Who We Are

Your Professional Tape & Reel Machine Partner in China

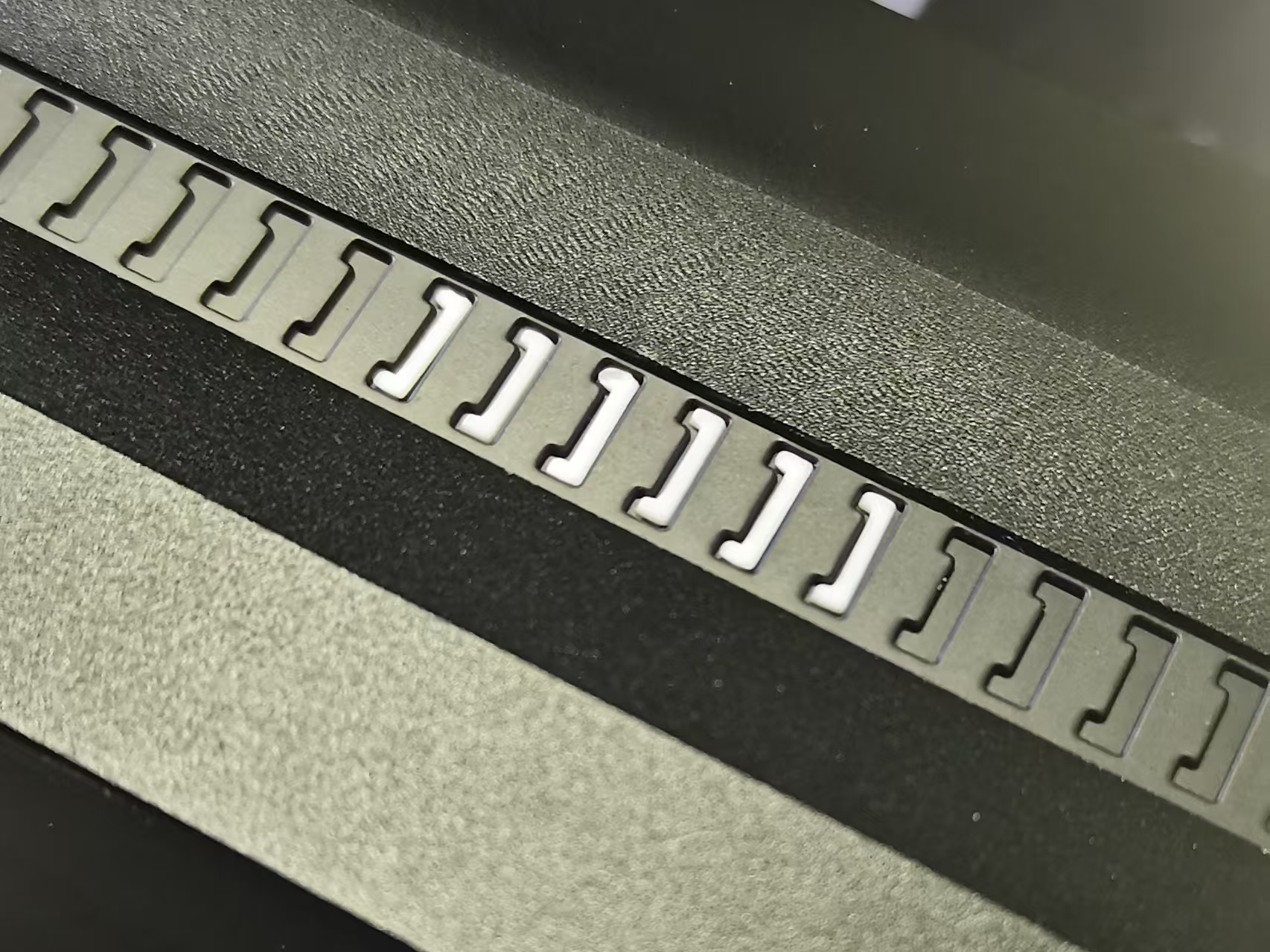

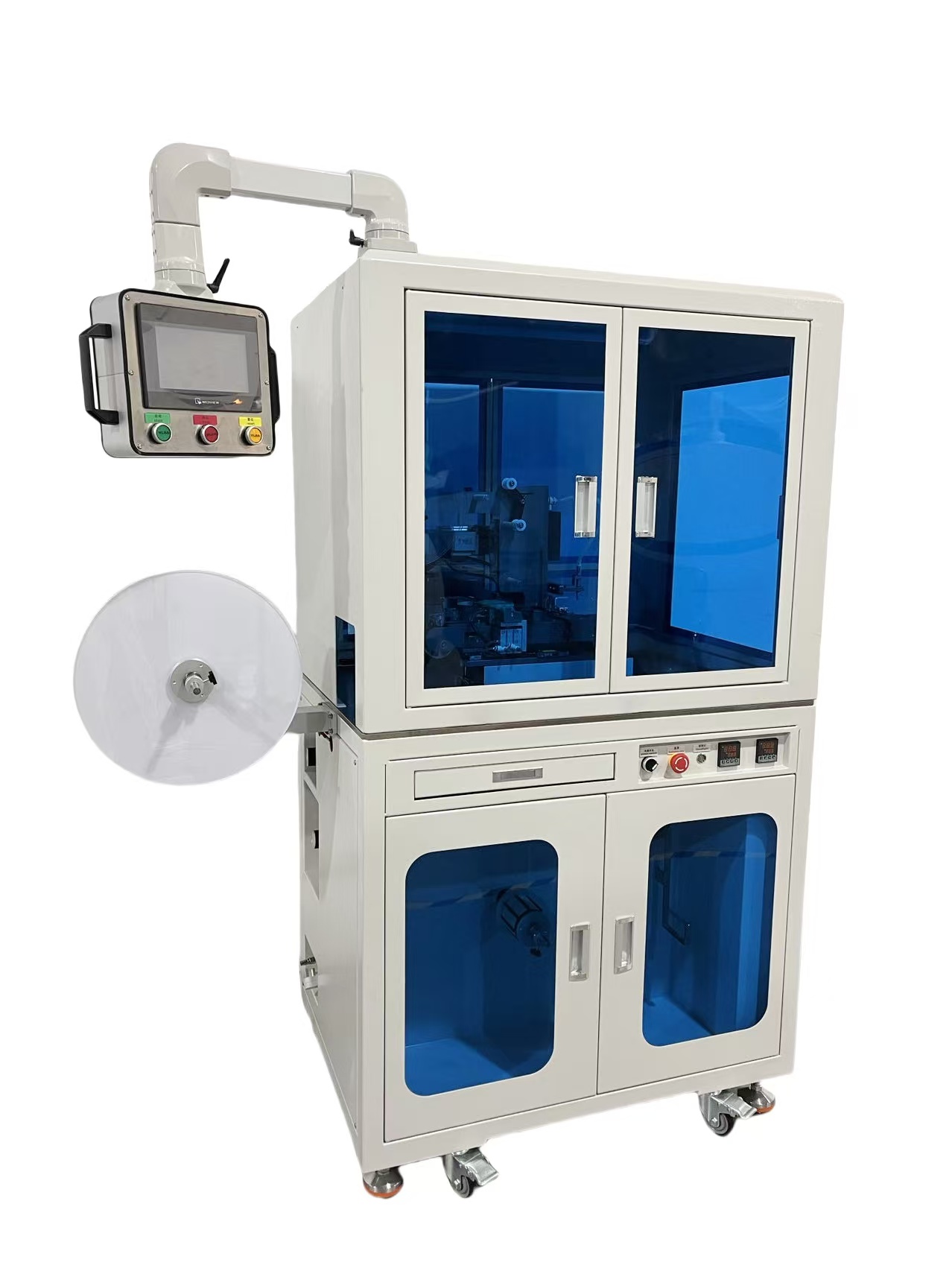

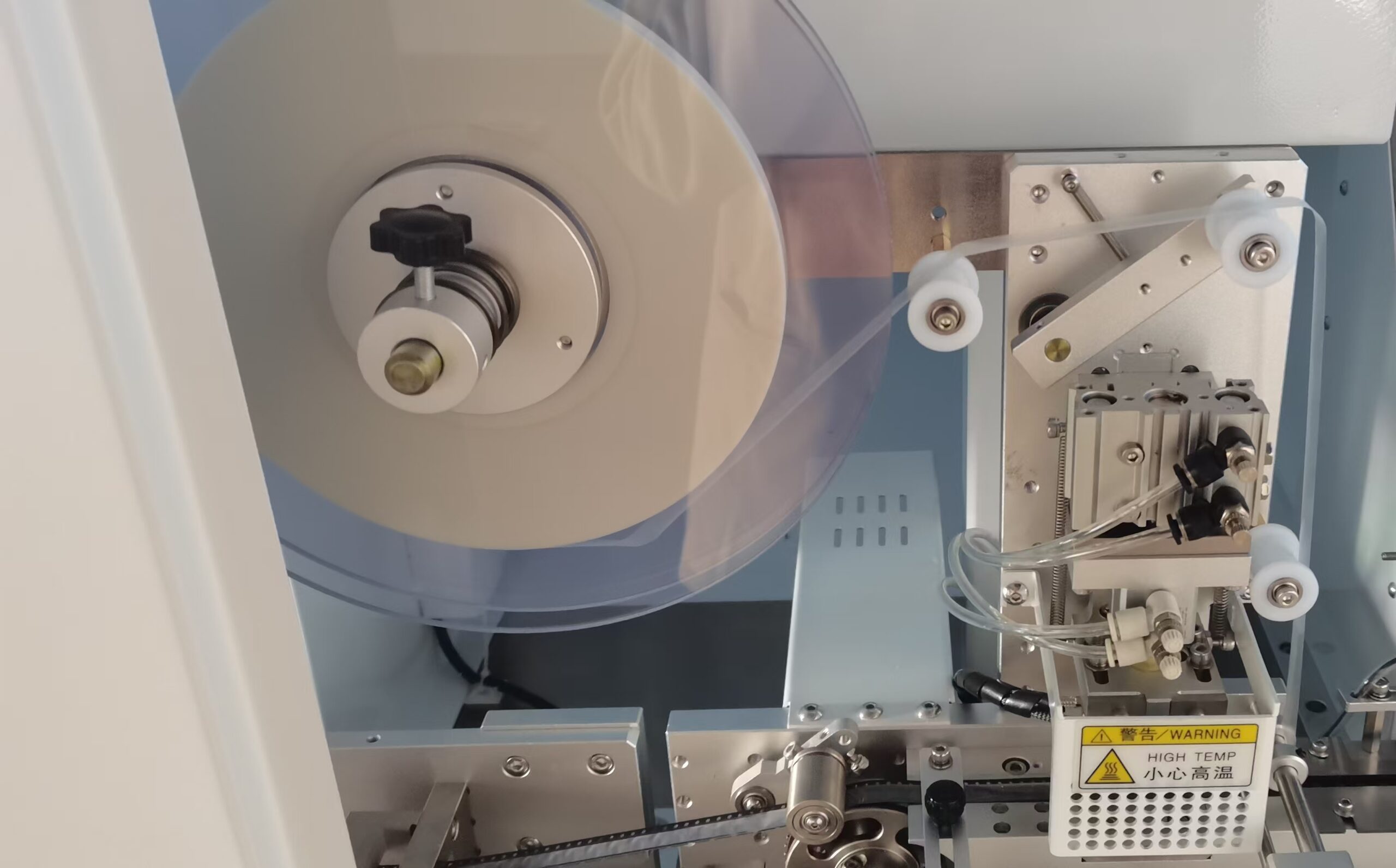

Professional Tape-and-Reel Machines Provider

KST Automation is headquartered in Shenzhen, and over the past 10 years, we have focused on the development and production of standard SMD testing and packaging equipment, as well as customized solutions tailored to meet the specific requirements of our clients.

We offer comprehensive services, including design, production, and sales of tape-and-reel machines and testing equipment for industries such as 3C electronics, semiconductors, new energy, hardware, automotive, cosmetics, medical devices, communications, optics, and various other manufacturing sectors.

With strong ODM capabilities, we provide custom solutions understanding your specific components and requirements for production capacity, efficiency, and packaging costs. Whether you need appearance inspection, functional testing, tape-and-reel packaging, tray placement, or other non-standard designs, we can meet your needs.