google Search)

| Accessory Type | Manufacturer Fitment Example (from Iowa 80) | Price Range | Notes |

|---|---|---|---|

| Aeroshield II Hood Shield | KW T660, T680, T800W, T880, W900B, W900L, W900S (1984+); PB 377/378/379; Volvo VNL; WS 4900 variants | $223.99–$236.99 | Fitment explicitly includes T660 (2007+); verify exact model year and hood style on T660. [Reference: Iowa 80 product list] |

Recommended Accessory Categories for T660 Fleets (to prioritize)

– Hood: Hood shields, deflectors, emblems.

– Cab & Sleeper: Steps, handles, visor/roof options (where compliant), battery/tool boxes.

– Back End: Mud flaps, license/permit holders, bumper elements, horn assemblies.

– Air Management: Air cleaner housings and inlets for hood/under-cab routing.

– Front End: Bumpers, fenders, fairings.

Supplier and Procurement Checklist

– Fitment Authority: Use manufacturer fitment lists and vendor-provided part numbers as the primary validation. Avoid “universal fit” assumptions on exterior components.

– Product Evidence: Record item number and fitment note (e.g., “Aeroshield II PB 335 compatible with T660”). [Reference: Iowa 80 product list]

– Price Confirmation: Capture price ranges when shown; ask for quotes if range-based or volume pricing applies.

– Stock Visibility: Review pagination/counts (e.g., 156 items; 12 per page). Request in-stock confirmations or lead times. [Reference: Iowa 80 product list]

– Warranty and Return: Confirm coverage and restocking terms prior to order.

– Documentation: Maintain installation guides and vendor SKUs in the fleet parts catalog.

Regulatory and Compliance Notes (USA and Europe)

– Lighting and Reflectivity: Accessories must not obscure OEM lighting or reflectors; verify local standards for exterior add-ons (USA FMVSS/SAE; Europe ECE).

– Vehicle Modifications: Air management and engine bay accessories must not impair cooling, intake filtration, or emissions-related systems.

– Type Approvals (Europe): Ensure component compliance (e.g., reflectors, mirrors, lighting) per ECE regulations; request documentation from the supplier.

– Insurance and Liability: Update fleet records to reflect accessory installations; ensure modifications do not affect coverage.

Ordering and Logistics Plan

– Ordering: Add items to cart using manufacturer SKUs; annotate PO with item numbers and fitment notes.

– Shipping: Request freight quotes and delivery windows; note cross-border documentation requirements for USA–EU shipments.

– Inspection: Verify fitment and condition upon delivery; store any installation instructions with the asset record.

Illustrative Image (Source: Google Search)

Quality Assurance and Documentation

– Asset Tagging: Associate accessories with truck VIN and serial data.

– Inspection: Conduct fit checks before final installation; retain returns if mismatch occurs.

– Recordkeeping: Maintain a structured parts library with item numbers, fitment notes, and warranty documents for auditability.

Practical Sourcing at a Glance

– Treat fitment lists as your compass; without them, the accessory landscape is fog. With them, your path is clear—like a lighthouse guiding a convoy safely to shore.

– Lock down SKUs and price ranges early; confirm warranty and lead times; then execute with the precision of a fleet operation at dawn—quiet, deliberate, and on schedule.

Comprehensive Cost and Pricing Analysis for kenworth t660 accessories Sourcing

Comprehensive Cost and Pricing Analysis for Kenworth T660 Accessories Sourcing

Price bands and market benchmarks (USA/EU)

- USA retail and distribution pricing is transparent on mainstream platforms such as Iowa 80. For example:

- Aeroshield II Hood Shield: $223.99–$236.99 on iowa80.com

- Many other exterior categories (e.g., bumpers, mud flaps, air cleaners, horns, fenders, steps, tool/battery boxes, fuel tanks, emblems, license/permit holders) are typically distributed by the same ecosystem, supporting standardized pricing across brands and fitments.

- EU pricing typically carries:

- 17–25% VAT (varies by member state)

- Duty treatment depends on the commodity (e.g., sheet-molded compound SMC/thermoplastic parts vs. painted/finished metal assemblies); always verify at HS-code level.

- Higher last-mile costs due to fragmented carriers and zone-based road tolls for heavy goods vehicles.

