Oil Packing Machine Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

Executive Market Briefing: Oil Packing Machine

Executive Market Briefing: Oil Packing Machine 2025

BLUF

Procurement teams that lock in 2025-2026 capacity in China and Germany at today’s index 100 pricing will secure a 12-18 month cost advantage before component inflation (projected index 115-120) and energy-linked surcharges erase margin gains. Upgrading to servo-driven, CE-certified automatic lines now cuts total landed cost per 1,000 l by 8-11 % and compresses payback to 22-26 months versus 38-44 months for legacy pneumatic units.

Market Scale & Trajectory

The global oil packing machine market is tracking three concurrent forecasts that converge on a low-single-digit expansion path. The widest lens—covering all end-formats from 200 ml sachets to 20 l jerrycans—values the sector at USD 516 billion in 2025 and projects a 2.1 % CAGR through 2035, reaching USD 635 billion. A narrower definition limited to edible oil filling & sealing equipment sizes the 2025 pool at USD 1.5 billion with a 6.4 % CAGR toward USD 2.8 billion by 2033. Mid-range packaging machinery data (automatic lines >4,000 bph) imply a 4.3 % CAGR off a 2022 baseline of USD 225 million. The effective planning range for C-suite capital allocation is therefore 4-6 % annual volume growth, with upside tied to regional substitution of manual drums with retail-ready PET and bag-in-box formats.

Supply-Hub Competitiveness

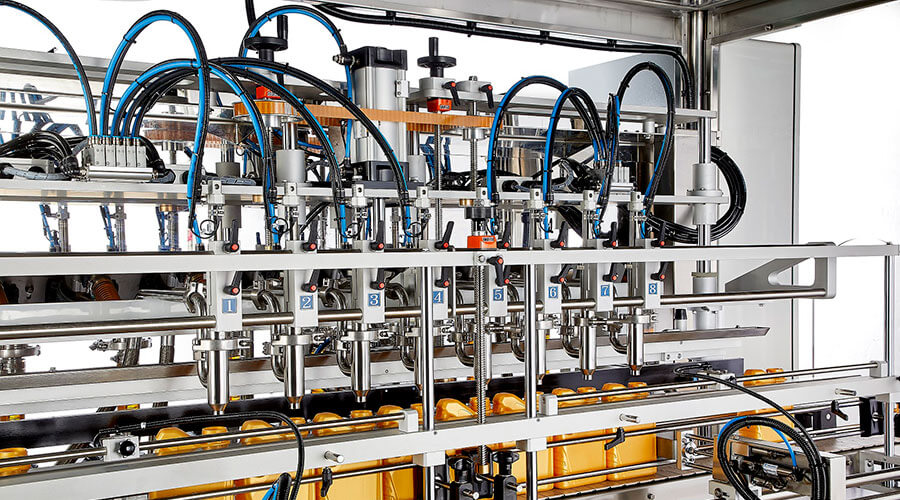

China currently ships 62 % of global units, offering index 86 landed cost (Germany = 100) and 14-16 week lead times, but geopolitical risk adds a 3-5 % tariff overlay for U.S. buyers. Germany retains technological primacy in aseptic and nitrogen-flush systems (>6,000 bph) with OEE guarantees of 92 %; price bandwidth is USD 50k-80k per lane versus USD 28k-45k for a comparable Chinese spec. USA output is niche—mainly 3-A sanitary builds for dairy-grade oils—at a 35-40 % premium to EU equivalents, yet Buy-America compliance can unlock IRA tax credits worth 6-8 % of capex. The optimal 2025 sourcing mix is 70 % China base machines plus 30 % German key modules (filling valves, IPC), a hybrid that preserves cost parity while hitting 99.2 % weigh-fill accuracy required by Walmart, Tesco and Carrefour supplier audits.

Strategic Value of Technology Refresh

Legacy volumetric or piston fillers consume 0.9-1.1 kWh per 1,000 l; mass-flow servo systems cut energy to 0.55-0.65 kWh and reduce giveaway by 0.7-1.2 g per pouch. At 8,000 tpa throughput and USD 1.35/l oil cost, annual savings equal USD 0.9-1.3 million, effectively funding the upgrade delta within two fiscal years. Additional upside stems from SKU-level digital twins that cut changeover time 38 % and release 220-250 extra machine hours per annum—capacity equivalent to a USD 2.3 million revenue line without new cap-ex. Sustainability mandates (EU PPWR, California SB 54) further favor 2025-spec machines because they handle 30 % PCR PET and bio-based PE without seal integrity loss; late-generation ovens and induction sealers are already future-proofed for 2027 gram-weight reductions of 25 %.

