Metallic Silver Car Paint Colors: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Metallic Silver Car Paint Colors

Metallic silver remains the most versatile neutral in automotive color strategy—balancing premium perception with durability and repairability. For distributors, jobbers, collision centers, fleet managers, and refinishers in the USA and Europe, the category is sizable but technically demanding. Buyers must reconcile finish consistency with color-matching across brands, flake-size variability, and regional compliance.

- Demand drivers

- USA: high collision volume, rental fleets, and premium segments favor fast-mix metallic systems and reliable color libraries.

-

Europe: premium OEM look, strong aftermarket focus on flake depth/orientation, and strict VOC/REACH compliance across brands.

-

Pain points

- Cross-brand color variance in metallics; undertone differences; metamerism under varied lighting.

- Flake size/orientation and film build interplay; tone and coverage variability with applicator techniques.

- Repairability and color lookup consistency (fleet, insurer standards, and digital matching workflows).

This guide simplifies selection and procurement by providing:

– B2B landscape overview by segment (refinish, fleet, OEM/aftermarket) in the USA vs. Europe

– Metallic silver system criteria (flake size, base/clears, effect control)

– Practical evaluation and testing (light booth, spray cards, panel integration)

– Distribution and procurement strategies (e.g., House of Kolor Silver Shades, aerosols, OEM color libraries)

– Compliance and process considerations (VOC/REACH, cross-coat compatibility, application standards)

A clear framework for metallic silver procurement reduces rework, accelerates cycle times, and secures margin—without sacrificing the premium visual standards your customers expect.

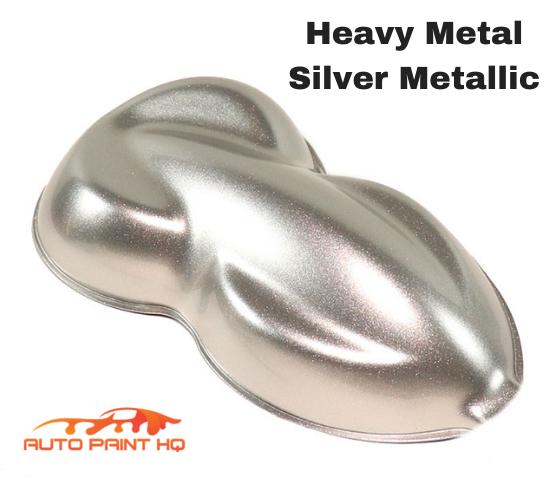

Illustrative Image (Source: Google Search)

Top 10 Metallic Silver Car Paint Colors Manufacturers & Suppliers List

1. House of Kolor Silver Shades – 66 Auto Color

Domain: 66autocolor.com

Registered: 2009 (16 years)

Introduction: 6-day delivery 30-day returnsHouse of Kolor Custom Auto Paint is known worldwide for its quality and sophisticated, classic range of custom colors. Pick your favorite silver color now!…

2. House of Kolor- the Official Site for House of Kolor Custom Finishes …

Domain: houseofkolor.com

Registered: 1997 (28 years)

Introduction: The official site for House of Kolor home of premium custom finishes since 1956, a division of Valspar Corporation, a worldwide leader in the coatings ……

3. Automotive Finishes – Sherwin-Williams Industrial Coatings

Domain: industrial.sherwin-williams.com

Registered: 1998 (27 years)

Introduction: Sherwin-Williams Automotive Finishes is the leading manufacturer and distributer of high-quality paint and coating systems for automotive and fleet ……

4. Automotive Paint Colors – Eastwood

5. Automotive OEM Coatings, OEM Paint Systems & Color Leaders

Domain: ppg.com

Registered: 1990 (35 years)

Introduction: PPG Automotive OEM Coatings is a global leader in high-performance auto paints and technologies including powder primers, clearcoats, and color leadership….

6. Custom Paint Pigment | Chameleon Paint | Pearl Paint | Candy

Domain: paintwithpearl.com

Registered: 2004 (21 years)

Introduction: Why Choose Us? Over 14 years of expertise in pearl paint, candy paint, and metal flake. Trusted provider in the coatings and car paint industry….

7. Looking for incredible “silver” paint – Corvette Forum

Domain: corvetteforum.com

Registered: 1999 (26 years)

Introduction: Mercedes Benz 744 Silver is the best. It is a brilliant silver. I have used it on a couple of my Corvettes and it pops like no other….

Understanding metallic silver car paint colors Types and Variations

Understanding metallic silver car paint colors: Types and Variations

Metallic silver families in professional bodyshop programs are defined by flake system, color medium, and binder chemistry. The table below summarizes the primary types and where they fit. Examples and families referenced are consistent with House of Kolor Silver Shades.

| Type | Features | Applications | Pros / Cons |

|---|---|---|---|

| Basecoat Metallic Silver (BC) | Medium flake aluminum; 1K or 2K BC variants; typically requires clearcoat; color families labeled “Silver Shades” | OEM color matching, production panels, base for graphics | + Broad compatibility; + strong metallic orientation; – requires clearcoat; – lower brightness than aluminum/flake systems |

| Aluminum Flake Metallic Silver (via BC + flake or dedicated metallics) | Extra-coarse aluminum flake geometry; “bright” metallic character | Custom work, show cars, high-contrast panels | + Very bright; + dramatic sparkle; – heavy texture; – requires careful blending/technique |

| Pearl Metallic Silver (PBC) | Aluminum flake plus clear or colored pearlescent pigments; three-stage (base/pearl/clear) | Premium finishes; depth-driven metallic effects | + High depth and flop; – more steps; – critical mixing and timing |

| Kandy Silver (KBC) | Transparent silver kandy concentrates over bright silver base; deep, translucent metallic | Accent panels, stripes, kandy graphics | + Extreme clarity and depth; – multi-stage process; – sensitive to undercoat uniformity |

| Silver Shades families (House of Kolor) | Pre-formulated metallic/paint family across BC, PBC, KBC; flake size and carrier vary by SKU | Bodyshop stock lines, batch-to-batch consistency | + Simplified ordering and batching; – specific to manufacturer’s formulation logic |

Basecoat Metallic Silver (BC)

- Features: Medium flake aluminum orientation; labeled “Silver Shades” across BC families; 1K/2K options; clearcoat required for durability.

- Applications: OEM replacement, production repair, custom basework.

- Pros/Cons: Versatile and compatible with most systems; limited brightness versus dedicated aluminum or kandy stacks.

Aluminum Flake Metallic Silver (via BC + flake or dedicated metallics)

- Features: Extra-coarse aluminum flake; bright “metallic” look with defined sparkle.

- Applications: Show cars, accent sections, customers seeking high chroma metallic effects.

- Pros/Cons: High visual impact; heavier texture; demands superior spray technique and blending control.

Pearl Metallic Silver (PBC)

- Features: Aluminum flake plus pearlescent medium; three-stage application (base/pearl/clear).

- Applications: Premium OEM+ refinishing; depth-oriented metallic finishes.

- Pros/Cons: Adds depth and color travel; increases process steps and timing sensitivity.

Kandy Silver (KBC)

- Features: Transparent silver kandy concentrates applied over bright silver base; translucent metallic with glass-like clarity.

- Applications: Kandy graphics, layered effects, accent work.

- Pros/Cons: Exceptional depth and sparkle; multi-stage complexity and strict undercoat control needed.

Silver Shades families (House of Kolor)

- Features: Pre-grouped metallic variants across BC, PBC, KBC families; flake size and tone vary by SKU.

- Applications: Bodyshop inventory for consistent batch matching and reduced downtime.

- Pros/Cons: Eases selection and batching; depends on manufacturer’s color logic and current stock.

Practical spray guidance across silver types: standardize gun setup and air cap for consistent flake orientation; mix to manufacturer reducer/activator ratios; confirm flash and re-coat windows; always seal with the recommended clearcoat. Verify local VOC and regulatory compliance, and use appropriate PPE.

Key Industrial Applications of metallic silver car paint colors

Key Industrial Applications of Metallic Silver Car Paint Colors

Metallic silver finishes deliver high brightness, strong reflectivity, and excellent edge concealment, making them well suited to applications where visibility, branding, and maintenance efficiency matter. For industrial and fleet operators in the USA and Europe, silver is often the default for service visibility, branding parity across mixed fleets, and lower heat buildup in sun-exposed use.

