Lorawan Water Meter: The Ultimate 2025 Sourcing Guide

LoRaWAN water meters enable low-power, wide-area, end-to-end encrypted metering for AMI and leakage programs. We begin with fundamentals: why LoRaWAN is preferred for meters, how unlicensed spectrum and the LoRaWAN architecture deliver scalable, secure, and long-lived connectivity, and what distinguishes LoRaWAN from cellular and mesh technologies. We then unpack the three-layer architecture—end devices (water meters), gateways, and a network server—explaining how data is encrypted, validated, deduplicated, and handed off to utility applications.

Next, we cover the US/EU operating environment: regional spectrum allocations, carrier-backed versus community or private networks, roaming, and certification considerations. We analyze the business case across CAPEX/OPEX, read rates, coverage planning, and ROI drivers, contrasting multi-tenant LoRaWAN services, public network providers, and do‑it‑yourself architectures. We detail RF design and deployment planning for urban, suburban, and rural districts, including gateway siting, link budgets, ADR, battery models, and firmware update strategies.

We proceed to devices and sensors: ultrasonic, electromagnetic, and mechanical flow meters; metrology accuracy; tamper/leak detection; and vendor selection criteria and certification paths. Finally, we address operations and scaling: network and device management, data integration (MQTT/AMQP/REST), cybersecurity frameworks, KPIs for leakage and revenue, multi-site rollout, and roadmap for interoperability with existing MDM/CRM. We will also present vendor and network service snapshots to guide procurement, with decision frameworks and checklists tailored for US/EU requirements.

Top 10 Lorawan Water Meter Manufacturers & Suppliers List

1. Top 15 Water Meter Manufacturers & Suppliers

Domain: bmagmeter.com

Registered: 2024 (1 years)

Introduction: Top water meter manufacturers include Kamstrup (Denmark), Badger Meter (USA), Zenner (Germany), and Neptune (USA)….

2. Top 10 Smart Water Meter Manufacturers Around Globe, 2022

Domain: fortunebusinessinsights.com

Registered: 2018 (7 years)

Introduction: WEGoT and Kerlink, a French Internet of Things solution provider, collaborated to bring a LoRaWAN-based solution to India in 2021….

Illustrative Image (Source: Google Search)

3. IoT Applications for Smart Water Metering with LoRa® Technology

Domain: semtech.com

Registered: 1996 (29 years)

Introduction: Hangzhou Water Meter Co. has incorporated LoRa devices and the LoRaWAN protocol into its smart water metering solutions enabling public utility companies to ……

4. China Lorawan Water Meter Manufacturers and Factory, Suppliers

Domain: lanry-instruments.com

Registered: 2021 (4 years)

Introduction: Lanry Instruments has more than 20 years experience in the flow meter industry, and our products have been exported to over 40 countries in global martket….

5. LoRaWAN Ultrasonic Valve Controlled Water meter – HKT LoRa

Domain: hktlora.com

Registered: 2023 (2 years)

Introduction: This LoRaWAN water meter features remote reading, valve control, automatic data upload, wireless metering, and measures cumulative flow. It also has alarms for ……

6. Badger Meter | Water Metering Technology & Flow Solutions

Domain: badgermeter.com

Registered: 1995 (30 years)

Introduction: Badger Meter is a leading manufacturer of metering products using flow measurement and control technologies. Learn more about our products and our ……

Illustrative Image (Source: Google Search)

7. LoRaWAN IoT Smart Water – Meshed Pty Ltd

Domain: meshed.network

Registered: N/A

Introduction: Meshed offers a comprehensive range of LoRaWAN-enabled smart water meters, data loggers, & accessories to support diverse water management needs. Our devices ……

8. Wholesale Lorawan Water Meter Manufacturer and Supplier, Factory

Domain: rf-module-china.com

Registered: 2009 (16 years)

Introduction: Lorawan Water Meter – China Manufacturers, Factory, Suppliers · 1. Apator water meter pulse reader · LoRaWAN dual-mode module · LoRaWAN Dual-mode Meter Reading ……

Understanding lorawan water meter Types and Variations

Understanding LoRaWAN Water Meter Types and Variations

Choosing the right LoRaWAN smart water meter starts with the metering principle. In the USA and Europe, four dominant families cover residential to industrial service: ultrasonic (static), electromagnetic (inductive), mechanical (turbine/multijet), and compound/multi-jet manifolds for large variations in demand. All can be integrated with LoRaWAN via embedded modules or external adapters; MID-compliant meters (Europe) and AWWA-certified options (USA) are widely available.

LoRaWAN Water Meter Types and Variations

| Type | Key Features | Typical Applications | Pros/Cons (B2B) |

|---|---|---|---|

| Ultrasonic (static) | No moving parts; inline multi-path ultrasonic sensors; high R80–R160 accuracy; IP68; large dynamic range; dry register; optional temperature/pressure | Residential to light commercial | Pros: High accuracy at low flows, no moving parts, long service life. Cons: Sensitive to entrained air/particulates; premium pricing. |

| Electromagnetic (inductive) | No moving parts; induced voltage proportional to velocity; no pressure loss; full-bore; R≥R40; requires conductive water (≥20–50 μS/cm) | Industrial, utilities, large-diameter mains | Pros: Accurate across wide flow range; ideal for large pipelines. Cons: Requires conductive fluid and power (battery-limited for larger sizes); higher cost. |

| Mechanical (turbine) | Moving rotor; wide availability; robust; R typically R40–R80; low-cost | Residential/commercial | Pros: Mature, affordable, widely stocked. Cons: Wear and debris sensitivity; pressure loss; lower accuracy at low flow. |

| Mechanical (multi-jet) | Multiple inlet jets spin turbine; stable at low flows; R typically R80; proven | Residential/municipal | Pros: Good low-flow sensitivity; proven technology. Cons: Moving parts; maintenance over long service; pressure loss. |

| Compound & multi-meter manifolds | Parallel meters (e.g., turbine + multi-jet); automatic changeover; R≥R80 | Large utilities, variable demand systems | Pros: Accuracy across high/low ranges; handles demand swings. Cons: Complexity; higher installed cost. |

Below is a closer look at each category and the LoRaWAN-related variations you will encounter in the market.

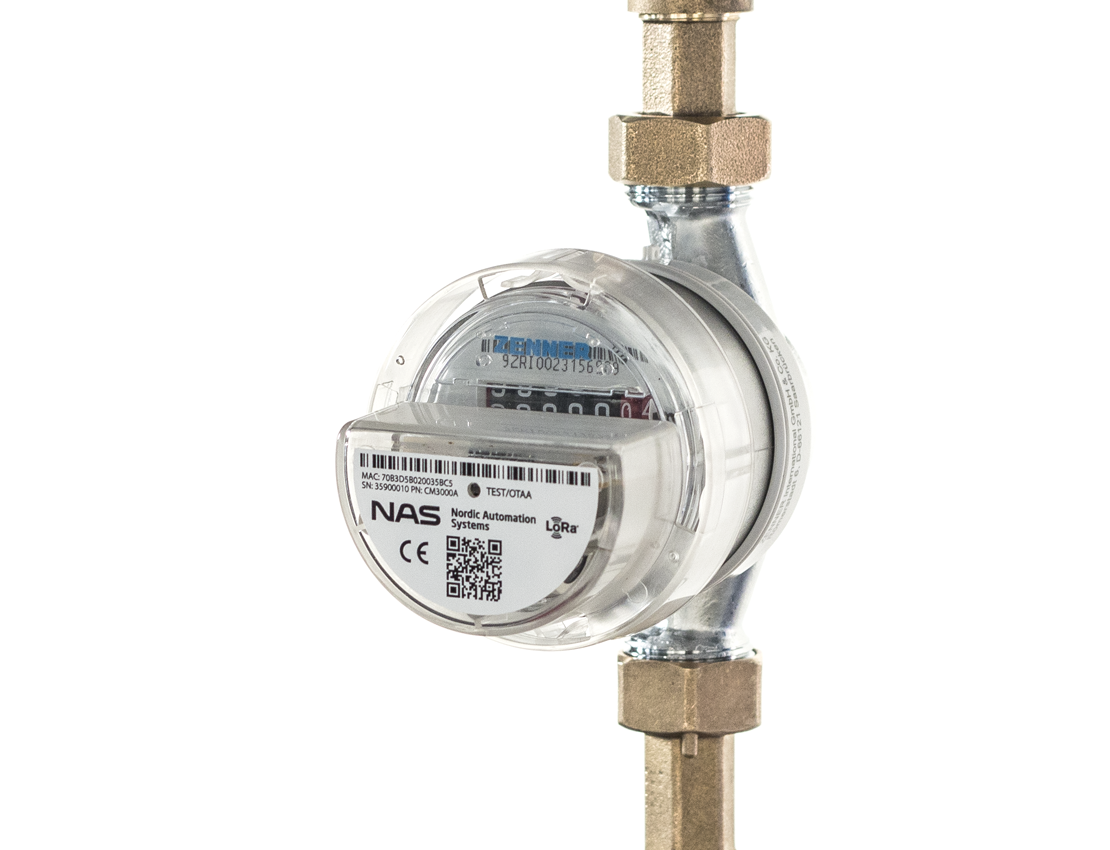

Illustrative Image (Source: Google Search)

