Pioneering Material Innovation Since 1993

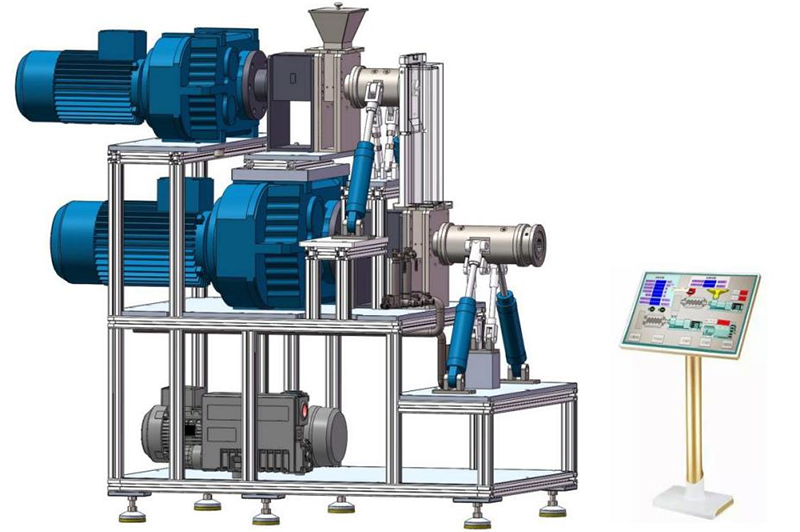

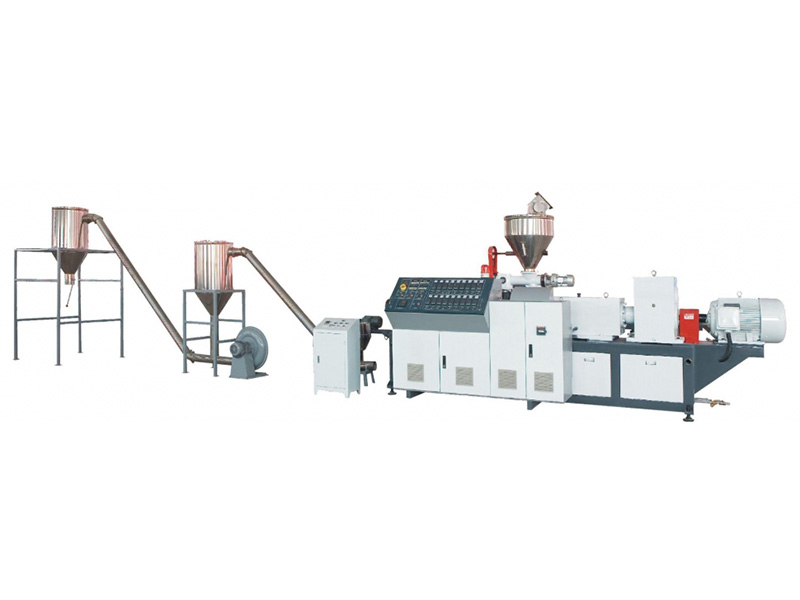

Shanghai Omega Co. is a leading enterprise in the design and production of abrasion and corrosion-resistant screws, barrels, and extruders used in extruding, blow molding, and injection molding of rubber and plastic products.

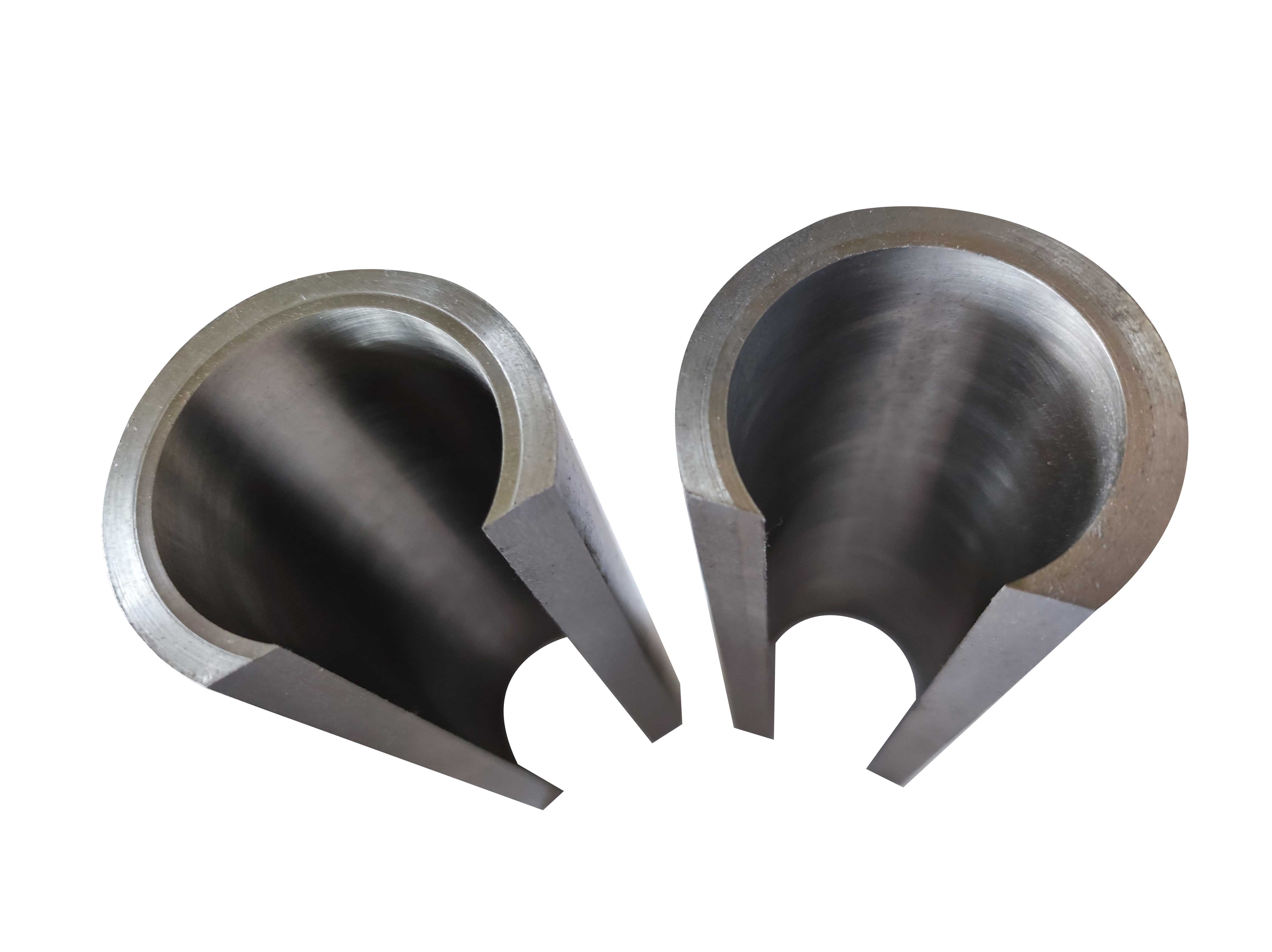

Our strength lies in material development. We have introduced proprietary alloys comparable to those of renowned European manufacturers. For example, our high vanadium cast iron Ω102A alloy matches the performance of W&P’s 99.3 alloy.

1993

Founded in Shanghai

China's First

In extruder material research

Ω102A Alloy

High vanadium iron performance

Global Reach

Serving plastic & rubber industries

Engineered for Longevity

High Chromium & Vanadium Iron Solutions