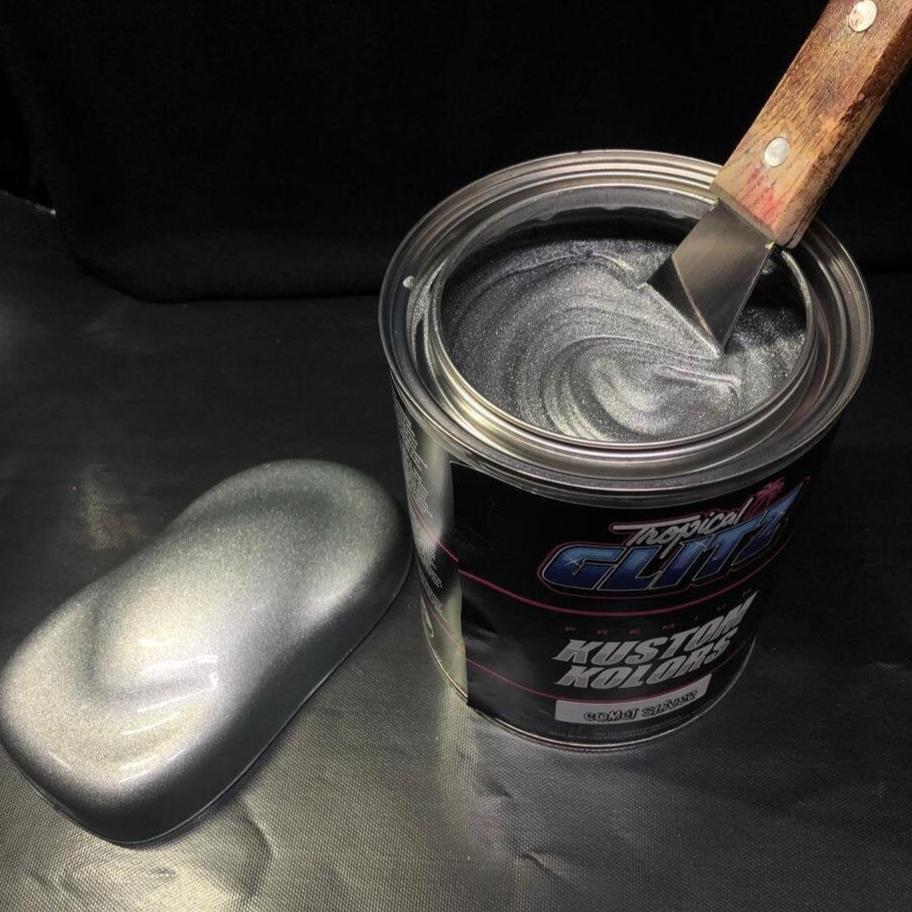

Illustrative Image (Source: Google Search)

Table: Industries/Applications vs. Metallic Silver Benefits

| Industry/Application | Typical Uses of Metallic Silver | Performance/Operational Benefits | Compliance/Notes |

|---|---|---|---|

| OEM Passenger Vehicles (sedans, SUVs, light trucks) | Standard exteriors; brand signature trims | High brightness; strong edge concealment; supports low defect visibility; robust metallic systems (BC/BC/CC) widely used | Meets OEM appearance standards; verify metallic effect consistency (BC/BC/CC process) |

| Passenger Fleet Operations (rental, car sharing, subscription) | Common neutral livery; mixed-brand fleets | Maintains brand identity across makes; lowers perceived dirt/scratches; supports fast detailing | Choose process compatible with repair protocols (BC/BC/CC or SBS systems) |

| Commercial Delivery & Light Commercial Vans | Service fleet exteriors; utility wraps | High daytime/nighttime visibility; heat gain reduction vs. darker colors; strong resale value retention | Consider durability under heavy wash cycles; optional anti-graffiti clears |

| Police & Emergency Services (US/EU) | Patrol vehicles; emergency fleets | High visibility for daytime recognition; reduced glare perception; clean appearance supports professional image | Confirm reflectivity requirements for markings; metallic effects generally compliant |

| Transportation & Logistics (long-haul trucks, last-mile vans) | Fleet standardization; corporate liveries | Consistent appearance; lower heat buildup; efficient refinish and repair workflows | Select flake type (standard vs. “dollar”) for gloss/contrast needs; color matching across brands |

| Agricultural & Construction Equipment | OEM finishes; service and demo units | Excellent edge concealment; heat load mitigation for dark equipment; strong brand identity | Use single-stage or multi-stage systems based on cost and performance targets |

| Off-Highway & Mining Equipment | OEM and maintenance refinish | Conceals wear; supports large-area coverage with low defect sensitivity | Ensure process durability for UV/abrasion; consider 2K polyurethane clears |

| Public Transport (buses, coaches) | OEM and re-livery projects | Corporate livery consistency; high visibility in mixed traffic; efficient maintenance | Coordinate markings and anti-graffiti clear requirements |

| Luxury & Specialty Vehicles | Brand-defining trims; restoration | Signature metallic appearance; premium gloss; customizable flake intensity | QC metallic effect; use OEM-approved systems (BC/BC/CC) |

| Aftermarket & Customization | Collision repair; color changes | Fast alignment to “silver” market demand; straightforward blending vs. solid whites | Train techs on metallic application consistency; verify VOC/regulatory compliance |

| Rental & Leasing Depots | High-turnover exteriors | Masking of minor defects; lower touch-up frequency; robust resale finish | Use durable clears and wash-resistant systems |

| OEM Accessory & Trim | Wheels, body add-ons | Visual coherence with vehicle color; consistent metallic level | Match metallic effect across components (flake size/type) |

| Corporate Mobility & Livery Partners | Multi-brand fleets | Neutral corporate identity; lower cost of ownership through resale value | Define corporate color bands and acceptable tolerances |

Why metallic silver performs in industrial settings

– High brightness and strong edge concealment: Reduces the visibility of minor imperfections, swirls, and stone chips, especially on large panels and in mixed lighting.

– Strong daylight and nighttime visibility: Light tones improve detection in complex backgrounds; complements retroreflective markings rather than competing with them.

– Heat management: Reflectivity reduces solar heat gain compared with darker colors, improving cabin comfort in sun-exposed fleets and lowering cooling loads in hot climates.

– Brand consistency: Silver’s neutral, premium appearance aligns well across different OEM brands and models, simplifying mixed-fleet identity programs.

– Efficiency in repair and maintenance: Common color availability, mature refinish workflows (e.g., basecoat/basecoat/clearcoat), and good blending characteristics reduce cycle time and cost.

– Resale and lifecycle value: Neutral tones help maintain residual values and facilitate remarketing.

– Dirt and wear concealment: Lower perceived soiling and marring between service intervals supports professional appearance and customer perception.

Product considerations for industrial use

– System architecture: Basecoat/basecoat/clearcoat (BC/BC/CC) is standard for metallic control; verify metallic effect consistency (flake type/size) with OEM or brand guidelines.

– Durability: Ensure VOC-compliant, chemical-resistant clears suited to frequent washing, road salts, and industrial cleaning.

– Process control: Control spray pattern, flash times, and overlapping to avoid mottling or burn-in; use OEM-approved silver shades or custom mixes for strict color matching.

– Compliance: Select systems meeting regional VOC regulations (e.g., EU directives) and any safety requirements relevant to emergency/public transport fleets.

3 Common User Pain Points for ‘metallic silver car paint colors’ & Their Solutions

3 Common B2B Pain Points for Metallic Silver Car Paint Colors & Their Solutions

Pain Point 1: Tight Color Matching Across Panels & Batches

- Problem: Flop sensitive metallic silvers shift between panels and lots, causing mismatch after buffing or under different light angles.

- Impact: Rework, time loss, and dissatisfaction on brand fleets or customer deliveries.

- Root causes: Grain size variations, flake distribution differences, panel curvature effects, and inadequate mixing/adhesion issues.

- Solutions:

- Use a consistent basecoat system and shade level.

- Control flash times and build evenly; avoid excessive recoats that change flop.

- Match texture and spray pattern across panels; use the same gun setup, distance, and technique.

- Use House of Kolor Universal Base Coats (BC) in proven silver tones like BC02 Orion Silver and BC03 Galaxy Gray.

House of Kolor alignment

| Pain Point 1 Solution | House of Kolor Product(s) | Key Process Control |

|—|—|—|

| Tight color matching | BC02 Orion Silver; BC03 Galaxy Gray | Keep flash times consistent; don’t over-recoat; match gun distance/pressure across panels |

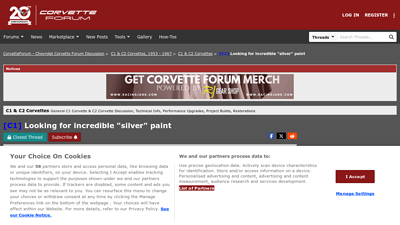

Illustrative Image (Source: Google Search)

Best practices

– Use a consistent pressure (typically around 18–22 psi at the cap), steady pass speed, and fixed gun distance for all panels.

– Mix according to HOK technical guidance and verify across large surface areas under neutral light before production-scale work.

– Maintain equipment maintenance and color logging for repeatability.

Pain Point 2: Hard to Control Flop, Sparkle, and Metallic Orientation

- Problem: Metallic orientation varies with panel shape and application technique, creating patchy sparkle and unwanted “flip” effects on complex curves.

- Impact: Time-consuming “fix” passes and inconsistent finish quality on mixed panel shapes.

- Root causes: Uneven spray overlap, changing distance/angle, incorrect flash, and variable coat build.

- Solutions:

- Maintain constant gun distance and overlap, avoid heavy coats that flood and shift metallic alignment.

- Adjust atomization and line choice while keeping passes parallel to panel edges to minimize swirl.

- Use basecoats engineered for predictable metallic behavior (e.g., HOK Universal BC silver line).

House of Kolor alignment

| Pain Point 2 Solution | House of Kolor Product(s) | Technique Control |

|—|—|—|

| Flop/sparkle/orientation control | BC02 Orion Silver; BC03 Galaxy Gray | Constant gun distance; steady pass speed; parallel passes; consistent flash before recoat |

Best practices

– Build in lighter, even coats and allow full flash before additional coats.

– Avoid excessive “tack” wetness which reorients metallic particles.

– Log gun settings by panel type (hood vs. door vs. bumper) for repeatability.

Pain Point 3: Durability, Clear Protection, and Wrap Adhesion on Silver

- Problem: Poor chip resistance, haze under clear, or wrap graphics lifting on silver metallic panels.

- Impact: Field returns, warranty costs, and compromised fleet livery quality.

- Root causes: Insufficient prep, incorrect clear selection, insufficient cure, or environmental conditions (temperature/humidity).

- Solutions:

- Follow proper prep with primers and appropriate scuffing; confirm film build meets spec.

- Use a high-quality clear from the House of Kolor line and follow correct activation/reducer/catalyst ratios.

- Adhere to recommended flash and bake windows; manage shop humidity and temperature during application and cure.

