Our Product Range

Discover our series of high-performance injection molding machines engineered for precision, speed, and energy efficiency.

AT Series

- • Repeatability precision: ±0.5mm

- • Mold open response: 1.28 sec

- • Mold close response: 1.19 sec

- • Strong clamping structure

- • High mold loading capacity

AM Series

- • High-speed servo proportional valve

- • Fast cycle time

- • Accurate positioning

- • Ideal for automation integration

- • Thickened mold plates for rigidity

AR Series

- • Mechanical direct-pressure clamping

- • Uniform force transmission

- • Larger mold opening stroke

- • Reduced elastic deformation

- • Mold protection optimized

VIVA Series

- • Servo motor energy-saving system

- • 25–30% power saving vs. traditional

- • High-speed production capable

- • Low heat loss, efficient operation

- • Stable for long production runs

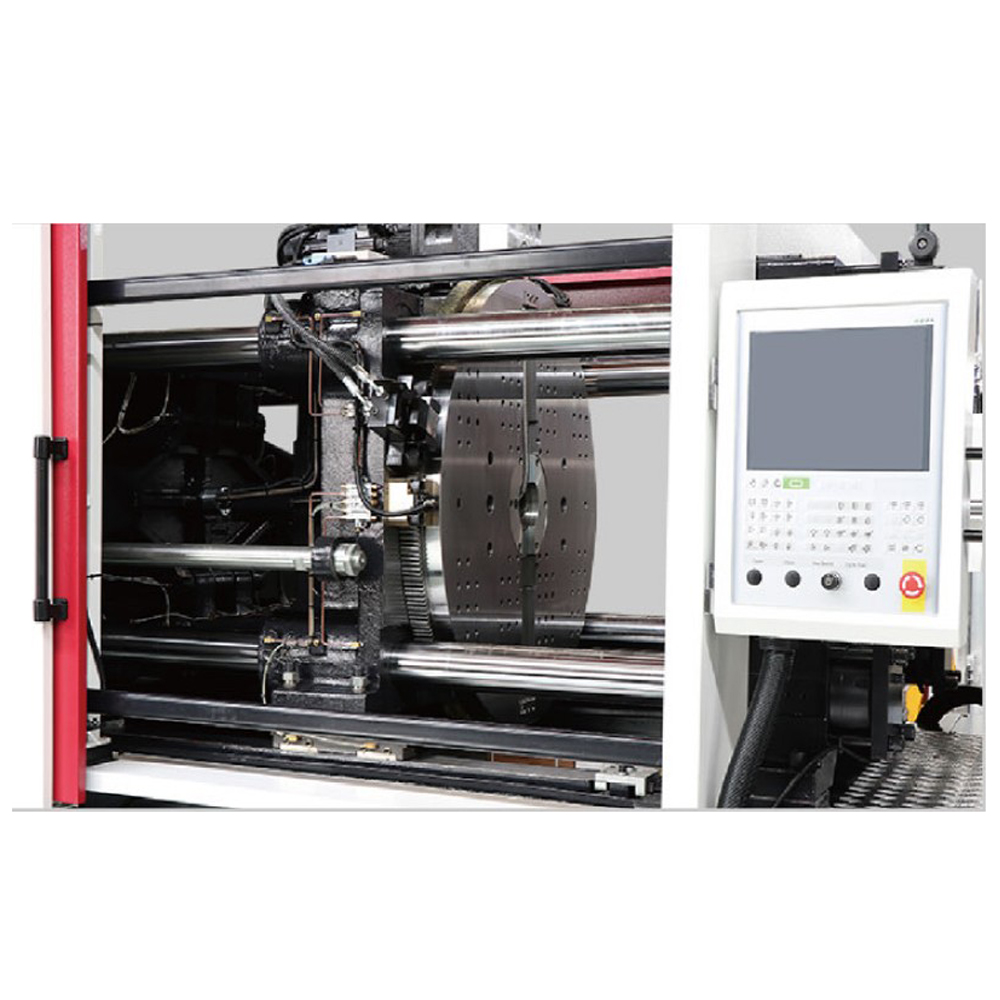

Clamping Unit

- • ±0.5mm repeatability precision

- • Overshoot < 2mm

- • High rigidity mold plates

- • Optimized for automation

- • Durable, low maintenance

Electric Unit

- • World-renowned brand components

- • Stable, comprehensive software

- • Easy-to-operate interface

- • Modular cabinet design

- • Safe electrical protection

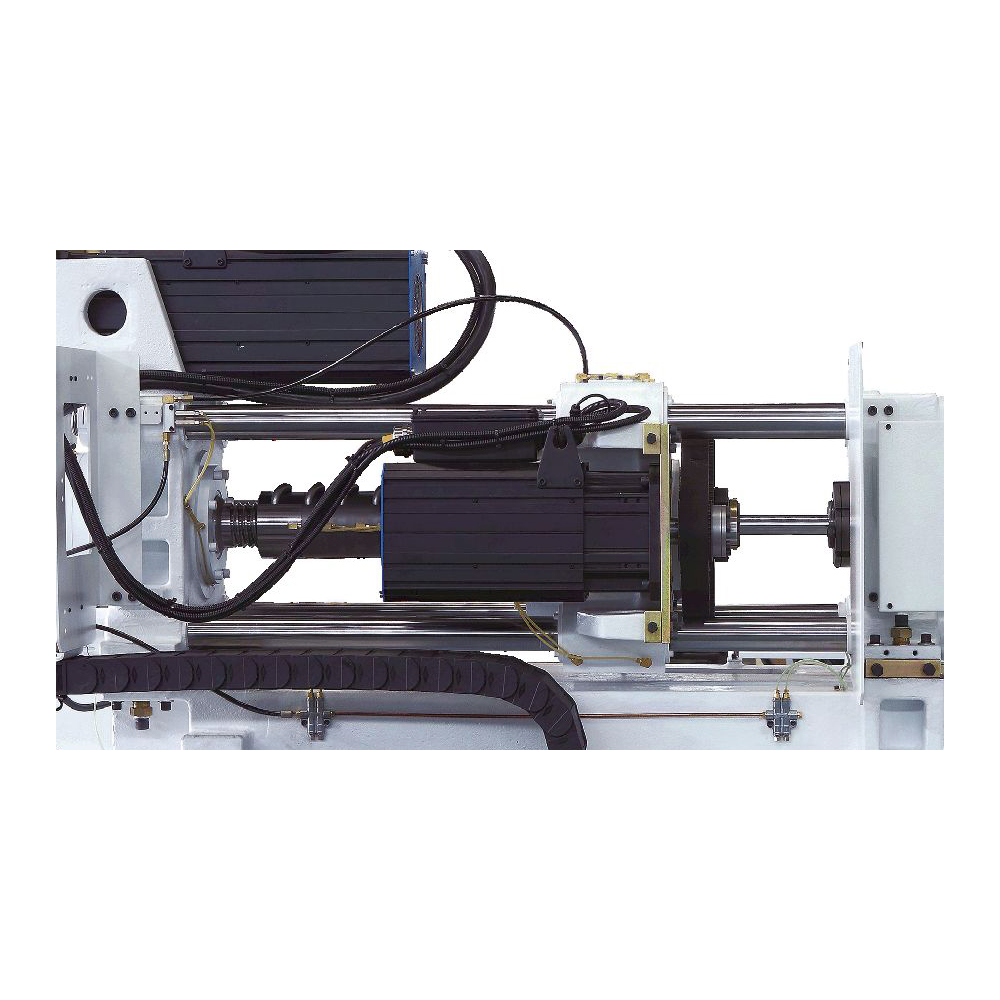

Injection Unit

- • Temperature control: ±1°C

- • Positioning: ±0.13mm

- • Injection repeatability: ±0.02mm

- • Faster injection speed

- • Higher injection pressure

Hydraulic Unit

- • Standard servo energy-saving system

- • 25–30% energy reduction

- • High efficiency on fast cycles

- • Low noise, smooth operation

- • Long service life