About Kunli Welding

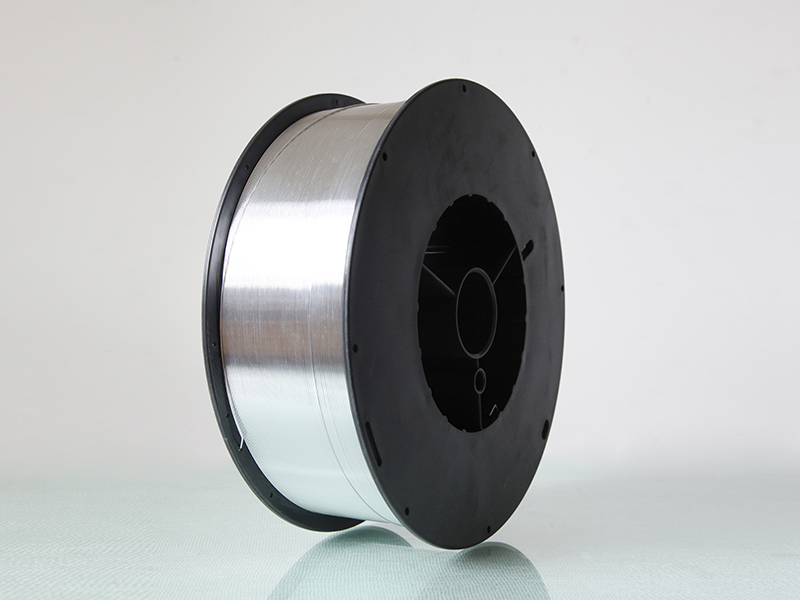

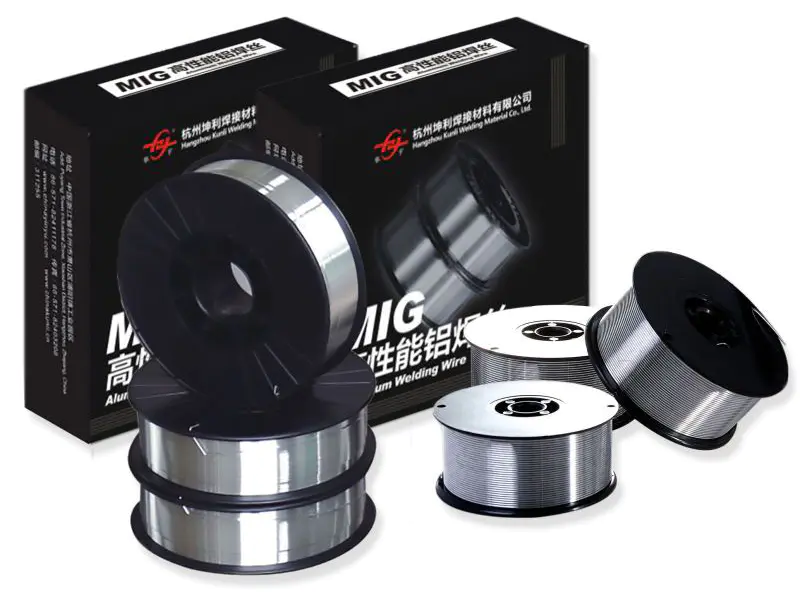

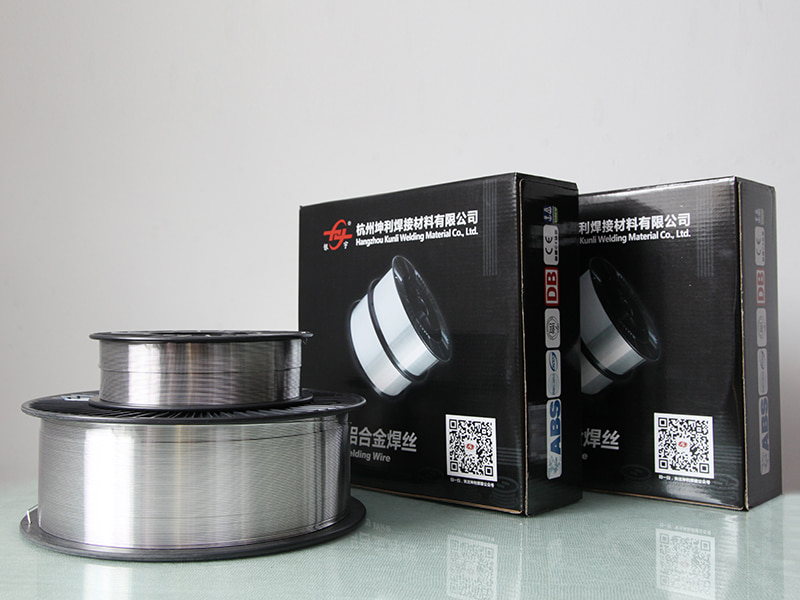

Hangzhou Kunli Welding Materials Co., Ltd. is located in the industrial zone of Puyang Town, Xiaoshan District, Hangzhou, Zhejiang Province. We are a high-technology enterprise specializing in the research, development, and manufacturing of high-performance aluminum alloy welding wire and aluminum alloy wire.

With over 20 years of production experience, international advanced manufacturing equipment, and a strict quality control system, we have successfully replaced imported products in key industries and become a qualified supplier for China CRRC, Maersk, and other leading enterprises.