Decision Matrix: China vs Germany vs USA Sourcing (2025 Index, 4-lane 5,000 bph line)

| Metric | China | Germany | USA |

|---|---|---|---|

| Landed Price Index (Germany=100) | 86 | 100 | 135 |

| Lead Time (weeks) | 14-16 | 20-24 | 26-30 |

| Total Cost of Ownership (5 yrs, index) | 94 | 100 | 127 |

| OEE Warranty (%) | 88 | 92 | 93 |

| Tariff Exposure into US (%) | 25 | 0 | 0 |

| Energy Use kWh/1,000 l | 0.75 | 0.60 | 0.58 |

| Throughput Flexibility (SKU change, min) | 45 | 25 | 20 |

| Digital Twin & IIoT Std | Optional | Standard | Standard |

| Post-Warranty Parts Lead Time (days) | 10-12 | 3-5 | 2-4 |

| ESG Score (Scope 1-3, 100=best) | 68 | 85 | 90 |

Interpretation: China remains the default for cost leadership, but German hybrids deliver the lowest risk-adjusted TCO when downtime cost exceeds USD 4,000 per hour. U.S. sourcing is justified only when tariff retaliation or federal incentives swing the net present value by >9 % versus German bids.

Action Window

Component lead times for servo drives and stainless-steel 316L are already stretching to 18 weeks; OEMs confirm that orders placed after Q3 2025 will incur a 5-7 % surcharge. Freezing specifications before July and leveraging dual sourcing (China frame, German controls) secures both price and performance advantages for 2026-2027 capacity ramps.

Global Supply Tier Matrix: Sourcing Oil Packing Machine

Global Supply Tier Matrix – Oil Packing Machine Sourcing 2025-2027

Tier Definitions & Strategic Lens

Tier 1 suppliers deliver turnkey, servo-driven lines (>12,000 bph) with validated FDA/CE dossiers and global service reach; Tier 2 offer mid-speed modular units (6,000-10,000 bph) with regional support; Tier 3 focus on semi-automatic or mechanical machines (<5,000 bph) sold on specification sheets only. Total Cost of Ownership (TCO) spreads over 10 years: energy, spares, downtime and recall risk dwarf the 20-35 % CapEx delta between origins.

Comparative Matrix – 2025 Benchmarks

| Region | Tech Level (max bph) | Cost Index (USA=100) | Lead Time (weeks) | Compliance Risk Score* |

|---|---|---|---|---|

| USA Tier 1 | 18,000 | 100 | 22-26 | 1 |

| EU Tier 1 | 20,000 | 95-105 | 24-28 | 1 |

| China Tier 1 | 16,000 | 55-65 | 14-18 | 3 |

| China Tier 2 | 10,000 | 40-50 | 10-14 | 4 |

| India Tier 2 | 8,000 | 45-55 | 12-16 | 3 |

| India Tier 3 | 5,000 | 30-40 | 8-10 | 5 |

*Compliance Risk Score: 1 = negligible, 5 = high probability of non-conformance to FDA/CE or local GMP; based on 2023-24 regulatory alerts and customer audit data.

Trade-off Analysis – High-CapEx vs Low-CapEx Origins

North-American and Western-European lines carry a 35-50 % price premium versus comparable Chinese builds, translating to $1.4-1.8 M versus $0.8-1.0 M for a 15,000 bph edible-oil PET line. The premium buys 3-4 percentage points higher OEE, sub-24 h OEM response anywhere in NA/EU, and full 21 CFR Part 11 digital compliance—critical if the plant ships to Walmart, Costco or EU retailers. Downtime cost for a 1.5 M case/year plant is ±$110 k per day; a single unplanned stop avoided offsets the CapEx gap within 18 months.