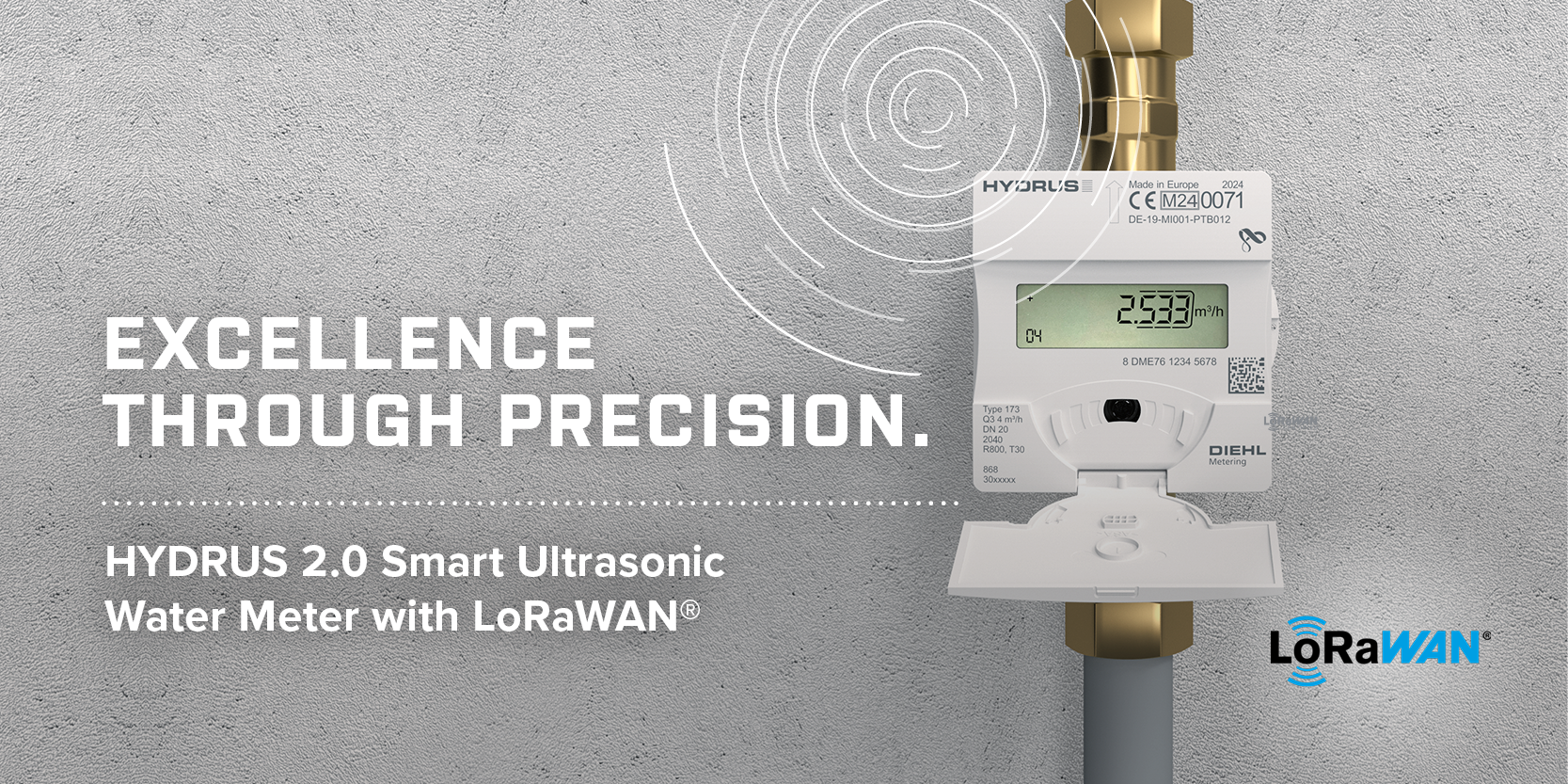

Ultrasonic Water Meters (Static, No Moving Parts)

Principle: Measures transit-time differences across one or more acoustic paths to calculate flow. Multi-path designs reduce sensitivity to profile effects and improve performance at low flow.

Features that matter:

– Accuracy classes typically R80–R160; some models extend to R200/R250.

– Large dynamic range, enabling leakage detection and continuous monitoring.

– No moving parts; no pressure loss; IP68 body; optional temperature and pressure sensors.

– LoRaWAN integration: either embedded in the register or as a retrofit module; over-the-air provisioning and join using activation-by-personalization (ABP) or over-the-air activation (OTAA).

– Applications: Residential to commercial buildings where high accuracy and low maintenance are priorities.

Pros:

– Excellent low-flow sensitivity and linearity; suited to consumption, leakage, and pressure event detection.

– Longer service intervals; no mechanical wear.

Cons:

– Performance can degrade with entrained air or suspended solids; select meters with air handling and robust signal processing.

– Higher initial cost than mechanical designs.

Illustrative Image (Source: Google Search)

Electromagnetic Water Meters (Inductive)

Principle: Generates a magnetic field and measures voltage induced by conductive water moving through the flow tube, proportional to average velocity.

Features that matter:

– Full-bore, no pressure loss; accuracy often R40–R160 depending on size and design.

– Requires electrically conductive water (typical minimum 20–50 μS/cm); not suitable for deionized water.

– LoRaWAN: available for medium sizes via in-head modules; for larger sizes, telemetry modules, pulse outputs, or 4–20 mA conversion to LoRaWAN gateways are common.

– Applications: Industrial processes, cooling water, wastewater with conductivity, large-diameter mains where accuracy and low loss are critical.

Pros:

– Accurate across a broad flow range; insensitive to viscosity; suitable for larger pipes.

– No internal obstructions.

Cons:

– Only works with conductive fluids; battery life and LoRaWAN duty cycle can limit continuous operation on larger meters.

– Higher capital cost.

Illustrative Image (Source: Google Search)

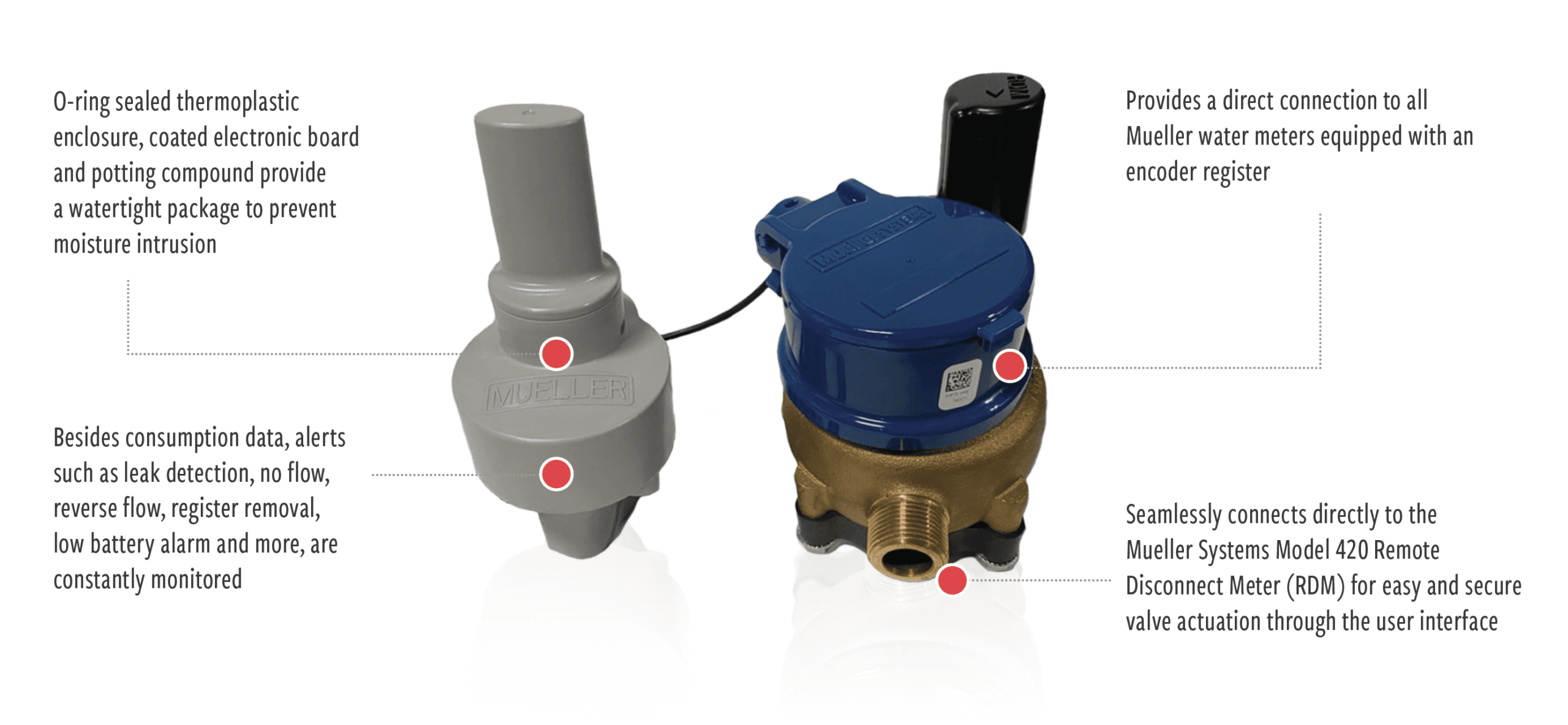

Mechanical Water Meters — Turbine (Velocity)

Principle: Water flow drives a rotor; register converts rotations to volume.

Features that matter:

– R typically R40–R80; high reliability at moderate to high flows.

– Standard sizes DN15–DN50 (1/2–2 in.) and larger; many units are MID-compliant or AWWA-certified.

– LoRaWAN: embedded modules or external “capsule” adapters for residential sizes; pulse-to-LoRa converters for larger ones.

– Applications: Residential supply, small commercial connections, district metering areas where simple, low-cost coverage is required.

Pros:

– Mature technology; widely stocked; straightforward to replace and maintain.

– Lower purchase price and simple integration with LoRaWAN.

Cons:

– Wear from solids; accuracy and longevity can suffer in abrasive water; some pressure loss.

– Lower sensitivity at low flow rates vs ultrasonic.

Illustrative Image (Source: Google Search)