House of Kolor alignment

| Pain Point 3 Solution | House of Kolor Product(s) | Control Variables |

|—|—|—|

| Durability and clear performance | House of Kolor Clear Coats | Confirm primer prep and scuff; use correct activation/reducer; manage flash/bake; monitor shop environment |

Illustrative Image (Source: Google Search)

Best practices

– Apply final clear to recommended film build; verify cure via tactile inspection before handling or wrapping.

– For wraps, ensure adhesion testing post-clear cure and follow wrap manufacturer guidelines on compatibility.

Strategic Material Selection Guide for metallic silver car paint colors

Strategic Material Selection Guide for metallic silver car paint colors

Purpose

– Deliver a bright, clean metallic silver with controlled flop and sparkle that remains uniform across complex geometries.

– Balance appearance (brightness, flop, texture) against application robustness, cost, and regulatory compliance.

Scope

– Substrate, primer/sealer selection.

– Binder system (solvent vs waterborne).

– Aluminum flake selection and size distribution.

– Basecoat family selection (e.g., House of Kolor Silver Shades variants).

– Process and QC controls.

1) Define the visual target

- Brightness: desired whiteness under sunlight/daylight; control with flake type and undertone adjustment.

- Flop: balance of sparkle vs darker mid-tones on vertical panels; adjust with flake size/orientation and clearcoat optics.

- Texture: smooth “fine metallic” (small flake) vs “glitter/sparkle” (larger flake); control via flake size and proper gun/bag/pressure technique.

- Stealth silver: low flop/no sparkle; use ultra-fine, duller flake with subdued tinting.

2) Substrate and build strategy

- Epoxy surfacer/sealer (US/EU standard):

- Use on all panel types for adhesion, corrosion resistance, and fill.

- Seal tinted gray when targeting darker silvers; white sealed bright silver; neutral gray for general-purpose bright silvers.

- Avoid direct silver-on-surfacer for uniformity; basecoat/sealer isolation prevents telegraphing.

- Primer considerations:

- Solvent surfacer with 2K urethanes aligns with solvent bases.

- If using waterborne base, confirm compatibility with primer; many shops run solvent sealer under WB base to avoid moisture issues.

- Non-conductive panels (aluminum/composites):

- Use non-conductive primers or isolate with dielectric primers where required by OEM procedures to ensure correct ESL coverage.

3) Binder system selection

- Solvent basecoats (universal basecoats and silver lines across suppliers):

- Fast, broad shop compatibility, robust color control with tintable bases and concentrates.

- Wider finish window in typical shop conditions.

- Waterborne basecoats:

- Lower VOC and easier toning adjustments, but stricter environmental control (temp/humidity, airflow).

- Typically require dedicated lines/booths and WB-compatible primers/clearcoats.

4) Flake strategy and undertone tuning

- Flake classes:

- Bright aluminum/coin silver: highest whiteness and brightness; used for clean, high-reflectance silver.

- Silver dollar/dollar flake: slightly warmer, rich brightness, finer texture; excellent for fine metallic cars.

- Micro-mica silver: neutral undertone, smooth texture; good for stealth/soft metallic looks.

- Specialty (tinted) metallics: subdued or complex neutrals, very low flop.

- Mixing strategies:

- Achieve white undertone by blending bright silver bases; add subtle micro-mica or silver dollar flake to smooth texture while preserving brightness.

- Maintain flop control by using balanced flake sizes and orientation techniques (spray pressure, gun distance, flash time).

- For premium dark silvers, select medium flake and add minute amounts of black pearl or blue/black concentrates for tone control.

5) Basecoat family selection (example reference)

- House of Kolor Silver Shades catalog at 66 Auto Color includes categories like Universal Base Coats (BC), Kandy Base Coats (KBC), and Pearl Base Coats (PBC) within a broader range of metallic options; specific silver variants (e.g., BC02 Orion Silver and BC03 Galaxy Gray) demonstrate the breadth of bright/neutral metallic tones available in comparable systems.

- Selection approach:

- Start from the target brightness and undertone, then choose the appropriate base family (BC, PBC) and silver shade variant.

- Use BC (universal basecoat) for standard bright silvers; consider PBC (pearl basecoat) for nuanced flops in complex light conditions.

6) Clearcoat and optics

- Apply high-build, high-solids 2K urethane clear for optimal clarity, DOI, and metallic depth.

- Avoid tinted clears for silvers; tinting shifts undertone unpredictably across panels.

- Maintain tight control over flash/dry times to prevent flop banding.

7) Application control for uniform texture

- Gun/bag selection and pressure:

- Small flake: smaller nozzle (1.3–1.4 mm), slightly lower pressure to reduce micro-banding.

- Medium flake: slightly larger nozzle (1.4–1.6 mm) with balanced air and fluid to avoid “zipper” or “mud” patterns.

- Spray technique:

- Cross-coat with consistent wet/dry edge blend; avoid heavy coats that lead to flop banding.

- Maintain consistent distance and pass speed; allow proper flash between coats to prevent silvering and splay.

- Environmental controls:

- Temp: 20–24°C; humidity: 40–60% RH (typical shop ranges; adjust to system instructions).

- Airflow: clean, dust-free booth with laminar flow; control overspray migration between metallic and solid panels.

8) Quality control and process checks

- Visual checks under daylight and LED:

- Scan for uniformity, sparkle distribution, and flop differences; adjust gun settings or blend coverage as needed.

- Gloss/DOI:

- Use proper sanding and polishing protocols; remove nibs from metallic surfaces gently to avoid burn-through.

- Color match:

- Use standardized light sources; confirm flake/undertone alignment to target formula; adjust tint only within system limits.

9) Compliance (US/EU)

- Confirm product lines are listed for intended use and region; verify VOC content against local limits and any customer-specific requirements.

- Solvent systems: adhere to EPA and local VOC rules; use compliant reducers/activators.

- Waterborne systems: typically lower VOC; follow supplier VOC and process guidelines for booth, line cleaning, and disposal.

Material System Comparison

| Scenario | Substrate/Sealer | Binder System | Basecoat/Category | Flake Class | Application Style | Expected Gloss/DOI | VOC Considerations | Use Cases |

|---|---|---|---|---|---|---|---|---|

| High-brightness, fine metallic | Epoxy surfacer; neutral/white sealer (US/EU standard) | Solvent basecoat | Universal Base Coats with bright silver variants (e.g., House of Kolor Silver Shades; BC family) | Bright aluminum/coin silver; small-to-medium size | Cross-coat; controlled pressure; consistent distance | High DOI; smooth sparkle | Solvent reducers/activators must meet VOC limits | OEM-style bright silver cars; complex geometries |

| Nuance, darker silver with refined flop | Epoxy surfacer; gray sealer tinted as needed | Solvent or waterborne base (per line) | Pearl Base Coats (PBC) or specialty silver variants | Silver dollar/dollar flake; micro-mica additions | Balanced air/fluid; light misting; controlled flash | Deep flop; smoother texture | Confirm VOC compliance per system | Premium trims; deep metallic finishes |

| Stealth/soft metallic | Epoxy surfacer; neutral/gray sealer | Solvent basecoat | Universal Base Coats with subdued silver variants | Micro-mica silver; minimal bright flake | Even wet/dry coats; avoid heavy buildup | Low flop; subdued sparkle | Solvent VOC compliance | Fleet, stealth, or elegant finishes |

| Repair/maintenance-friendly re-spray | Epoxy surfacer; gray or tinted sealer | Solvent basecoat | Universal Base Coats; standard silver shades | Micro-mica or silver dollar for easier blending | Blend into adjacent panels; control overlap | Consistent appearance post-repair | Solvent VOC compliance | Repair shops; panel blending |

| Modern OEM with low-VOC goals | Epoxy surfacer; WB-compatible sealer | Waterborne basecoat | Waterborne Base Coats with silver families | Fine micro-mica/bright blends | WB process (temp/humidity control, airflow) | High DOI with WB system line | WB systems typically lower VOC | Facilities with WB booths/lines |

Notes:

– The silver variants referenced (e.g., House of Kolor BC02 Orion Silver, BC03 Galaxy Gray) demonstrate the breadth of bright/neutral metallic options available within comparable systems.

– For each build, maintain compatibility among primer/sealer, base, and clear to avoid adhesion or optical issues.

– Final visual outcomes depend on flake size distribution, undertone balance, and spray technique as much as on material selection.

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for metallic silver car paint colors

In-depth Look: Manufacturing Processes and Quality Assurance for Metallic Silver Car Paint Colors

Why metallic silver demands tighter process and QA control

Metallic silver is high on both visual sensitivity and customer scrutiny. Because it leans on fine aluminum flakes to achieve lightness, flop, and sparkle, even small shifts in flake size, orientation, or dispersion are visible in reflections. This makes consistent manufacturing, precise process control, and disciplined QC non-negotiable. The most common quality escalations—mottle, graininess, dark or light banding, and flop loss—trace back to shear control during mixing, color-match variability, and inadequate booth filtration.

How metallic silver is manufactured

The process below aligns to both USA and Europe practices for aftermarket and production refinish systems. It emphasizes the control points that most influence flake behavior and color fidelity.

- Formulation design

- Select binder system: 2K urethane, 1K acrylic, or UHS waterborne bases common in USA/EU.

- Choose flake: aluminum particle size and thickness drive brightness, sparkle, and flop; flake surface treatments affect dispersibility and corrosion resistance.

-

Addants: anti-settling agents, dispersants, flow/leveling additives, thixotropes, and UV stabilizers.

-

Raw material control

- Incoming quality: flake morphology (D50, distribution), surface chemistry, solvent/hazardous air pollutants (HAPs) profile (especially in the USA), and VOC content (EU REACH context).

-

Lot traceability to batch and customer.

-

Dispersion and milling

- Target shear profile: high-shear mixing with low-shear let-down to preserve flake integrity and avoid orientation issues.

