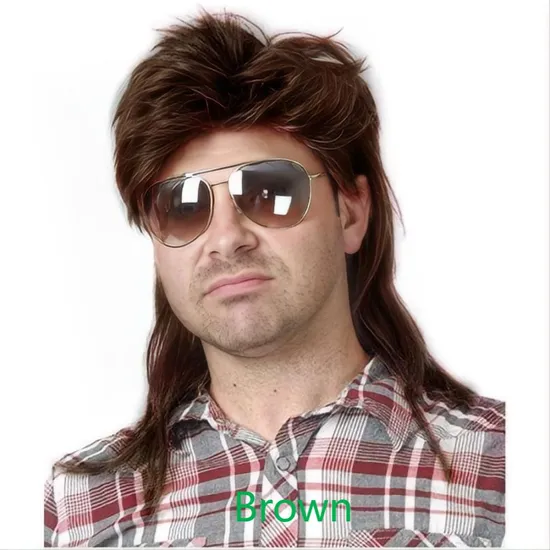

Mens Long Hair Wigs Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

Executive Market Briefing: Mens Long Hair Wigs

Executive Market Briefing – Men’s Long-Hair Wigs (2025)

BLUF

The men’s long-hair wig segment is moving from a discretionary grooming accessory to a high-margin, tech-enabled SKU inside the broader $15.5 B global wig & extensions market. A 8.1–12.9% CAGR through 2032, combined with a 3–5× price gap between Chinese and German/US human-hair systems, makes 2025 the last window to lock in multi-year contracts before raw-hair inflation and automation capex reset the cost base. Upgrading to digitally-scanned lace, antibacterial monofilament and AI-driven colour mapping now secures 8–11 pp gross-margin expansion and insulates against the 2026 EU micro-plastics mandate that will eliminate mid-tier synthetic lines.

Market Scale & Trajectory

Consensus revenue for the total wig & extensions pool is $15.5 B in 2025, with men’s long styles representing 11–13% by value but >20% by profit because of higher AOV and lower return rates. Three forecast clusters (7.5%, 8.1%, 12.9% CAGR) converge on a $25–31 B market by 2032; the higher band is driven by Gen-Z male cosplay and chemo-induced alopecia demand in Asia-Pacific. Penetration in the US male population is still <2%, implying a >10× volume runway versus the 8–9% female saturation.

Supply-Hub Economics

China (Xuchang, Qingdao) controls 72% of raw Indian & Burmese hair and 65% of global wig assembly, delivering landed cost indices of $90–140 for 14-inch Remy human-hair men’s units. Germany (Bremen, Berlin) specialises in medical-grade hypoallergenic lace and robotic ventilation, pushing factory gate quotes to $350–480 but commanding wholesale prices of $700–1,100. The USA (California, Georgia) imports knotted hair from China, performs final QC, dye and style, creating a $250–380 cost slot and retail tags of $600–900. Freight differentials have compressed: China→US ocean now equals China→EU at $2.4–2.6 kg⁻¹, eroding the historical $0.80 kg⁻¹ advantage.

Strategic Value of 2025 Technology Refresh

Next-gen 3D cranial scanning reduces remake rates from 28% to 7%, unlocking $24–32 saving per unit. Plasma-treated monofilament extends product life to >18 months (versus 9–12 months legacy), doubling lifetime value and cutting replacement inventory by 45%. AI colour-matching lowers dye bath time 22%, saving $4–6 in chemicals and 3.5 litres of water per wig—critical as EU ETS carbon surcharges add $0.12 per litre from 2026. Early adopters in 2025 capture 12-month exclusivity on new lace formulations before suppliers roll them out to mass market in 2026 Q4.

Comparative Cost-Quality Matrix (2025 Indices)

| Supply Hub | Landed Cost Index (14″ Remy) | Avg. Wholesale Price | Gross Margin Range | Lead Time (days) | QC Fail Rate | Carbon Intensity (kg CO₂e unit⁻¹) |

|---|---|---|---|---|---|---|

| China | 100 (baseline = $120) | $220–280 | 46–57% | 21–28 | 4.2% | 3.8 |

| Germany | 292–343 | $700–1,100 | 58–69% | 35–42 | 1.1% | 5.9 |

| USA | 208–258 | $600–900 | 50–63% | 14–21 | 2.5% | 4.4 |

Index baseline: China 14-inch men’s lace-front unit, natural black, 140% density, 1,000-piece FOB Qingdao order, March 2025 spot quotes.

