About Miyou Group

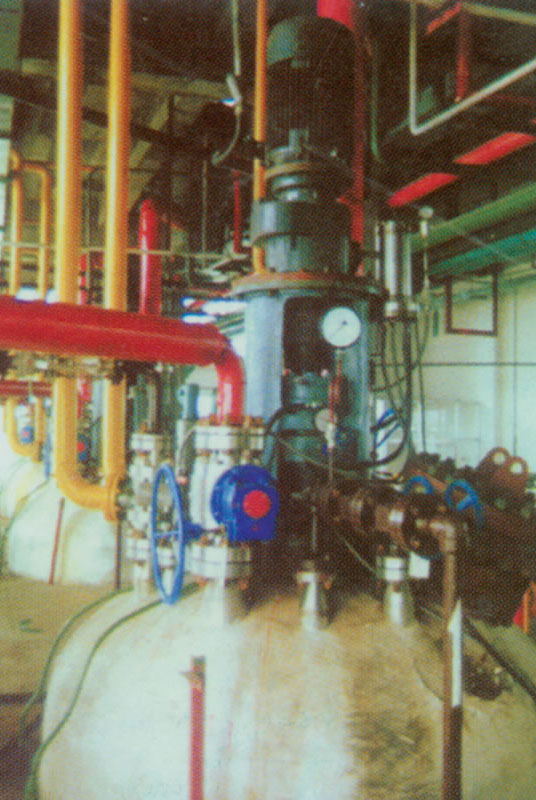

Established in 1985, Miyou Group Co., Ltd. is a national high-tech enterprise based in Kunshan, Jiangsu Province, China. We specialize in the design and manufacturing of advanced grinding systems, mechanical seals, reactors, and nanometer materials.

As a leading grinding mill and mechanical seal manufacturer, our products serve industries such as coatings, agrochemicals, lithium batteries, ceramics, and environmental protection. With decades of engineering excellence, we deliver reliable, energy-efficient, and scalable solutions to clients worldwide.

- ISO-Certified Manufacturing

- 40+ Years of Industry Experience

- Global Export to 50+ Countries

- In-House R&D and Testing Labs