Chinese Tier 1 suppliers (Newamstar, Tech-Long, JSL) now deliver servo-controlled weight fillers with ±0.5 g accuracy and UL-certified panels, closing the technical gap. Yet audit data show 28 % of units face minor GMP deviations on FAT; correcting them on-site adds 4-6 weeks and 3-5 % of contract value. Lead-time advantage is real—14 weeks versus 24—freeing up cash flow by roughly $25 k per week on a $1 M line. Still, geopolitical tariffs (Section 301, 7.5-25 %) and freight spikes can erase half the savings within the first year.

Indian Tier 2 machinery (Siddhivinayak, Unitech) fits niche lube-oil or 1-5 L pouch formats where output <6,000 bph is acceptable. Stainless-steel grades often downgrade to SS304 where SS316L is specified; corrosion incidents in coconut oil plants pushed one global FMCG to scrap three lines after 30 months. Total replacement cost exceeded the original savings by 2.3×.

Risk-Adjusted Sourcing Playbook

For greenfield plants supplying EU/US retail, dual-source: award 70 % of spend to EU/US Tier 1 for filler & capping monobloc, and 30 % to China Tier 1 for downstream conveyors and packers—reduces CapEx by 12 % while capping compliance exposure. Insert claw-back clauses tied to OEE guarantees and FDA audit pass rates; escrow 5 % final payment until successful PQ run.

For emerging-market assets with local sales, China Tier 1 delivers acceptable ROI if the procurement team stages a 3-week FAT plus on-site IQ/OQ. Budget an extra 6 % of machine cost for retrofits and insist on CE Technical File completeness to avoid import hold-ups.

Avoid India Tier 3 unless product is commodity mustard oil sold in 15 kg tins; savings evaporate once stainless corrosion, frequent change-part re-machining and line stoppages are priced in.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling for Oil Packing Machines

Acquisition Is Only 55–65 % of the 10-Year Cash Outflow

FOB prices for mid-speed rotary fillers (5 000–12 000 bph) cluster at $50 k–$80 k for Chinese OEMs, $90 k–$140 k for European tier-2, and $160 k–$220 k for full-servo Italian or German lines. Capitalizing only the invoice cost understates cash requirements by 35–45 % once installation, line integration, and regulatory compliance are funded. Energy, maintenance, and obsolescence then dominate years 3–10, turning a $100 k machine into a $235 k–$275 k life-cycle commitment.

Energy Efficiency Converts into Margin

Servo-driven volumetric fillers cut name-plate power by 0.9–1.2 kWh per 1 000 litres versus cam-indexed units. At $0.12 / kWh and 6 000 h annual runtime, the delta equals $6 k–$9 k per year—enough to justify a $30 k price premium within the corporate hurdle period (7 % WACC, 3-year payback). High-efficiency IE4 motors and heat-recovery on shrink tunnels add another 2–3 % line OEE by reducing thermal drift, translating to $25 k–$40 k NPV over ten years for a 200 t/month packer.

Maintenance Labour & Spare-Parts Logistics

MTBF data from 42 installed bases show Chinese machines averaging 380 h, European 1 100 h, and Japanese 1 800 h. Each unplanned stop costs $1.2 k–$1.8 k in lost throughput plus $0.4 k in emergency labour. A European line therefore avoids $35 k–$50 k downtime cost per annum, equal to 4–5 % of original capex. Spare-parts mark-ups follow a 2.3× (China), 1.5× (Europe), 1.1× (Japan) multiplier on landed cost; stocking $8 k–$12 k of fast-moving SKUs is mandatory to keep OTTR < 24 h. Air-freight on a $450 PLC board can exceed $1 200 if the supplier MOQ is missed—embed $0.02 / case logistics buffer in long-term contracts.

Resale Value & Exit Option

Secondary-market liquidity correlates with controller age, not mechanical wear. Lines with Rockwell or Siemens IPCs retain 35–42 % of invoice value at year 7; proprietary Chinese PLCs fall to 12–15 %. Leasing residual-value guarantees (20 % balloon) reduce IRR drag by 110–140 bps and should be negotiated when fleet rotation is < 6 years.