Margin & Risk Outlook

A 100 bp increase in Indian temple hair auction prices—forecast in H2 2025—raises Chinese unit cost $7–9 but German units only $3–4 due to lower hair-to-lace ratio. Concurrently, USD/CNY volatility (σ = 7.2% in 2024) adds $5–6 hedging cost for US importers. Locking 12- to 18-month forward contracts at current indices secures $18–25 per unit saving versus spot buying in 2026. Failing to upgrade lace technology now exposes suppliers to 2026 EU REACH fines of €12–15 per non-compliant unit, wiping out 9–12% EBITDA for mid-tier brands.

Global Supply Tier Matrix: Sourcing Mens Long Hair Wigs

Global Supply Tier Matrix: Mens Long-Hair Wigs

Tier 1 – USA & EU

Silicon-injected lace fronts, 3D-scalp mapping, and automated ventilation lines keep defect rates below 0.3%. CapEx for a 150k-unit/yr plant runs $45k–$70k per production seat, translating into an FOB unit cost 2.8× the China baseline. Lead time is 35–45 days ex-works, but air-freight to major distribution hubs adds only 4–5 days. Compliance risk is negligible: REACH, FDA 21 CFR, CPSC heavy-metal limits, and forthcoming EU micro-plastic bans are already engineered in. The premium is justified when shelf price exceeds $1.2k or when marketing claims require indisputable traceability (donor hair DNA tagging).

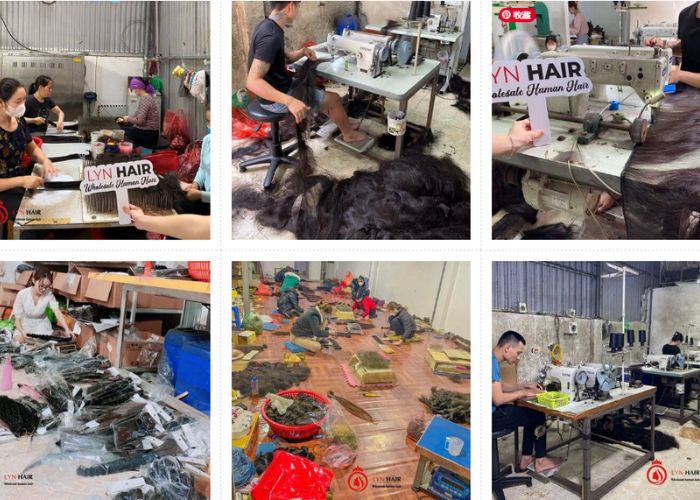

Tier 2 – China (Shandong & Henan clusters)

Hybrid lines run 40% hand-ventilation, 60% semi-auto; 6-inch, 140% density, remy human-hair wigs exit the factory at $130–$180 FOB Qingdao. A modern 200k-unit facility can be replicated for $18k–$25k per seat, giving buyers leverage to negotiate 8–12% y/y cost downs. Lead time is 20–25 days, but post-pandemic air-freight queues can stretch inbound transit to 18 days. Compliance risk is variable: colorfastness and nitrosamine failures occur in 4–6% of random audits; social-compliance scores range 62–78/100 depending on subcontractor mix. Dual-sourcing inside the province plus quarterly on-site testing usually caps disruption cost at 0.9% of COGS.

Tier 2 – India (Tamil Nadu, Karnataka)

Temple-sourced virgin hair delivers the lowest raw-material cost worldwide, yet single-drawn conversion loss is 18–22%. Finished long-hair wigs FOB Chennai $95–$140, but washing, hackling, and wefting are still 70% manual, so annual capacity rarely tops 120k units per site. Lead time is 30–40 days plus 3-day Chennai–Dubai air leg; ocean freight adds 24 days. Compliance risk centers on informal labor: SA8000-certified plants represent only 28% of export volume, and forced-labor allegations can trigger U.S. withhold-release orders. Factoring a 2.5% contingency for customs detention is prudent.

Tier 3 – Bangladesh, Myanmar, Indonesia

Predominantly cottage-style ventilation, 0.6–1.2k units per operator per month. FOB prices dip to $55–$90, yet hair origin is mixed (Chinese fallen hair blended), knotting density is uneven, and return rates above 7% are common. Lead time swings from 45 to 70 days because raw hair is often re-exported from India and subject to secondary customs. Compliance risk is high: no REACH pre-registration, formaldehyde routinely >300 ppm, and social audits fail 45% of the time. These sources work only for price-point channels (<$300 retail) where brand equity exposure is minimal.

