About Shanghai LJ Metal

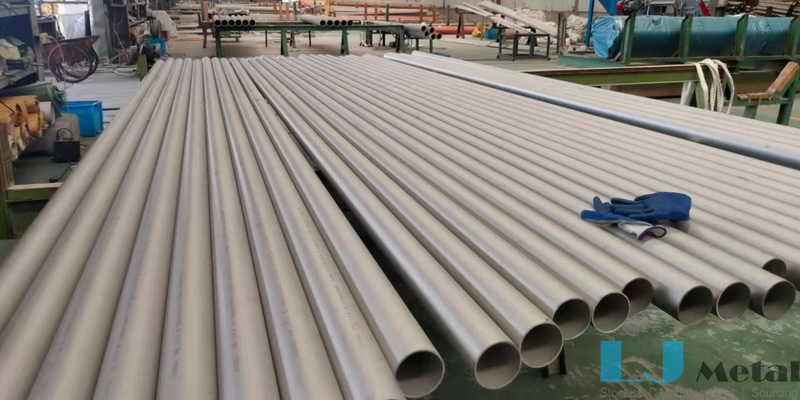

Shanghai LJ Metal Industrial Co., Ltd. is a leading Chinese manufacturer and exporter specializing in high-performance stainless steel, duplex steel, and nickel alloy pipes, tubes, and accessories. With a strong focus on quality and reliability, we serve global industries requiring materials resistant to high temperatures, corrosion, and aggressive chemical environments.

Our product range includes seamless and welded tubing in grades such as 1.4539 (904L), 1.4845 (310S), 1.4462 (S32205), 1.4410 (S32750), and nickel alloys like N08825, N10276 (Hastelloy C276), N06625 (Inconel 625), and more. All products are manufactured to international standards including ASTM, ASME, and EN.

We maintain ready stock lists updated regularly and have successfully delivered to projects across Europe, Asia, the Middle East, and beyond—supporting petrochemical plants, offshore platforms, power generation, and industrial equipment manufacturers.