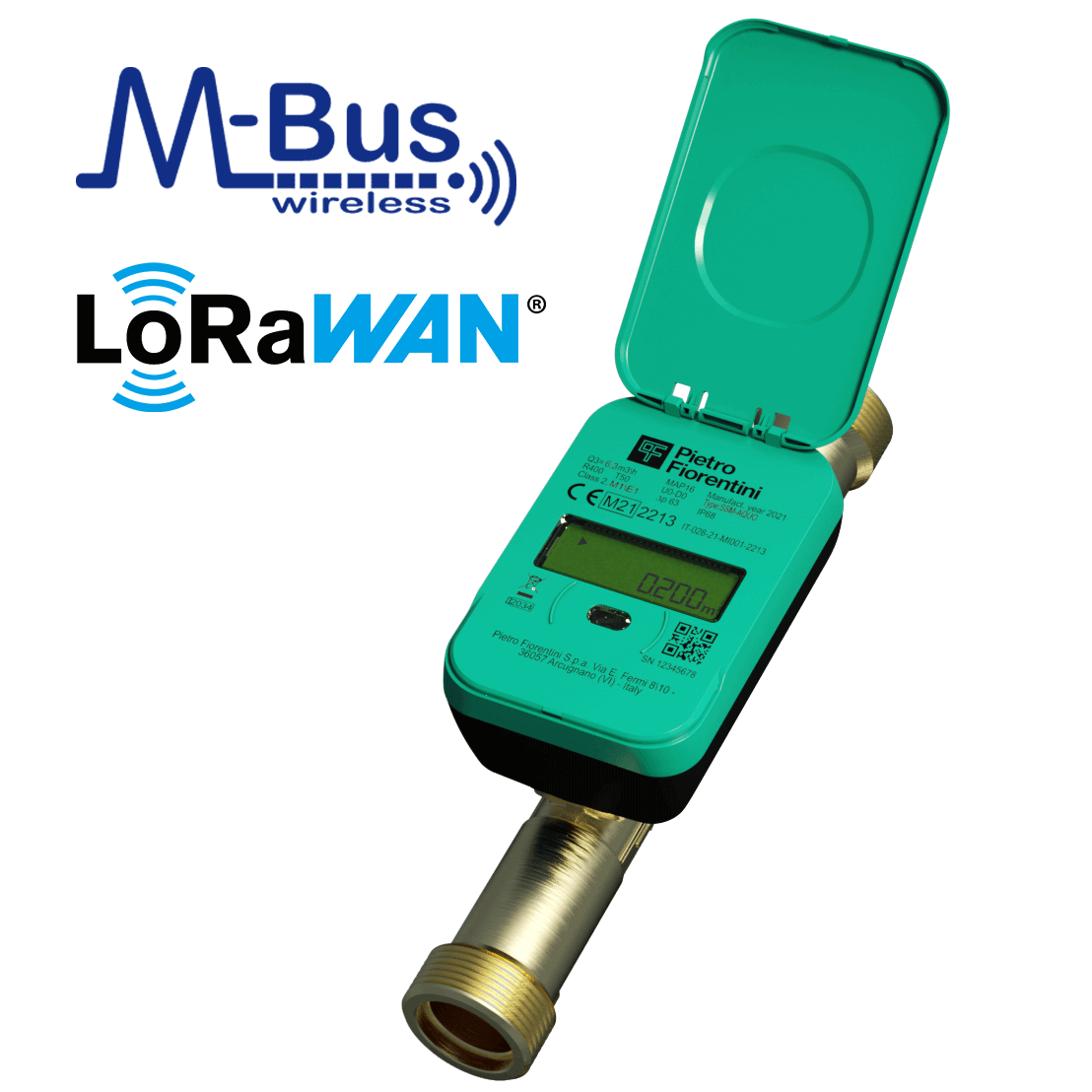

Mechanical Water Meters — Multi-Jet

Principle: Multiple inlet jets improve stability at low flows by distributing energy evenly to the turbine.

Features that matter:

– R often R80 or higher; accurate at low flow.

– Standard residential to light commercial sizes; MID/AWWA approvals common.

– LoRaWAN: in-register module or external cap with pulse-to-LoRa.

– Applications: Residential and municipal networks, including submetering in multi-family buildings.

Pros:

– Better low-flow performance than single-jet/turbine designs; proven long-term reliability.

– Cost-effective for deployments prioritizing low-flow sensitivity.

Cons:

– Moving parts and pressure loss; requires maintenance or replacement over decades.

– Some models may be sensitive to water quality and particulates.

Illustrative Image (Source: Google Search)

Compound and Multi-Meter Manifolds

Principle: Combines two meter assemblies (e.g., a multi-jet for low flow and a turbine for high flow) with automatic changeover valves or differential pressure logic to cover extreme demand variations.

Features that matter:

– R≥R80; excellent performance across wide, variable demand profiles.

– Installed in utility-grade custody transfer and district metering stations.

– LoRaWAN: one device reporting multiple endpoints or aggregate consumption from a manifold controller; redundancy options improve data reliability.

Pros:

– Accuracy and coverage in systems with widely varying loads (e.g., industrial parks, hospitals, university campuses).

– Better billing fairness when demand spikes occur.

Cons:

– Higher installed cost and complexity; larger footprint.

– More components to service and manage.

Practical LoRaWAN Integration Notes (for all types)

- Integration modes: embedded module in the register, external “cap” or pulse converter, or gateway conversion (e.g., analog/pulse to LoRaWAN).

- Security and reliability: support end-to-end encryption (AES-128) with DevNonce anti-replay; leverage confirmed uplinks for critical events and ACK handling; use redundancy (multiple gateways) where coverage is challenging.

- Compliance and approvals: In Europe, choose MID-compliant meters for legal metrology; in the USA, verify AWWA performance and certification per meter class and application. For LoRaWAN, ensure radio compliance with local regulations (e.g., FCC Part 15 in the U.S., ETSI RED in the EU).

- Maintenance and data: LoRaWAN’s low power enables multi-year battery life on smaller meters; implement OTA configuration and diagnostic telemetry (e.g., temperature alarms, flow profile anomalies) to reduce site visits.

Conclusion: For most utility and building portfolios, ultrasonic meters provide the best coverage with LoRaWAN due to their high accuracy and maintenance profile. Mechanical turbine and multi-jet designs remain economical for residential coverage. Electromagnetic meters dominate in industrial and large-pipe scenarios where conductivity and full-bore performance are essential. For variable-demand networks, compound manifolds deliver the broad R-range you need to capture both peak and leakage scenarios.

Key Industrial Applications of lorawan water meter

Key Industrial Applications of LoRaWAN Water Meter

LoRaWAN (Long Range Wide Area Network) delivers wide-area connectivity, low power consumption, end‑to‑end security, and high scalability—making it well-suited for smart water metering in diverse industrial settings across the USA and Europe. The following table highlights the core industries/applications and the specific benefits LoRaWAN water meters bring to each.

| Industry/Application | Typical Use Cases | Key Benefits for Water Metering |

|---|---|---|

| Water Utilities & Municipalities | District metered areas (DMA) and zone monitoring; AMI rollout; leakage and non-revenue water (NRW) reduction; remote readouts | Long range (2–5 km urban; 15–30 km rural) enables citywide coverage; low power (up to ~16 years battery) minimizes site visits; secure data; scalable to tens of thousands of meters |

| Multi-Dwelling Units (MDUs) & Commercial Buildings | Submetering for tenant billing; consumption optimization; building analytics integration | Low power devices in high-density deployments; secure, encrypted telemetry; scale to large device counts per building or portfolio |

| Industrial Manufacturing & Process Plants | Cooling, boiler feedwater, wash and CIP lines; leak detection; process optimization; production quality | Reliable long-range coverage on complex sites; low maintenance batteries; end‑to‑end security; scalable across plants and sites |

| Healthcare & Hospitals | High‑risk water compliance; Legionella risk monitoring; continuous consumption tracking | Secure, reliable data supports compliance; low power sensors for continuous monitoring; scalable across facilities and campuses |

| Education & Campus Environments | Dorms and labs submetering; leak alerts; budgeting | Wide coverage across campus; secure, encrypted telemetry; efficient for large student housing counts |

| Retail & Hospitality | Submetering for tenants; back‑of‑house consumption; leak alerts | Low power, secure reads enable tenant billing and efficiency without intrusive site access |

| Data Centers & Mission‑Critical Facilities | Cooling tower and chiller water monitoring; anomaly/leak detection | Continuous, secure telemetry; low power for hard‑to‑reach sensors; scalable across racks and sites |

| Agricultural & Food Processing | Irrigation water monitoring; washdown water metering | Long‑range links in rural environments; low power for field deployments; secure data for compliance and audit trails |

| Transportation Hubs (Airports, Ports, Rail) | Facility water monitoring; tenant/lease submetering; leak alerts | Secure, scalable coverage in complex structures; low power supports distributed sensors |

| Government & Public Buildings | Consumption monitoring; leak alerts; budget control | Low maintenance, secure metering across public estates; scalability for large portfolios |

| New Developments & Smart Cities | Smart infrastructure rollouts; master planning of water networks | Scalable deployment; long‑range coverage; low power operation for greenfield projects |

Why LoRaWAN Water Meters Fit These Industries

- Long range: 2–5 km in urban environments and up to 15–30 km in rural areas, supporting both dense cities and dispersed assets.

- Low power consumption: Device batteries can last up to ~16 years, reducing field maintenance.

- Scalability: Tens of thousands of meters per network, enabling citywide, portfolio-wide, or multi‑site deployments.

- Security: End‑to‑end encryption from meter to application, suitable for compliance-focused sectors.

Region‑Specific Considerations (USA & Europe)

| Region | Coverage Model | Spectrum & Licensing | Notes |

|---|---|---|---|

| USA | Public/community networks; third‑party LoRaWAN carriers; on‑premise gateways | Unlicensed ISM band | Rapid coverage via carriers; roaming capabilities exist; supports large‑scale AMI with limited CAPEX |

| Europe | Public/community LoRaWAN networks; carrier IoT services; campus/private gateways | Unlicensed ISM band subject to local limits | Regional operator ecosystems; roaming and carrier‑grade services; privacy and metering compliance per jurisdiction |

Implementation Quick Wins

- Deploy meters in priority zones (e.g., DMA endpoints, critical building risers).

- Integrate with existing BMS/SCADA via secure network server/application APIs.

- Standardize data models for consumption, alarms (e.g., leakage), and periodic audit trails.

- Start with a scalable gateway backbone; expand coverage incrementally based on device density and RF conditions.

3 Common User Pain Points for ‘lorawan water meter’ & Their Solutions

3 Common User Pain Points for LoRaWAN Water Meters & Their Solutions

1) Coverage and connectivity inconsistency across mixed urban/rural terrain

Problem. LoRaWAN’s long range still faces attenuation in dense cities, basements, or underground meter pits. Interference, gateway placement, and building materials reduce signal quality, causing late or missing reads and higher operations costs.

Solution. Establish a robust coverage plan before rollout:

– Conduct on-site surveys with a calibrated gateway to map signal margins (e.g., ≥10 dB margin at the meter location).

– Optimize gateway placement on rooftops or tall structures; use a sufficient number of gateways to ensure overlap in critical service areas.

– Tune device and network parameters: select lower data rates (e.g., DR0–DR2 for US 915 MHz, DR0–DR5 for EU 868 MHz), enable ADR, and extend RX2/SF12 receive windows to improve reliability for weak links.

– Prioritize ADR for stable nodes and keep conservative join settings for devices in difficult environments.

– Verify regulatory compliance: US FCC Part 15 Subpart C limits 915 MHz TX duty cycle; EU 868 MHz has medium access rules.

– Operational control: limit retried uplinks to reduce collisions; implement link margin alarms and targeted gateway capacity upgrades.

Illustrative Image (Source: Google Search)

Expected outcomes. >98% packet delivery ratio; fewer truck rolls for on-site reads; reduced customer service calls.

2) Battery life degradation under frequent uplinks and poor RF conditions

Problem. High data rates, frequent transmissions, and frequent joins rapidly drain batteries. Real-world deployments often miss 10–16 year targets due to RF retries, join storms, and excessive message sizes.

Solution. Optimize power and data strategy:

– Reduce uplink frequency and payload size (use delta consumption where possible); stick to daily reads for residential and align with business rules for leaks or tampering.

– Enable ADR and keep devices on lower data rates (SF7–SF12) to maximize link budget and reduce time-on-air.

– Prevent join storms by managing keys and device activation; set reasonable join acceptance windows and monitor new devices per gateway.

– Leverage Class C (continuous downlink listening) only where critical control is required; default to Class B/A elsewhere to conserve power.

– Align message rates to regional duty cycle limits (e.g., US 915 MHz; EU 868 MHz) to avoid retransmissions and regulatory violations.