-

Particle fineness: grind to avoid visible agglomerates; use bead mills or high-shear dispersers as needed.

-

Let-down and conditioning

- Adjust viscosity and solids to support optimal flake orientation during application.

-

Additives for leveling and gloss; avoid systems that trap flakes near the surface, which increases mottling.

-

Color matching and batching

-

Spectrophotometry with multiple angles (ASTM E1347/E1349; ISO 3668 referencing), plus human panel review; confirm flake content within tolerance.

-

** Filtration, packaging, and storage**

- Bag and surface filters (≤25–50 µm) to catch agglomerates; sealed pails/drums; storage per tech data sheet.

From substrate to final clear: shop application process (Prep–Forming–Assembly–QC)

Metallic finishes perform best when the shop process is tightly controlled, particularly around prep and spraying.

- Prep (substrate and masking)

- Wash, degrease, and ensure environmental control (temperature 18–24°C; RH 40–60%).

- Sanding plan according to system: correct primer surfacer selection, blocking/sanding to proper profile.

-

Masking edges to avoid bleed-through and to support smooth blend transitions for metallic colors.

-

Forming (sealer/base/clear application)

- Sealer: sealer/tinted ground control to set hue and reduce burn-through.

- Basecoat:

- Flash to mat (no gloss); flash time and gun technique control mottle risk.

- Spray pattern: even wetness, minimal overlap, controlled passes.

- Flake orientation control: pressure, distance, overlap; balance speed and fluid delivery.

-

Clearcoat:

- 2K urethane or UHS clear; pot-life and induction-time management.

- Bake or air-dry per specification; verify cure metrics (hardness, solvent resistance).

-

Assembly (blends, hardware, and handling)

- Color blending into adjacent parts to mitigate metallic differences.

- Parts sequencing: avoid contamination and protect against dust; maintain booth airflow and cleanliness.

-

Tape removal and masking management: remove while clear is still slightly soft to reduce lifting.

-

QC (inspection and corrective action)

- Visual inspection under directional and diffuse light; use gray scales if available.

- Angle-based color checks (usually 15°, 45°, 110°), record data; flag deviations.

- Document repairs; if necessary, re-sand or re-shoot per procedure.

What QA must test—and how often

Test points and metrics are summarized below. Adjust frequencies to risk level and customer expectations.

Illustrative Image (Source: Google Search)

| Test/Control | Metric/Method | Pass Criteria (typical targets) | Frequency | Notes |

|---|---|---|---|---|

| Flake morphology | Particle size/distribution; microscopy | Within lot spec; no agglomerates | Incoming; per batch | Directly impacts mottle and sparkle |

| Color (multi-angle) | ΔE*ab; ISO 3668 (ASTM E1347/E1349) | ΔE*ab ≤ 1.0 (customer-dependent) | Pre-ship; per lot | Report as ΔE, ΔE Lab*; include pass/fail decision |

| Flop response | Measurement of lightness change vs angle | Match target; minimal deviation | Pre-ship; per run | Flop loss indicates orientation/flake issues |

| Viscosity | Ford Cup or similar | Per spec | Per batch | Viscosity drives flake orientation and spray quality |

| Particle fineness | Grind gauge | No ≥25 µm agglomerates | Per batch | Critical for metallic clarity |

| Solids/VOC | Calculation and gas analysis | Per tech data sheet | Per lot | Ensure regulatory compliance (USA/EU) |

| Gloss | 20°/60° | Per spec | Per part; audit | Metallic can expose texture; maintain gloss targets |

| DFT (dry film thickness) | Measurement | Per spec | Per part | Indirectly affects coverage and flop |

| Adhesion | Cross-cut (ISO 2409) | Per spec | Per batch; per panel | Ensures system integrity |

| Humidity and dust | Environmental monitoring | Clean environment; RH within band | Daily; per booth | Control for metallic clarity |

- Key control levers:

- Environmental set points (temperature, RH, airflow) before and during spraying.

- Shear profile in mixing to prevent flake degradation.

- Gun technique and flash discipline to avoid mottling and banding.

- Proper primer/sealer selection to manage ground tone and burn-through risk.

Quality standards and compliance (USA and Europe)

Most quality systems and technical tests are harmonized via ISO or US/ASTM methods. Regions differ more on environmental regulations and approvals than on test content.

- Management and process

- ISO 9001 for quality management systems (QMS).

-

IATF 16949 often required by Tier-1 automotive supply chains.

-

Color and measurement

-

ISO 3668 (color matching of paints—visual evaluation); ASTM E1347/E1349 for multi-angle color measurement.

Illustrative Image (Source: Google Search)

-

Environmental

- ISO 14001 for environmental management systems.

-

EPA/MACT (USA) and EU REACH/CLP (EU) for VOC limits and chemical compliance; always verify jurisdictional specifics.

-

Performance testing

- ISO 2409 (adhesion), ISO 2813 (gloss), ISO 4628 (defect ratings).

-

ISO 11997 (moisture/chemical resistance).

-

Color consistency

- Use ΔE tolerances agreed with customers; many programs target ≤1.0 ΔE, but specific tolerances vary by market and vehicle segment.

Non-negotiables for a stable metallic silver program

- Rigorous flake control (incoming verification, low-shear let-down, filtration).

- Environmentally controlled booth conditions with active humidity/temperature management.

- Multi-angle color measurement and documented ΔE pass/fail, not visual-only acceptance.

- Gun technique standards for coverage, overlap, and flash windows to minimize mottle.

- Cleaned, validated spray lines and filters to prevent contamination.

- Traceability and corrective action tied to QMS (ISO 9001/IATF 16949).

These controls and standards deliver the reproducibility, brightness, and flop that define premium metallic silver—without the visual defects that drive rework and customer dissatisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metallic silver car paint colors’

Practical Sourcing Guide: A Step-by-Step Checklist for Metallic Silver Car Paint Colors

1) Define Requirements Upfront

- Technical:

- Paint system (e.g., BC/BCQ, urethane 2K, KBC/PBC for special effects), activator/reducer compatibility.

- Color target (codes, known references, benchmark vehicles).

- Aesthetic thresholds: metallic flop, sparkle density, texture, grain size (e.g., 20–50 μm for fine, 80–150 μm for large).

- Texture and gloss targets (measured gloss units and DOI).

- Process:

- Application (gravity/siphon cup, HVLP), film build and flash/gun distance.

- Typical job coverage (sq ft per gallon) and waste factors.

- Compliance:

- USA: VOC targets (e.g., < 4.2 lb/gal for basecoats; verify local regulations and CARB/SCMD requirements).

- EU: VOC category per Directive 2004/42/EC (e.g., Cat IIB d for automotive paints).

- Safety: PPE, SDS availability, hazardous classification.

2) Supplier Shortlist

- Sources to include:

- House of Kolor “Silver Shades” category (e.g., BC02 Orion Silver, BC03 Galaxy Gray; commonly available through 66 Auto Color).

- Other candidates (for broader validation): PPG, Sherwin-Williams, AkzoNobel (Sikkens/Lesonal), BASF (R-M), and 1K/2K systems from reputable distributors (e.g., East Coast Paint Supply, FinishMaster).

- Criteria:

- Regional availability (USA/EU), stocking locations, lead times.

- System compatibility (BC/BCQ/KBC/PBC; activators/reducers).

- Metallic control process; support for toners for small shade adjustments.

3) Request Information (RFI) — Data to Collect

| Requirement | Data to Request | Acceptance Criteria | Decision Gate |

|---|---|---|---|

| Color target | Silver variant options; sample swatches | Matches OEM/specified sample within ΔE tolerance | Proceed if in-spec |

| System | BC/BCQ/KBC/PBC; 2K urethane; activators/reducers | Compatible with your booth/process | Proceed |

| VOC | VOC grams/liter or lb/gal; regulatory label | Meets USA/EU thresholds for job site | Proceed if compliant |

| TDS/SDS | Technical Data Sheet; SDS | Complete and current | Proceed |

| Packaging | Quart/gallon; aerosols (for spot repairs) | Job-size packaging available | Proceed |

| Shelf life | Months; storage conditions | ≥ 6 months; 15–27°C typical | Proceed |

| Metallic controls | Particle size distribution; tint strength; flop | Matches specified texture/flip | Proceed |

| Lead time | Stock vs. backorder; ship-from | ≤ lead time SLA (e.g., < 5 business days) | Proceed |

| Price | Unit per qt/gal; volume breaks | Competitive within band | Proceed |

4) Quote and Cost Model

| Quote Item | Notes | Decision Gate |

|---|---|---|

| Basecoat per gallon | Include potential toners/balance coats | Price vs. target |

| Activator/Reducer | Compatibility and cost | Bundled or separate pricing |

| Flake add-ons | If separate metallic effect packages | Included if needed |

| Clearcoat | If part of finish; ensure compatibility | Full-system pricing |

| Freight | Regional lanes; DOT/hazardous shipping | Freight add-on |

| Minimums/MOQs | Cases, pallet, palletization fees | Order cadence fits MOQs |

| Volume discounts | Tiered pricing, rebates | Commit to tiers if feasible |

5) Sample and Pilot Evaluation

- Request samples:

- Panel substrates (E-coat, primer-surfacer), process-matched application.

- A2/BCQ test cards and spray-outs to confirm metallic flip and texture.

- Acceptance criteria:

- ΔE tolerance (typically ≤ 1.0–1.5 in controlled light).

- Match metallic grain and flop vs. reference; gloss DOI on par or better.

- Solvent resistance and process robustness (flash times, tip dry avoidance).

- Pilot plan:

- Spray multiple silver variants (e.g., fine silver vs. medium sparkle) under booth humidity and temperature ranges.

