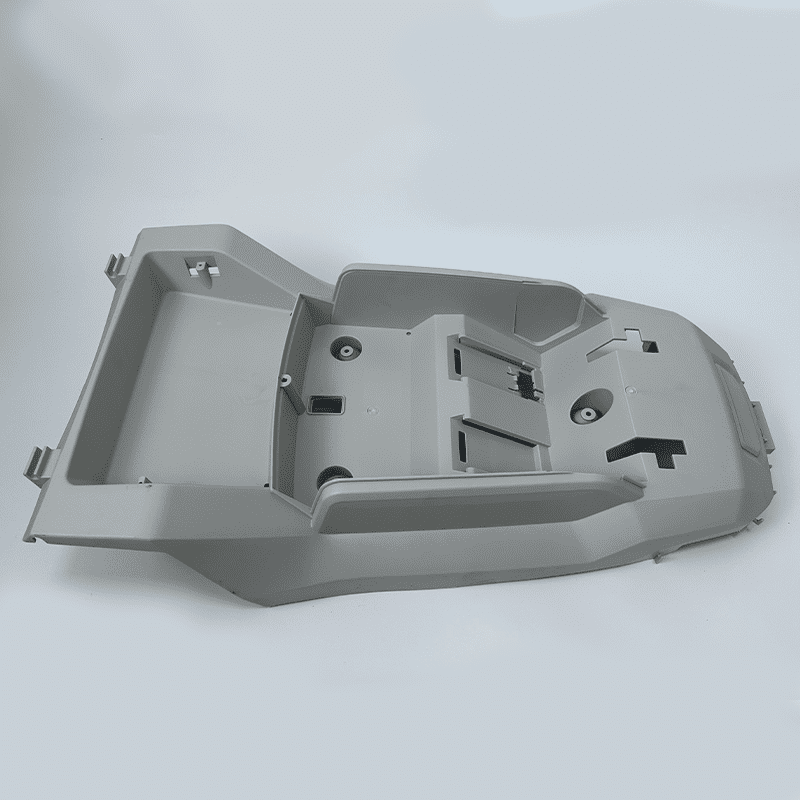

Mould Manufacturing

Custom mold design and precision machining for complex plastic parts with tight tolerances and high durability.