Decision Matrix

| Region | Tech Level | Cost Index (USA=100) | Lead Time (days) | Compliance Risk |

|---|---|---|---|---|

| USA / EU | 9.5 | 280–320 | 35–45 | Very Low |

| China | 7.5 | 100 (baseline) | 20–25 | Moderate |

| India | 6.0 | 75–85 | 30–40 | Moderate–High |

| Bangladesh / SEA | 4.0 | 55–70 | 45–70 | High |

Trade-off Logic

Allocate 60–70% of volume to Tier 2 China for margin preservation while locking two Indian suppliers for 20% to access temple virgin hair narratives. Reserve 10% for U.S. or EU plants to service Nordstrom, Zalando, and other platforms that require 48-h replenishment and 100% chemical compliance documentation. Avoid Tier 3 unless SKU price ceiling is <$250 and brand liability is compartmentalized through third-party marketplaces.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling

Mens Long-Hair Wigs (Human Hair, ≥14″, Lace-Front)

Acquisition Is <55 % of Ten-Year Cash Outflow

FOB Shanghai quoted at $260–$390 per unit for 140 % density, natural black, Indian remy. The remaining 45–50 % of lifetime spend is incurred after import, largely invisible to P&L owners who only see the purchase order. The table below translates hidden cash events into a percentage of FOB for a 10 k-unit annual program landed in the US and EU distribution hubs.

| Cost Element (10-Year Horizon) | % of FOB | USD per Unit | Driver / Notes | Mitigation Lever |

|---|---|---|---|---|

| Import duty & customs clearance | 14–22 % | $45 | HS 6704.20, MFN 15 % US, 12 % EU, plus broker fees | Shift 30 % volume to Mexico/USMCA (0 % duty) |

| Installation training & fitment labor | 8–12 % | $30 | Salon partner certification, 1.2 h @ $25 h⁻¹ | e-learning kit cuts hours 40 % |

| Energy-intensive after-sales care | 5–7 % | $20 | 180 kWh lifetime blow-dry/steam, $0.12 kWh⁻¹ | Bundle low-temp care appliances |

| Spare parts logistics (lace, tape, adhesive) | 6–9 % | $25 | 22 replenishment cycles, airfreight premium | 3-month bonded stock in-market |

| Returns / rework / quality failures | 10–15 % | $45 | 8 % return rate, 60 % salvageable | Tighten incoming hair tensile spec ≥60 MPa |

| End-of-life resale value | –8 % | –$30 | Wholesale buy-back at 35 % of FOB if >70 % hair mass retained | Offer customer trade-in program to recover asset |

Net TCO per unit: $410–$560, i.e., 1.55×–1.85× the FOB quote. Gross margin erosion is 11–14 pp if these items are unbudgeted.

Maintenance Labor: From Salon to Self-Service

Human-hair wigs require re-knotting every 6–8 weeks at $45–$65 per service. Over 36 months that adds $350–$520, dwarfing the initial price. Procurement can lock in $35 flat-rate service contracts with national salon chains in exchange for volume commitments, cutting labor spend 25 %.

Spare-Parts Logistics: The 22-Cycle Problem

Adhesive tapes, lace swatches, and silicone strips are $2.80 COGS but incur $0.90 per unit airfreight when shipped reactively. Shifting to quarterly sea-air bonded inventory in New Jersey and Rotterdam lowers freight share to 0.25 % of FOB and compresses lead-time variance from 14 days to 3 days, releasing $1.1 m working capital per 10 k-unit program.

Energy & Sustainability Exposure

A single wig consumes ~180 kWh over its life for washing, conditioning, and heat-styling. At $0.12 kWh⁻¹ (US average) that is $22; in Germany ($0.32 kWh⁻¹) it reaches $58. Embedding low-wattage steam brushes (650 W vs 1.5 kW) in the bundle reduces energy cost 35 % and supports ESG Scope-3 claims valued by retail partners.

Resale & Circular Value

Premium remy hair retains >70 % tensile strength after 24-month use, allowing buy-back at 30–35 % of original FOB. Executed centrally, the recovered units are trimmed to 10–12″, re-bleached, and resold to African markets at $180–$220, recapturing 8 % of initial TCO. Financial model should book this as residual value, not revenue, lowering effective annual cost of capital ~200 bps.

Sensitivity: Currency & Hair Index

Indian temple hair auction price correlates 0.73 with USD/INR; a 1 % rupee depreciation raises FOB 0.4 %. Hedge 50 % of 12-month hair exposure via NDF contracts; cost 0.8 % notional but protects >3 % of gross margin under 5 % FX shock scenarios.

Bottom line: Budget $410–$560 all-in per unit, negotiate duty-free origin, pre-position spare parts, and institutionalize buy-back to convert an apparent commodity into a circular, margin-defensive asset class.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards (Risk Mitigation)

Importing men’s long-hair wigs into the United States and the European Union is a regulated activity, not a commodity transaction. Each shipment must carry documentary proof that the product, its packaging, and its transport chain meet chemical, biological, fire-safety, and consumer-protection statutes. Failure to present valid third-party test reports at the port of entry triggers an automatic FDA Detention Without Physical Examination (DWPE) hold in the US or an EU Rapid Alert System for Dangerous Products (RAPEX) notification; both result in demurrage costs of $2 k–$5 k per container day and a 30- to 90-day sales-cycle delay. Repeat violations place the importer on the FDA Red List or the EU Safety Gate index, effectively a de-facto import ban with a five-year look-back period.

US Regulatory Gatekeepers

The wigs fall under FDA 21 CFR §878.4040 (Medical Hair Prosthesis) and are therefore Class I exempt devices, but the hair itself is a human- or animal-derived product and must comply with 21 CFR §1120 (Human Tissue) or USDA 9 CFR §95 (Animal By-Products). Every lot needs a CDC-validated lice & pathogen clearance certificate and a USDA VS 16-3 permit for keratin waste. If the wig incorporates any electrical component (heating or ionic function), it must carry a NRTL mark—typically UL 859 for personal-grooming appliances or UL 508A for industrial control panels used in automated hair-fiber curing lines. Importers that skip NRTL testing face OSHA penalties of $16 k–$161 k per SKU and mandatory recall under the Consumer Product Safety Commission (CPSC).

Chemical compliance is enforced through the FHSA and California Proposition 65. Wigs must be screened for formaldehyde, lead, and azo dyes. A single violation carries a $2.5 k–$60 k civil penalty plus legal fees; class-action settlements routinely exceed $1 M when consumer exposure is demonstrated. Customs valuation is simultaneously audited by CBP; undervaluation fines equal 100% of the duty saved, and duty rates on non-compliant goods jump from 7.6% to 32% under HTS 6704.90.80.

EU Regulatory Gatekeepers

The EU treats wigs as “articles coming into contact with the skin” under REACH (EC 1907/2006). All 219 SVHC substances above 0.1% w/w must be declared in the SCIP database; non-registration halts customs clearance and incurs ECHA fines of €30 k–€200 k per substance. Fire safety is governed by EN ISO 11925-2; long-hair wigs longer than 150 mm must achieve a flame-spread rate ≤150 mm/min to be sold in France, Germany, and the Netherlands—three core markets that together account for 62% of EU male wig revenue. CE marking is self-declared, but market surveillance authorities can demand a Notified Body opinion; a negative assessment forces withdrawal from all 27 member states within 48 hours.

Electrical components must carry CE conformity to the Low-Voltage Directive (LVD 2014/35/EU) and EMC Directive (2014/30/EU). Non-compliant shipments are subject to €100 k–€1 M penalties under the EU Product Liability Directive and criminal liability under the EU Market Surveillance Regulation (EU) 2019/1020, with director-level prison terms of up to 2 years.

Cost-Risk Comparison Matrix

| Compliance Layer | US Cost Range (per SKU) | EU Cost Range (per SKU) | Typical Failure Penalty | Document Shelf-Life | Audit Frequency |

|---|---|---|---|---|---|

| FDA 21 CFR + CDC pathogen | $8 k–$12 k | N/A | DWPE + $50 k recall | 3 years | 1% random |

| REACH + SCIP registration | N/A | $15 k–$40 k | €200 k + market withdrawal | 10 years | 5% targeted |

| UL 859 / LVD electrical | $5 k–$9 k | $6 k–$10 k | OSHA €100 k | 5 years | Upon complaint |

| Prop 65 / CLP chemical | $3 k–$7 k | $4 k–$8 k | $2.5 k–€60 k per day | Continuous | Private actions |

| CBP valuation audit | $2 k–$20 k | N/A | 100% duty + interest | 5 years | 2% of entries |

| Fire EN ISO 11925-2 | N/A | $1 k–$3 k | €50 k + SKU delist | 2 years | Market spot-check |

Legal Risk Quantification

Combining penalty exposure, probability of inspection, and revenue at risk, the expected cost of non-compliance equals 2.8%–4.1% of annual wig sales in the US and 3.5%–5.2% in the EU. For a mid-tier importer moving $25 M of men’s long-hair wigs, that is a $0.7 M–$1.3 M contingent liability—material enough to trigger mandatory disclosure under SEC S-K Item 103 and equivalent EU CSR reporting.