- Evaluate adhesion, leveling, and recoat windows; document nozzle setups and gun passes.

6) Quality and Compliance Verification

| QC Step | Test/Inspection | Notes |

|---|---|---|

| TDS/SDS review | Confirm VOC and system specs | Version control in QMS |

| VOC spot check | Calculated per job mix | Ensure site compliance |

| Colorimetry | ΔE under D65/45° and multi-angle | Acceptance thresholds |

| Metallic texture | Grain size comparison; visual flop | Side-by-side with benchmark |

| Film build | Wet/dry mils; coverage | Optimize for cost and performance |

| Cross-coat adhesion | Tape/cross-hatch tests | Verify substrate prep and primer |

| Gloss/DOI | Gloss meter; orange peel assess | Meets shop standards |

| Storage stability | Shelf-life confirmation; label checks | Avoid color drift from age |

| Labeling | Hazard symbols; EU classification | USA/EU legibility and symbols |

| Documentation | MSDS/SDS, COAs | Keep in job file |

7) Process Fit and Training

- Confirm spray parameters (fluid tip, atomization pressure, fan size) to control metallic orientation.

- Train on:

- Tinting balance coats for tight shade corrections.

- Application technique to minimize tiger-striping and directional effects.

- Booth humidity control and flash time windows.

8) Contracting and Operational Setup

| Item | Contract Term | Operational Spec |

|---|---|---|

| Lead time | SLA (e.g., 5 days) | Stock locations per region |

| Pricing | Tiered per qt/gal; caps for VOCs | Quarterly reviews |

| Inventory | Reorder points; safety stock | MOQs aligned to cadence |

| Change control | Versioned TDS/SDS | Color management SOP |

| Returns | Color mismatch policy | Sample confirmations prior |

| Warranty | Material defects | Site issue reporting window |

9) Execution and Monitoring

- Place initial order:

- Basecoats, activators/reducers, clearcoats if applicable.

- Maintain aerosol options for spot repairs.

- Track:

- Batch/lot traceability; sample spray-out retained.

- Job coverage vs. costing model; refine estimates for future quotes.

- Review:

- Quarterly cost/performance; update supplier shortlist as needed.

10) Alternative/Backup Options

- Keep at least two compatible silver variants on hand (fine vs. medium flake; alternate vendors like PPG/SW/Akzo/BASF).

- Maintain a small stock of toners for micro adjustments in the booth.

Notes:

– The House of Kolor Silver Shades category (e.g., BC02 Orion Silver, BC03 Galaxy Gray) provides a viable metallic silver palette for B2B sourcing; verify availability, VOC compliance, and compatibility with your system via the supplier’s latest TDS/SDS.

Comprehensive Cost and Pricing Analysis for metallic silver car paint colors Sourcing

Comprehensive Cost and Pricing Analysis for Metallic Silver Car Paint Colors Sourcing

Sourcing price baseline (illustrative)

House of Kolor Silver Shades – 66 Auto Color:

– Orion Silver (BC02) – US$48.05 per quart (list)

– Galaxy Gray (BC03) – US$48.05 per quart (list)

– “Unidentified Flying Object” – prices not disclosed (mix-to-order)

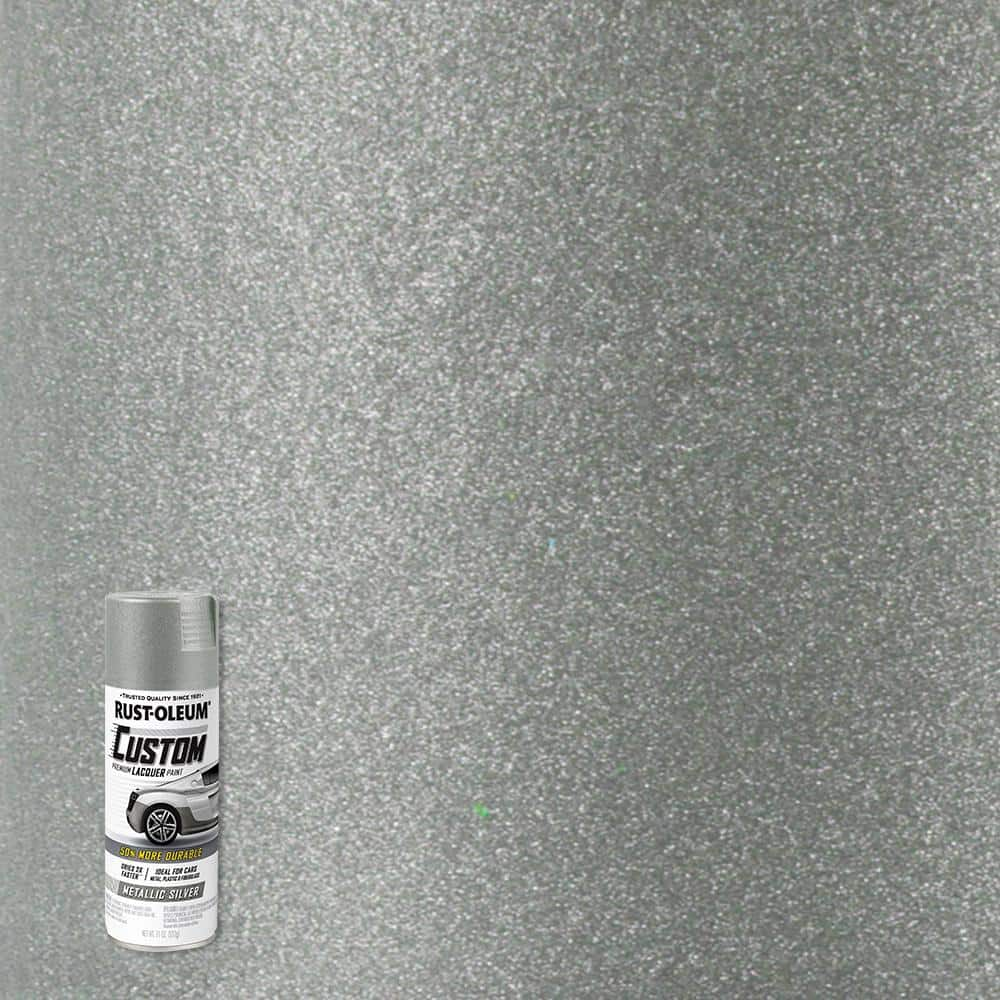

Illustrative Image (Source: Google Search)

Price indications are per single unit; bulk programs typically price at case, gallon, and concentrate levels.

Total cost component breakdown (per vehicle)

Assumption: US/Canada standard refinish process (2.2–2.8 mils wet film for base; 1.8–2.2 mils wet film for clear); spray gun transfer efficiency ~50% actual solids to panel; VOC-compliant 2K clears; body shop labor $60–$95/hour.

| Segment | Items included | Cost example (compact sedan) | Cost example (SUV/pickup) | Notes |

|---|---|---|---|---|

| Materials | Base (metallic silver), reducer, 2K hardener, 2K clear, prep cleaners/solvers | $40–$75 | $75–$140 | Based on House of Kolor “Orion Silver” per-quart list; per-vehicle depends on body area, spray loss, and coverage. |

| Labor | Prep, masking, spray, teardown | $180–$260 | $240–$380 | 3.0–4.0 billable hours (sedan) vs 4.0–6.0 hours (SUV). |

| Logistics | Inbound shipping, hazmat fees, customs (EU), delivery | $7–$25 | $9–$35 | US ground is more efficient; EU inbound may add 3–7%. |

| Compliance/overhead | Waste handling, VOC recordkeeping, QA | $6–$12 | $8–$16 | Lower for controlled shop workflows. |

Indicative range: US small sedan $230–$370; US SUV $330–$570. EU pricing typically reflects VAT and customs; expect higher landed cost per case (see EU vs US section below).

EU vs US cost considerations

- VAT: EU invoices include VAT (e.g., 19–27%), not shown on US invoices; plan for this in margin.

- Customs: Import duties on paints may apply depending on HS code and origin; check local classification.

- Packaging labeling: EU REACH/CLP/GHS labeling may add minor incremental packaging/labeling cost.

- Logistics: EU cross-border shipping can cost more than US ground; consolidate to reduce per-unit logistics.

| Factor | US typical | EU typical | Implication |

|---|---|---|---|

| VAT on list price | Not shown | Included | EU gross margin higher vs net if VAT excluded; cash flow impact. |

| Customs/duties | Lower | Possible | Verify HS code; may increase landed cost 5–12%. |

| Transport | Road-efficient, lower | Mixed modes, higher | EU may add $3–$7/case vs US ground average. |

| Label/SDS | GHS-based | REACH/CLP | Slightly higher packaging cost; fewer compliance differences for retail brands. |

Materials yield & coverage (metallic silver system)

Coverage is highly dependent on metallic orientation and spray technique. The ranges below convert solids usage to panels coated per quart under realistic shop conditions.

Illustrative Image (Source: Google Search)

| Vehicle type | Body area (ft²) | Base (metallic) coverage/coat | Clearcoat coverage/coat | Spray passes | Transfer efficiency (effective solids) |

|---|---|---|---|---|---|

| Compact sedan | 600–700 | 320–400 ft²/qt (base) | 370–460 ft²/qt (clear) | 1.5–2.0 | ~50% |

| SUV/pickup | 850–1,050 | 280–360 ft²/qt (base) | 330–420 ft²/qt (clear) | 1.5–2.0 | ~50% |

| Full-size sedan | 720–800 | 300–380 ft²/qt (base) | 360–450 ft²/qt (clear) | 1.5–2.0 | ~50% |

Implications:

– Metallic silver can require extra fog/lean coats and careful blending to minimize flop differences; more passes increase material use and labor.