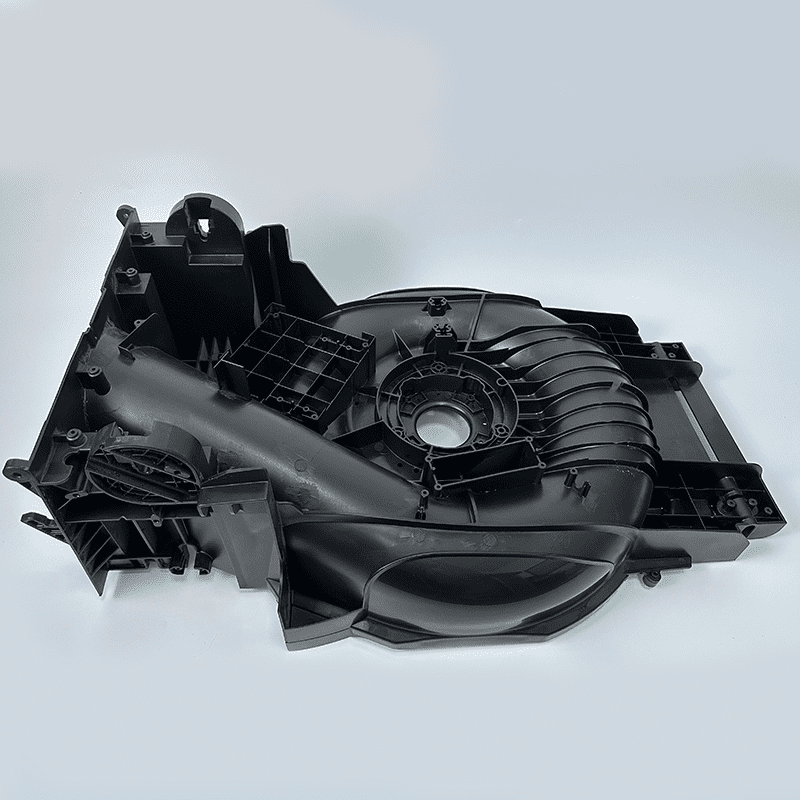

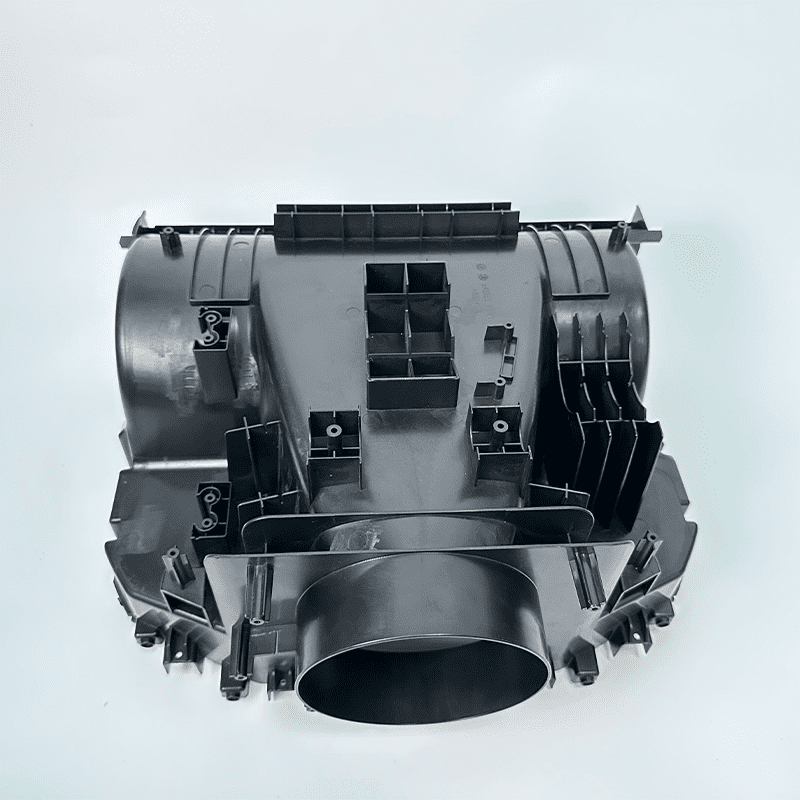

Custom Injection Molding

High-volume and low-volume production using advanced 80T–3500T machines with materials like ABS, PVC, Nylon, and POM.

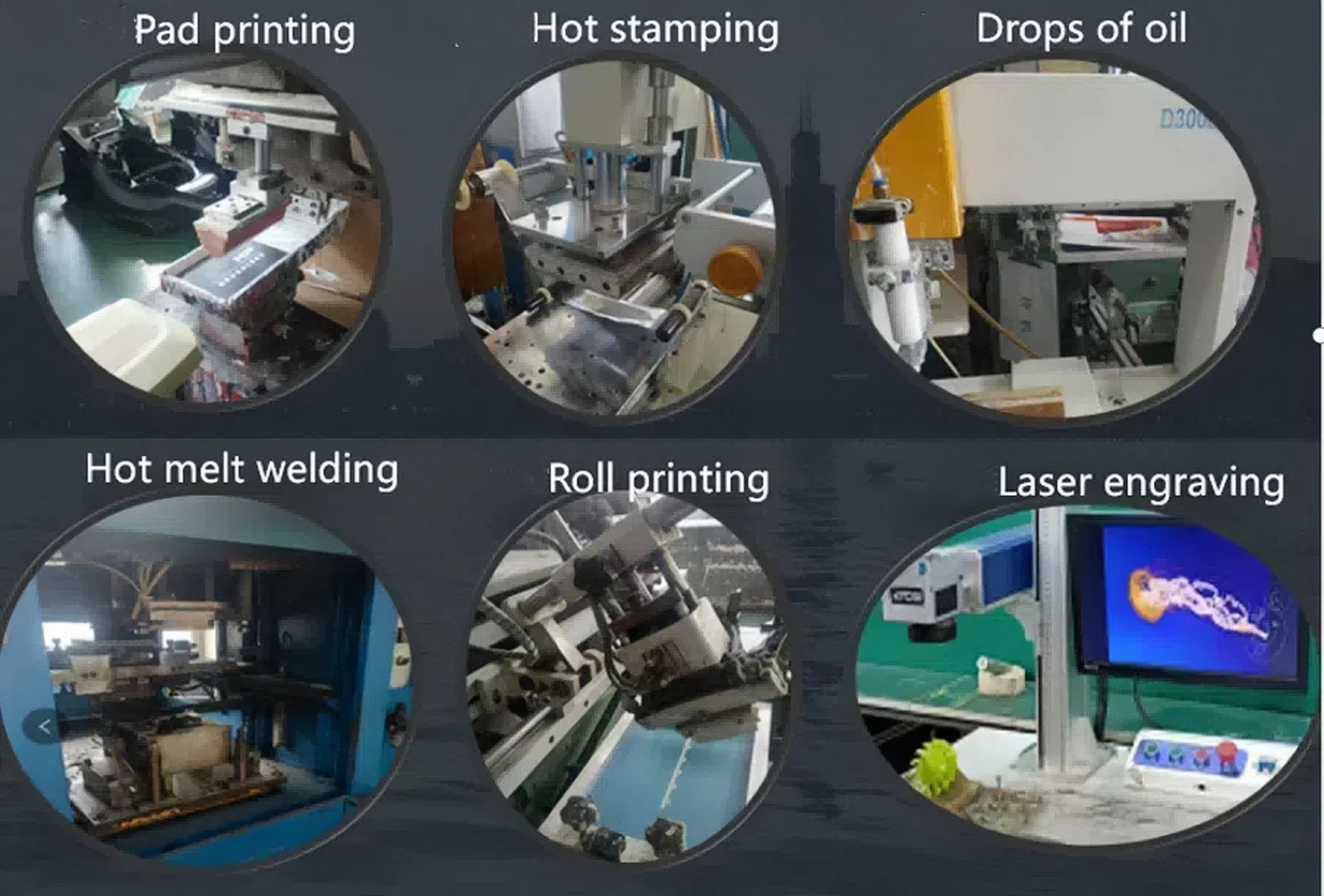

Secondary Processing

Post-molding services including ultrasonic welding, painting, silk screening, and assembly for finished components.

Quality Inspection

Rigorous testing and inspection protocols including dimensional checks, material verification, and compliance with ISO, RoHS, and REACH.