– Monitor and forecast battery life per cohort; re-tune DR/ADR and join policies as coverage evolves.

Expected outcomes. Extended battery life toward design targets; fewer replacement cycles; lower total cost of ownership.

Illustrative Image (Source: Google Search)

3) Data integrity and reporting reliability issues

Problem. Duplicate frames, clock drift, time-stamp mismatches, and dropped messages produce incorrect volume readings, reconciliation gaps, and audit risk.

Solution. Strengthen end-to-end data quality:

– Enforce device and network server security (end-to-end encryption, secure key management, rotation policies).

– Validate MAC and message integrity; enable server-side frame counter checks and deduplication.

– Synchronize device and network time; use confirmed uplinks for critical events and implement timeouts with controlled retransmissions.

– Architect for redundancy: multi-region gateways, persistent buffers, and out-of-order delivery handling.

– Validate meter IDs and activation states at onboarding; block unknown or mismatched devices.

– Use quality-of-service (QoS) dashboards with alerts for join failures, repeated ACKs, and sudden DR shifts.

Expected outcomes. Accurate daily reads and event logs; reduced reconciliation effort; stronger compliance and auditability.

At-a-glance: Pain points, causes, and actions

| Pain Point | Typical Causes | Recommended Actions |

|---|---|---|

| Coverage and connectivity | Urban attenuation; underground pits; gateway placement | Coverage survey; gateway optimization; lower DR; ADR; RX2/SF12 tuning; manage retries; monitor link margin |

| Battery life degradation | Frequent joins; high data rates; large payloads; uncontrolled retransmissions | Reduce uplink frequency/size; ADR; limit joins; minimize Class C usage; adhere to regional duty cycles; monitor per-cohort battery |

| Data integrity issues | Duplicate frames; clock drift; dropped packets | End-to-end encryption; frame counter & deduplication; time sync; redundancy; device validation; QoS monitoring |

What to measure (US/EU)

- Packet delivery ratio (target ≥98%) and join success rate

- Battery life forecast per cohort; transmission counts per device

- Time-on-air budget vs regional duty cycle; ADR effectiveness

- Duplicate frame ratio (<1% recommended) and average time drift

- Gateway capacity utilization and collision metrics

Focus on RF planning, conservative link budgets, duty-cycle compliance, and operational observability. These practices consistently resolve the top three LoRaWAN water meter issues in mixed USA and Europe deployments.

Strategic Material Selection Guide for lorawan water meter

Strategic Material Selection Guide for LoRaWAN Water Meters

Materials determine reliability, safety, compliance, and total cost of ownership. For LoRaWAN water meters, the primary material decisions center on the wetted housing, electronics enclosure, and sealing strategy. The right choices ensure long battery life, regulatory compliance, and stable radio performance in harsh conditions.

1) Wetted Materials: Meter Body and Wetted Internals

- Brass (lead-free)

- Pros: Mature manufacturing, good mechanical strength and pressure resistance, familiar to utilities.

- Risks: Dezincification risk in chlorinated, low-alkalinity, or aggressive waters; can lead to porosity and leaching.

- When to use: Stable chemistry waters, municipal systems with established corrosion monitoring.

- Stainless Steel (304/316)

- Pros: Strong corrosion resistance, durability, broad chemical compatibility.

- Risks: pitting in high-chloride environments; cost; fabrication complexity for complex geometries.

- When to use: Industrial/municipal environments, high-chloride waters, extended service life priorities.

- Polymer (PP, PPS, PVDF)

- Pros: Excellent corrosion resistance, lighter weight, often DRINKING WATER CONTACT material.

- Risks: Thermal limits and creep at elevated temperatures; mechanical toughness varies by grade.

- When to use: Aggressive water, desalination zones, domestic installs with DRINKING WATER CONTACT and cold water focus.

Decision matrix:

– Municipal cold water with known aggressive chemistry → Prefer 316 SS or PPS; use brass only with verified compatibility and inhibitors.

– Industrial water, brackish or high-chloride → Prefer 316 SS or PVDF/PPS.

– Domestic cold water where weight and corrosion are concerns → PP or PPS.

– Budget-constrained, non-critical water profiles → Lead-free brass with DVGW/NSF-compliant internal seals.

2) Electronics Enclosure and External Housing

- ABS

- Pros: Good impact resistance at low temperature; easy processing; cost-effective.

- Cons: Lower UV stability without additives; chemical stress cracking with some solvents.

- Polycarbonate (PC)

- Pros: Highest impact strength and temperature tolerance; can be PC/ABS blends for balance.

- Cons: Stress cracking from certain chemicals (e.g., strong solvents); requires UV stabilization for outdoor service.

- PBT

- Pros: Good dimensional stability; decent electrical properties; resistance to environmental stress cracking.

- Cons: Lower impact resistance versus PC; consider blends.

Guidance:

– Choose PC or PC/ABS for outdoor, high-impact environments; UV-stabilized and pigmented for UV resistance.

– Use ABS for indoor/low-UV utility rooms; add UV stabilizers if near windows.

– Flame rating: Target UL94 HB or better; confirm with certification.

3) Sealing and O-Rings (Elastomers)

- EPDM

- Pros: Excellent hot/cold water compatibility; steam resistance; good compression set.

- Cons: Poor hydrocarbons (oils/solvents) resistance; ensure DRINKING WATER CONTACT certification.

- FKM (Viton)

- Pros: Broad chemical resistance; high-temperature stability.

- Cons: Potential extractables; ensure DRINKING WATER CONTACT compliance.

- NBR

- Pros: Good oils/hydrocarbons; cost-effective.

- Cons: Poor hot water and steam resistance; less suitable for DRINKING WATER CONTACT without specific compounding.

Guidance:

– Drinking water service with temperature < 60°C: EPDM with KTW/W270 or NSF/ANSI 61 certified compounds.

– Hot water/industrial: FKM with appropriate approvals; avoid NBR for DRINKING WATER CONTACT.

– Chemical-exposed industrial water: FKM or perfluoroelastomers as required.

4) Adhesives, Potting, and Coatings

- Adhesives: Use acrylic, epoxy, or polyurethane adhesives designed for potable water; confirm DRINKING WATER CONTACT.

- Potting: Epoxy or polyurethane compounds; balance vibration damping vs. reworkability; confirm migration/extractables.

- Coatings:

- E-coat or powder coat (epoxy/polyester) for external corrosion protection on metal housings.

- UV-cur or solvent-based exterior coatings for UV resistance on PC/ABS.

- Anti-microbial surface treatments in potable water applications can reduce biofilm.

- Anti-scale: Consider internal coatings or additive programs for hard-water scaling; ensure DRINKING WATER CONTACT compliance.

5) Antenna Materials and Placement

- External antenna with IP67/NEMA 6P enclosure and UV-stable materials (UV-resistant ABS/PC blends, PTFE, PE).

- Internal antenna (FPC/ceramic):

- Metal housings require antenna windows or external placement; plastic housings can support internal FPC antennas with careful mechanical isolation from high-power noise.

6) Key Standards and Certifications to Align

- Drinking water contact:

- USA: NSF/ANSI/CAN 61 (listed materials and components).

- EU: 4MS Common Approach (e.g., KTW-BWGL/DVGW W270, WRAS BS 6920).

- Mechanical and measurement:

- AWWA C700/C701/C706 (water meters); ISO 4064 measurement standards.

- Environmental and ingress:

- IP68 (continuous submersion), IK impact rating; temperature class per local climate (e.g., -25°C to +50°C).

- Electrical and radio:

- FCC (USA) and CE (EU) radio approvals; RoHS and REACH compliance.

7) Material Interaction with LoRaWAN

- Battery chemistry: Lithium thionyl chloride (Li-SOCl₂) offers higher energy density and stable voltage; lithium manganese dioxide (Li-MnO₂) has lower energy density. Choose cell chemistry based on duty cycle; ensure cell and case materials are ETP materials with vent design if required.

- Power optimization: Low-leakage adhesives/pottings and high-quality passives reduce current draw; metal housings can attenuate radio if not antenna-optimized.

- Temperature: Match elastomer and plastic choices to local conditions (freezing, high ambient); material selection affects reliability and battery performance.

8) Risk Controls and Validation

- Water chemistry screening: Assess alkalinity, chloride, chloramines, hardness, pH; match materials accordingly.

- Corrosion monitoring: Inspect dezincification and pitting; use inhibitors where appropriate and validated.

- Material data sheets and compliance: Maintain traceability of DRINKING WATER CONTACT materials and certification documents.

- Environmental testing:

- Salt spray for corrosion resistance.

- UV exposure tests for outdoor enclosures.

- Thermal cycling and freeze/thaw for O-rings and internal seals.

- Long-term field trials: Validate battery life and radio performance across representative water chemistries.

9) Cost and Lifecycle Trade-offs

- Brass offers lower initial cost but may demand corrosion monitoring or faster replacement in aggressive water.

- Stainless steel increases CAPEX; lowers OPEX via extended service life in harsh conditions.

- Polymers (PP/PPS/PVDF) minimize corrosion risk and weight; suitable where mechanical loads are lower and thermal constraints are acceptable.

- Materials and certifications (DRINKING WATER CONTACT, DVGW) influence both price and compliance burden; plan procurement accordingly.

Quick-Start Recommendations by Scenario

- Municipal cold water (varied chemistry):

- Wetted: 316 SS or PPS internals; EPDM O-rings; DRINKING WATER CONTACT adhesives/pottings.

- Enclosure: PC or PC/ABS, UV-stabilized, IP68, IK10.

- Antenna: External IP67.

- Brackish/high-chloride municipal water:

- Wetted: 316 SS preferred; PVDF internals if temperature allows; FKM seals.

- Industrial water (chemicals present):

- Wetted: 316 SS; PVDF/PPS; FKM seals and compatible adhesives.

- Validate solvent exposure and temperature limits.

- Domestic cold water and price-sensitive deployments:

- Wetted: Lead-free brass (with dezincification safeguards) or PP; EPDM seals.

- Enclosure: UV-stabilized ABS or PC/ABS.