– High-solids clears and concentrates typically reduce material volume per job; negotiate high-solids equivalents when available.

Cost drivers specific to metallic silver

- Metallic orientation: Flake size and orientation affect perception; larger flakes increase sparkle but can exacerbate mottling if not controlled.

- Color build: Achieving opacity may need extra leaning/fogging; plan 10–20% material buffer vs non-metallic.

- QC: Minor flop differences can drive rework; ensure tight gun distance, consistent fan width, and proper flash times.

- Blending panels: Adjacent panel blending to hide metallic “tiger stripes” adds time.

How to use House of Kolor silver pricing to set expectations

- Orion Silver (BC02) list ~US$48.05/qt (as listed by 66 Auto Color). Per-vehicle base material spend typically falls within $40–$75 for sedans and $75–$140 for SUVs, inclusive of waste and typical pass counts.

- Confirm concentrate vs ready-mix pricing: Kandy Koncentrates and universal base coats may have different unit economics; ask for gallon pricing and concentrate ratios.

- EU case pricing: Expect minor uplifts vs US list once VAT, duties, and transport are applied.

Tips to save cost

| Area | Action | Impact |

|---|---|---|

| Materials | Use high-solids clears and concentrates; validate cross-compatible primers/catalysts | 10–25% lower material cost; faster flash reduces cycle time |

| Materials | Optimize mix ratios with shop-specific “golden guns” and water-miser spray techniques | 5–10% less paint used without sacrificing coverage |

| Materials | Match metallic to substrate and gun setup; test panel alignment before full job | Reduces rework and extra fogging |

| Labor | Standardize prep kits and masking patterns by vehicle model | Cuts prep time by 10–20% |

| Labor | Train for consistent gun distance, fan width, and overlap; enforce flash windows | Improves appearance; fewer resprays |

| Labor | Parallel prep stages and clearcoat staging to reduce booth idle time | Gains booth throughput |

| Logistics | Order by lane (US or EU) and consolidate to full pallets | 10–15% lower freight |

| Logistics | Negotiate drop-ship to multiple shops within a region | Reduces last-mile fees |

| Compliance | Track VOC usage, waste, and solvent swaps per jurisdiction | Avoids fines; qualifies for local incentives |

| Pricing | Negotiate tiered pricing with case/gallon commitments; align to expected color portfolio | 5–12% lower unit cost |

Regional compliance/regulatory considerations

- US: Verify VOC limits for your state/county; ensure base/clear meet category-specific VOC requirements; maintain SDS and recordkeeping.

- EU/UK: Ensure CE marking and SDS compliance where applicable; consider CLP labeling; confirm VOC content complies with local directives for refinish products.

- Logistics: Air vs ground has major cost gaps; dangerous goods surcharges may apply for solvent-heavy systems.

Recommended sourcing approach

- For US/EU fleets/body shops: Start with Orion Silver (BC02) as a price anchor and performance benchmark; qualify Galaxy Gray (BC03) and other silver shades for specific effects.

- Ask suppliers for gallon pricing, concentrate ratios, and high-solids clears; request technical bulletins on metallic flake orientation and recommended spray settings.

- Quantify per-vehicle consumption on your standard test vehicles (e.g., compact sedan) and convert to $/vehicle metrics for procurement KPIs.

- Secure regional distribution partners in the US and EU to lower landed cost and stabilize lead times.

Alternatives Analysis: Comparing metallic silver car paint colors With Other Solutions

Alternatives Analysis: Comparing metallic silver car paint colors with other solutions

Quick comparison

| Attribute | Metallic silver (e.g., House of Kolor Orion Silver) | Pearlescent metallic silver (e.g., House of Kolor PBC) | Solid non‑metallic silver (e.g., BC03 Galaxy Gray) |

|---|---|---|---|

| Visual effect | Bright, reflective sparkle with metallic grain | Softer, smooth shimmer with depth and color travel | Flat-to-minimal sparkle, even tone |

| Touch‑up match | High risk of flop/grain mismatch; requires professional spray | Moderate risk; depth makes blending more forgiving | Lowest risk; uniform color is easier to match |

| Coverage & hiding | Good when built properly; metallic can telegraph under color | Similar to metallic; pearl adds depth but needs careful build | Stronger hiding power; fewer metallic telegraphing issues |

| Process control | Sensitive to gun technique, spray pattern, and flash times | Requires consistent application to maintain pearl orientation | Least sensitive; simpler to produce consistent results |

| Durability (clearcoat dependent) | Comparable to pearlescent and solid when fully cured | Comparable; depth is optical | Comparable; depends on system and clearcoat |

| Cost per set | Similar across basecoat lines (e.g., Orion Silver: from $48.05) | Similar to metallic basecoats within a brand | Similar to metallic basecoats within a brand |

| Recommended use | Premium, modern finishes with metallic character | Sophisticated, lustrous finishes where depth is desired | Fleets, repairs, and environments where consistency trumps sparkle |

Analysis

- Appearance and brand impact

- Metallic silver delivers a contemporary, light‑responsive look. It is suitable for high‑gloss, premium finishes where sparkle contributes to brand perception.

- Pearlescent silver produces a smoother, deeper luster and subtle color travel, lending a higher‑end appearance in markets that favor understated elegance.

-

Solid non‑metallic silver minimizes visual noise; it is advantageous where uniformity and easy spot repairs are critical.

-

Repairability

- Metallic silver requires precise spray technique and careful blending to avoid mismatches caused by light‑angle effects and metallic flop.

- Pearlescent silver can be forgiving because the pearl effect masks minor variations, but consistent orientation is essential.

-

Solid silver offers the lowest risk of mismatch, making it ideal for quick, cost‑effective repairs and service environments with variable skills.

Illustrative Image (Source: Google Search)

-

Coverage and hiding

- Pearlescent and metallic systems can telegraph underlying color when under‑applied; building to proper opacity is key.

-

Solid silver hides more uniformly at lower film builds, reducing the chance of underlying defects appearing in the final color.

-

Process control

- Metallic and pearl systems demand tight control of viscosity, flash times, spray distance, and overlap.

-

Solid silver tolerates more process variation without visible defects, shortening setup and QA cycles.

Illustrative Image (Source: Google Search)

-

TCO considerations

- Within a single brand, price per unit tends to be similar across metallic, pearl, and solid basecoats (e.g., House of Kolor Orion Silver available from $48.05; other silver tones similarly positioned).

- Metallic and pearl finishes may incur higher labor and rework risk due to blending requirements, particularly on complex geometry or low‑angle panels.

Practical guidance (USA and Europe)

- Choose metallic silver when the brand signature depends on a bright, reflective finish and your team can enforce strict spraying standards.

- Use pearlescent silver to balance premium aesthetics with improved repair forgiveness.

- Deploy solid silver when fleets, service centers, or cost‑controlled programs demand repeatable, low‑variability color.

Always validate environmental compliance and local VOC requirements, especially for EU markets and regulated US states.

Essential Technical Properties and Trade Terminology for metallic silver car paint colors

Essential Technical Properties and Trade Terminology for metallic silver car paint colors

Key technical properties

Metallic silver’s optical effect is governed by flake type, particle size distribution, and orientation; the surrounding binder, film build, and curing schedule dictate flop and flop index. The following properties, test methods, and targets are the minimum set for consistent OEM-acceptable finishes.

Table 1. Critical metallic-silver properties and acceptable ranges

Illustrative Image (Source: Google Search)

| Property | Why it matters | Typical range | Test method | Notes |

|---|---|---|---|---|

| Flake type | Determines brightness, texture, and flop | Natural mica, coated mica (aluminum-free), aluminum flake (flake size measured in μm), hybrid systems | Supplier spec; optical microscopy | Natural mica avoids aluminum; coated mica offers enhanced sparkle without metal |

| Median particle size (D50) | Controls micro-sparkle vs smooth metallic | 8–25 μm (micro-sparkle); 40–80 μm (coin-sparkle); 100–200 μm (coin) | Laser diffraction; optical image analysis | Match median, span (width of distribution), and maximum size to target effect |

| Particle size distribution (PSD) span | Controls uniformity and mottling | Span 1.0–2.0 (narrow PSD reduces texture) | Calculated from D90/D50 − D10/D50 | Narrow span reduces flop banding risk |

| Flake orientation | Affects flop and brightness vs face | Align to ~parallel to substrate for high flop | Microscopic examination of cross-section | Excessive vertical orientation causes flop-darkness on curves |

| Flop index | Quantifies lightness change vs angle | Varies by system; specify and target ±ΔFlop tolerance | Colorimetry at high- and low-angle | Acceptable tolerance typically agreed during PPAP; no fixed “good” number |

| Delta flop (batch-to-batch) | Ensures color stability | Match agreed master; typically | Specular plus geometry spectrophotometer | Use tight tolerances; align cure, film build, and application |

| L* (lightness) at face | Sets brightness baseline | Target OEM standard at 25° or 45° illuminant geometry | Spectrophotometer | Use D65/10°, common in automotive colorimetry |

| Clearcoat color saturation vs sparkle | Balance visibility of metallic effect | Neutral clear preferred; slight hue adjustments possible | Spectrophotometer; visual evaluation | Over-hueing clear impacts appearance |

| Film build (DFT) | Ensures metallic orientation and coverage | Primers: 15–30 μm; color: 12–25 μm; clear: 35–60 μm | DFT gauge per ISO standards | DFT is measured; wet film thickness must be calibrated to target DFT |

| Gloss (85°) | Surface finish quality | ≥80 GU for topcoat; body clear often ≥90 GU | 85° gloss meter | 20° may be used for premium gloss assessment |

| Solvent pop/Boil marks | Indicates cure profile | No solvent pop, craters, or micro-bubbles | Visual at bake; DFT/IR gel checks | Adjust flash/bake to avoid solvent entrapment |

| Adhesion | Cohesion to primers/clears | ≥2B (A/B), 0–2 (cross-hatch) depending system | ASTM D3359 / ISO 2409 | Confirm intercoat adhesion for color-to-clear |

| Chip resistance (integrity) | Durability on edges | Within OEM spec (no delamination at edges) | Stone-chip tests or field validation | Primers and e-coats heavily influence |

| VOC/Regulatory compliance | Legal and branding alignment | See regional matrix | Calculated VOC by formulation | VOC calculations exclude exempt solvents; see Table 2 |

| Batch uniformity (viscosity, solids) | Predictable spray and coverage | Viscosity within ±5–10%; solids within spec | Viscometer; gravimetric | Tight control reduces waviness in metallic |

Application-sensitive parameters

- Waviness, mottling, and flop-darkness are driven by application technique and process limits. Define and lock:

- Spray gun type, nozzle, and pressure

- Flash time and bake schedule (film build vs cure)

- Static/dynamic viscosity and solids at spray viscosity

- Orientation and distance to panel during spraying

- Batch-to-batch PSD and dispersion quality (grind and mix-in flake)

Regulatory and standards references

Table 2. VOC/regulatory quick reference (US/EU)

| Region/regulatory | Product type | VOC/solvent limit (typical by category) | Notes |

|---|---|---|---|

| US EPA Consumer Products Reg. (40 CFR Part 59, Subpt. C) | Aerosol auto refinish (not specialty) | ≤250 g/L VOC | Product categories vary; verify category before compliance |

| CARB Suggested Control Measure (SCM) for Auto Refinish | Topcoats (incl. metallics/colors) | ≤420 g/L VOC | California; may include limits for hardeners/reducers |

| EU Decopaint Directive 2004/42/CE | Category II (one-coat topcoats) | ≤840 g/L VOC | Applies to consumer and trade paints within EU |

| EU Decopaint Directive 2004/42/CE | Category II (two-coat systems) | ≤840 g/L VOC | Many car refinish topcoats classified here |

| EU Decopaint Directive 2004/42/CE | Category I (primers/fillers, 2K) | ≤200 g/L VOC | Stricter limits; confirm product class |

| US/EU | Exempt solvents | Typical: Acetone, t-Butyl acetate, PARC exempts | Excluded from VOC calculation; regulatory lists vary |

| Colorimetry | Geometry | Recommended: Multi-angle spectrophotometer; commonly D65/10° | Use consistent lighting and illuminant (D65 vs D50) |

Notes: Exact limits vary by product classification and state; use supplier SDS and regional regulations for precise limits and exemptions.

Trade terminology (B2B essentials)

Table 3. Trade terms glossary

| Term | Definition | Application example | Notes |

|---|---|---|---|

| OEM | Original Equipment Manufacturer; in paint supply, brands or standards approved by OEMs | Reference “OEM silver” effect to specify target | Distinguish from aftermarket |

| OE/OE spec | Original Equipment/specification | “OE-specified silver” means align to OEM shade and appearance | Requires color match protocol |

| MOQ | Minimum Order Quantity | MOQ 20 L per SKU per batch | Driven by dispersion runs, packaging |

| Lead time | Time from order to shipment | 3–5 weeks for stock; 6–8 weeks for new dispersion | Includes QA release |

| Pack size | Discrete units | 1 L pints; 4 L quart kits; 20 L pails; 200 L drums | Kits include activator/base components |

| SKU/PN | Stock Keeping Unit/Part Number | “BC02-ORION-SILVER-PN-HOK” | Use unique SKU per effect/variant |

| Batch/lot | Manufacturing run | “Batch 25B06, T=48 h pot life” | Tie to QA and Certificate of Analysis |

| Certificate of Analysis (CoA) | Batch QC document | Includes solids, viscosity, VOC, flake PSD, ΔFlop | Required for release |

| Pot life | Working life after activation | 48 h at 20–25°C (2K systems) | Define temperature |

| Recoat window | Time to reapply without deglossing | 10–30 min at 20–25°C | Varies by hardener and temperature |

| Gloss level | Surface reflectance | “≥90 GU at 85°” | Confirm geometry and standards |

| Viscosity | Resistance to flow | “17–22 s in Ford cup #4 at 25°C” | Match spray equipment |

| Solids | Non-volatile content | “40–45% by weight” | Impacts coverage |

| VOC | Volatile Organic Compound content | “≤420 g/L (CARB limit for topcoats)” | Exempt solvents excluded |

| Coverage/DFT | Dry Film Thickness | “Color 12–18 μm; clear 45–55 μm” | Use calibrated DFT, not just WFT |

| Coverage rate | Area per unit volume | “12–15 m²/L at 35 μm DFT” | Theoretical; confirm practical |

| Flash/bake | Solvent evaporation and cure | “Flash 10–15 min; bake 60–70°C object temp 20 min” | Follow SDS |

| Potency (pigment) | Tinting strength | “Silver potency 100% vs master” | For tint adjustments |

| Flake potency | Effect level by particle size | “Coin sparkle 100% vs coin master” | Controls visual effect |

| Flop index | Lightness change vs viewing angle | “FI target ±0.5 from master” | Geometry and method matter |

| Shade matching | Color control | “ΔE00 ≤0.5 at face; ΔFlop within spec” | Use multi-angle instruments |

| Mix ratio | Component proportion | “2:1 color:hardener” | Includes reducer as needed |

| Sheen | Low-angle sheen variation | ≤5 GU difference across panels | Avoid patchiness |

| Waviness/Mottle | Surface texture from application | ≤Threshold by OEM standard | Process-driven |

| Color library | Reference standards | “HOK Silver Shades—BC02 Orion Silver” | Label and protect samples |

| SDS/TDS | Safety/Technical Data Sheets | “SDS rev. 2024-05; TDS rev. 3.2” | Always current versions |

| MSDS/SDS | Safety sheet naming | SDS is current term | Use regionally correct term |

| HS code | Customs classification | “3208/3209 for paints/varnish” | For export/import |

| Incoterms | Delivery responsibility | “EXW, FCA, DDP” | Define risk/transfer points |

| Palletization | Unit load spec | 32 pails per pallet; wrap film; corner boards | Ensure safe transport |

| REACH | EU chemical regulation | “REACH compliant—no restricted substances” | EU market |

| CARB | California Air Resources Board | “VOC limits per SCM” | US-CA market |

| GHS | Hazard communication | Pictograms; signal words | Align with SDS |

| PPE | Personal Protective Equipment | Respirator, gloves, eye protection | Required during mixing/spray |

| Lot traceability | Tracking by batch/date | Lot 25B06—dispersion lot 240523 | QC and recall readiness |

| PPAP | Production Part Approval Process | Required for OEM-specified parts | Includes color/part submission |

| Change control | Process/QC change management | “Specification revision 2.1” | Manage revisions with approval |

| Shelf life | Storage life unopened | “12 months @ 20–25°C” | Controlled warehouse only |

| Storage temp | Storage conditions | “10–30°C; protect from freezing” | Follow supplier guidance |

| QA sign-off | Release by quality | “Approved by QA; seal lot” | CoA issued |

| COC/CoC | Certificate of Conformity | “COC confirms VOC and solids” | Often required by customer |

| Warranty/claims | Appearance performance | “Appearance integrity for 24 months” | Specify maintenance conditions |

| Sample/approval | Pre-production verification | “Customer-signed panel for BC02 Orion Silver” | Lock-in color, gloss, DFT |

| Return/exchange | QC issue handling | “Return policy within 30 days if non-conforming” | Pre-approve RMA |

Procurement essentials (US/EU)

- Use regional SDS/TDS and VOC calculations per jurisdiction.

- Define pack size, palletization, and lead time by region; US often uses gallons (US), EU liters, with drum shipments common for 200 L.

- Incoterms should reflect lead times and transport mode (e.g., EXW for quick-turn domestic; FCA/DDP for import/export).

- Ensure REACH and CARB compliance for EU and California sales respectively; align HS codes for customs.

- Lock-in QA: CoA, batch/PSD/flop index, viscosity/solids, and VOC calculations required for release.

Packaging and logistics (typical for B2B)

- Pails: 4 L, 20 L

- Drums: 200 L

- Aerosol: Cases of 12 or 24, per category

- Mix kits: 1 L and 4 L with activators/reducers

- Palletization: Standard pallets with wrap, corner boards, and weight limits per carrier

Incoming QC checklist

- Viscosity (flow cup/Zahn), solids (oven method), VOC (regulatory method)

- Flake PSD (laser diffraction), orientation check (microscopy)

- Gloss at 85°, ΔE and ΔFlop (multi-angle colorimetry)

- Film build mapping (DFT), visual waviness/mottling assessment

- Batch-to-batch consistency against master panel and CoA

Notes

- All numeric ranges and limits are for formulation and acceptance planning; actual specification limits should be defined by the OEM customer or project-specific requirements.

- Always cross-check VOC calculations and compliance with the applicable regional regulations and product classifications.

Navigating Market Dynamics and Sourcing Trends in the metallic silver car paint colors Sector

Navigating Market Dynamics and Sourcing Trends in the Metallic Silver Car Paint Colors Sector

The metallic silver automotive paint market continues to evolve with changing consumer preferences, regulatory requirements, and technological advancement. Industry professionals across USA and Europe must navigate complex supply chains, sustainability mandates, and quality standards to maintain competitive advantage in this premium color segment.

Illustrative Image (Source: Google Search)

Market Overview

Metallic silver represents one of the most technically demanding automotive finish categories, requiring precise formulation of aluminum flakes, pearlescent pigments, and resin systems. The market segment demonstrates steady growth driven by premium vehicle segments and aftermarket customization trends.