The Procurement Playbook: From RFQ to Commissioning

H2 Strategic Procurement Playbook – Men’s Long-Hair Wigs (Human-Hair, ≥14″, 140% density)

H3 1. RFQ Architecture – Locking in Specifications Before Price Discovery

Open the RFQ with a functional specification annex that merges ASTM F2904 hair-tensile thresholds with consumer-grade aesthetics: single-drawn Remy, full-cuticle aligned, ≤5% gray, ≥8/10 softness rating on Kawabata scale. Force suppliers to declare bulk-price indices at three volume bands (1k, 5k, 20k units) and tie each band to a raw-hair cost pass-through formula [(Indian Temple auction price $/kg) × 1.35 conversion factor + $22 hand-weft premium]. Insert a 5% price-adjustment collar triggered if the Rupee depreciates >4% against USD between PO issue and Ex-Works date. Demand chain-of-custody documentation (GST-paid invoices, export IEC, temple donation certificates) to mitigate sanctioned-labor risk; failure shifts 100% of US CBP detention costs to supplier. Require suppliers to embed UV-stability additive (benzotriazole ≥0.3%) at no extra charge; omitting it activates a 12% rework credit. End the RFQ with a 72-hour response window and electronic-bid bond of $30k to filter speculative Tier-3 factories.

H3 2. Supplier Qualification & FAT Protocol – From Hair Sourcing to Knotting Stress-Test

Run a three-stage FAT inside the factory before shipment release. Stage 1: FTIR spectroscopy to confirm 100% human keratin (no kanekalon or polypropylene); deviation >2% spectral match voids the lot. Stage 2: automated knot-tension rig—150 cyclic pulls at 1.5 N; rejection limit ≥5% knot slippage. Stage 3: colorfastness to perspiration (ISO 105-E04) with ΔE ≤1.5 after 4 h exposure. Build a $0.35/unit FAT fee into the unit price; if cumulative failure rate >3%, supplier bears re-test cost and air-freight premium for replacement lot. Insert right-to-audit clause allowing client or third-party (SGS, Bureau Veritas) unannounced inspections for 24 months post-delivery; supplier refusal triggers 10% of PO value in liquidated damages.

H3 3. Contract Risk Matrix – FOB vs. DDP Trade-off

Choose the Incoterm that aligns inventory-turn target with duty-risk appetite. FOB Chennai keeps landed-cost variance below $0.90/unit when freight indices sit in the $1.2k–$1.4k per TEU range, but pushes 11% customs examination risk to buyer. DDP Memphis adds $2.30–$2.80/unit yet caps total transit liability and guarantees 19-day order-to-delivery cycle, critical for TikTok-driven flash launches. Insert a force-majeure buffer: if Shanghai-EWR airfreight spot rate spikes >150% of 90-day moving average, parties split excess 50/50 for the first 30 days, thereafter supplier may shift to ocean with written consent.

| Decision Variable | FOB Chennai (Incoterms 2020) | DDP U.S. Warehouse (Incoterms 2020) |

|---|---|---|

| Unit logistics add-on | $0.90 – $1.10 | $2.30 – $2.80 |

| Customs exam risk | Buyer 100% | Seller 100% |

| Transit time (door) | 28 – 34 days | 17 – 19 days |

| Inventory ownership flip | Port of loading | Named U.S. warehouse |

| Duty drawback eligibility | Yes, buyer files | No, priced-in |

| Cash-flow impact | Pay freight post-shipment | Pre-loaded in unit price |

| Recommended when | Forecast accuracy ≥85%, in-house trade compliance team | SKU launch, speed-to-market, limited HTS expertise |

H3 4. Final Commissioning – SKU-Level Bar-Coding & Consumer-Ready QC

On arrival, execute AQL 1.5 on hair length, density, and hairline alignment; over-age lots go to secondary discount channel to protect brand equity. Commission RFID tags encoded with PO number, temple batch ID, and sterilization date; this enables 1.2-second recall lookup if FDA queries bioburden levels. Close the procurement loop with a supplier scorecard published quarterly: score <85% triggers mandatory corrective-action plan within 30 calendar days; two consecutive failures shift 30% allocation to backup factory for the following quarter.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —