About LORI Thermal

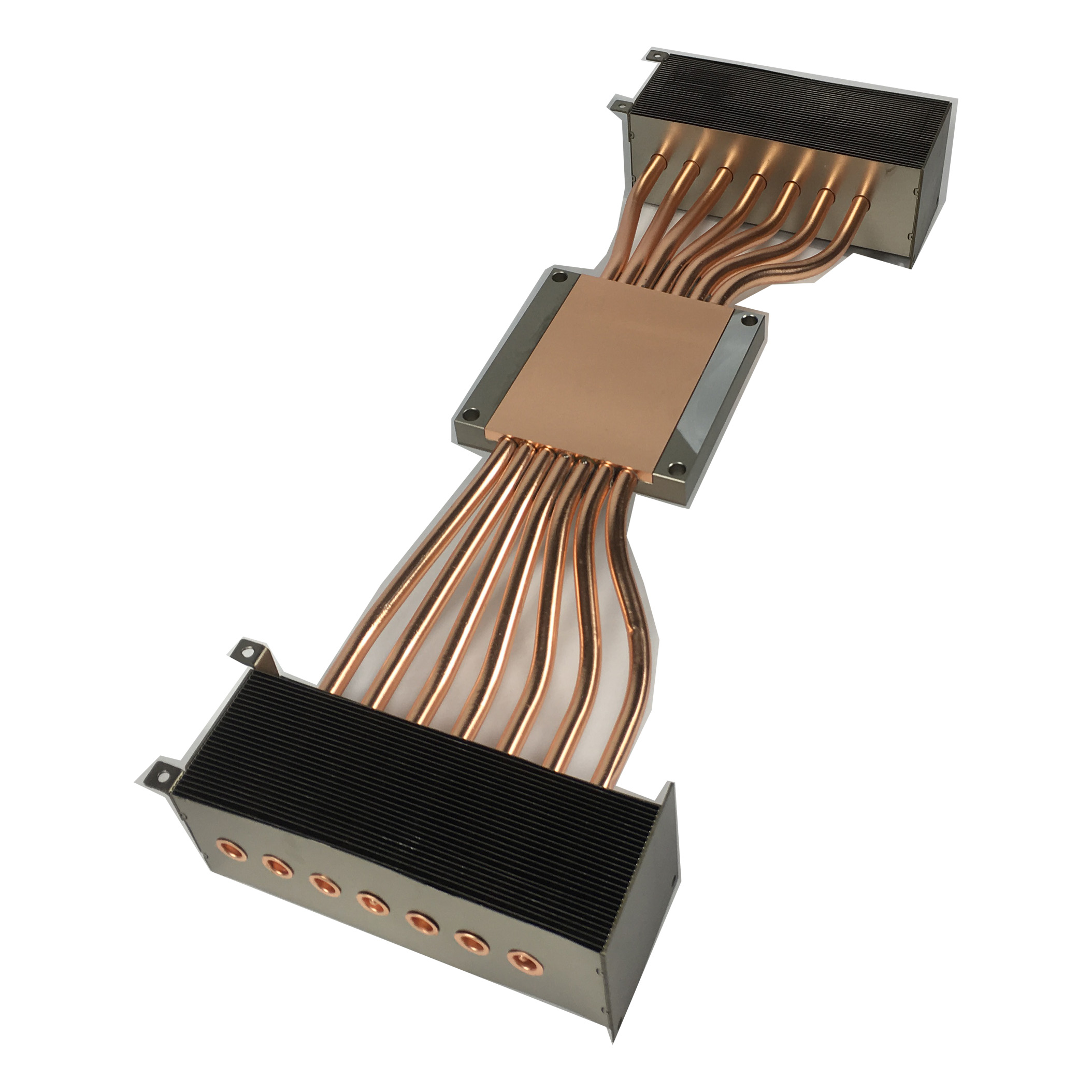

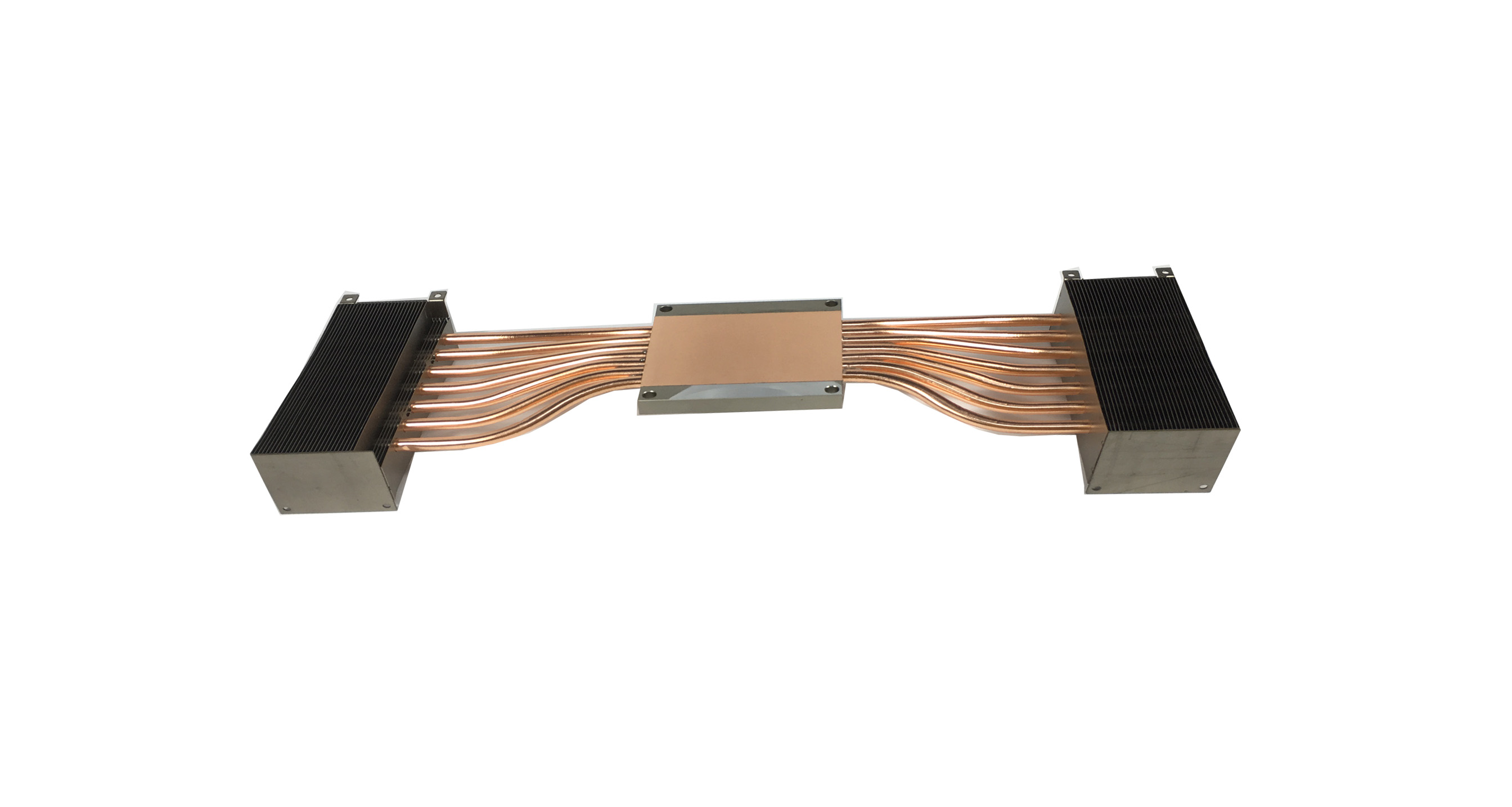

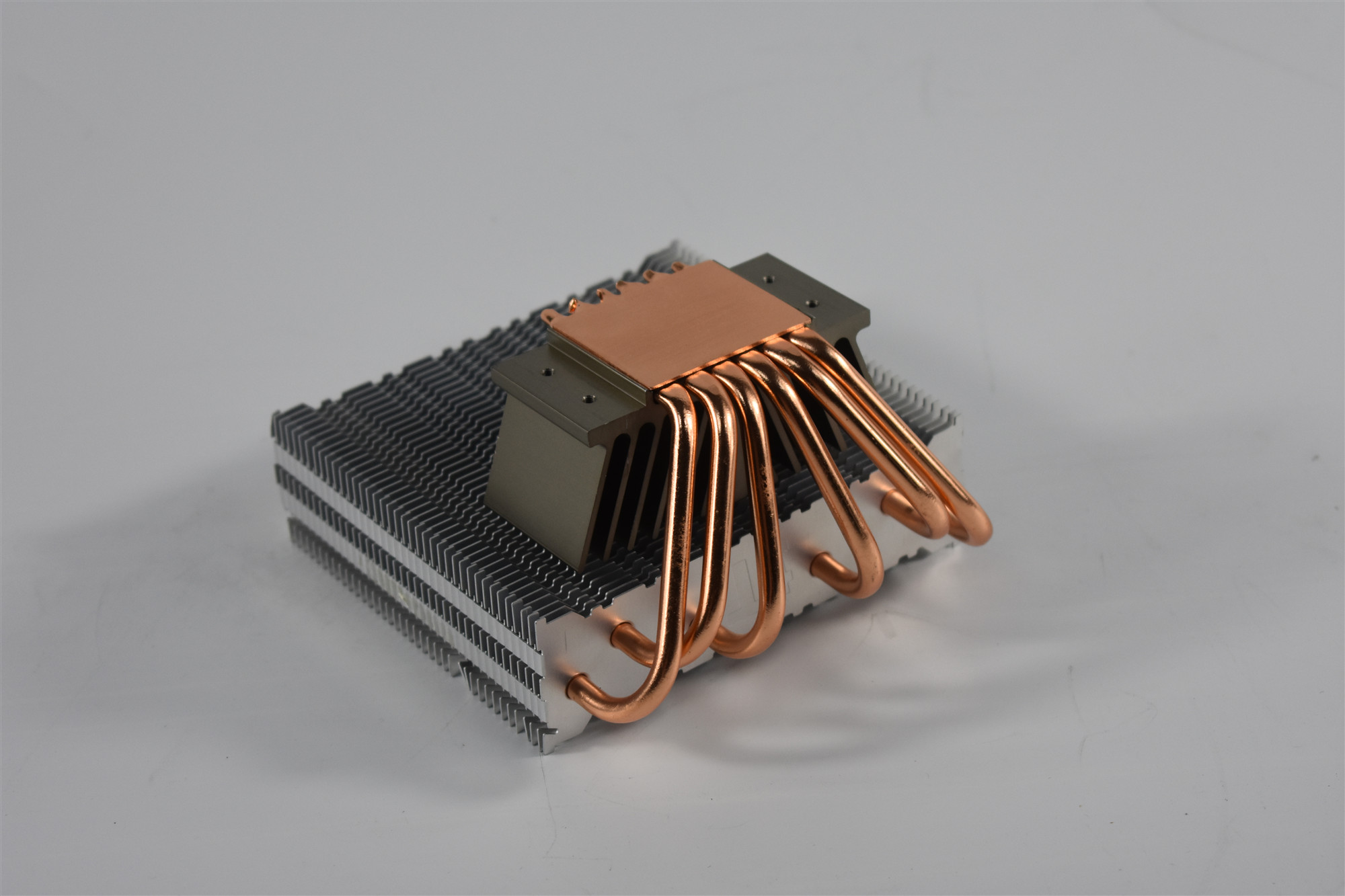

LORI is a professional high-power cooling solution service provider and custom heat sink manufacturer with years of experience in thermal design, simulation, prototyping, and mass production.

We specialize in delivering optimized thermal performance across industries such as new energy vehicles, renewable energy, data centers, medical equipment, and industrial automation.