Material Comparison Table

| Component | Material options | Key pros | Key cons/risk | DRINKING WATER CONTACT suitability | Typical use cases |

|---|---|---|---|---|---|

| Wetted housing | Brass (lead-free), 304/316 SS, PP, PPS, PVDF | Brass: cost, familiarity; SS: corrosion; PP/PPS/PVDF: corrosion-free | Brass: dezincification; SS: cost; polymers: thermal limits | Brass/SS: if processed/cert; PP/PPS/PVDF: often compliant | Municipal, industrial, domestic |

| External housing | ABS, PC, PC/ABS | ABS: cost; PC: impact; PC/ABS: balance | ABS: UV; PC: stress cracking; PC/ABS: mid-cost | Requires compliant compounds | Indoor, outdoor harsh environments |

| Seals (O-rings) | EPDM, FKM, NBR | EPDM: hot/cold water; FKM: chemicals; NBR: oils | EPDM: poor solvents; FKM: potential extractables; NBR: hot water poor | EPDM/FKM with KTW/W270 or NSF/ANSI | Potable hot/cold; industrial chemicals |

| Adhesives/pottings | Epoxy, Polyurethane, Acrylic | Structural bonding; damping | Chemical compatibility, migration risk | Certified potable water compounds | Bonding components, protecting electronics |

| Coatings | E-coat, Powder coat, UV coating | Corrosion protection; UV resistance | Adhesion failures; coating migration | Use potable-certified where applied | Metal housings; outdoor enclosures |

| Antennas/assembly | FPC ceramic, External IP67 antenna | Integration; high durability | Metal attenuation; design constraints | External antennas are independent | Indoor radio; outdoor external antenna |

| Battery enclosure | ABS/PC, ETP materials | Impact and heat resistance | Thermal expansion; hermeticity needs | Ensure inert and non-reactive | Sealed battery packs, external power access |

In-depth Look: Manufacturing Processes and Quality Assurance for lorawan water meter

In-depth Look: Manufacturing Processes and Quality Assurance for LoRaWAN Water Meters

LoRaWAN (Long Range Wide Area Network) is the communication backbone that makes smart water meters practical at scale in both USA and Europe. Operating in unlicensed spectrum, LoRaWAN offers long‑range coverage, very low power consumption, scalable device counts, and end‑to‑end encryption. For utilities, it enables wide‑area deployments with remote monitoring, real‑time data collection, and efficient network management without the overhead of owning the radio infrastructure. The standard architecture—end nodes (meters), gateways, and a network server—connects devices to cloud applications while enforcing security from the meter to the application layer.

From manufacturing to field deployment, QA must ensure the meter’s metrology, enclosure integrity, electronics reliability, and radio compliance across both regions.

Manufacturing Process (End‑to‑End)

- Prep

- Incoming inspection of metering module, LoRaWAN radio board, antenna, battery, housing, seals.

- Clean room assembly for electronics; ESD controls; component traceability.

-

Pre‑check firmware and firmware‑over‑the‑air (FOTA) capability; generate root keys with device unique identifiers; secure key injection into secure element/microcontroller.

-

Forming

- Injection molding of outer body (brass/plastic composite or engineered polymers).

- Insert‑molded threads/ports and fittings; ultrasonic or vibration welding of internal sub‑assemblies.

-

Over‑mold sensor/electronics as needed to protect components.

-

Assembly

- Install metering module (ultrasonic/electromagnetic); connect to LoRaWAN radio board.

- Fit LoRaWAN radio module and antenna (ceramic/pcb whip); verify impedance and cable integrity.

- Install battery pack; attach connector/header; apply conformal coating.

-

Assemble housing; torque fasteners; install and compress seals; fill the electronics compartment with potting if required.

-

Quality Control (QC)

- Metrology accuracy across tested flow rates; verify OIML R49/MID acceptance thresholds (e.g., Class 1/2, depending on regional accuracy class).

- Pressure/leak testing; dielectric strength test for insulated parts.

- Environmental/EMC tests: temperature cycling, humidity, vibration, shock; EMC radiated/conducted per target market requirements (EMC basics and EMC performance verification remain essential, even if specific CISPR/EN numbers vary).

- Radio certification in target bands (e.g., ETSI EN 300 220 in EU; FCC Part 15 in USA); duty cycle and transmit power conformity; antenna radiation pattern checks; join/network handshake verification to confirm secure LoRaWAN connectivity.

- Ingress protection (e.g., IP68) via pressure/vacuum and dust/water ingress tests.

- Final functional test: read intervals, data payload encoding, OTAA/ABP provisioning, downlink behavior where supported.

- Calibration and documentation: calibration certificates and test reports; device and batch traceability; packaging and storage for prolonged battery life.

LoRaWAN Integration & Final QC

Table: LoRaWAN Integration & Verification at Final QC

| Item | Purpose | How/Where Tested | References/Notes |

|---|---|---|---|

| Region/profile setup (EU868 vs US915) | Ensure correct band, channels, power limits | Region config in firmware; radio RF exposure confirm | LoRaWAN regional parameters (varies by region) |

| Join OTAA or ABP provisioning | Secure device authentication and session keys | Join flow verified; session established | LoRaWAN end‑to‑end security at network server |

| Uplink payload encoding | Correct, scalable data format for applications | Payload verification; schema checks | LoRaWAN Application Layer conventions |

| Packet delivery ratio (PDR) | Confirm link reliability across profiles | Link margin test; gateway simulation | LoRaWAN long‑range characteristics |

| Firmware‑over‑the‑air (FOTA) | Field maintainability and updates | Over‑the‑air firmware update | LoRaWAN security for updates |

| Power profile | Low‑current mode, optimal TX duration | Battery life verification; sleep behavior | LoRaWAN low power benefits |

Quality Standards and Compliance (USA and Europe)

Table: Key Quality Standards & Certifications

| Domain | Standard | Scope | Typical Use in USA/EU |

|---|---|---|---|

| Quality Management | ISO 9001:2015 | Design and manufacturing QMS | Factory quality assurance and continuous improvement |

| Metrology | OIML R49 (Class 1/2), MID 2014/32/EU Annex VI | Cold water meter accuracy and metrology | Accuracy certification and type approvals |

| EMC | General EMC compliance | Radiated/conducted emissions and immunity | FCC Part 15 (USA) and ETSI EMC compliance (EU) basics; specific EN/CISPR numbers vary by vendor |

| Radio | ETSI EN 300 220 (EU), FCC Part 15 (USA) | SRD radio equipment | Transmitter compliance in EU (868 MHz), USA (915 MHz) |

| Electrical safety | IEC/UL/CE basics | Dielectric strength, creepage/clearance | Equipment safety marking |

| Environmental | IEC 60068 series | Temperature cycling, humidity, shock, vibration | Reliability testing across climates |

| Ingress protection | IEC 60529 (e.g., IP68) | Dust/water ingress resistance | IP class testing for enclosures |

| Environmental product | RoHS/REACH compliance | Restricting hazardous substances | EU product compliance |

Notes:

– Battery lifetime up to 16 years is achievable in some meter designs but depends on ambient conditions, reporting intervals, radio settings, and vendor implementation.

– Radio certification specifics (sub‑band selections, power limits, and duty cycles) vary by vendor and regional market; consult test reports and certifications for exact operating parameters.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lorawan water meter’

Practical Sourcing Guide: A Step-by-Step Checklist for LoRaWAN Water Meters

Use this checklist to plan, procure, integrate, deploy, and accept LoRaWAN water meters in the USA and Europe. Where relevant, LoRaWAN attributes (long range, low power, scalability, end-to-end security) inform selection and deployment decisions.

Illustrative Image (Source: Google Search)

Step-by-Step Sourcing Checklist

| Step | Objective | Required Checks | USA / Europe References |

|---|---|---|---|

| 1. Define use case and KPIs | Translate business goals into measurable requirements | Coverage target (urban/rural), read interval, latency tolerance, battery-life target (e.g., ≥10 years for Class A), data accuracy class, leak/alarm needs, integration scope | — |

| 2. Select meter technology | Ensure metrology and environmental fit | Mechanical meter size/diameter, accuracy class (Mxx), metrology certification, pulse output compatibility, material approvals (drinking water contact), enclosure rating (e.g., IP68) | USA: NSF/ANSI 61, NSF/ANSI 372; EU: Drinking Water Directive 98/8/EC, UK WRAS |

| 3. Confirm LoRaWAN technical profile | Align device with network and vendor capabilities | LoRaWAN version (1.0.x/1.1), MAC class (A/B/C), payload profile (Cayenne LPP or custom, with encryption), join method (OTAA preferred), ADR support, MAC options (e.g., ADRACK), confirmed uplinks, data security | LoRa Alliance Certification Program (devices/network); end-to-end security (AES-128) |

| 4. Choose radio bands | Ensure regional compliance | Supported frequencies: USA 902–928 MHz (ISM), EU 863–870 MHz; duty-cycle constraints (USA TX-limit for Class A); confirm regional variant(s) | USA: FCC Part 15; EU: RED/ETSI EN 300 220, EMC (EN 61326), safety for fixed equipment |

| 5. Select gateway strategy | Design coverage that meets your KPIs | Coverage model (e.g., 2–5 km urban, 15–30 km rural typical), placement and backhaul (Ethernet/Wi‑Fi/cellular), interference management, redundancy (overlap), CAPEX vs hosted options | — |

| 6. Confirm network server capabilities | Ensure reliable delivery and integration | Packet delivery success rate (e.g., ≥95% typical), end-to-end security, handling of confirmed vs unconfirmed uplinks, MAC command support (ADR/LinkCheck), webhooks/APIs, event processing | — |

| 7. Validate data schema and security | Align billing/alarm data and protection | Payload fields (consumption, alarms, tamper, battery, RSSI/SNR), data encryption in transit, retention/privacy, tamper-evident logs, OTAA joining | — |

| 8. Integration readiness | Connect data to billing/SCADA | Interface format (JSON/Cayenne LPP), push/pull method (webhooks/MQTT/API), IAM/auth, latency SLAs, retry/fallback, data model mapping | — |

| 9. Procurement plan | Reduce risk and ensure delivery | MOQs, lead times, inventory strategy, warranty/returns, firmware management process, regional SKU availability, spare parts | — |

| 10. Field deployment plan | Optimize installation and connectivity | Gateway commissioning checklist, site survey, RSSI/SNR thresholds, ADR tuning, device provisioning, join procedure, mounting/reading requirements, labeling, maintenance access | — |

| 11. Compliance and certifications | Meet regulatory obligations | Meter approvals/pattern approvals, radio certifications (e.g., FCC), CE marking/RED, EMC, IP rating, battery compliance (UN38.3), cybersecurity (security testing optional), labeling | FCC Part 15; CE/RED (ETSI EN 300 220), UL/IEC as applicable; EU: GDPR if personal data |

| 12. Acceptance testing and go-live | Prove performance and reliability | Proof-of-Concept pilots and scale test, coverage validation, battery-life simulation, integration end-to-end, read accuracy, alarm handling, ADR behavior, documentation handover | — |

Notes:

– Typical LoRaWAN ranges are 2–5 km in urban areas and 15–30 km in rural areas; plan gateway density accordingly.

– Class A devices maximize battery life but require downlink to be initiated after an uplink; verify this is acceptable for valve/remote control scenarios.