- For the T660 specifically, accessory fitment is aligned to the W900B/W900L/W900S family and the pre-2011 T660 platform. Confirm part fitment by Kenworth model code, year, and hood/sleeper configuration.

Cost breakdown methodology

Use a full landed-cost model to compare suppliers, shipping routes, and make-vs-buy decisions.

| Component | Definition | Data to collect | Notes |

|---|---|---|---|

| Direct materials | Core substrates (e.g., ABS/PMMA, SMC, stainless/aluminum alloys), fasteners, sealants, packaging | kg/m per SKU; unit count; supplier quotes | Consider corrosion-resistant alloys for coastal exposure. |

| Manufacturing (labor) | Fabrication (cutting, bending, molding), finishing (deburr, polish), assembly | Labour hours; overhead allocation; yields | Tooling amortization for SMC or stamped parts. |

| Quality and compliance | CAD fit checks, dimensional inspection, corrosion/salt-spray tests, ADR/E‑mark where applicable | Test plans; lab time | ADR or e‑mark for exterior lighting; ECE/SAE electrical. |

| Freight | Primary (linehaul/SEA/AIR), drayage, cross-border fees | Mode, origin/destination, incoterms | USA East/West port choices; EU main hubs (Hamburg, Rotterdam, Felixstowe). |

| Customs and duties | Tariffs, VAT, customs clearance fees | HS-code, EU customs rate, US customs bond | EU: VAT post-clearance; pre-registration for local EORI. |

| Storage and handling | Warehouse reception, putaway, WMS/ERP integration | Pallet positions, dwell time, pick/pack | High-turn vs long-tail SKUs: separate carrying-cost assumptions. |

| Payments and risk | Terms, FX, bank/escrow fees | Net terms, FX rate, deposit % | FX lock windows; hedging for EU/US mixed currencies. |

Example applied to the Aeroshield II Hood Shield:

– Baseline landed cost framework (illustrative structure):

– Bill-of-materials (materials): e.g., PMMA/ABS composite, edge caps, fasteners, protective film/packaging

– Manufacturing time (cutting, trimming, fitment to templates, finishing, packaging)

– Freight (origin → USA/EU): parcel last mile or LTL consolidation

– Duties and taxes: determine by HS classification (e.g., molded plastic parts vs. finished accessory assembly); confirm VAT in EU

– Overheads (receiving, storage, handling): amortized per unit

– Key levers:

– Minimize breakage and re-shipments by investing in first-fit quality checks (CAD-to-template verification for T660 hood variants).

– Use consolidated shipments to reduce per-unit freight and customs fees.

– Source domestic replacements for frequently damaged or high-wear items to avoid lead times and returns overhead.

Illustrative Image (Source: Google Search)

Pricing models

| Model | Best use case | Pros | Cons |

|---|---|---|---|

| Direct B2B per-SKU pricing | Standard catalog accessories with clear fitment | Predictable cost; easy approval workflows | Less dynamic; may miss volume incentives |

| Value-based pricing | High-dependability components (e.g., bumpers, steps) | Aligns price to uptime and safety value | Requires proof of uptime and returns avoided |

| Tiered pricing by volume | Accessories used across fleets | Scales with usage; simplifies purchasing | Forecasting accuracy becomes critical |

| Bundling by category | Cab/sleeper kits, “prep” packages for new builds | Improves sell-through; reduces SKU complexity | Risk of unused components, excess inventory |

| Consignment or VMI | High-turn consumables (e.g., mud flaps, horns) | Reduces working capital; improved fill rates | Requires vendor SLAs and demand visibility |

Logistics and lead-time cost effects

- Lead times and holding cost:

- Fast-turn accessory SKUs (mud flaps, emblems, license holders) carry higher carrying cost per lead-time day due to frequent cycle stock; protect margins by favoring near-shore replenishment.

- Lead-time variability is the largest driver of expediting fees. Set buffer days at 15–25% above typical lead time for EU routes and 7–15% for USA domestic shipments.

- Consolidation:

- LTL: minimize handling units (HUs) by using pallets with stable height and weight; target 18–22 kg per box for parcel-courier eligible parts to enable mixed-mode flexibility.

- Sea freight: full-container loads (FCL) compress per-unit cost but require longer planning horizons; use for high-volume, low-damage accessories.

- Returns and damages:

- Define a no-damage rate target (e.g., <2%) and cap returns admin per return (documentation, re-packaging). Use fitment pre-checks to reduce fit-related returns.