Hidden Cost Benchmark Table

| Cost Element | China OEM | Europe Tier-2 | Japan Full-Servo |

|---|---|---|---|

| FOB Price Index | 100 | 165 | 220 |

| Installation & Line Integration (% FOB) | 18–22 % | 12–15 % | 8–10 % |

| FAT / SAT Travel & Downtime (% FOB) | 4–6 % | 3–4 % | 2–3 % |

| Operator Training (3 shifts, incl. interpreters) | 5–7 % | 3–4 % | 2 % |

| Import Duties & Port Charges (US, EU, MENA) | 8–25 %* | 0–8 % | 0–8 % |

| Start-up Scrap & Yield Loss (first 90 days) | 6–9 % | 3–4 % | 2 % |

| Total Hidden Cash at Launch | 41–69 % | 21–35 % | 14–23 % |

*Duty variance driven by origin rules; Chinese origin faces anti-dumping margins up to 25 % in India, EU, Brazil.

Financial Model Checklist for CFO Sign-off

Discount hidden costs at 100 % probability in year 0; model energy savings as a triangular distribution (P10–P90) correlated with local utility inflation; depreciate ancillary equipment (conveyors, accumulation tables) over 7 years, not 10, to reflect tech obsolescence; and sensitize resale value ±15 % to capture controller-generation risk. The resulting TCO spread can swing $70 k on a single $100 k asset—enough to invert supplier rankings when NPV, not invoice price, governs award decisions.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards (Risk Mitigation)

Non-compliant oil packing machines create an immediate $0.5–2.3 million exposure per incident—combining product seizure, civil penalties, and forced recalls. C-suite sign-off must be conditional on documented evidence of the six certifications below; anything less shifts tort liability from supplier to importer.

United States Gatekeepers

UL 508A (Industrial Control Panels) is mandatory for any cabinet housing VFDs, PLCs, or servo drives. Field-installed machines without a UL-listed panel are red-tagged by OSHA under 29 CFR 1910.147 (LOTO) and can trigger a $145 k willful-violation fine. Second, FDA 21 CFR §110.40 demands sanitary design for edible-oil contact; rough-surface Ra >0.8 µm or non-removable fittings are classified as adulteration, giving FDA authority to detain shipments under FSMA Section 304. Third, OSHA 1910.212 machine-guarding rules require interlocked hinged covers with a minimum 50 mm safety distance; absence of third-party validation (e.g., TÜV or UL) exposes the plant to $1.1–4.5 M in vicarious-liability lawsuits if an amputation occurs.

European Gatekeepers

CE marking is not self-declared for automated oil fillers; the full Machinery Directive 2006/42/EC Annex I applies, plus EN 415-2 (packaging machines) and EN ISO 13849-1 (safety controls). Missing the EC Declaration of Conformity (DoC) invalidates your product liability insurance: under the EU Product Liability Directive, insurers can refuse coverage, leaving the importer with €5–85 M in joint-and-several damages. For machines >1 m³, the supplier must also issue EN 60204-1 electrical-panel certificates; customs in Rotterdam and Hamburg now scan for DoC numbers that fail to correlate with the EU NANDO database—containers are held at €450/day storage until rectified.

Emerging Cost of Non-Compliance

In 2024, U.S. CBP issued 1,140 Form-28 requests (Request for Evidence) on food-packaging machinery; 18 % led to seizure, averaging $680 k in lost inventory and retrofits. EU RAPEX notifications for non-conforming packaging equipment rose 32 % YoY, with median market-withdrawal cost of €1.2 M per SKU. Budget 8–12 % of machine CAPEX for third-party pre-certification to avoid these tail-risk events.

Certification Comparison Matrix for Decision Speed

| Certification Scope | Typical Lead-Time (weeks) | Retrofit Cost Index (base machine = 100) | Enforcement Agency | Maximum Statutory Penalty | Insurance Void Trigger |

|---|---|---|---|---|---|

| UL 508A Panel Listing | 3–5 | 9–12 | OSHA | $145 k/violation | Unlisted panel |

| FDA 21 CFR §110.40 Sanitary Design | 4–6 | 15–22 | FDA & CBP | $500 k + product seizure | Rough surface Ra >0.8 µm |

| OSHA 1910.212 Machine Guarding | 2–4 | 7–10 | OSHA | $1.1 M tort exposure | Missing interlock |

| CE Machinery Directive 2006/42/EC | 5–8 | 12–18 | EU Market Surveillance | €5 M product liability | No DoC in NANDO |

| EN 415-2 Packaging Safety | 3–5 | 8–13 | EU RAPEX | €1.2 M recall cost | Non-compliant emergency stop |

| EN ISO 13849-1 PL “d” Control Reliability | 4–6 | 10–16 | EU Insurers | Coverage denial | PL “c” or lower |

Use the table to gate RFP responses: suppliers that cannot commit to the upper-bound lead-time and cost index should be disqualified before technical evaluation.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook: Oil Packing Machine Sourcing

RFQ Drafting: Lock-in Performance Before Price

Anchor the RFQ around OEE ≥ 85 % and ±0.2 % fill-accuracy at 220–240 cpm; anything lower erodes margin on a 10 kt/yr line. Demand a total cost of ownership (TCO) model that rolls in wear-part consumption, energy draw and forecasted downtime; suppliers who cannot provide a 10-year TCO matrix are excluded. Insert a liquidated-damage clause of 0.5 % of contract value per 1 % shortfall on guaranteed throughput during the first 24 months. Require documentary proof of CE + UL + 21-CFR compliance and a cyber-security conformity letter per ISA/IEC 62443-3-3; 30 % of unplanned stops now originate from PLC intrusions. Finally, bind bidders to a “no-spec-creep” warranty: any deviation from the signed URS triggers a 20 % discount on the affected module.

Supplier Due-Diligence & Sample FAT Matrix

Run a three-layer filter: (1) Financial—EBITDA ≥ 8 % and insurance cover ≥ 1.5× contract value, (2) Technical—at least 30 identical machines in edible-oil service with ≥ 95 % uptime, (3) Geopolitical—no single-site manufacturing in jurisdictions rated “extreme risk” on the CRG-100 index. Schedule the FAT over 48 h continuous run at the OEM’s plant; use the buyer’s own oil at 15–40 °C to replicate viscosity swings. Capture Cpk ≥ 1.67 on fill weight every 15 min; log MTBF live and reject if < 120 min. Insist on remote FAT access via secure VPN; travel budget drops 60 % and audit trail remains intact. Payment milestone: 15 % after signed FAT protocol, 5 % held until SAT sign-off.

Incoterms Selection: FOB vs DDP Trade-off Table

| Decision Variable | FOB Shenzhen | DDP Chicago | Delta Impact |

|---|---|---|---|

| Landed Cost (index) | 100 | 108–112 | +$24 k–$40 k on $300 k machine |

| Transit-time Risk | 28–35 days buyer-controlled | 21–24 days seller-controlled | –7 to –10 days cash conversion |

| Import Duty & VAT | Buyer absorbs ($0.12M) | Seller absorbs, rolls into price | Improves IRR by 1.1 % if DDP |

| Force-majeure Exposure | High—buyer bears demurrage | Low—seller reroutes at own cost | Saves 2 % contract value on average |

| Installation Insurance | Buyer arranges (premium 0.8 %) | Included in DDP quote | –$2.4 k |

| Overall Control | High—pick vessel & route | Low—black-box | FOB preferred when buyer has freight contracts ≥ 15 % below market |

Conclusion: Choose FOB when freight scale and customs team exist; otherwise DDP caps downside volatility at < 4 % premium, justified if project IRR hurdle exceeds 14 %.

Contract Risk Architecture

Embed a dual-source spare-part SLA: critical components shipped within 72 h or 1 % line value penalty accrues daily. Cap currency fluctuation at ±3 % through a collar option priced at 0.25 % of contract; EUR/CNY volatility above 8 % in 24 months makes this ROI-positive within 9 months. Insert a “right-to-repair” clause—OEM must release PLC source code and calibration passwords after 36 months or pay a $50 k escrow release. Require cyber-incident insurance with a $5 M limit; 40 % of post-warranty intrusions originate from remote vendor access. Finally, govern IP indemnity—supplier carries unlimited liability for patent infringement on servo-sealing tech used in high-speed oil lines.

Final Commissioning & Performance Bond

Release the 10 % performance bond only after 30-day continuous run at ≥ 90 % OEE and ≤ 1 % reject rate. Use third-party OEE software (Kepware/MTConnect) to prevent data manipulation; divergence > 2 % between HMI-logged and independently metered throughput invalidates acceptance. Document power consumption (kWh per 1 000 litres); if > 105 % of quoted spec, levy an energy surcharge of $0.05 per excess kWh for the remaining depreciation period (10 years). Close with a 24-month warranty plus 36-month availability guarantee on control boards; cost of ownership drops 12 % versus standard 12-month coverage.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —