Metalpower Fin Tube

Nantong Metalpower Industries Co., Ltd.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Nantong Metalpower Industries Co., Ltd.

Nantong Metalpower Industries Co., Ltd. delivers high-quality laser welded fin tubes, high frequency finned tubes, and extruded fin tubes engineered for superior heat transfer performance across global industries.

Nantong Metalpower Industries Co., Ltd. is a leading manufacturer of high-quality finned tubes based in Nantong, Jiangsu, China — just one hour from Shanghai. We specialize in advanced welding and forming technologies to produce reliable, high-performance heat exchange components.

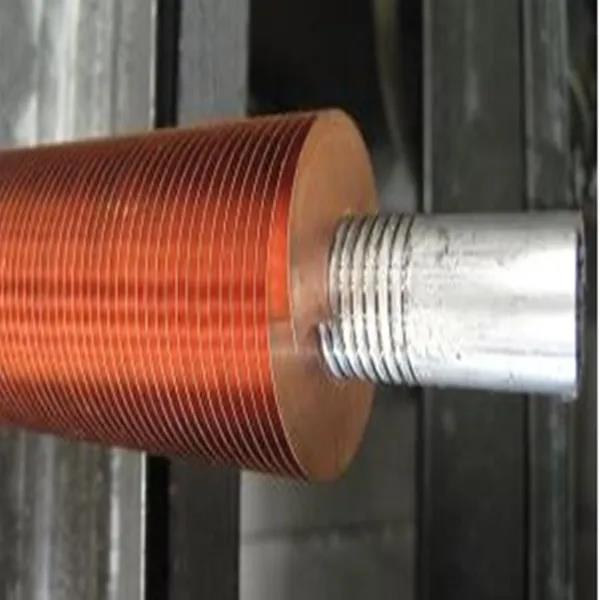

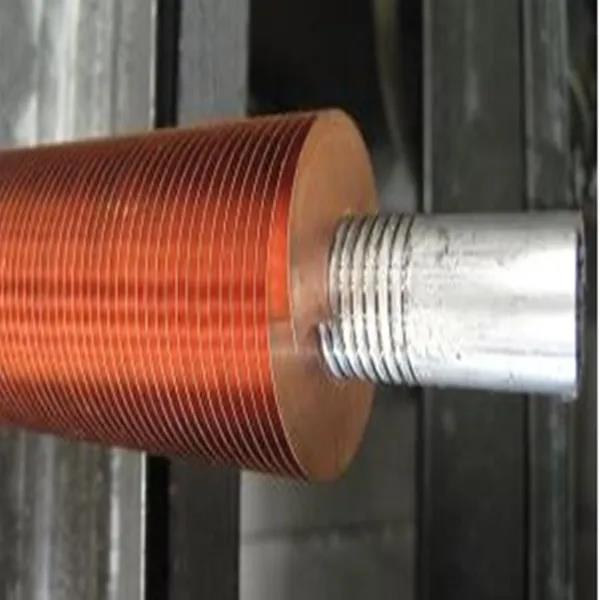

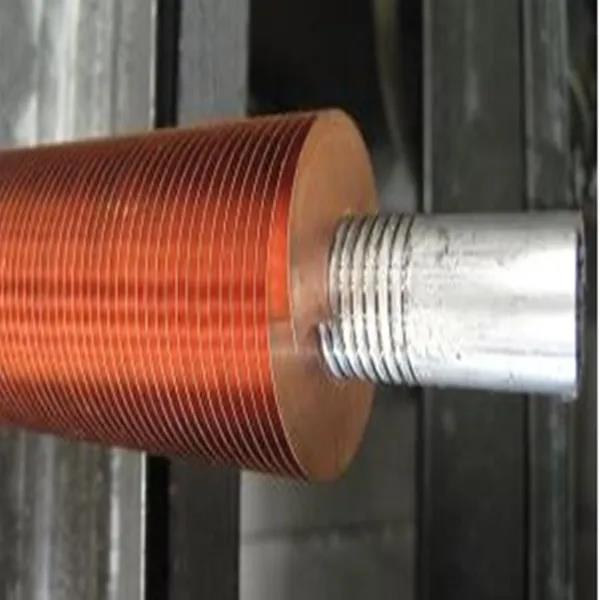

Our product range includes laser welded fin tubes, extruded fin tubes, high frequency welded fin tubes, winding fin tubes, embedded fin tubes, longitudinal fin tubes, and studded pipes. We support diverse material combinations including carbon steel, stainless steel, aluminum, copper, nickel, and titanium.

We take customer demand as our guidance and continuously enhance product quality while optimizing pricing to create win-win partnerships with clients worldwide.

To exceed customer expectations through continuous improvement of our processes and systems. We build lasting relationships by understanding client needs and delivering consistent quality and service.

Engineered for efficiency, durability, and performance in heat exchange applications.

High-strength, precision-welded fin tubes ideal for high-temperature and high-pressure environments. Available in carbon steel, stainless steel, aluminum, copper, nickel, and titanium.

Formed by extruding fins directly onto the base tube, ensuring excellent mechanical bonding and durability in corrosive environments.

Utilizing high-frequency induction welding for strong, consistent bonds between fins and base tubes.

Fins are embedded into the base tube under high pressure, creating a secure mechanical bond without welding.

Continuous fin material wound around the base tube, suitable for compact heat exchangers and space-constrained applications.

Fins run parallel to the tube axis, ideal for gas-to-gas or gas-to-liquid heat exchange with low fouling risk.

Designed with square or double-H profile fins for enhanced rigidity and heat dissipation in high-stress environments.

Pipes with welded studs or pins to increase surface area for heat transfer in fluidized bed boilers and catalytic reactors.

Precision engineering, global standards, and customer-focused innovation.

Precision manufacturing with strict quality control ensures reliable performance in demanding environments.

Efficient production and logistics ensure timely delivery to support your project schedules.

We support custom designs, materials, and configurations to meet your exact specifications.

Optimized manufacturing processes allow us to deliver high value without compromising quality.

Find answers to common questions about our fin tubes and services.

We offer fin tubes in carbon steel, stainless steel, aluminum, copper, nickel, and titanium. Material combinations can be customized based on your application requirements.

Yes, we support custom fin heights, thicknesses, spacing, and profiles including L, LL, KL, H, and Double H types. We also offer coiled and straight configurations.

Laser welding provides a precise, narrow weld with minimal heat input, ideal for thin materials and high-strength applications. High frequency welding is faster and cost-effective for mass production with excellent bond strength.

Yes, our engineering team provides full technical support, CAD drawings, and specifications to ensure compatibility with your system design.

Our products are used in power generation, petrochemical, HVAC, refrigeration, waste heat recovery, and industrial boiler systems worldwide.

Reach out for quotes, technical inquiries, or partnership opportunities.

Our team is ready to assist with product selection, technical specifications, and custom solutions.

Visit Official Website to ContactNotice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info