Comprehensive Cost and Pricing Analysis for lorawan water meter Sourcing

Comprehensive Cost and Pricing Analysis for LoRaWAN Water Meter Sourcing

1) Pricing Model Overview

- Device BOM (build-of-materials) + Factory cost

- Certification & compliance (EU/US)

- Logistics (freight, duties, warehousing)

- Network costs (gateways, NaaS, cloud)

- Post-deployment operations (O&M)

- Warranty and service

2) Cost Drivers: Materials, Labor, Logistics

Note: Ranges below are indicative for OEM manufacturing at 10k–50k annual volumes with moderate quality and design. They vary with design choices and region-specific requirements.

2.1 Materials (per unit)

| Component | What it is | Typical BOM range | Key notes |

|---|---|---|---|

| Water measurement module (ultrasonic or mechanical) | Core measurement engine | $12–$28 | Accuracy class and materials drive cost; ultrasonic offers remote diagnostics |

| LoRaWAN module | Transceiver + MCU + secure element | $5–$9 | 915 MHz (US) / 868 MHz (EU); Class A with ADR; secure boot optional |

| Battery | Primary lithium (8–20 Ah) | $2–$6 | 16-year life depends on duty cycle; capacity and temp range matter |

| Antenna | PCB or external ceramic | $0.50–$1.80 | PCB antenna acceptable if gateway density is sufficient |

| Enclosure & O-rings | IP68-rated, brass/DNxx threaded | $7–$16 | Brass adds cost but improves durability; thread standardization simplifies procurement |

| Sensor PCB, connectors, cabling | Interconnects, wiring | $2–$4 | Cost impacted by connector specs and protection level |

| Firmware & security | Firmware dev/license, keys | $1–$3 | Secure element storage and dev/testing effort |

| Packaging | Protective inserts, labeling | $0.30–$0.90 | Minimal packaging reduces breakage and unit cost |

| BOM subtotal (device) | — | $29.80–$69.70 | Typical mid design often lands in $45–$60 |

Interpretation: Upgrading the measurement module and enclosure typically offers the largest single changes to BOM. For the LoRaWAN module, selecting a well-supported 915/868 variant and enabling LoRaWAN Class A features balances performance and cost.

2.2 Labor & Factory Cost (per unit)

| Process step | Typical labor range | Notes |

|---|---|---|

| Assembly & test | $2.20–$4.00 | Scales with design-for-manufacturing and test coverage |

| Factory overhead | $1.20–$2.20 | Includes facility, QA, calibration |

| Factory cost subtotal | $3.40–$6.20 | Assumes 10k–50k annual volumes |

Interpretation: Factory cost is highly sensitive to test automation and design complexity. Clear test vectors and automated checks reduce cycle time and variability.

Illustrative Image (Source: Google Search)

2.3 Compliance & Certification (per unit, amortized across batch)

| Compliance item | EU (868 MHz) | US (915 MHz) | Notes |

|---|---|---|---|

| CE (RED/EMC + LVD), RoHS, REACH | $0.30–$0.80 | — | EU certification fees amortized per unit |

| FCC (Part 15, Subpart C) | — | $0.30–$0.80 | US certification fees amortized per unit |

| Certification batch fees | $3,000–$12,000 | $3,000–$8,000 | Per model; dependent on test scope and pre-testing strategy |

Interpretation: Planning certification as a batch (multi-SKU or multi-region) amortizes costs and reduces per-unit burden.

2.4 Logistics (per unit)

| Item | Air (US/EU) | Ocean (US/EU) | Notes |

|---|---|---|---|

| Freight | $0.90–$2.50 | $0.35–$0.90 | Unitized pallets reduce per-unit freight |

| Duties (US vs EU) | 0%–2.5% | 0%–2.5% | Depends on HTS code and origin; verify HS 9028.20 |

| Duties (EU from CN) | 3.7% | — | EU industrial machinery duty; check current rates |

| Customs/clearance | $0.10–$0.40 | $0.10–$0.40 | Broker and local fees vary |

| Warehousing & handling | $0.20–$0.60 | $0.20–$0.60 | Distribution planning impacts this line item |

| Incoterms delta (EXW vs DDP) | $1.20–$2.50 | $0.90–$1.70 | Risk transfer and admin overhead |

| Logistics subtotal | $1.50–$4.60 | $0.85–$3.25 | Air is faster; ocean reduces unit logistics cost |

Interpretation: Choosing the right incoterms and freight mode balances speed and total cost. Warehousing near target regions shortens lead time and reduces stock-outs.

3) Total Device Cost Build-up (typical mid-range)

| Cost block | US | EU | Notes |

|---|---|---|---|

| BOM | $35–$60 | $38–$62 | EU variants often need specific threads or labeling |

| Factory labor | $3.40–$6.20 | $3.40–$6.20 | Same manufacturing lines; EU variants add slightly |

| Certification | $0.30–$0.80 | $0.30–$0.80 | Amortized per unit |

| Logistics subtotal | $1.50–$4.60 | $1.50–$4.60 | Air vs ocean choices apply |

| Ex-works per-unit | $38.90–$66.80 | $41.90–$68.80 | Factory-gate cost |

| Total landed cost (air) | $40.40–$71.40 | $43.40–$73.40 | Typical for moderate volumes |

Interpretation: For most deployments, total landed cost including certification and logistics falls within $42–$73 per unit for moderate volumes, with room to expand depending on design choices.

4) Network Costs

LoRaWAN uses unlicensed spectrum and relies on gateways and a network server. Costs vary by deployment model.

Illustrative Image (Source: Google Search)

| Component | Customer-owned (private) | NaaS (carrier/operator) | Notes |

|---|---|---|---|

| Gateways (hardware + install) | $300–$800 per gateway | Included or bundled | Gateway density is critical to device join rate and reliability |

| Network server / cloud | $1–$5 per device/year | Often included | Some carriers add minimal platform fees |

| Cellular backhaul | $120–$360 per gateway/year | Usually included | Optional if Ethernet/Wi-Fi is available |

| Ongoing management | $1–$4 per device/year | Often included | Monitoring, updates, maintenance |

| Site acquisition (EU) | $50–$300 per site | Included or minimal | Antenna rights and rooftop fees vary |

Interpretation: For greenfield utility deployments, NaaS simplifies cost management and reduces upfront capex. Private networks suit dense districts or dedicated coverage, but require more capex and operations.

5) TCO Over 12–15 Years (device + network)

| Scope | US | EU | Notes |

|---|---|---|---|

| Devices (10–15 years) | $40–$80 per device | $40–$80 per device | Replacement rate of ~10–15% depending on environment |

| Network (10 years, NaaS) | $30–$50 per device | $30–$50 per device | If customer-owned, capex amortizes over 8–10 years |

| Maintenance & warranty | $3–$8 per device/year | $3–$8 per device/year | Depends on RMA strategy and SLA |

| Total TCO per device | $120–$160 | $120–$160 | Ballpark for 10–15 years |

Interpretation: LoRaWAN’s long battery life (up to ~16 years under favorable duty cycles) keeps device capex low. Network model choice drives the balance between upfront cost and recurring fees.

6) Tips to Save Cost

- Consolidate SKUs: Align thread sizes and enclosure variants to reduce BOM complexity and certification scope.

- Batch certification: Share test vectors across similar SKUs; pre-qualify module variants to minimize re-certification.

- Optimize RF design: Use high-gateways density to enable cost-efficient PCB antennas; reduce external antenna add-ons.

- Battery sizing discipline: Target Class A with ADR to lower payload frequency; avoid oversized batteries unless the duty cycle requires it.

- Lean assembly: Invest in automated testing and jigs; reduce manual steps and rework.

- Incoterms and freight: Use EXW with unified carrier contracts for scale; consider ocean freight for planned deployments.

- Label and packaging: Minimize packaging materials and standardize labels to cut unit cost.

- Secure element reuse: Standardize provisioning and key management; reduce per-unit firmware customization costs.

7) Pricing Strategy and Target Range (2025 market, indicative)

| Segment | US per unit | EU per unit | Notes |

|---|---|---|---|

| Budget (DN15–DN25, PCB antenna, Class A) | $45–$70 | $48–$75 | Suitable for dense city deployments |

| Mid (DN15–DN40, brass enclosure, secure element, remote firmware) | $75–$130 | $78–$135 | Balanced accuracy and durability |

| Premium (DN50–DN100, advanced telemetry, higher temp range) | $130–$220 | $135–$230 | Larger pipe size, tougher environments |

Interpretation: Pricing should align with accuracy class, enclosure materials, network deployment model, and service level. Ensure clear value articulation: reliability, diagnostics, and battery life.

8) Risk-Price Dynamics

- High gateway density → lower device radio cost and better join rates → potential price leverage.

- Over-specified battery → increases BOM with limited benefit → reduce if duty cycle is light.

- Multiple SKUs without reuse → higher certification and tooling → price pressure increases.

- NaaS with SLAs → lower capex but recurring fees → total cost depends on contract terms.

9) Quick Reference: LoRaWAN Benefits and Cost Implications

- Long range (rural ~15–30 km, urban ~2–5 km) → fewer gateways per area → lower network capex.

- Low power (up to ~16 years) → fewer device replacements → favorable TCO.

- Scalability (tens of thousands per network) → supports citywide rollouts without significant per-unit overhead.

- End-to-end security → minimal price impact but improves trust and reduces operational risk.

Interpretation: LoRaWAN’s architecture and capabilities directly reduce network and operational costs, especially in wide-area utility deployments.

Illustrative Image (Source: Google Search)

10) Action Checklist

- Define meter size, accuracy class, and required telemetry; standardize SKUs.

- Select LoRaWAN module variant aligned to region (915 MHz US; 868 MHz EU) and include secure element.

- Specify battery capacity for 10–15 years under planned duty cycle; validate with field tests.

- Plan batch certification (EU: CE/RED/EMC/LVD/RoHS/REACH; US: FCC Part 15).

- Choose incoterms and freight mode; consolidate shipments; align labeling.

- Decide network model (NaaS vs customer-owned); map gateway density and backhaul options.

- Lock vendor QMS; define test coverage; implement automated assembly and burn-in.

These ranges and recommendations provide a structured, vendor-neutral basis to plan costs and pricing across US and Europe. Adjust figures based on final design choices, volume, SLA requirements, and local regulations.

Alternatives Analysis: Comparing lorawan water meter With Other Solutions

Alternatives Analysis: Comparing LoRaWAN Water Meter With Other Solutions

LoRaWAN provides wide-area, low-power connectivity with end‑to‑end encryption and large-scale network management capabilities, which makes it well-suited for multi-site utility deployments; however, depending on carrier coverage, local spectrum policy, and cost targets, NB‑IoT/4G and Sigfox can offer complementary or alternative pathways for smart water metering.