EU vs USA pricing differences

- VAT handling:

- USA: sales tax varies by state; not included in list price.

- EU: VAT shown at checkout; must plan for invoice VAT and reverse charge if B2B with valid VAT IDs.

- Compliance:

- Lighting and reflectors: EU requires e‑mark; USA typically requires SAE. Ensure correct compliance labels to avoid re-export/returns.

- ADR for hazardous goods equipment if shipping chemicals or gas struts: ADR labeling, packaging, and transport documentation required in the EU.

- Freight structure:

- USA: strong parcel and LTL networks with predictable last-mile. Truckload rates rise with diesel and driver capacity constraints.

- EU: tolls, variable service taxes, and cross-border transit increase cost-to-serve; favor bonded logistics in the Netherlands or Germany for intra-EU distribution.

Tips to save cost without compromising quality

- Consolidate by category and fitment:

- Purchase “cab/sleeper exterior kits” to secure negotiated bundle discounts; tailor bundles for T660 configurations (e.g., short vs long hood, Heritage vs sloped).

- Negotiate freight at the shipment level, not per-SKU:

- Target minimum order value (MOV) for free shipping; use Iowa 80’s published coupons as reference for discount structures (e.g., tiered percentage off). Use seasonal or quantity-based promotions to reduce unit landed cost.

- Validate fitment before purchase:

- Use supplier fitment databases and your CAD/BOM alignment checks; reduce returns by confirming year, hood type, and sleeper length.

- Select materials by duty exposure:

- For corrosion-prone regions, choose 304/316 stainless steel for bumper hardware and SMC/ABS for hood shields to improve longevity and reduce warranty claims.

- Right-size packaging and shipping mode:

- Use protective, compact packaging to qualify for parcel when feasible; otherwise, batch into LTL/FCL where costs per unit drop meaningfully.

- Pre-book and lock freight rates:

- Book lane contracts quarterly; use buffer days to avoid premium freight and expedite surcharges.

- Implement vendor scorecards:

- Track on-time delivery, damage rate, lead-time variance, and quote-to-invoice variance; prioritize suppliers meeting SLAs to minimize emergency buys.

- Use tax and compliance planning:

- Ensure correct HS codes and EU VAT registration where applicable; document EORI and customs broker requirements to avoid clearance delays and storage fees.

Decision gates and risk controls

- Make vs buy:

- Evaluate manufacturing for high-volume, high-margin accessories (e.g., bumpers, hood shields). Offload specialty items to specialty vendors to avoid tooling and QC overhead.

- Payment and FX:

- Align currency exposure to where costs are incurred. Use FX forwards for EU-USD transactions to stabilize margins across quarters.

- Warranty reserve:

- Reserve 1–3% of annual sales of exterior accessories for fitment/finish defects; adjust after first 90 days based on returns rate.

- Compliance audit:

- Verify lighting and reflectors have correct e‑mark/SAE labels; avoid shipments held at customs due to mislabeling.

By combining fitment-first procurement, disciplined landed-costing, and freight consolidation, procurement teams in the USA and Europe can reduce per-SKU cost for Kenworth T660 exterior accessories while maintaining uptime and compliance. Use the tiered pricing and bundle strategies to unlock volume incentives, and enforce SLAs and compliance checks to prevent hidden costs downstream.

Alternatives Analysis: Comparing kenworth t660 accessories With Other Solutions

Alternatives Analysis: Comparing Kenworth T660 Accessories With Other Solutions

B2B buyers commonly weigh two paths for T660 exterior accessories: (A) OEM/TruckTech+ and select OE-style accessories for the Kenworth T660, and (B) high-quality universal aftermarket (e.g., catalog-based suppliers like Iowa 80) with cross-brand fitment. The decision is driven by uptime, compliance, and total cost of ownership.