Key Market Drivers

- Premium vehicle adoption: Silver remains a dominant choice in luxury automotive segments

- Aftermarket customization: Growing demand for specialty finishes like House of Kolor’s BC02 Orion Silver and BC03 Galaxy Gray

- Regulatory compliance: VOC reduction mandates driving formulation changes

- Technology integration: Advanced metallic systems requiring specialized application techniques

Supply Chain Considerations

USA Market Dynamics

The North American market shows strong demand for established formulations with reliable color matching capabilities. Sourcing strategies must account for:

- Regional climate variations affecting paint curing and application

- Distribution network complexity for specialized products

- Regulatory compliance with state-level environmental regulations

- Local technical support requirements for complex metallic systems

European Market Trends

European buyers emphasize sustainability and technical precision, creating distinct sourcing requirements:

- REACH compliance for all chemical components

- Premium formulation expectations

- Regional distribution partnerships for specialized products

- Enhanced documentation and traceability requirements

Sustainability Imperatives

The sector faces increasing pressure to reduce environmental impact while maintaining premium aesthetic performance.

Illustrative Image (Source: Google Search)

Key Sustainability Challenges

- Aluminum flake sourcing: Supply chain transparency and ethical mining practices

- Volatile Organic Compounds: Formulation reformulation to meet stricter limits

- Waste management: Aerosol waste and unused paint disposal protocols

- Carbon footprint: Production and transportation optimization

Solution Pathways

Industry leaders are implementing several strategies to address sustainability concerns:

- Waterborne formulations: Development of low-VOC silver metallic systems

- Recycled aluminum: Incorporation of recycled flake materials

- Efficient production: Concentrated formulations reducing shipping impacts

- Technical support: Enhanced application training minimizing waste

Historical Development Context

The evolution of metallic silver automotive paints reflects broader industry innovation:

Traditional Formulations

Early metallic systems relied on coarse aluminum flakes, creating bright, reflective finishes suitable for mass production environments. These formulations prioritized durability and cost efficiency over aesthetic refinement.

Modern Advanced Systems

Contemporary metallic silver paints incorporate:

– Ultra-fine aluminum flake systems for superior reflectivity

– Multi-layer pearlescent additives for depth perception

– Specialized clearcoat integration for enhanced protection

– Computer-formulated color matching capabilities

Illustrative Image (Source: Google Search)

Sourcing Strategy Recommendations

Supplier Evaluation Criteria

- Technical capability: Demonstrated expertise in metallic formulation

- Regional support: Local technical assistance and troubleshooting

- Regulatory compliance: Current certifications and documentation

- Supply reliability: Consistent production capacity and inventory management

Risk Mitigation Approaches

- Diversified sourcing: Multiple qualified suppliers for critical components

- Inventory management: Strategic stock levels for standard and specialty products

- Technical training: Ongoing education for application and troubleshooting

- Quality assurance: Rigorous testing and certification protocols

Regional Market Intelligence

USA Market Preferences

- Established formulation reliability

- Strong after-sales technical support

- Competitive pricing structures

- Flexible payment terms

European Market Priorities

- Premium formulation quality

- Comprehensive regulatory compliance

- Sustainable sourcing practices

- Detailed technical documentation

Future Outlook

The metallic silver paint sector will continue adapting to regulatory pressures and consumer demand for enhanced aesthetic performance. Successful market navigation requires balancing technical innovation with sustainability compliance while maintaining cost competitiveness.

Industry professionals should anticipate continued evolution in formulation technology, expanded sustainability requirements, and increasing regional customization needs across both USA and European markets.

Frequently Asked Questions (FAQs) for B2B Buyers of metallic silver car paint colors

Frequently Asked Questions (FAQs) for B2B Buyers of Metallic Silver Car Paint Colors

1) What is the difference between “silver” and “metallic silver” for automotive refinishing?

Metallic silver contains aluminum or aluminum/mica flakes to create a reflective, flip-flop effect; standard silver is a solid-tone without flake. Flake size and particle shape control brightness and flop:

– Microflake (10–30 μm) yields tight metallic with higher brightness and subtle flip.

– Medium flake (30–80 μm) is commonly used for balance of brightness and coverage.

– Coarse flake (80–100+ μm) adds dramatic flake and distinct visual texture but increases risk of orientation issues and texture telegraphing.

Metallic silver typically requires a clearcoat for appearance and durability. Use appropriate metallic orientation techniques (high solids, medium wet, minimal flash between coats) to minimize mottling.

2) What regulatory and compliance requirements should I consider for US and EU markets?

US and EU formulations must meet volatile organic compound (VOC) limits for the intended use category; always verify product-level regulatory statements and local/state/Country rules before procurement. Key frameworks:

– US: EPA regulations; CARB for California; customer or OEM-specific VOC specs where applicable; some shops or fleets may require low-VOC systems to meet regional or customer mandates.

– EU: REACH for chemical substance registration/authorization; country-specific VOC limits for automotive paints; supplier declarations (e.g., lead and chromium VI free) may be requested.

Confirm regulatory labeling, safety data sheets, and any product claims (e.g., low VOC performance) with the supplier prior to purchase.

Illustrative Image (Source: Google Search)

3) Which paint system is recommended for a durable metallic silver refinish?

Use a two-stage system:

– Basecoat: Urethane (2K) or waterborne basecoat containing metallic pigments, applied over correctly prepared, tinted or sealered substrate to achieve color coverage and metallic effect.

– Clearcoat: High-solids 2K clear (or Performance Clear for severe service) applied within the recommended window (flash/dry times per supplier guidelines) to achieve gloss,DOI, and UV/chemical resistance.

Follow the supplier’s specific reducer, activator, and mixing ratios for the chosen system. Film build and flash control affect flake orientation; avoid over-reduction or excessive spray passes that can cause dark/light banding.

4) How do I control metallic flake orientation and color appearance on complex panels?

Metallic appearance is highly sensitive to application variables. Key controls:

– Technique: Use consistent gun distance (15–20 cm), overlap (50–75%), and fan pattern; apply in smooth, even passes with stable atomization.

– Viscosity/solids: Mix per spec; avoid over-thinning. Maintain mid-wet film to allow flake to settle upright without flooding.

– Flash management: Allow proper flash between coats as specified; do not force dry between basecoat coats to avoid “tiger-striping.”

– Environmental: Maintain stable shop temperature and RH to reduce mottling; avoid drafts across panels during application.

– Panel strategy: On large or complex panels, plan cross-spray patterns and apply additional “drop-coats” to help equalize orientation and texture.

5) What quality control steps ensure consistent metallic silver across batches and fleets?

- Color and flake verification: Use calibrated spectrophotometers and established color tolerances; include metallic flop angles and/or visual under standardized lighting (D65/50, booth lighting).

- Substrate and texture control: Standardize surface prep (sanding level and scuff pattern) to reduce texture telegraphing.

- Test panels: Spray drawdowns or test panels for each batch before production; confirm clearcoat compatibility and texture response.

- Coverage and film build: Validate hiding power and metallic effect within recommended film build ranges to avoid excess solvent retention or excessive speckle.

- Data capture: Document mix ratios, pot life, environmental conditions, and spray parameters for repeatability and traceability.

6) What packaging options and order sizes are available?

Most metallic silver systems are supplied as:

– Pints, quarts, and gallons of basecoat and clearcoat (2K/activators or reducers as required).

– Optional pre-mixed aerosol kits for sampling or small repairs; not suitable for full panel production jobs.

Lead times vary by formulation and region; confirm MOQs, lot sizes, and retinting lead times before deployment. Some suppliers offer custom mixing to match OEM codes or fleet standards.

7) How can I match existing OEM metallic silvers or blend complex parts?

- Code identification: Confirm OEM color codes and verify against supplier swatches or lab-mixed standards.

- Layered approach: Use basecoat layering to control brightness and coverage, followed by appropriate sealing or blending techniques before clearcoat.

- Panel blending: Slightly adjust metallic tone across adjacent panels and into door jambs and edges to create a harmonious visual match under varied lighting.

- Final checks: Validate across light sources (natural daylight and booth lighting) and multiple viewing angles before final clear application.

8) What troubleshooting steps fix common metallic silver defects?

- Mottling/flake banding: Reduce variability in technique, avoid over-reduction, maintain consistent pass speed and overlap; consider adding a light “drop-coat” to even orientation.

- Dark edges (hot spotting): Ensure proper ground coverage and apply mid-wet films to reduce edge pickup; maintain flash and tack procedures per spec.

- Clear orange peel/soft cure: Confirm activator ratio, reduce/reducer selection, and booth temperature; extend flash/dry if needed and avoid recoating within specified windows.

- Dry spray/excess texture: Increase fluid output or adjust viscosity slightly; keep gun at correct distance; reduce air pressure or droplet size to reduce dry overspray.

- Color shift after clear: Verify compatibility and timing; allow proper basecoat dry/flash before clear; ensure clearcoat solids are adequate for metallic coverage and gloss.

Strategic Sourcing Conclusion and Outlook for metallic silver car paint colors

Strategic Sourcing Conclusion and Outlook

Metallic silver remains a high-value, high-visibility category demanding precise color control and reliable supply. Short lists anchored in proven lines—such as House of Kolor Silver Shades with BC02 Orion Silver and BC03 Galaxy Gray—reduce variance, secure coverage across base systems, and streamline replenishment.

Illustrative Image (Source: Google Search)

| Decision driver | What to verify | Why it matters |

|---|---|---|

| Color match | Master sample and OEM code correlation | Minimizes rework and customer returns |

| Flake performance | Brightness, flop, texture uniformity | Controls pop and hiding across repair and OEM |

| System compatibility | BC/PBC/KBC and clear selection | Ensures proper adhesion and clarity |