Comparison Matrix

| Attribute | LoRaWAN | NB‑IoT/4G | Sigfox |

|---|---|---|---|

| Network type | Unlicensed LPWAN | Licensed cellular LPWAN (3GPP) | Unlicensed LPWAN (ultra‑narrowband) |

| Spectrum | 863–870 MHz (EU), 902–928 MHz (US) | 700/800/850/900 MHz (varies by market) | 868 MHz (EU), 902–928 MHz (US) |

| Range (urban) | 2–5 km | 1–3 km (depends on cell density/band) | 2–5 km (similar LoRaWAN, often shorter indoor penetration) |

| Range (rural) | 15–30 km | 10–20 km | 15–30 km (path‑dependent) |

| Battery life | Up to ~16 years (Class C with optimized config) | Typically 3–8 years (Class 3), 6–10 years (Class 5 on/off modes) | Often shorter due to strict duty cycle; <10 years common |

| Payload & uplink volume | Robust high‑density uplink support | Robust high‑density uplink support | Restricted: very small payloads and 140‑up/down msgs/day (typ.) |

| Connectivity ownership | Neutral host (utilities or third‑party networks) | Carrier‑owned or hosted by MNO/MVNO | Carrier‑owned or third‑party networks |

| Security | End‑to‑end encryption at network/app layers | 3GPP security; carrier‑level TLS to application | Secure over Sigfox platform; limited control for utility‑managed keys |

| Roaming | Multi‑network roaming via NaaS, roaming agreements | Global roaming with SIM/eSIM (carrier managed) | Limited roaming (regional coverage variations) |

| CAPEX | Gateways and backhaul (Ethernet/cellular/fiber); no license fees | Gateways not required; use carrier cells | Minimal meters/gateways; network coverage constrained by operator |

| OPEX | Network‑agnostic; predictable network/server OPEX | SIM/data (per‑meter) OPEX plus application | SIM/data (per‑meter) OPEX plus application |

| Best fit | Utility‑owned or neutral‑host networks; high‑density, frequent data | Broad carrier footprint; minimal network build; per‑device OPEX acceptable | Low‑data, infrequent events; utility seeking minimal deployment overhead where coverage exists |

Decision Drivers and Trade‑offs

- Deployment model and CAPEX/OPEX dynamics:

- LoRaWAN enables utility‑owned or neutral‑host models, which favor predictable OPEX at scale; NB‑IoT leverages existing carrier coverage and reduces CAPEX but shifts recurring OPEX to per‑meter data charges; Sigfox reduces CAPEX but imposes OPEX ceilings and payload limits.

- Battery performance and maintenance frequency:

- LoRaWAN Class A/B/C configurations and regional duty‑cycle allowances frequently support extended lifespans; NB‑IoT Class 3 designs struggle with 10+ years without aggressive duty‑cycle and reporting throttling; Sigfox’s strict duty cycle and limited uplink capacity constrain lifetime, especially with frequent reporting.

- Coverage and densification:

- LoRaWAN requires gateway densification for urban buildings but scales efficiently with mesh‑like coverage where needed; NB‑IoT benefits from mature carrier macro coverage though in‑building penetration can be weak; Sigfox coverage depends on operator deployment density and may be discontinuous in some markets.

- Security and data governance:

- LoRaWAN provides end‑to‑end encryption with app‑layer keys, supporting utility‑controlled data sovereignty; NB‑IoT inherits carrier‑grade security and typically requires application‑level encryption; Sigfox security is robust within its stack but offers less utility‑controlled key management.

- Payload and data strategy:

- LoRaWAN supports higher payloads and flexible uplink windows; NB‑IoT supports high uplink density suitable for metering; Sigfox is suited for infrequent events (leak/alarm) rather than continuous flow/hourly reads due to its 140‑message/day limit.

- Time‑to‑market and spectrum policy:

- Unlicensed LoRaWAN and Sigfox generally avoid spectrum licensing delays but must comply with regional duty‑cycle rules; licensed NB‑IoT depends on carrier availability and local licensing timelines, which can extend deployment lead times.

Bottom Line

- Select LoRaWAN when utility control, predictable OPEX, long battery life, and high‑density uplink are critical, and when network build or NaaS partnership can be funded at portfolio level.

- Choose NB‑IoT when carrier coverage is strong, capital budgets favor minimal infrastructure, and recurring data OPEX is acceptable, noting the battery‑life trade‑offs in dense urban deployments.

- Consider Sigfox for infrequent event reporting or for projects prioritizing minimal deployment overhead where coverage exists, acknowledging payload and duty‑cycle constraints that may limit detailed water‑quality or high‑frequency metering.

Essential Technical Properties and Trade Terminology for lorawan water meter

Essential Technical Properties and Trade Terminology for LoRaWAN Water Meter

Why LoRaWAN matters for water metering

LoRaWAN is a low-power, wide-area networking protocol for wireless battery-operated devices. In water management, it enables wide-area deployment of smart meters with remote monitoring and real-time data collection. For utilities, this reduces network overhead while improving efficiency and customer service.

Core Technical Properties

| Property | Description | Typical/Example Values | Notes |

|---|---|---|---|

| LoRaWAN version | Protocol and MAC layer version used by the meter | 1.0.x (commonly 1.0.3/1.0.4); 1.1 in some regions | Check interoperability with your network server. |

| Device class | LoRaWAN device behavior mode | Class A (receive windows after uplink) | Class B and C exist but are uncommon in water metering. |

| Regional bands | Operating RF bands for US/EU | US915; EU868 | Verify for target deployment countries. |

| Link budget / Sensitivity | Ability to receive weak signals | Typical sensitivity −130 dBm at SF12; link budgets >150 dB | Improves coverage in basements and rural areas. |

| Coverage range | Practical device-to-gateway distances | 15–30 km (rural); 2–5 km (urban) | Assumes unobstructed path and compliant gateways. |

| Channel plan | Uplink/Downlink channels per region | US915: 64 uplink, 8 downlink; EU868: 3 uplink, 3 downlink | Set per regional specification. |

| Uplink/downlink duty cycles | Compliance with regulatory limits | EU868: ≤1% per sub-band; no explicit limit in US915 (must avoid harmful interference) | Enforced by regional regulations, not LoRaWAN spec. |

| Spreading factors & data rates | LoRa modulation settings (SF7–SF12) | SF7 (DR5, fastest) to SF12 (DR0, slowest) | Lower SF improves capacity; higher SF extends range. |

| Adaptive Data Rate (ADR) | Server-controlled data rate and transmit power | On by default | Improves capacity and battery life when network density is high. |

| Confirmed uplinks | App-layer acknowledgment of messages | Optional | Confirms delivery; increases airtime and battery usage. |

| MAC options | LoRaWAN MAC commands | LinkCheck, ADR, DutyCycle, DevStatus, etc. | Enables network diagnostics and optimization. |

| Join modes | OTAA vs. ABP | OTAA preferred; ABP possible | OTAA provides session keys and stronger security. |

| Join/EUI identifiers | Join addressability | DevEUI (unique per device); AppEUI/AppKey (OTAA) | Some vendors use JoinEUI in place of AppEUI. |

| Application port | LoRaWAN “port” number for payloads | 1–223 (LoRaWAN) | Vendor-defined mapping for measurement frames. |

| Payload size | Effective payload per message | Commonly 1–20 bytes (vendor-specific) | Larger payloads increase airtime. |

| Uplink frequency | How often the meter sends data | 15 min to 24 h (typical for Class A) | Event-based or periodic; ADR/LinkCheck optimize. |

| Airtime | Time on air per uplink | Depends on SF, payload, bandwidth | Longer airtime increases energy use and interference risk. |

| TX power | Transmit power level | Up to +14 dBm typical; regional maxs differ | Lower TX power reduces interference and battery use. |

| Security | Encryption and integrity | AES-128 end-to-end encryption; NWK/APP session keys | LoRaWAN 1.0.x secure; 1.1 adds enhanced features. |

| Battery life | Typical operating time on primary battery | Up to ~16 years | Highly dependent on join success rate, ADR, confirmed uplinks, and duty cycle. |

| Battery type | Primary battery chemistry | Lithium Thionyl Chloride (Li-SOCl2) typical | Replaceability varies by vendor design. |

| Ingress protection | Environmental sealing | IP67/IP68 (vendor-specific) | Important for outdoor pits and submersion. |

| Enclosure materials | Housing durability | Brass, composite, stainless steel | Impacts corrosion resistance and media compatibility. |

| Metering accuracy | Measurement accuracy class | Typically Class 2 (2%) | Confirm regional standards (e.g., OIML R49, MID). |

| Measurement resolution | Readout units | Liters, gallons | Vendor-defined granularity (e.g., 0.1 L). |

| Event alarms | Low flow, leak, tamper, backflow, high temp | Event-driven uplinks | Some alarms require additional sensors. |

| Reverse flow detection | Direction-sensitive measurement | Optional | Useful for tamper/backflow detection. |

| Temperature range | Operating conditions | Typical: −20 to +60 °C; storage −30 to +70 °C | Verify for local extremes and pit environments. |

| Certifications | Conformity for RF and metering | CE, RED, FCC, IC | Confirm product-specific IDs; not all meters are MID-certified. |

| Installation orientation | Horizontal vs vertical, straight-run requirements | Vendor-specific | Often requires upstream/downstream straight runs (e.g., 5×D/3×D). |

| Interface | Reed, hall sensor, ultrasonic/pulse, M-Bus, Modbus | Vendor-specific | Choose to match current reading/integration approach. |

| Firmware management | OTA updates | LoRa MAC/FW OTA in some vendors | Requires application-level update protocol. |

| Management MAC options | Diagnostics | LinkMargin, ResetInd, etc. | Use with network server to optimize deployment. |

| Local connectivity | On-site service port | NFC/ISO14443; UART/USB | For commissioning, firmware, diagnostics. |

Regional Configuration Notes (US/EU)

- US915

- Uplink channels: 64; Downlink channels: 8

- TX power: limited by FCC Part 15.247; vendor typically defaults within allowed limits

-

Duty cycle: not specified in LoRaWAN; avoid harmful interference

Illustrative Image (Source: Google Search)

-

EU868

- Uplink channels: 3; Downlink channels: 3

- TX power: per ETSI/RED; commonly ≤14 dBm

- Duty cycle: ≤1% per sub-band (enforced by regional regulations)

Interoperability Checklist

- Network server supports your region and LoRaWAN version (1.0.x or 1.1).

- Gateways cover target sites with sufficient uplink/downlink availability.

- Meter uses OTAA (AppEUI/AppKey or JoinEUI) and supports ADR/LinkCheck.

- Payload formats are documented and consistent with application server.

- Join procedures and application ports are aligned across devices and servers.

Trade Terminology and Commercial Practices

| Term | Meaning | Example/Considerations |

|---|---|---|

| MOQ (Minimum Order Quantity) | Minimum quantity per SKU/variant | Example: 500 units. Confirm band and packaging options per batch. |

| Lead time | Time from PO to shipment | Typical: 6–12 weeks for meter-only; longer with customization/peak periods. |

| Customization | Branding, firmware, packaging, labeling | Request NDA before sharing designs. Confirm data logging and MAC options. |

| OEM/ODM | Manufacturer produces to your spec (OEM) or designs (ODM) | Evaluate LoRaWAN version, RF bands, payload schema, and enclosure materials. |

| Packaging | Unit and bulk packing standards | Vendor default: individual carton; bulk pallet; protective inserts for transit. |

| Incoterms | Delivery responsibility terms | Common: FOB, CIF, DAP; align with logistics partner. |

| Warranty | Coverage against defects | Typically 24–36 months (verify water tightness and electronics). |

| Calibration | Measurement accuracy checks | Often aligned to OIML R49/MID; vendor may offer traceable calibration certificates. |

| Spare parts | Replacement components | Battery pack, reed/hall module, gasket, connector. |

| Compliance documents | RF and safety/EMC declarations | FCC/CE/RED/IC IDs, safety (e.g., EN 60730-1), and RoHS/REACH (EU) upon request. |

| Labeling | Device identification | DevEUI, IMEI/Barcode, certifications; US/EU labeling requirements vary. |

| Documentation | Deployment guides | Payload definitions, commissioning tools, firmware notes, test reports. |

| Sample/PO terms | Trials and orders | Sample orders for field validation; commercial orders with payment terms (Net 30–60 typical). |

| Service plan | Support options | Device/app support, RMA process, firmware patches, regional compliance updates. |

| Logistics | Shipments and customs | Shipping method, HS code (e.g., 9028.20), insurance, and import documentation. |

| Support level | After-sales resources | Helpdesk SLA, OTA update windows, network integration assistance. |

Buying and Integration Questions to Ask Vendors

- What LoRaWAN version and class do the meters use, and what MAC options are supported?

- Which regional bands are supported (US915, EU868), and can units be preconfigured?

- What is the default payload schema (application port, field definitions, units)?

- How is power consumption characterized (profile, airtime, battery capacity, lifetime model)?

- What join mode is supported (OTAA, ABP), and how are keys provisioned ( JoinEUI/AppEUI/AppKey )?

- Do units support ADR, confirmed uplinks, and diagnostic MAC commands (LinkCheck, DevStatus)?

- What are ingress protection, operating temperature range, and enclosure materials?

- What compliance documents are provided (FCC, CE/RED, IC, safety, MID/OIML where applicable)?

- What are MOQ, lead time, warranty terms, packaging options, and available Incoterms?

- What is the OTA firmware support, and how are updates managed?

- Do alarms and events exist (low flow, leak, tamper, reverse flow), and how are they reported?

- Are mounting requirements documented (orientation, straight-run lengths, thread sizes)?

Quick Examples

- Confirmed uplinks use extra airtime; if a meter uplinks every 15 minutes with frequent ACKs, expect shorter battery life than one uplinks every 24 hours without ACKs.

- ADR adjusts a closer meter from SF12 to SF7, reducing airtime and battery use while keeping link reliability with higher TX power and smaller payloads.

- In the EU, duty cycle limits mean large networks benefit from ADR and optimized payload sizes to avoid hitting ≤1% constraints.

This section focuses on the technical properties and trade terms that matter for US/EU buyers and integrators planning LoRaWAN smart water metering deployments.

Navigating Market Dynamics and Sourcing Trends in the lorawan water meter Sector

Navigating Market Dynamics and Sourcing Trends in the LoRaWAN Water Meter Sector

Market Evolution and Historical Context

LoRaWAN water metering emerged from the broader LPWAN (Low-Power Wide-Area Network) movement that gained traction in the mid-2010s. The technology addressed critical gaps in traditional AMR/AMI systems—particularly the need for cost-effective, long-range communication without reliance on cellular infrastructure.

| Era | Development Phase |

|---|---|

| 2015-2017 | Early adoption; pilot programs in European utilities |

| 2018-2020 | Standardization; LoRa Alliance expansion; US market entry |

| 2021-Present | Mass deployment; integration with smart city infrastructure |

Current Market Dynamics

Key Drivers:

– Regulatory pressure for water conservation (EU Water Framework Directive, US EPA standards)

– Aging infrastructure requiring non-invasive monitoring solutions

– Operational cost reduction through remote meter reading

– Battery longevity (up to 16 years) reducing total cost of ownership

Illustrative Image (Source: Google Search)

Regional Considerations:

| Factor | USA | Europe |

|---|---|---|

| Network Coverage | Expanding; utility-led deployments | Mature; public/private networks available |

| Frequency Band | 915 MHz (ISM) | 868 MHz (ISM) |

| Procurement Model | Direct vendor or distributor | Utility consortiums common |

Sourcing Trends

Vendor Selection Criteria:

– Interoperability with existing network infrastructure

– Certification (LoRa Alliance compliance, regional certifications)

– Data security standards (end-to-end encryption capability)

– Scalability for deployments supporting thousands of endpoints

Procurement Shifts:

– Move from hardware-only purchases to Metering-as-a-Service (MaaS) models

– Increased demand for pre-integrated gateway-meter bundles

– Growing preference for vendors offering network server management

Sustainability Alignment

LoRaWAN water meters directly support ESG objectives:

Illustrative Image (Source: Google Search)

- Resource Conservation: Real-time leak detection reduces non-revenue water losses

- Carbon Footprint: Low-power operation and reduced truck rolls for manual readings

- Longevity: Extended battery life minimizes electronic waste cycles

- Infrastructure Efficiency: Single gateway coverage of 2-5 km (urban) to 15-30 km (rural) reduces hardware density requirements

Strategic Sourcing Recommendations

- Evaluate total network architecture costs, not just per-unit meter pricing

- Confirm vendor roadmap alignment with LoRa Alliance standards evolution

- Assess local gateway infrastructure availability before committing to deployment scale

- Prioritize suppliers with proven interoperability across multi-vendor environments

Frequently Asked Questions (FAQs) for B2B Buyers of lorawan water meter

Frequently Asked Questions (FAQs) for B2B Buyers of LoRaWAN Water Meters

1) What is a LoRaWAN smart water meter?

– A water meter that embeds a LoRaWAN® (Long Range Wide Area Network) radio for secure, long‑range, low‑power data transmission.

– Designed for LPWAN IoT: unlicensed spectrum, low power, wide area coverage, and end‑to‑end security.

– Enables remote monitoring and real‑time data collection for utilities without the buyer needing to operate the network.

2) How does the LoRaWAN technology work?

– Architecture has three layers:

– End nodes: Water meters collect and transmit data.

– Gateways: Bridge devices and the network server over IP (Ethernet, Wi‑Fi, cellular).

– Network server: Central controller that manages communication, processes data, and enforces security, connecting end nodes to applications.

– LoRaWAN provides customizable security and data integrity for the device‑to‑application path.

3) What are the main benefits for utilities?

– Long range: 15–30 km in rural areas; 2–5 km in urban environments.

– Low power consumption: Typically multi‑year operation on small batteries (see specifications).

– Scalability: Networks support tens of thousands of devices.

– Secure transmission: End‑to‑end security from device to application.

4) What performance and energy specs should we expect?

– Typical ranges:

– Rural: 15–30 km

– Urban: 2–5 km

– Battery life: Up to 16 years, depending on configuration, environment, and reporting profile. Consult the device datasheet for exact profile details.

5) What spectrum and compliance considerations apply in the US/EU?

– LoRaWAN operates in unlicensed spectrum, subject to local regulations and power limits.

– Utilities typically leverage carrier/public networks or private LoRaWAN networks where permitted.

– In the US, regional ISM bands such as 915 MHz are used; in the EU, 868 MHz. Always confirm country‑specific rules and gateway/transmit limits before deployment.

6) Which device class should we select and how does it affect battery life?

– LoRaWAN supports different device classes that trade off uplink behavior and energy consumption:

– Class A (default): Bidirectional with lowest power; uplinks only after receive windows; very long battery life.

– Class B: Adds scheduled receive windows for downlink responsiveness; moderate power.

– Class C: Continuously open receive window; best responsiveness; highest power.

– Summary:

– Want longest life and minimal complexity → Class A

– Need periodic downlinks while preserving battery → Class B

– Require constant two‑way comms, accept higher power → Class C

7) How is data security handled in LoRaWAN?

– End‑to‑end security: Data is encrypted between the device and the application layer.

– The network server manages keys and session integrity; gateways forward encrypted packets without handling application data.

8) Do we need a private network or can we use a public network?

– LoRaWAN supports both approaches. You can use a public carrier network (where available) or deploy private infrastructure.

– Utilities can expand and diversify deployments across covered areas without managing the underlying LPWAN.

Strategic Sourcing Conclusion and Outlook for lorawan water meter

Strategic Sourcing Conclusion and Outlook for LoRaWAN Water Meters

LoRaWAN delivers the right mix of long-range coverage, low power, scalability, and end‑to‑end security for smart water metering across the USA and Europe. It reaches 2–5 km in urban and 15–30 km in rural areas, scales to tens of thousands of endpoints, and keeps devices running on small batteries for up to 16 years. End nodes, gateways, and a centralized network server architecture simplify scale and reduce complexity, enabling remote monitoring, real-time data, and better network management.

Value realized

– Faster field deployments with reduced infrastructure

– Lower operational costs through low power and remote operation

– High reliability and multi‑vendor interoperability via standard devices and gateways

– Secure data transmission from device to application

– Global availability in unlicensed spectrum (no licensed fees)

| Core value driver | LoRaWAN capability | Business impact |

|---|---|---|

| Range | 2–5 km urban; 15–30 km rural | Fewer gateways; broader coverage |

| Battery life | Up to 16 years | Lower maintenance; fewer site visits |

| Scalability | Tens of thousands of devices | Citywide rollouts without re‑architecture |

| Security | End‑to‑end encryption | Compliance with regional standards |

| CAPEX/OPEX | Minimal spectrum fees; remote management | Lower TCO; predictable unit costs |

Strategic sourcing criteria

– Vendor ecosystem and certifications (e.g., LoRa Alliance)

– Device and gateway interoperability; network server

– Performance SLAs (uptime, latency, DR strategy)

– Roaming/MVNO options; coverage maps

– Cybersecurity posture; data ownership and data retention

– Regional support and compliance; TCO over 10–15 years

– Deployment model flexibility: private network, carrier, or managed service

Outlook

Unlicensed LPWAN adoption will continue to accelerate. Buyers should standardize on LoRaWAN, lock in interoperability requirements, leverage carriers’ managed LoRaWAN where coverage is proven, and keep networks private where coverage is self‑owned. The strongest commercial outcomes will come from clear SLAs, multi‑year service contracts with predictable per‑device pricing, and disciplined supply chain strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.