Option overview

| Category | Option A: Kenworth OEM/TruckTech+ | Option B: Universal Aftermarket (e.g., Iowa 80 catalog) |

|---|---|---|

| Fitment precision | Exact fit for T660 trims; minimal trial-and-error | May require verification of part numbers and configurations; some universal or vehicle-specific SKUs available (e.g., PB series hood shields) |

| Compliance (FMVSS/ECE/SAE) | Strong alignment with OEM standards; documented labels and CoCs | Varies by vendor; some products (LED lamps, reflective parts) meet DOT/SAE; buyer must verify |

| Warranty & support | OEM-backed warranty and dealer support | Supplier warranty varies; claim processing via vendor/catalog |

| Price | Premium | Lower to mid-tier; variable |

| Availability (USA) | Dealer distribution; some lead time on specialty items | Broad availability; ready stock common on common categories |

| Availability (EU) | Limited; requires import and country compliance verification | Requires import; catalog brands often accessible but require ECE compliance checks |

| Documentation | OE drawings, CoC, FMVSS/ECE labels | Varies; request datasheets for compliance |

| Integration & aesthetics | OE-matched styling and mounting | Broad styling; may require modifications for OE aesthetics |

Price and total cost of ownership (illustrative)

Prices vary by product and supplier; example ranges are indicative.

| Category | Option A typical (USD) | Option B example (USD) | Expected service life | Downtime risk |

|---|---|---|---|---|

| Hood shield | $230–$450 | $225–$350 | 3–5 years | Low for both when properly installed |

| Steps (entry/landing) | $200–$700 | $150–$500 | 3–6 years | Low–Moderate (stamped vs. welded concerns for heavy use) |

| Tool/battery boxes | $250–$700 | $180–$550 | 4–7 years | Low; quality hinges on hardware and lock mechanisms |

| Mud flaps/hangers | $80–$250 | $60–$200 | 2–4 years | Low; replacement wear items |

| LED lighting upgrades | $120–$500 | $80–$400 | 4–7 years | Low if DOT/SAE compliant; moderate if non-compliant |

Notes:

– Option B example hood shield pricing references catalog listings like the Aeroshield II Hood Shield ($223.99–$236.99) for common model ranges.

– LED prices assume DOT/SAE/E-marked products; use non-compliant LED setups in North America at your own compliance risk.

Illustrative Image (Source: Google Search)

Implementation path (USA vs. Europe)

| Region | OEM/TruckTech+ (Option A) | Universal Aftermarket (Option B) |

|---|---|---|

| USA | Strong fitment and dealer support; straightforward warranty claims | Wide selection; confirm DOT/SAE compliance; align with carrier policy |

| Europe | Limited OE availability; import and CoC verification required | Import and ECE compliance checks mandatory (especially lighting and reflectives) |

When to choose what

- Choose Option A when:

- Fitment certainty and OE-aligned aesthetics are critical.

- Operating under strict compliance mandates (fleet compliance officers, safety audits).

-

Warranty and dealer support trump marginal price savings.

-

Choose Option B when:

- Cost and availability lead-time are top priorities.

- Items are wear-and-tear (mud flaps) or low-risk (non-structural exterior parts).

- You can verify compliance and accept slightly variable fitment.

Practical recommendations

- Build a category matrix: hood shields, steps, boxes, lighting. Use a fitment checklist to reduce returns and trial-and-error.

- For fleets, standardize on one or two aftermarket lines to simplify spares and warranty.

- In Europe, insist on E-marked products and maintain documentation for inspections; avoid importing non-compliant accessories.

Compliance and warranty checklist

| Item | Compliance | Documentation | Warranty | Notes |

|---|---|---|---|---|

| Hood shield | Vehicle-specific fit; verify | Installation instructions | Supplier | Low-risk accessory |

| Steps/landing | Structural strength; corrosion | Load ratings | Supplier/Dealer | Inspect mounting annually |

| Tool/battery boxes | Corrosion resistance | Material specs | Supplier | Lock quality affects uptime |

| Mud flaps | Reflectivity compliance | DOT/SAE or ECE | Supplier | Replace frequently |

| LED lighting | DOT/SAE (USA), E13 (EU) | CoC/labels | Supplier | Avoid non-compliant kits |

Essential Technical Properties and Trade Terminology for kenworth t660 accessories

Essential Technical Properties and Trade Terminology for Kenworth T660 Accessories

B2B overview

– Fitment: T660 is an extended-cab long-hood platform using Kenworth standard cowl, hood, and fender mounting geometry; accessory fitment is defined by compatible hood/fender families and hardware spacing/clearance checks.

– Materials and finishes: coated steels, aluminum, and stainless are the default bases; corrosion specifications and UV stability drive service life; finish options typically include powder coat, anodize, and e-coat; specify salt spray hours and coating type per accessory.

– Compliance: USA (DOT/FMVSS), Europe (ECE/UN R), and general safety references (SAE) must be verified for lamps, reflective devices, horns, bumpers, and mounts; US-only parts cannot be used on road in the EU.

– Performance: stiffness/strength (yield/tensile), vibration and road load resistance, temperature range, UV/chemical resistance, and aerodynamic drag influence are key; claim numbers must be test-based.

– Packaging and labeling: bulk or retail packaging with SKU, batch/lot, fitment list, QR/barcode; pallets conform to freight guidelines and include MSDS where applicable.

Fitment and specifications (T660 context)

- Model/year compatibility: confirm exact application for T660 long-hood variants and any cowl/sleeper/fender combinations that change mounting.

- Hood family and cowl mapping: T660 uses Kenworth extended long-hood configurations; ensure the accessory matches the hood top, cowl, or fender line family and that hardware spacing aligns with available bolt patterns and brackets.

- Part numbering and OE equivalents: specify OEM/OEM equivalents where applicable (e.g., “Kenworth OEM #” or “Aftermarket PN” with cross-references); use part number formats that distinguish base part, kit, and sub-kits.

- Dimensions and weights: provide cut dimensions for shields/fenders, installed weights for tanks/boxes, and CG reference for bolt-on items; include torque specs and torque sequence for critical fasteners.

- Fasteners and hardware kits: include corrosion class (e.g., grade 5/8.8 bolts with anti-seize acceptable in steel/aluminum interfaces), gasket/shim sets, and torque values; offer metric and imperial options for USA/EU buyers.

- Gasket and sealing: specify EPDM or NBR for weather seals; state compression set and temperature range; note compatibility with OEM hood/fender surfaces.

- Aerodynamics and clearance: hood shields, bug deflectors, and fender extenders must not obstruct hood access or service components; report aerodynamic change (delta Cd if relevant) and maintain service clearances.

Materials and finishes

- Coated steels (e.g., bumper shields): choose ASTM-A36 or equivalent; prefer e-coat + powder coat; specify zinc phosphate pretreatment where available; define salt spray performance (e.g., ≥ 720 h per ASTM B117 for coastal exposure) and coating thickness.

- Aluminum (e.g., steps, tanks, boxes): use 5052-H32 or 6061-T6; specify thickness, yield/tensile strength, and finish (clear anodize or powder coat); state corrosion resistance and maximum temperature (≤ 200°F typical for powder coat cure).

- Stainless steel (e.g., horns, mounts): type 304/316; include pickling/passivation; specify fasteners grade (A2/A4 metric or 18-8 imperial); define minimum thickness and weld procedures if applicable.

- Coatings: powder coat systems (TGIC polyester or epoxy hybrid for durability), anodized aluminum, e-coat for steel; provide VOC content and environmental compliance (RoHS/REACH as requested).

- UV/chemical resistance: provide UV stability ratings for exterior polymers (UVR ratings or material specs) and chemical resistance charts (diesel, DEF, glycol, de-icer, salts).

Compliance and certifications (USA and Europe)

- USA: lamps and reflectors must meet FMVSS 108; backup alarms may reference SAE J994; horns require SAE J44/J1455; brake/tail lamps and reflective devices require DOT certification and marking; verify US-only vs. EU-compatible markings.

- Europe: ECE/UN regulations for lighting and reflective devices (e.g., UN R3 for reflective devices, UN R148 for lamps); parts for road use must carry E-mark; ensure dual-compliant variants or region-specific SKUs.

- General safety and testing: reference SAE standards for vibration/impact (e.g., SAE J887, J1455), and ASTM B117 for salt spray; include ISO 9001 supplier quality if available.

- Documentation: provide CoC/COC for regulated items, declaration of conformity, test reports on request; maintain change control documentation (PPAP-level where applicable for metallic components).

Performance and testing

- Strength and stiffness: state design load and margin (e.g., 3:1 on structural brackets), yield strength, and fatigue rating for moving parts; report deflection under service load.

- Vibration and road load: include test profiles (琴-琴 rough road or equivalent), cyclic count, and pass/fail criteria (no crack, < 2 mm fastener loosening); provide results summary.

- Temperature and UV: specify operating range (e.g., −40°F to +120°F / −40°C to +49°C) and UV exposure performance; include thermal cycling data for painted/coated parts.

- Chemical/salt resistance: salt spray hours per ASTM B117, salt/ice melt compatibility, and material discoloration limits; define gasket compression set post-cycling.

Manufacturing and QA

- Tolerance stacks: define critical dimensions with tolerance bands; provide GD&T where structural fitment is critical; specify datum features referencing OEM mating surfaces.

- Welding and assembly: define welding standards (AWS D1.1 or equivalent), weld procedures, and NDT options (visual, dye penetrant); report burr/scale removal and edge prep.

- Documentation: use EPC/PCN for change control; maintain lot traceability (lot/batch number); provide test reports on request and supplier certificates (ISO 9001).

Packaging, logistics, and labeling

- Packaging: protect against abrasion and moisture; use foam or paper interleave for coated surfaces; include mounting hardware in labeled kits; ensure palletized shipments comply with freight height/weight limits.

- Labeling: SKU, part description, model/year fitment list, lot/batch, date code, coating spec, torque spec, installation instructions; include QR/barcode for WMS integration.

- Shipping terms: define Incoterms (EXW/FCA/CIP/DDP), lead times, packaging unit (EA/KIT/PAIR), and weight/dimension for quote; offer drop-ship to fleet locations.

- Compliance labeling: include DOT/ECE/E-mark where applicable, and MSDS for paints/adhesives.

Trade terminology (B2B purchasing)

- MOQ (Minimum Order Quantity): quantity bands by product family; define per-run and annual commitments.

- Lead time (LT): engineering lead for custom parts, standard LT for stocked items, add-on for special finishes; specify cut-off times and calendars.

- OEM vs. aftermarket: define OEM/OE and aftermarket categories; specify whether aftermarket parts are OE-equivalent or performance-enhanced.

- Part number structure: use parent/child SKUs, suffixes for finish/region, and kit IDs; map cross-references and discontinued codes.

- Certifications and documentation: provide material certs (MTC), RoHS/REACH where applicable, declarations of conformity, and test reports.

- Warranty and RMA: standard warranty term, exclusions, and approval process; RMA windows, inspection criteria, and restocking policies.

- Tooling/NRE: one-time charges for custom molds, fixtures, and setup; define ownership and amortization options.

- Pricing terms: unit price by volume tiers, annual rebate or growth incentive, currency and escalation clauses, and discount ladders; state price validity period.

- Incoterms: specify delivery terms (EXW/FCA/CIP/DDP) and risk transfer; define carrier and insurance when applicable.

- Payment terms: net 30/45, cash discount options, and credit limits; outline late fee policies; specify invoicing and tax handling per region.

- Engineering/approval timelines: development and validation schedule (design, DVP&R, PPAP where relevant), release process, and sample approvals.

- Lot traceability: batch/lot tracking, COA for chemical processes, and material substitution policy with change notification windows.

Fitment data example (generic format)

- Model: Kenworth T660 (extended long-hood)

- Compatible hood/fender families: verify against Kenworth T660 and adjacent long-hood series (W900/W900L/W900B as geometry proxies only); confirm through part catalog.

- Mounting pattern: specify fastener sizes, spacing, and bracket datum points; include torque sequence and gasket placement.

- Clearance: maintain access to hood latches, air filters, and service panels; avoid interference with cab extenders and sleeper fairings.

- Kit contents: base shield/panel, fasteners, gaskets/shims, and installation instructions; provide optional mounting spacers for different cowl/fender tolerances.

Key outcomes

– Fitment accuracy depends on mapping the T660 hood/fender geometry and confirming dimensional tolerances; offer verification services or fitment guarantees.

– Corrosion resistance and material quality drive lifecycle costs; specify coatings and testing explicitly to avoid premature failure.

– Regional compliance must be separated into US (DOT/FMVSS) and EU (ECE/UN R) SKUs; avoid cross-market labeling mistakes.

– Purchasing efficiency improves with clear MOQ, Incoterms, part-numbering, and documented change control (PCN/PPAP) aligned to fleet standards in the USA and Europe.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics and Sourcing Trends in the kenworth t660 accessories Sector

Navigating Market Dynamics and Sourcing Trends in the Kenworth T660 Accessories Sector

1) Demand drivers: what’s shaping buyer behavior

- Uptime and maintenance windows: Accessories that reduce drivetrain debris, improve access, or protect high-usage parts (e.g., Aeroshield II hood shields, mud flaps, steps) are prioritized around scheduled PM intervals.

- Spec standardization and consolidation: Fleets standardize exterior accessories by model year and configuration to simplify SKUs and inventory.

- Online research and coupon-led purchasing: Buyers increasingly research on vendor sites and price-aggregate stores before committing. For example, typical online offers include percentage-off codes such as $50 off $350 (CYBER50) or $100 off $700 (CYBER100), excluding already discounted items.

- Warranty and fitment assurance: Buyers favor vendors that confirm vehicle compatibility at the SKU level and provide clear exclusions. Example: a T660 owner should confirm whether an Aeroshield II for Kenworth’s PB line aligns with their specific T660 fitment before ordering.

2) Core market themes shaping sourcing strategy

| Theme | What it means for T660 accessories sourcing | Practical sourcing action |

|---|---|---|

| Fitment accuracy and inventory availability | Older models require precise fitment mapping to avoid returns and warranty disputes. | Require SKU-to-vehicle mapping (e.g., confirm “KW T660” coverage). Maintain a master compatibility list. |

| Price transparency and promotions | Digital retailers drive price discovery; coupon-based promotions shift purchase timing. | Track vendor promotion calendars; time purchases for known events (e.g., Cyber Week). |

| Channel strategy (OE vs. Aftermarket vs. Aggregators) | Accessory sourcing often balances OEM quality with cost via specialized aftermarket or aggregator platforms. | Split orders: use aggregators for breadth and availability, OE/aftermarket for critical wear items. |

| Sustainability and material choices | Buyers increasingly request recyclable metals (stainless, aluminum), powder-coated finishes, and reduced packaging. | Prefer stainless/aluminum components; ask for powder-coated finishes and minimal packaging. |

| Supply continuity and lead-time variance | Long-run SKUs can face extended lead times; return policies help de-risk. | Favor vendors with clear lead-time SLAs and flexible returns/exchanges. |

Simple example: A mid-haul fleet replaces hood shields quarterly. They split orders—50% via an aggregator to secure immediate availability and 50% via the vendor’s direct channel for warranty and fitment assurance.

3) USA vs. EU: Differences that matter to procurement

| Factor | USA | EU |

|---|---|---|

| Preferred channels | Aggregators and category-specific e-commerce (e.g., truck accessory retailers). | Mix of OEM-partnered networks, national distributors, and online shops. |

| Fitment documentation | Clear SKU-fitment lists and year-model ranges; often detailed on product pages. | Similar, with additional emphasis on CE/EN conformity for certain accessories. |

| Coupon-driven sales | Prominent during peak retail events (e.g., Cyber Week). | Less prominent; promotions focus on seasonal clearance and distributor rebates. |

| Packaging/sustainability expectations | Moderate; recyclable metals and low-waste packaging are appreciated. | Strong; preferences lean toward stainless/aluminum, powder-coated finishes, and REACH/RoHS compliance where applicable. |

4) Top accessory categories for T660 and their sourcing considerations

| Category | Typical buyer objectives | Common procurement checks |

|---|---|---|

| Hood | Protect leading edge; reduce stone chips; aerodynamics | Confirm fitment to Kenworth PB/hood lines; material (stainless/aluminum), finish, mounting hardware included |

| Cab & Sleeper | Access, storage, corrosion resistance | Fitment (cab/sleeper variant), finish compatibility, warranty coverage |

| Back End | Structural protection, compliance with mud flap rules | Material choice (stainless/HDPE), mounting approach, regional regulatory alignment |

| Mud Flaps | Road legality, debris control | Length/height compatibility, material durability, mounting brackets |

| Steps | Safety, frequency of use | Step count, grip coating, anti-corrosion finish |

| Air Cleaners & Air Inlet | Filtration efficiency, maintenance access | Inlet diameter, filter rating, accessibility of service points |

| Tool & Battery Boxes | Theft deterrence, durability | Locking mechanism, corrosion resistance, fit to frame rails |

| Bumpers & Fenders | Protection, appearance | Material and coating, welding vs. bolt-on installation |

| Horns | SAE sound compliance, reliability | Voltage rating, mounting bracket, sound level conformity |

| Fuel Tanks | Capacity and corrosion protection | Material (aluminum/stainless), capacity, fitting compatibility |

5) Sourcing playbook for buyers

- Standardize fitment checks: Every T660 accessory order must confirm year, model, hood length, and sleeper configuration to prevent return friction. Example: a “PB” hood shield may not match a T660 long-hood unless explicitly supported.

- Use promotions strategically: If planning a bulk refresh, time purchases around storewide coupons (e.g., $50 off $350 or $100 off $700). Note exclusions for items already on sale.

- Select channels by objective:

- Aggregator: breadth, quick comparison, convenience.

- Specialty aftermarket vendor: fitment depth, warranty clarity.

- OEM: guaranteed fitment, sometimes premium pricing.

- Prefer sustainable materials: Request stainless or aluminum, powder coating, and minimal packaging to align with fleet ESG goals.

6) Sustainability signals shaping supply decisions

| Signal | Why it matters | How buyers respond |

|---|---|---|

| Recyclable metals | Reduces lifecycle impact and scrap waste | Specify stainless/aluminum in RFQs; request material specs |

| Powder-coated finishes | Lower VOCs, improved corrosion resistance | Include finish requirements (powder coat preferred) |

| Reduced packaging | Cuts waste and shipping costs | Specify minimal packaging, recyclable materials |

| Longer service intervals | Fewer replacements, lower total cost of ownership | Evaluate warranty terms and component durability; run pilot tests |

7) Risks and mitigations

| Risk | Impact | Mitigation |

|---|---|---|

| Fitment mismatch | Returns, downtime, customer dissatisfaction | Enforce SKU-fitment verification; keep T660-specific compatibility matrix |

| Lead-time volatility | Delayed installs, schedule disruption | Order buffers; split channels; pre-book critical SKUs |

| Warranty ambiguities | Out-of-pocket repairs | Require written warranty terms; document exclusions and limitations |

| Overpriced promotions | Budget overrun | Compare base prices and effective discounts; track historical price patterns |

| Sustainability non-compliance | Brand/reporting risk | Request material data sheets; require REACH/RoHS attestations where applicable |

8) Quick checklist (use before every purchase)

- Fitment verified for Kenworth T660 (year, hood length, sleeper variant).

- Material and finish specified (stainless/aluminum; powder coat preferred).

- Warranty and exclusions reviewed; return policy understood.

- Promotions confirmed (e.g., applicable coupon codes; exclusions for sale items).

- Packaging minimized; sustainability claims substantiated.

- Lead time and installation time confirmed.

Simple example: A fleet replacing Aeroshield II hood shields selects powder-coated stainless units from a vendor listing compatibility across Kenworth PB lines. They time the order for Cyber Week, apply the $50 off $350 coupon, and verify the SKU fits their T660’s hood length before purchase. The result: lower cost, accurate fitment, and reduced waste.

Frequently Asked Questions (FAQs) for B2B Buyers of kenworth t660 accessories

Frequently Asked Questions (FAQs) for B2B Buyers of Kenworth T660 Accessories

1) How do I confirm fitment and part compatibility for the Kenworth T660?

- Verify compatibility using:

- Full truck VIN and detailed cab/sleeper configuration.

- Model year, hood style (sloped nose/Aerocab), and any option packages (e.g., extended hood length).

- OEM Kenworth references and the accessory vendor’s fitment database or part finder.

- Some catalog entries don’t include T660 explicitly. Confirm T660 coverage by VIN or cross-reference against the vendor’s numbered compatibility matrix before purchase. If your fleet uses atypical mods (custom bumpers, non-standard air inlets, alternate tank/step hardware), request photos and drawings to avoid mismatch.

2) Do these accessories meet US and EU regulations? What documentation is available?

- US:

- Exterior lamps and reflective devices should comply with FMVSS 108 (lighting, reflectors). Ensure only DOT-compliant lighting is used for on-road operation.

- Structural components (e.g., bumper wraps, roof fairings) should not impede safety-critical components (sensors, ADAS cameras/radar) or interfere with driver visibility.

- Verify that any hardware used for mounting complies with applicable SAE standards (e.g., fasteners, hitches).

- EU:

- Exterior lighting should comply with ECE Regulations. Only use approved lamps and markers; equip vehicles appropriately by market category.

- Mud flaps with reflective markings typically require ECE R104 or equivalent reflective material certification; check documentation.